page 1 February 2014

Product Data Sheet

HIT-HY 200

with HIT-Z

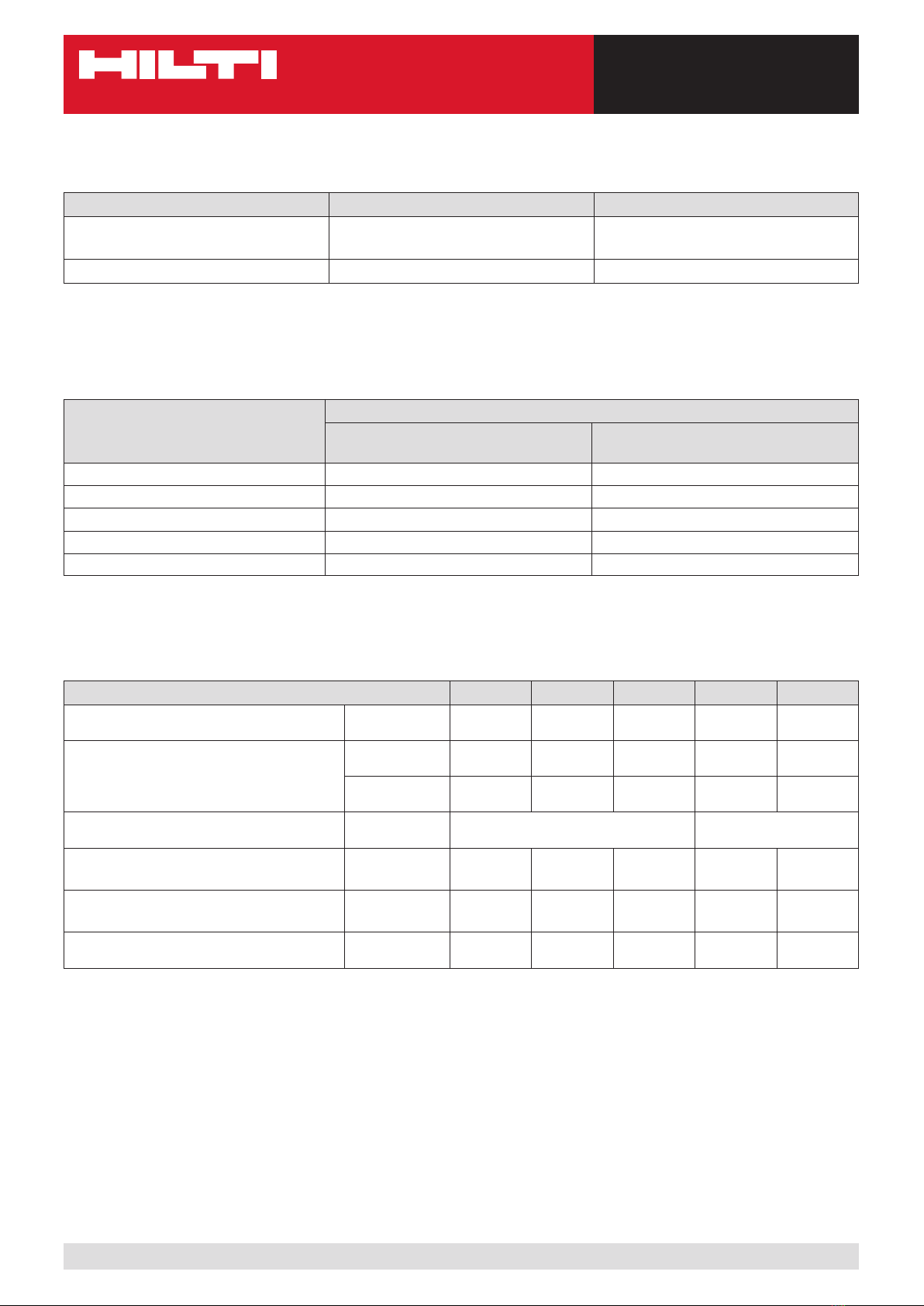

Basic loading data (for a single anchor)

All data in this section applies to

■Correct setting (See setting instruction)

■No edge distance and spacing inuence

■Steel failure

■Base material thickness, as specied in the table

■Embedment depth, as specied in the table

■One anchor material, as specied in the tables

■Non cracked concrete fc,cyl = 32 MPa

■Temperate range I (min. base material temperature -40°C, max.

long term/short term base material temperature: +24°C/40°C)

■Installation temperature range -10°C to +40°C

Embedment depth and base material thickness for the basic loading data

Recommended loads

Anchor size M8 M10 M12 M16 M20

Typical embedment depth hef [mm] 80 90 110 145 180

Base material thickness h [mm] 140 150 170 245 280

Recommended loads

Anchor HIT-Z

Anchor size M8 M10 M12 M16 M20

Tensile Nrec [kN] 11.4 18.1 25.9 45.7 69.5

Shear Vrec [kN] 6.9 10.9 15.4 27.4 41.7

Note: For varied embedment depths please contact your local Hilti engineer for further details.

