HIMA H41q User manual

Programmable Systems

HIMA Paul Hildebrandt GmbH + Co KG

Industrial Automation HI 800 263 CEA

The H41q and H51q System Families

Catalog

Caution

The safety-related H41q/H51q systems as described in this manual can be used for several different pur-

poses. The knowledge of regulations and the technically perfect transfer carried out by qualified staff are

prerequisites for the safe installation, start-up and for the safety during operation and maintenance of the

H41q/H51q systems.

In case of unqualified interventions into the automation devices, de-activating or bypassing safety func-

tions, or if advices of this manual are neglected (causing disturbances or impairments of safety func-

tions), severe personal injuries, property or environmental damage may occur for which we cannot take

liability.

Important Notes

All HIMA products mentioned in this manual are protected with the HIMA trade-mark. As not differently

noted down this is possibly also valid for other mentioned manufacturers and their products.

All listed modules are CE certified and meet the requirements of the EMC Guideline of the European

Community.

All technical statements and data in this manual have been worked out very carefully, and effective

checks and inspections have been applied. This manual may however contain flaws or typesetting er-

rors. Therefore HIMA does not offer any warranties nor assume legal responsibility nor any liability for

the possible consequences of any errors in this manual. HIMA would appreciate being informed on pos-

sible errors.

The technology is subject to changes without notice.

Delivery Conditions

For our deliveries and services apply the “General Conditions for Delivery of Products and Services of

the German Electrical Industry“ - edition January 2002 -, resp. the “Conditions of Delivery for System

Software and Peripheral Devices for the HIMA Automation System“ (e.g. programmer units, printers,

screen monitors). The products of this price list are subject to the valid export regulations.

Eventual complaints can be recognized only when we are being notified within 14 days after receipt of

the merchandize.

The prices shown in a special list are valid ex works, packing charges excluded. The prices are subject

to change.

Table of Contents

I

Table of Contents

1 The HIMA PES ........................................................................................ 2

2 Concept of the HIMA PES ..................................................................... 3

2.1 Safety and Availability ............................................................................. 3

2.2 Designs and Types of the PES ............................................................... 4

2.2.1 Concept of H41q-M, MS / H51q-M, MS ................................................... 4

2.2.2 Concept of H41q-H, HS / H51q-H, HS..................................................... 5

2.2.3 Concept of H41q-HR, HRS / H51q-HR, HRS .......................................... 5

3 The H41q System Family ...................................................................... 7

3.1 Overview Assembly Kits H41q ................................................................ 7

3.2 Concepts of the Safety Switch-Off at H41q ............................................ 8

3.3 The Input/Output Level ........................................................................... 9

3.3.1 24 VDC Supply and Distribution .............................................................. 9

3.3.2 I/O Modules ........................................................................................... 10

3.3.3 ATEX (Ex)i-Modules .............................................................................. 10

3.3.4 Safety-Related Output Modules for SIL 3.............................................. 10

3.3.5 Special Features of the Output Modules ............................................... 10

3.4 System Voltage 24 VDC ....................................................................... 11

4 The H51q System Family .................................................................... 13

4.1 Overview Assembly Kits H51q .............................................................. 13

4.2 Concepts of the Safety Switch-Off at H51q .......................................... 14

4.3 The Input/Output Level ......................................................................... 16

4.3.1 The I/O Subrack..................................................................................... 16

4.3.2 24 VDC Power Supply and Distribution ................................................. 16

4.3.3 5 VDC Distribution ................................................................................. 17

4.3.4 Extension of the 5 VDC Power Supply .................................................. 17

4.3.5 The I/O Bus............................................................................................ 18

4.3.6 I/O Modules ........................................................................................... 18

4.3.7 ATEX (Ex)i-Modules .............................................................................. 18

4.3.8 Safety-Related Output Modules for SIL 3.............................................. 18

4.3.9 Special Features of the Output Modules ............................................... 19

4.4 System Voltage 24 VDC ....................................................................... 19

5 Technical Data ..................................................................................... 21

5.1 Mechanical Design ............................................................................... 21

5.2 System Data ......................................................................................... 21

5.3 Data of the Central Module (CU) .......................................................... 21

5.4 Interfaces .............................................................................................. 22

5.4.1 RS 485 Interfaces.................................................................................. 22

5.4.2 Ethernet Interfaces ................................................................................ 22

5.4.3 Profibus-DP interfaces........................................................................... 22

5.5 Definition of Signals .............................................................................. 22

6 Operating Conditions .......................................................................... 23

6.1 Climatic Conditions ............................................................................... 23

6.2 Mechanical Conditions .......................................................................... 24

6.3 EMC Conditions .................................................................................... 24

6.4 Voltage Supply ...................................................................................... 25

Table of Contents

II

7 Application Notes ................................................................................ 27

7.0.1 Programming System ELOP II and Operating System.......................... 27

7.0.2 Cabinet Engineering .............................................................................. 27

7.0.3 Usable Function Blocks ......................................................................... 27

8 Installation and Connections.............................................................. 29

8.1 ESD Protection ..................................................................................... 29

8.2 How to Insert and to Remove Modules ................................................. 29

8.2.1 I/O Modules ........................................................................................... 29

8.2.2 Coupling Modules .................................................................................. 29

8.2.3 Central Modules (CU) ............................................................................ 30

8.2.4 Power Supplies...................................................................................... 30

8.2.5 Communication and Coprocessor Modules........................................... 31

8.3 Earthing of the 24 VDC System Voltage ............................................... 31

8.3.1 Floating Supply ...................................................................................... 31

8.3.2 Earthed Operation ................................................................................. 31

8.4 Measures to Install a Cabinet According to the

CE Requirements ................................................................................. 31

