OPERATION

INSPECTION & MAINTENANCE

BEFORE EACH USE A VISUAL INSPECTION SHALL BE MADE FOR ABNORMAL CONDITIONS

SUCH AS CRACKED WELDS, DAMAGED, BENT, WORN, LOOSE OR MISSING PARTS. DO NOT

USE THE STANDS IF THEY ARE DAMAGED IN ANY WAY

THIS JACK SHOULD BE INSPECTED IMMEDIATELY IF IT IS BELIEVED TO HAVE BEEN SUBJECTED

TO AN ABNORMAL LOAD OR SHOCK. OWNER/OPERATORS SHOULD BE AWARE THAT REPAIR

OF THIS JACK REQUIRES SPECIALISED EQUIPMENT AND KNOWLEDGE.

1. REFER TO YOUR VEHICLE OWNER’S MANUAL FOR

PROPER JACKING PROCEDURES.

2. POSITION STANDS UNDER VEHICLE AT POINTS

SPECIFIED BY VEHICLE MANUFACTURER AS

PROPER LOAD SUPPORT POINTS.

3. PULL THE SAFETY PIN (3).

4. PUT LIFTING SADDLE (2) TO DESIRED HEIGHT.

5. ONCE THE DESIRED HEIGHT IS REACHED, INSERT

THE SAFETY PIN THROUGH THE HOLE IN THE BASE

(1) AND THE LIFTING SADDLE (2).

6. CAREFULLY LOWER LOAD ONTO STANDS.

1

2

3

SAFETY INFORMATION

FAILURE TO HEED THESE WARNINGS MAY RESULT IN LOSS OF LOAD, DAMAGE TO JACK

STANDS AND PERSONAL INJURY OR PROPERTY DAMAGE. THESE INSTRUCTIONS CANNOT

COVER ALL POSSIBLE CONDITIONS OR SITUATIONS THAT MAY OCCUR. USE COMMON SENSE

AND CAUTION AT ALL TIMES WHEN WORKING WITH THESE AXLE STANDS.

1. DO NOT OVERLOAD JACK STANDS BEYOND RATED CAPACITY.

2. POSITION LOAD ON CENTRE OF SADDLE ONLY. ENSURE THE VEHICLE IS LOWERED

SLOWLY AND CAREFULLY.

3. ALWAYS USE STANDS IN PAIRS ON A HARD, LEVEL SURFACE.

4. APPLY THE HANDBRAKE AND CHOCK THE WHEELS BEFORE JACKING THE VEHICLE (AU-

TOMATICS IN PARK)

5. ENSURE THE VEHICLE IS STABLE BEFORE YOU START WORKING ON IT.

6. DO NOT USE AN AXLE STAND ON ITS OWN. ONLY USE IN PAIRS.

7. DO NOT LIFT ONE END OF THE VEHICLE IF THE OTHER END IS ALREADY ON STANDS, OR

THERE IS A RISK THE LOAD MAY TOPPLE.

8. DO NOT USE WITH 3 WHEELED VEHICLES OR TRAILERS.

9. STORE THE STANDS IN A SAFE, DRY, CHILDPROOF LOCATION

EC Declaration of Conformity

This is an important document and should be retained

MANUFACTURER’S NAME:

TYPE OF EQUIPMENT:

PART NUMBER:

I, the undersigned, hereby declare that the equipment specied above con-

forms to the above European Communities Directive(s) and Standard(s).

PLACE:

DATE: (Signature)

Robert Wyatt

Company Secretary

Derby, UK

24th JUNE 2015

SGS Engineering (UK) Ltd

SGS Engineering (UK) Ltd

2 West Side Park

Raynesway

Derby, DE21 7AZ

Axle Stands

JS1.5

2006/42/EC Machinery Directive

(amending Directive 95/16/EC)

APPLICATION OF EC COUNCIL DIRECTIVES / STANDARD:

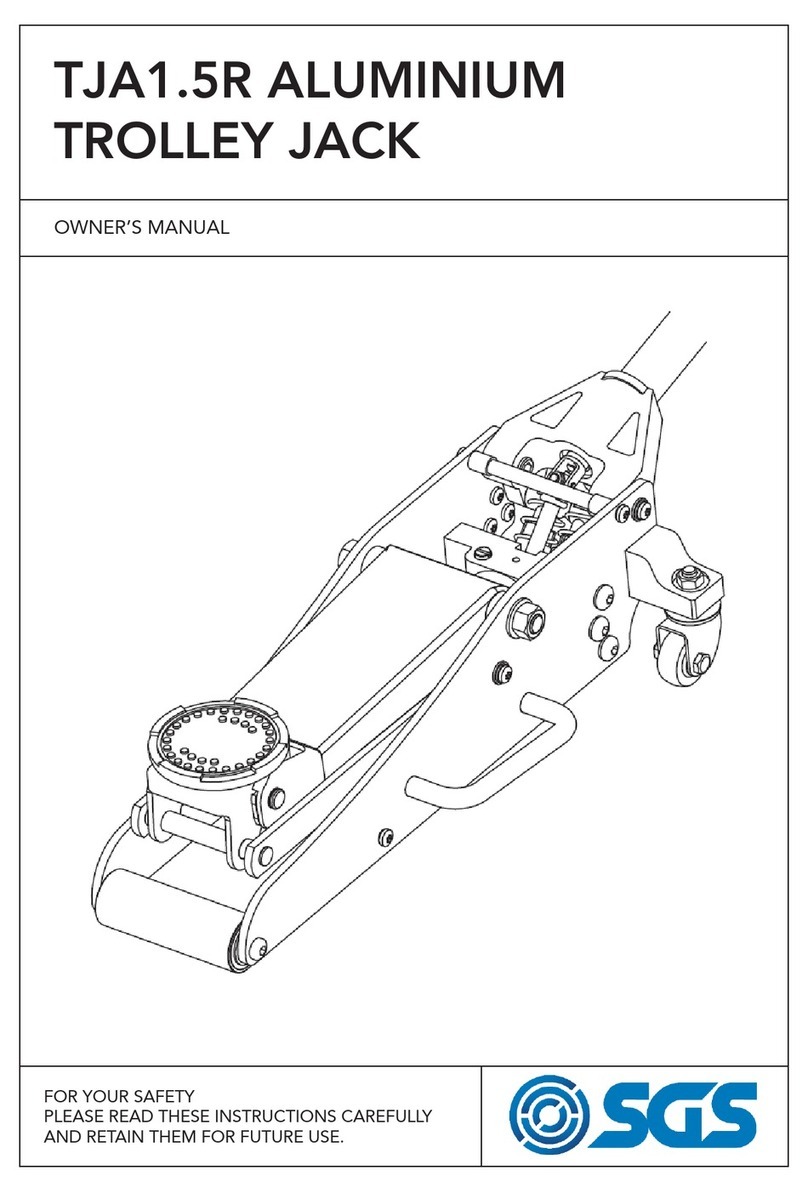

FOR YOUR SAFETY

PLEASE READ THESE INSTRUCTIONS CAREFULLY

AND RETAIN THEM FOR FUTURE USE.