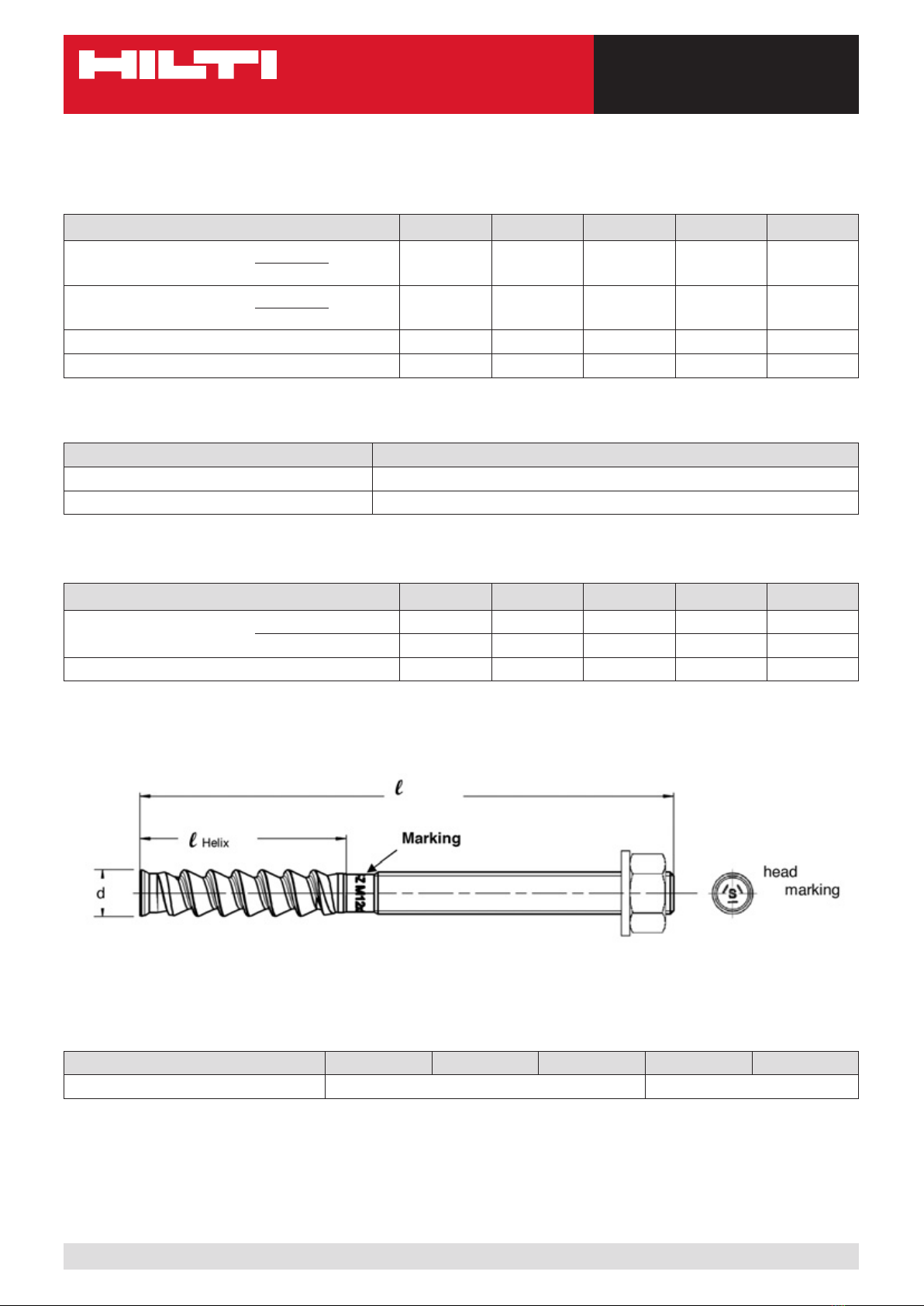

Hilti HIT-HY 200 with HIT-Z

Injection Mortar System Benefits

■no cleaning required: zero

succeptability to borehole cleaning

conditions with dry and water

saturated concrete base material

■maximum load performance in

cracked concrete and uncracked

concrete

■suitable for cracked and non-cracked

concrete C 20/25 to C 50/60

■suitable for use with diamond cored

holes in non-cracked or cracked

concrete with no load reductions

Hilti HIT-HY 200-R

500 ml foil pack

(also available as 330 ml

foil pack)

Static mixer

HIT-Z

HIT-Z-R rod

CE

conformity

European

Technical

Approval

Concrete

A4

316

Corrosion

resistance

Tensile

zone

PROFIS

anchor design

software

No cleaning

required for

approved

loads

Seismic Diamond

drilled

holes