8.5 Earthing in the HIMA PES .................................................................... 32

8.5.1 Earthing Connections ............................................................................ 32

8.5.2 Fastening of the Earthing Straps ........................................................... 34

8.5.3 Interconnecting the Earth Terminals of Multiple Switchgear Cabinets .. 35

8.6 Shielding of Data Lines in the HIMA Communication Systems ............ 35

8.7 Shielding in the Input/Output Area ........................................................ 36

8.8 Lightning Protection in HIMA Communication Systems ....................... 37

8.9 Cable Colors ......................................................................................... 37

9 Startup and Maintenance .................................................................... 39

9.1 Recommended Devices for Startup and Maintenance ......................... 39

9.2 Installing the System ............................................................................. 39

9.3 Earthing the 24 VDC System Voltage ................................................... 39

9.4 Starting up the Control Cabinet ............................................................ 39

9.4.1 Testing All Inputs and Outputs for External Voltage .............................. 39

9.4.2 Testing All Inputs and Outputs for Earth Faults ..................................... 39

9.5 Switching on Power Supply .................................................................. 40

9.6 Functional Testing ................................................................................ 40

9.6.1 Preparing Functional Testing................................................................. 40

9.6.2 Testing in the Central Devices............................................................... 40

9.6.3 Testing in the Input/Output Subracks .................................................... 41

9.6.4 Switching on the HIMA PES .................................................................. 41

9.6.5 Starting the Communication between Programming Device and PES .. 41

9.7 Maintenance ......................................................................................... 41

9.7.1 Exchange of the Buffering Batteries ...................................................... 42

9.8 Faults .................................................................................................... 43

9.8.1 Faults in the Central Device................................................................... 43

9.8.2 Faults in the Input/Output Modules........................................................ 43

9.8.3 Faults in the Coprocessor and Communication Modules ...................... 44

9.8.4 Repair of Modules.................................................................................. 44

9.8.5 HIMA Service, Training and Hotline....................................................... 44

10 Data Sheets .......................................................................................... 45

10.1 Assembly Kits ....................................................................................... 45

10.2 Data Connection Cables ....................................................................... 45

10.3 Central Modules .................................................................................... 46

10.4 Power Supplies ..................................................................................... 46

10.5 Current Distribution Modules and Drawers ........................................... 46

Table of Contents

III

10.6 Additional Devices for Power Supply .................................................... 46

10.7 Modules for I/O Bus Coupling ............................................................... 47

10.8 Communication Modules ...................................................................... 47

10.9 Relays in Terminal Block Housing ........................................................ 47

10.10 Bus Connection Modules for HIBUS ..................................................... 47

10.11 Accessories .......................................................................................... 47

10.12 Input and Output Modules .................................................................... 48

10.12.1 Digital Input Modules ............................................................................. 48

10.12.2 Analog Input Modules ............................................................................ 48

10.12.3 Digital Output Modules .......................................................................... 49

10.12.4 Analog Output Modules ......................................................................... 49

10.13 General Notes on the Data Sheets ....................................................... 50

10.13.1 I/O Modules ........................................................................................... 50

10.13.2 Modules within the Central Subrack ...................................................... 50

10.13.3 Communication Modules ....................................................................... 50

10.13.4 Symbols in the Data Sheet Diagrams.................................................... 51

10.13.5 Color Code for Lead Marking in Accordance to DIN IEC 60757............ 53

10.13.6 Description of the Order Code for Cable Plugs ..................................... 53

B 4234: Assembly Kit / H41q-M: System............................................... 55

B 4235: Assembly Kit / H41q-MS: System ............................................ 63

B 4236-1/-2: Assembly Kit / H41q-H/HR: System.................................. 71

B 4237-1/-2: Assembly Kit / H41q-HS/HRS: System............................. 79

B 5230: Assemly Kit / H51q-M: System................................................. 87

B 5231: Assembly Kit / H51q-MS: System ............................................ 97

B 5232-1/-2: Assembly Kit / H51q-H/HR: System................................ 109

B 5233-1/-2: Assembly Kit / H51q-HS/HRS: System........................... 121

B 9302: Assembly kit ........................................................................... 135

B 9361: Assembly kit ........................................................................... 143

BV 7002: Data connecting cable ......................................................... 149

BV 7032: Data connecting cable ......................................................... 151

BV 7040: Data connecting cable ......................................................... 153

BV 7043: Data connecting cable ......................................................... 155

BV 7044: Data connecting cable ......................................................... 157

BV 7045: Data connecting cable ......................................................... 159

BV 7046: Data connecting cable ......................................................... 161

BV 7048: Data connecting cable ......................................................... 163

BV 7049: Data connecting cable ......................................................... 165

BV 7050: Data connecting cable ......................................................... 167

BV 7051: Data connecting cable ......................................................... 169

BV 7052: Data connecting cable ......................................................... 171

BV 7053: HSR cable............................................................................ 173

BV 7055: Data connecting cable ......................................................... 175

BV 7201: Connection cable ................................................................. 179

F 3221: 16-channel input module ........................................................ 181

F 3222: 8-channel input module .......................................................... 183

F 3224A: 4-channel input module (Ex)i ............................................... 185

F 3236: 16-channel input module ........................................................ 193

F 3237: 8-channel input module .......................................................... 195

F 3238: 8-channel input module (Ex)i.................................................. 199

F 3240: 16-channel input module ........................................................ 209

F 3248: 16-channel input module ........................................................ 211

F 3322: 16-channel output module ...................................................... 213

F 3325: 6-channel supply unit (Ex)i ..................................................... 217

F 3330: 8-channel output module ........................................................ 225

F 3331: 8-channel output module ........................................................ 229

Table of Contents

IV

F 3332: 4-channel output module ........................................................ 233

F 3333: 4-channel output module ........................................................ 235

F 3334: 4-channel output module ........................................................ 237

F 3335: 4-channel output module (Ex)i................................................ 241

F 3348: 8-channel output module ........................................................ 253

F 3349: 8-channel output module ........................................................ 255

F 3422: 8-channel relay module .......................................................... 259

F 3430: 4-channel relay module .......................................................... 261

F 5203: 14 bit ring counter................................................................... 263

F 5220: 2-channel counter module...................................................... 265

F 6214: 4-channel analog input module .............................................. 271

F 6215: 8-channel analog input module .............................................. 279

F 6216A: 8-channel analog input module

with transmitter supply ...................................................................... 285

F 6217: 8-channel analog input module .............................................. 289

F 6220: 8-channel thermocouple input module (Ex)i,

safety-related .................................................................................... 297

F 6221: 8-channel analog input module (Ex)i,

safety-related .................................................................................... 307

F 6705: 2-channel converter digital/analog.......................................... 333

F 6706: 2-channel converter digital/analog.......................................... 337

F 7126: Power supply module ............................................................. 341

F 7130A: Power supply module........................................................... 343

F 7131: Power supply monitoring with buffer batteries........................ 345

F 7132: 4-channel power distribution................................................... 347

F 7133: 4-channel power distribution................................................... 349

F 7553: Coupling module..................................................................... 351

F 8621A: Coprocessor module ............................................................ 353

F 8627X: Ethernet module................................................................... 355

F 8628X: PROFIBUS-DP slave module .............................................. 411

F 8650X: Central module..................................................................... 445

