Installation Manual 501.5 Series 5000

Unirac, Inc.

www.unirac.com

1411BroadwayBoulevardNE

AlbuquerqueNM87102-1545USA

505.242.6411

505.242.6412Fax

Page

4

10yearlimitedProductWarranty

Unirac, Inc., warrants to the original purchaser

(“Purchaser”) of product(s) that it manufactures

(“Product”) at the original installation site that

the Product shall be free from defects in material

and workmanship for a period of ten (10) years,

from the earlier of 1) the date the installation

of the Product is completed, or 2) 30 days after

the purchase of the Product by the original

Purchaser.This Warranty does not cover damage

to the Product that occurs during its shipment,

storage, or installation.

This Warranty shall be VOID if installation of

the Product is not performed in accordance

with Unirac’s written installation instructions, or

if the Product has been modified, repaired, or

reworked in a manner not previously authorized

by Unirac IN WRITING, or if the Product is

installed in an environment for which it was

not designed. Unirac shall not be liable for

consequential, contingent or incidental damages

arising out of the use of the Product by the

Purchaser under any circumstances.

If within the specified Warranty period the

Product shall be reasonably proven to be

defective, then Unirac shall repair or replace the

defective Product, or any part thereof, in Unirac’s

sole discretion. Such repair or replacement shall

completely satisfy and discharge all of Unirac’s

liability with respect to this limited Warranty.

Under no circumstances shall Unirac be liable

for special, indirect or consequential damages

arising out of or related to use by Purchaser of

the Product.

Manufacturers of related items, such as PV

modules and flashings, may provide written

warranties of their own. Unirac’s limited

Warranty covers only its Product, and not any

related items.

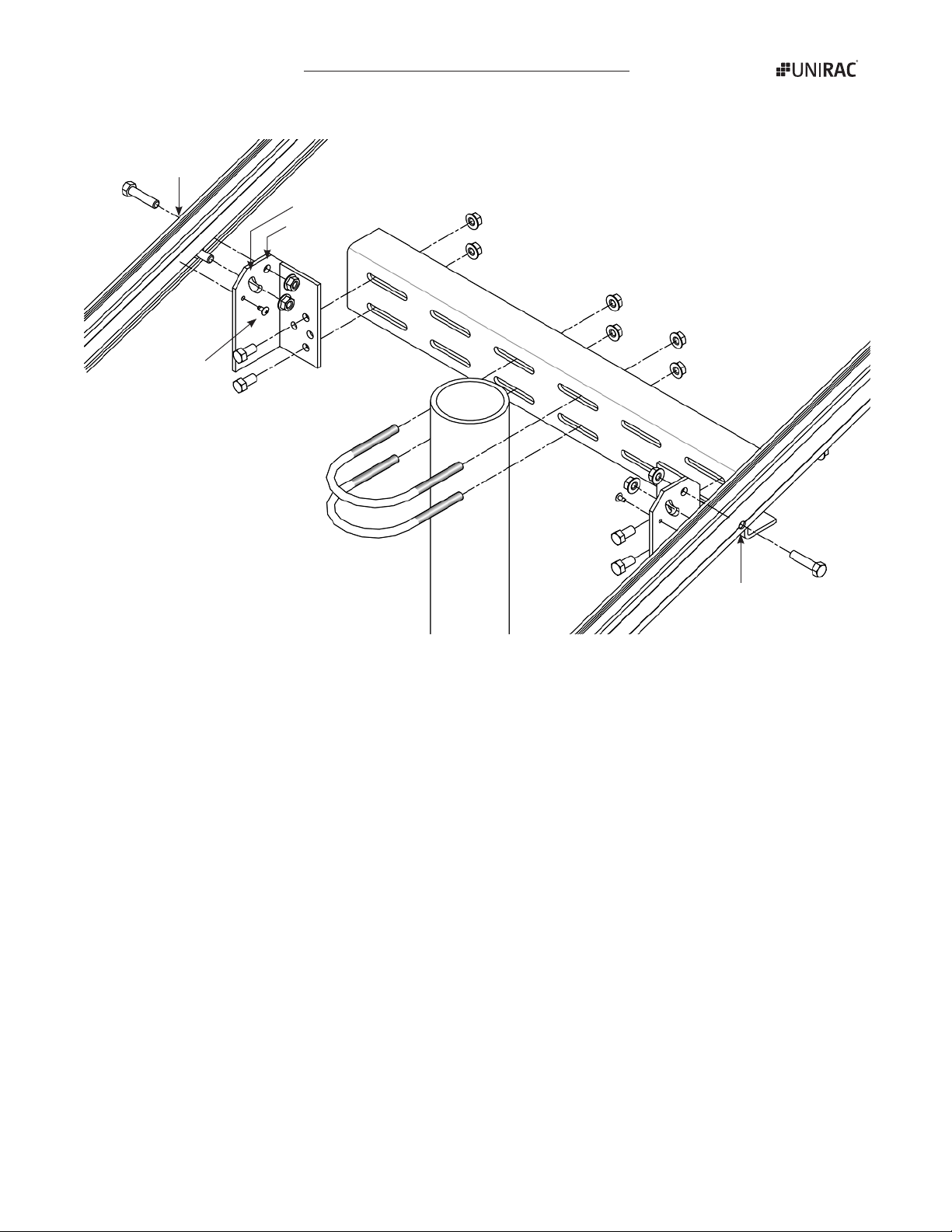

Final adjustments

Once the rack/PV module assembly is attached to the pole,

raise and rotate the assembly as needed. Never let the as-

semblyslidedownthepole. Tighten the flange nuts on the

U-bolt and channel bracket bolts. Then tilt the rails to bring

the module to the desired angle. Tighten the bracket/rail and

module.

If desired, install the self-tapping screws to permanently

fix the angle of the rack/PV module assembly.

Module attachment

Attach the PV module to the rack using clips and ¼-inch hard-

ware. Be sure to center the module on the channel. If channel

slotsdonotallowcorrectspacingandcentering:(1)movethe

clips to the other side of the rails, (2) reverse the brackets, or

(3) move the rails to the other side of the brackets.

PV module

SolarMount

heavy-duty rail

(cross section)

Module

mounting clip

Flat Washer: Most PV modules have mounting holes small enough

to secure the module bolt without the washer. Use the washer

with larger holes. If in doubt, use the washer.

Module bolt

Flange

nut

Module

mounting hole

Opposite clip

slot employed