F 8651X: Central module..................................................................... 449

F 8652X: Central module..................................................................... 453

F 8653X: Central module..................................................................... 457

H 4116: Relay in an electronic housing ............................................... 461

H 4135: Relay in an electronic housing ............................................... 465

H 4136: Relay in an electronic housing ............................................... 469

H 7013: Power supply filter.................................................................. 473

H 7014: Electronic fuses...................................................................... 477

H 7015A: Terminal module .................................................................. 481

H 7016: Terminal module .................................................................... 487

H 7017: Shunt with low-pass filter ....................................................... 489

H 7018: Terminal module .................................................................... 493

H 7020: Terminal Module .................................................................... 497

H 7021: Power supply filter.................................................................. 503

H 7505: Multifunctional interface converter ......................................... 507

H 7506: Bus terminal ........................................................................... 513

RS 485 PCI: Interface card.................................................................. 515

The H41q and H51q System Families

1

The H41q and H51q System Families

Notes to the Manual

This manual contains the description of the Programmable Electronic Systems (PES) of the

HIMA system families H41q and H51q.

Beside this manual and the data sheets you will find further informations to the system families

H41q and H51q on the ELOP II CD.

The first part contains general notes to the PES and is followed by the description of the indi-

vidual types. All the descriptions have the same structure so that they can each be used inde-

pendently as device documentation.

The descriptions are followed by general information about both system families, e.g. technical

data, test standards, applications, start-up and maintenance.

The second part of the manual contains all data sheets of the systems and the modules. Each

type of PES has a corresponding assembly kit.

After the descriptions of the systems and the assembly kits the data sheets are arranged in

alphanumerical order according to their type numbers.

HIMA Automation Devices are developed, manufactured and tested according to the relevant

safety standards. They must only be used for the applications described in the instructions and

with specified environmental conditions, and only in connection with approved external devic-

es.

In case of unqualified interventions into the automation devices, de-activating or bypassing

safety functions, or if advices of this manual are neglected (causing disturbances or impair-

ments of safety functions), severe personal injuries, property or environmental damage may

occur for which we cannot take liability.

The HIMA PES The H41q and H51q System Families

2

1 The HIMA PES

The HIMA PES described here consists of the H41q and H51q system families. Both system

families are based on the same hardware and software, and they are the third generation of

the field-proven HIMA PES to control preferably process engineering plants. PCs (PADT)* are

used for programming, configuration, data logging, operation and trend recording.

Digital and analog inputs can be processed. Some input modules are designed for intrinsically

safe circuits as well as for electric position sensors (proximity switches) according to DIN EN

60947-5-6. Digital and analog outputs are also available.

The HIMA PES are installed in 19-inches subracks. The H41q system family is a compact sys-

tem consisting of one subrack, holding all components such as central unit, interface exten-

sions, communication modules, power supplies, fusing and power distribution, as well as input/

output modules.

The H51q system has a modular structure. A central rack contains the central unit(s), interface

exten-sions, communication modules, monitoring and power supplies, and it can have up to 16

associated input/output subracks.

*PADT = Programming and Debugging Tool

Concept of the HIMA PES

3

2 Concept of the HIMA PES

The HIMA PES of the H41q and H51q system families consist of 19 inches subracks for central

devices 5 HU and modules for binary and analog input/output signals which are assembled in

H51q systems within 19 inches subracks, 4 HU.

The HIMA PES use PCs (PADTs) with the tool ELOP II for programming, configuration, mon-

itoring, operation and documentation. The entry of the user program and the compilation into

the machine code is made only on the PC without connected PES. To load, test and to monitor

the PES the PC is connected via a serial interface RS 485 or a bus system to the PES.

2.1 Safety and Availability

HIMA PES are designed both for safety-related applications up to SIL 3 (definition according

to IEC 61508) and for high availability. Depending on the required safety and availability, HIMA

PES can be supplied as one-channel or two-channel (redundant) devices with the same mod-

ules in the central device as well as in the input/output level. Redundant modules increase the

availability, as in case of an error in a safety-related module this is automatically switched off

while the redundant module continues the operation.

The following table gives an overview:

1) Individual I/O modules can also be used as redundant modules or connected to sensors in

a 2-out-of-3 voting to increase the availability.

The inputs have to be therefore configured on 3 different I/O modules.

Mono = single channel system structure

Redundant = redundant central modules and/or separated I/O bus system structure

Safety SIL 3 SIL 3 SIL 3

Availability normal (MS) high (HS) very high (HRS)

Central module mono redundant redundant

I/O modules mono 1) mono 1) redundant

I/O bus mono mono redundant

Table 1: Safety and Availability

Concept of the HIMA PES

4

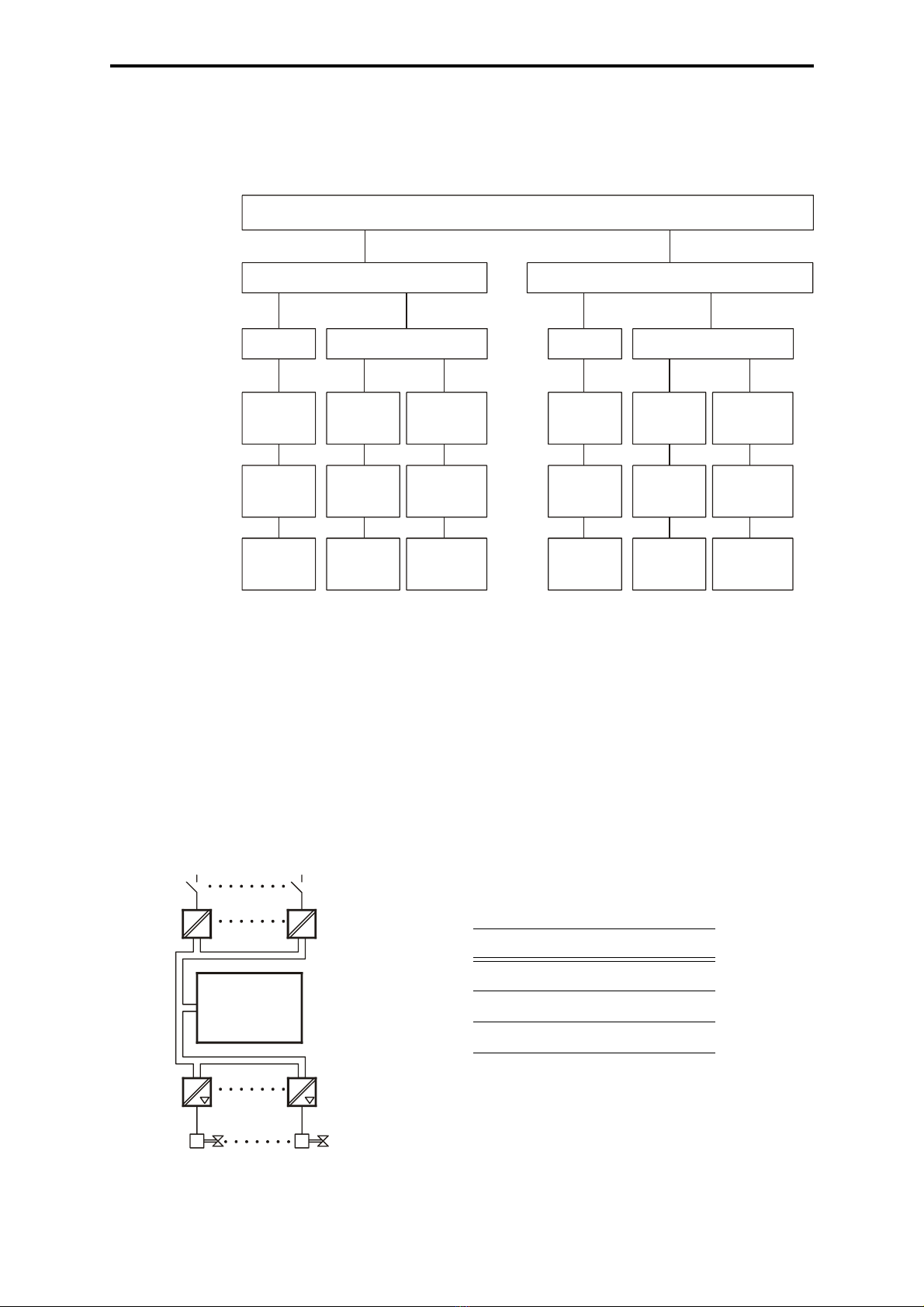

2.2 Designs and Types of the PES

The controls can be adapted to the requirements of the plant by equipping them with the ap-

propriate central modules. The following structures are possible with the H41q or H51q system

family:

* Central modules, communication modules and I/O modules are installed in the system sub-

rack.

Figure 1: Designs and Types of the PES

Notes:

Mono = single channel system structure

Redundant = redundant central modules and/or separated I/O bus system structure

SIL = Safety Integrity Level according to IEC 61508

I/O = input and output

2.2.1 Concept of H41q-M, MS / H51q-M, MS

Figure 2: Concept of H41q-M, MS / H51q-M, MS

Designs and Types of the PES

The H41q compact system The H51q modular system

Mono Redundant

normal

H41q-M H41q-H H41q-HR

TÜV

H41q-MS TÜV

H41q-HS

SIL 3

TÜV

H41q-HRS

- *

1

Mono Redundant

- *

1- *

2

normal

H51q-M

high

H51q-H

very high

H51q-HR

SIL 3

TÜV

H51q-MS

SIL 3

TÜV

H51q-HS

SIL 3

TÜV

H51q-HRS

16

116

12 x 8

2

Design

Availability

Type

Certificate

Type

Techn. features

Max. I/O-rack

I/O buses

Safety

Mono

high very high

SIL 3 SIL 3

I/O bus

I/O bus

CU

Input modules

Central module

Output modules

Characteristics

CU mono

I/O modules mono

I/O bus mono

Concept of the HIMA PES

5

H41q-M / H51q-M

single channel central module and single channel I/O bus

H41q-MS / H51q-MS

with double processors, safety-related

single channel central module and single channel I/O bus with TÜV certificate up to SIL 3 ac-

cording to IEC 61508

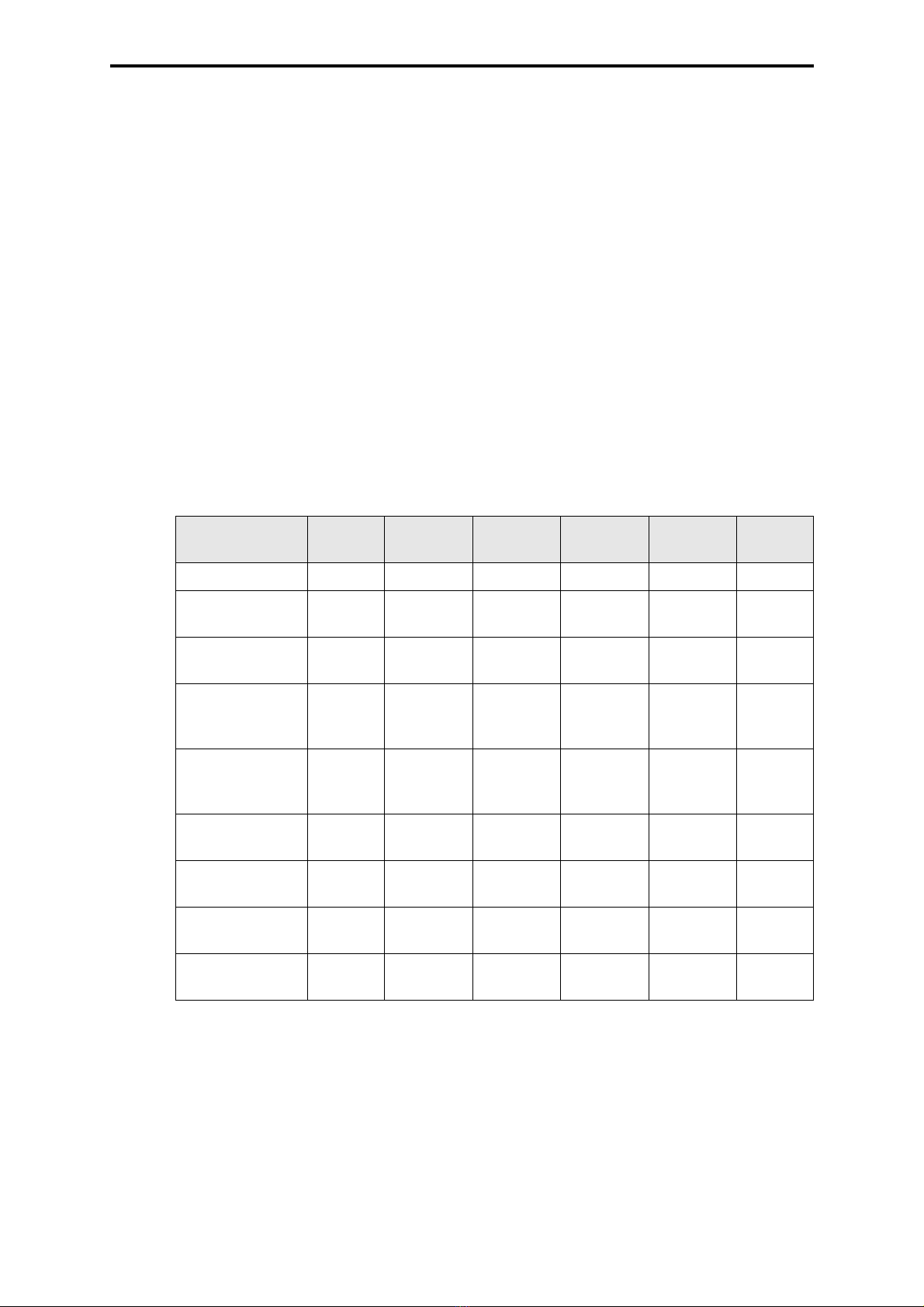

2.2.2 Concept of H41q-H, HS / H51q-H, HS

Figure 3: Concept of H41q-H, HS / H51q-H, HS

H41q-H / H51q-H

redundant central modules and a single channel I/O bus for highly available PES

H41q-HS / H51q-HS with double processors, safety-related

redundant central modules and a single channel I/O bus for highly available and safety related

PES with TÜV certificate up to SIL 3 according to IEC 61508

2.2.3 Concept of H41q-HR, HRS / H51q-HR, HRS

Figure 4: Concept of H41q-HR, HRS / H51q-HR, HRS

I/O bus

I/O bus

CU 2

Input modules

Central module

s

Output modules

CU 1

DPR DPR

Characteristics

CU redundant

I/O modules mono/

redundant

I/O bus mono

I/O bus

I/O bus

CU 2

Input modules

Central module

s

Output modules

CU 1

DPR DPR

I/O bus

I/O bus

Characteristics

CU redundant

I/O modules redundant/

mono

I/O bus redundant

Concept of the HIMA PES

6

H41q-HR / H51q-HR

Redundant central modules and two channel I/O bus for highly available PES.

H41q-HRS / H51q-HRS with double processors, safety-related

redundant central modules and redundant I/O bus for highly available and safety-related PES

with TÜV certificate up to SIL 3 according to IEC 61508

Remarks to the drawings:

CU = central module

I/O modules = input / output modules

I/O bus = bus system for inputs and outputs

DPR = Dual Port RAM

The H41q System Family

7

3 The H41q System Family

The H41q system family comprises compact designed PES in single channel and redundant

models, also with TÜV safety certificate.

All input/output modules can be used with both redundant and single channel models of the

central modules.

All modules of the H41q system family meet the requirements for electromagnetic compatibility

and immunity according to article 10 of the EG guideline 89/336/EWG for the electromagnetic

conformity. This is demonstrated with the CE sign within the data sheets of the modules. Also

the systems and modules are wearing a label with this sign.

All models of the H41q system family have all the components required for control tasks in one

19 inches subrack, 5 units high, with an integrated cable tray (see also data sheets of H41q

systems or assembly kits).

3.1 Overview Assembly Kits H41q

The components required for a working system are included in assembly kits:

* Options

Abbreviations: CM Coprocessor Module

CoM Communication Module

CU Central Module

I/O Input/Output

System H41q-M H41q-H H41q-HR H41q-MS H41q-HS H41q-

HRS

Safety – – – SIL 3 SIL 3 SIL 3

Quantity/type

CU

1 x

F 8653X

2 x

F 8653X

2 x

F 8653X

1 x

F 8652X

2 x

F 8652X

2 x

F 8652X

Quantity/type

CM *

1 x

F 8621A

(2 x) 1 x

F 8621A

(2 x) 1 x

F 8621A

1 x

F 8621A

(2 x) 1 x

F 8621A

(2 x) 1 x

F 8621A

Quantity/type

CoM

(Fast Ethernet) *

1 x

F 8627/

F 8627X

(2 x) 1 x

F 8627/

F 8627X

(2 x) 1 x

F 8627/

F 8627X

1 x

F 8627/

F 8627X

(2 x) 1 x

F 8627/

F 8627X

(2 x) 1 x

F 8627/

F 8627X

Quantity/type

CoM

(Profibus-DP) *

1 x

F 8628/

F 8628X

(2 x) 1 x

F 8628/

F 8628X

(2 x) 1 x

F 8628/

F 8628X

1 x

F 8628/

F 8628X

(2 x) 1 x

F 8628/

F 8628X

(2 x) 1 x

F 8628/

F 8628X

Quantity/type

power supply

1 x

F 7130A

2 x

F 7130A

2 x

F 7130A

2 x

F 7130A

2 x

F 7130A

2 x

F 7130A

Quantity

I/O buses

112112

max. quantity

I/O modules

13 13 7 + 6 13 13 7 + 6

Assembly kit

number

B 4234 B 4236-1 B 4236-2 B 4235 B 4237-1 B 4237-2

Table 2: Overview Assembly Kits H41q

The H41q System Family

8

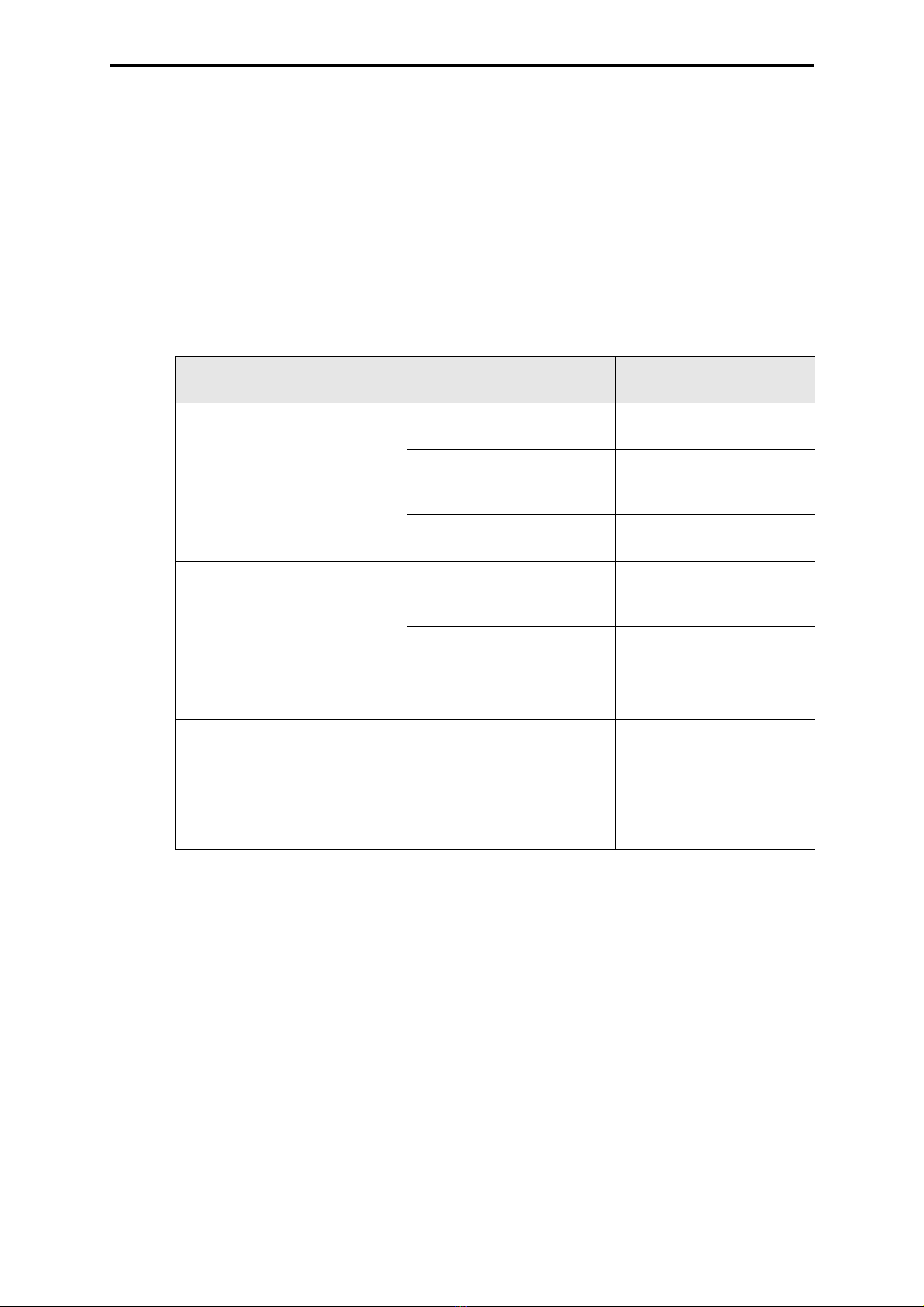

3.2 Concepts of the Safety Switch-Off at H41q

In the system descriptions of the safety-related PES H41q-MS, -HS, -HRS the ways for shut-

down if a fault occurs are shown. Depending on the fault location the reactions of the systems

are fixed or they can be defined in the user program.

Parameters are set

– in the resource properties I/O parameter

– by activating of a system variable for emergency shutdown

– via function block H8-STA-3.

An overview of the system variables including the corresponding error code you will find in the

operating system manual.

Reaction to faults of safety related digital I/O modules during operation:

Definition:

Double fault = fault within an output channel and the switch-off electronic part of this testable

output module.

Abbreviations used in the table:

CU Central Module

I/O bus Input/output bus

WD Watchdog signal

More explanations on the following page.

Location of fault I/O parameter in the pro-

perties of the resource Reaction of the system

Output modules

Single error

(also voltage failure)

- display only or

- normal operation

Module switch-off

- normal operation and

one function block

H8-STA-3 per group

Group shutdown

- Emergency off WD switch-off of the

appertaining CU

I/O bus or

double fault of

output modules

- display only Slot with error code in I/O

bus display of the CPU,

WD is still switched on

- normal operation or

- Emergency off

WD switch-off of the

appertaining CU

Central modules independent of the I/O

parameter

WD switch-off of the

appertaining CU

Input modules independent of the I/O

parameter

Operation of 0-signal for all

inputs of this module

Independent of a fault of the

output module

System variable for emer-

gency switch-off activated,

independent of the I/O

parameter

WD switch-off of the

appertaining CU

Table 3: Concepts of the Safety Switch-Off at H41q

The H41q System Family

9

Explanations to the table:

Parameter “Display only“

Switch-off by means of the integrated safety shutdown inside the output amplifier. If not possi-

ble then shutdown of the watchdog signal in the I/O rack by means of the coupling module (only

in systems H51q). No shutdown of the watchdog signal of the appertaining central unit. This

parameter is permissible only up to SIL 1.

Parameter “Normal operation“

Reaction as with parameter “Display only“, additionally switch-off of the watchdog signal of the

appertaining central unit if necessary. Parameterization required from SIL 2. Normal and re-

commended parameter.

Parameter “Emergency off“

Switch-off of the watchdog signal of the appertaining central unit and thus shutdown of the out-

put amplifiers in case of a fault in the output module.

The watchdog signal is not switched off at faults in the input modules.

Module switch-off

A faulty testable output module with integrated safety shutdown will be switched automatically

to the safe de-energized status.

Group shutdown

If it is requested, a group shutdown may be defined in the user program in a way that all test-

able output modules appertaining to the group with the faulty module are also switched off.

Inside the user program up to 10 testable output modules can be assigned to one group by

means of the function block H8-STA-3.

WD switch-off of the appertaining CPU

In case of a fault the watchdog signal (WD) of the appertaining central module is switched off.

If systems with redundant central modules and a common I/O bus are used then the output

modules are related to both central modules. In case of a fault both the watchdog signals of

the central modules are switched off. That means all the I/O modules are switched off (only at

H41q-H/HS).

If systems with redundant central modules and redundant I/O bus are used then the output

modules are related to one central module and one I/O bus. In case of a fault only the watchdog

signal of the related central module is switched off. That means only the related I/O modules

are switched off (only at H41q-HR/HRS). The redundant central module is still in operation.

3.3 The Input/Output Level

In the subrack, slots 1 to 13 are provided for the input/output modules. Any arrangement of

I/O module types is possible. In PES with redundant I/O bus, the modules on slots 1 to 7 are

assigned to the first I/O bus and 8 to 13 to the second I/O bus.

There is an integrated cable tray under the subrack. It is equipped with a receptacle for the

label which can be flapped open to provide easy access to the cables.

3.3.1 24 VDC Supply and Distribution

For 24 VDC supply and distribution we recommend to use the K 7212, K 7213, K 7214, K 7215

subassemblies or fuse distributor K 7915.

They include all components for the fusing of up to 18 individual supply circuits with circuit

breakers.

The K 7212 is additionally equipped with decoupling diodes and filters with monitoring relays

for mains supply.

Additionally you could use also a power supply of the PS1000 series (see ELOP II CD).

The H41q System Family

10

3.3.2 I/O Modules

The I/O modules are used for signal transfer and signal matching between the plant and the

central modules. The input and output circuits are always fed into the I/O modules via cable

plugs on the front side. The status of the digital output signals is shown on the LEDs of the

cable plugs. The power supply is either via the cable plugs or via the I/O bus board. The order

of the different I/O module types does not matter.

All I/O modules can be removed or inserted during operation (see chapter 8.1.1).

3.3.3 ATEX (Ex)i-Modules

The current (Ex)i modules exist in 2 construction models:

– non-varnished, with PCB covering

– varnished, with PCB covering

Any models can be equipped together without empty slots between them.

Non-varnished (Ex)i modules may combined together with non-(Ex)i modules without any re-

strictions. There are no free slots necessary on the left or on the right.

With varnished (Ex)i modules with PCB covering the right slot has to remain free in combina-

tion with non-(Ex)i modules, or has to be equipped with a front plate with partition plate

(M 2214). This is also valid for slot no. 15. The slot left to the (Ex)i module may be equipped

with any other module. Spare slots have to be covered by front plates M 2215 (4 spacing units

SU) or M 2217 (8 spacing units SU).

Usable front plates with partition or front plates:

M 2214 Front plate with partition plate 100 x 160 mm

M 2215 Front plate 4 SU

M 2217 Front plate 8 SU

Cable plugs for intrinsically safe circuits are marked and have coded pins, so that they can only

be plugged into the appropriate modules.

3.3.4 Safety-Related Output Modules for SIL 3

All the safety-related output modules meet the requirements of SIL 3.

The safety-related output modules have three semiconductors connected in series. That

means that more than the required second independent component for safety shutdown is now

integrated in the output module.

In case of a fault of an output module the requirements of SIL 3 are valid without time limit. In

the following this feature is called the integrated safety shutdown.

If a safety-related output module should fail during operation then it will be automatically

switched off by the integrated safety shutdown to get the safe de-energized status.

3.3.5 Special Features of the Output Modules

All output modules have the following special features:

– To increase the availability the outputs of the safety-related output modules can be

switched in parallel without external diodes.

Decoupling diodes are already integrated on the module (see the corresponding data

sheets).

– No output voltage is generated if the supply voltage L- is cut at the output module.

– The connection of inductive loads can be done without using protection diodes at the coil.

However, it is recommended to connect a diode directly at the inductive load avoiding

noise voltages.

– The LED signaling the output status is controlled separately.

The H41q System Family

11

– The design of the cable plugs enables the two-pole connection of the actuators. Together

with a two-pole supply of the output module an earth fault detection will be simplified by

means of a totalizing current transformer.

The cable plugs are available in two specifications:

• L- in cable plug, one-pole with common L-

• L- in 2-pole type, 2-pole with L- per channel

see also chapter 10.13.6 , “Description of the Order Code for Cable Plugs”, option P2

• No time-limited operation in case of a faulty output module.

3.4 System Voltage 24 VDC

HIMA systems will be connected to 24 VDC. The connection terminals are labelled with L+ and

L-. The power supply units made available by HIMA, e.g. the power supply PS1000, meet the

requirements according to CE for electrical safety and EMC.

All used power supplies must fulfill the requirements SELV (Safety Extra Low Voltage) or PELV

(Protective Extra Low Voltage). See also chapter 6.4.

The power supply units meet the requirements of the NAMUR recommendation NE 21 for the

safety during short-time voltage dips up to 20 ms.

For the supply of 24 V sources, which cannot guarantee a buffering during voltage dips of at

least 20 ms, the following measures must be taken in the H41q system family:

• decoupling of the power supply for the central units and

• noise blanking (parameterizable).

Note Due to the high inrush current of lamps the correct dimensioning of the

power supply units for lamp loads must be regarded.

The H41q System Family

12

The H51q System Family

13

4 The H51q System Family

The H51q system family comprises modular designed PES in single channel and redundant

models, also with TÜV safety certificate.

All input/output modules can be used with both redundant and single channel models of the

central devices.

All modules of the H51q system family meet the requirements for electromagnetic compatibility

and immunity according to article 10 of the EU guideline 89/336/EWG for the electromagnetic

conformity. This is marked with the CE sign within the data sheets of the modules. Also the

systems and modules are wearing a label with this sign.

The H51q system family consists of one 19 inches central rack, 5 units high, and up to 16 input/

output racks in the 19 inches size, 4 units high (see also data sheets for H51q systems or as-

sembly kits).

4.1 Overview Assembly Kits H51q

The components required for a working system are included in assembly kits:

* Options (max. 5 communication slots per central module)

Abbreviations: CM Coprocessor Module

CoM Communication Module

CU Central Module

I/O Input/Output

System H51q-M H51q-H H51q-HR H51q-MS H51q-HS H51q-

HRS

Safety – – – SIL 3 SIL 3 SIL 3

Quantity/type

CU

1 x

F 8651X

2 x

F 8651X

2 x

F 8651X

1 x

F 8650X

2 x

F 8650X

2 x

F 8650X

Quantity/type

CM *

3 x

F 8621A

2 x 3

F 8621A

2 x 3

F 8621A

3 x

F 8621A

2 x 3

F 8621A

2 x 3

F 8621A

Quantity/type

CoM

(Fast Ether-

net) *

5 x

F 8627/

F 8627X

2 x 5

F 8627/

F 8627X

2 x 5

F 8627/

F 8627X

5 x

F 8627/

F 8627X

2 x 5

F 8627/

F 8627X

2 x 5

F 8627/

F 8627X

Quantity/type

CoM

(Profibus-DP) *

5 x

F 8628/

F 8628X

2 x 5

F 8628/

F 8628X

2 x 5

F 8628/

F 8628X

5 x

F 8628/

F 8628X

2 x 5

F 8628/

F 8628X

2 x 5

F 8628/

F 8628X

Quantity/type

power supplies

2 (+1*) x

F 7126A

3 x

F 7126A

3 x

F 7126A

2 (+1*) x

F 7126A

3 x

F 7126A

3 x

F 7126A

5 V monitoring F 7131 F 7131 F 7131 F 7131 F 7131 F 7131

Battery

buffering

F 7131 +

F 8651X

F 7131 +

F 8651X

F 7131 +

F 8651X

F 7131 +

F 8650X

F 7131 +

F 8650X

F 7131 +

F 8650X

Quantity

I/O buses

112112

max. quantity

I/O modules

256 in

16 I/O

subracks

256 in

16 I/O

subracks

2 x 128 in

2 x 8 I/O

subracks

256 in

16 I/O

subracks

256 in

16 I/O

subracks

2 x 128 in

2 x 8 I/O

subracks

Assembly kit

number

B 5230 B 5232-1 B 5232-2 B 5231 B 5233-1 B 5233-2

Table 4: Overview Assembly Kits H51q

The H51q System Family

14

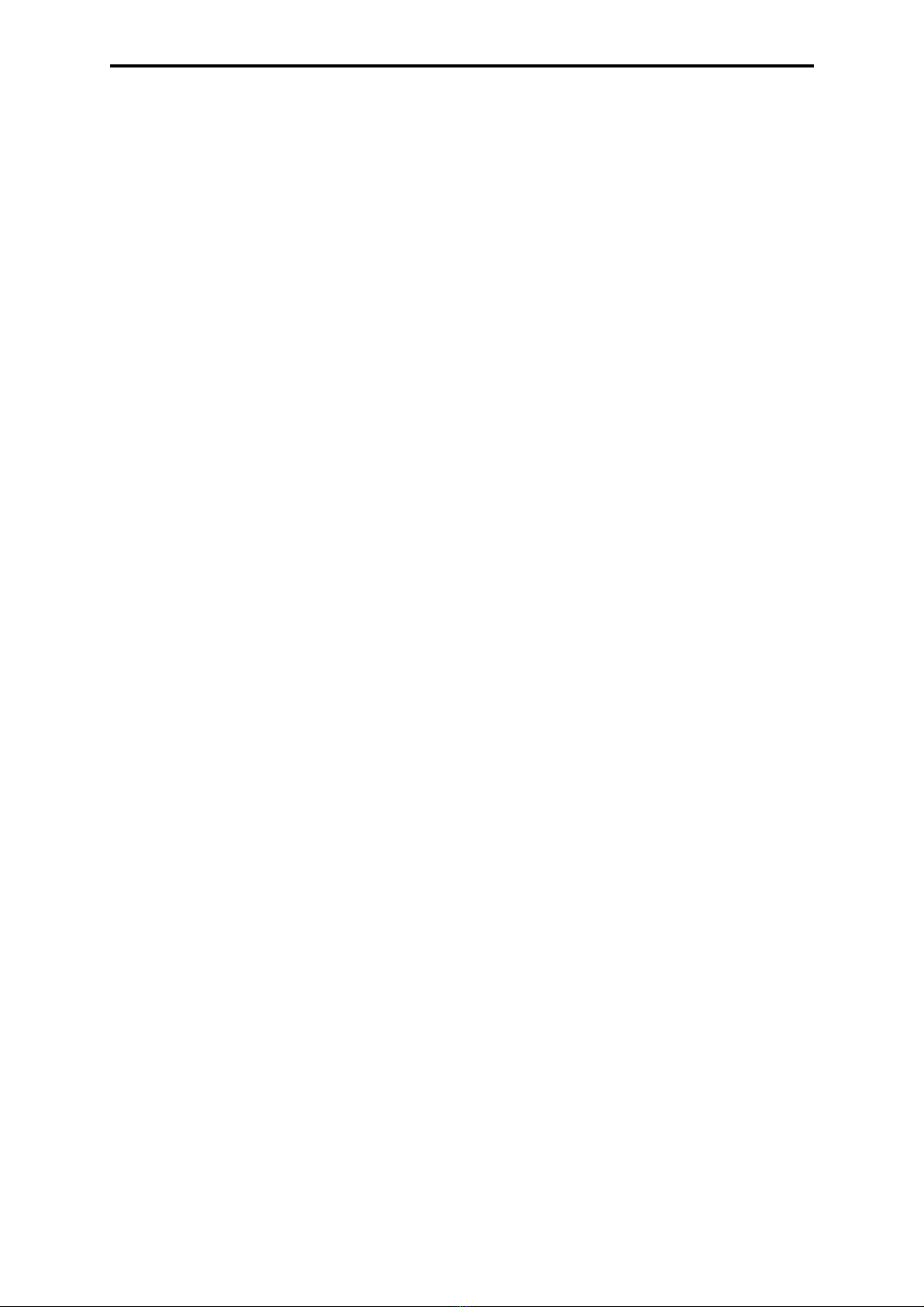

4.2 Concepts of the Safety Switch-Off at H51q

In the system descriptions of the safety related PES H51q-MS, -HS, -HRS the ways for shut-

down if a fault occurs are shown. Depending on the fault location the reactions of the systems

are fixed or they can be defined in the user program.

Parameters are set

– in the resource properties I/O parameter

– by activating of a system variable for emergency shutdown

– via function block H8-STA-3.

An overview of the system variables including the corresponding error code you will find in the

operating system manual.

Reaction to faults of safety-related modules during operation:

Definitions:

Double fault = fault within an output channel and the electronic switch-off part of a testable out-

put module

Abbreviations in the table:

CU Central Module

I/O bus Input/output bus

I/O subrack Input/output subrack

WD Watchdog signal

More explanations on the following page.

Location of fault I/O parameter in the pro-

perties of the resource Reaction of system

Output modules

single error

(also voltage failure)

- display only or

- normal operation

Module switch-off

- normal operation and

one function block

H8-STA-3 per group

Group shutdown

- Emergency off WD switch-off

of the appertaining CU

I/O bus within I/O subrack or

double fault in

output modules

- display only Slot with error code in I/O

subrack display of the

CPU,

WD is still switched on

- normal operation WD switch-off of the apper-

taining coupling module

- Emergency off WD switch-off

of the appertaining CU

Central modules (CU) or

I/O bus between CU and cou-

pling modules

independent of the I/O

parameter

WD switch-off

of the appertaining CU

Input modules independent of the I/O

parameter

Operation of 0-signal for all

inputs of this module

Independent of a fault of the

output module

System variable for emer-

gency switch-off activated,

independent of the I/O

parameter

WD switch-off

of the appertaining CU

Table 5: Concepts of the Safety Switch-Off at H51q

This manual suits for next models

1

Table of contents

Other HIMA Industrial Equipment manuals