Himoinsa KT8000 Service manual

INSTALLATION, USE AND

MAINTENANCE MANUAL

LIGHTING TOWERS | APOLO KIT TOWER: KT8000, KT12000

RAMIRENT

LIGHTING TOWERS | PAG. 2

INDEX

3 1. Introduction

4 2. Safety regulations

7 3. Lighting tower: composition and location of its components

9 4. Technical information

10 5. Start up

14 6. Operations to carry out after use

15 7. Maintenance

15 8. Failures

16 9. Guarantee conditions

RAMIRENT

INTRODUCTION | PAG. 3

1. INTRODUCTION

By means of this handbook we intend to provide the basic instructions and

information for a proper installation, use and maintenance of the HIMOINSA

Lighting Tower.

All activities to do with the internal functioning of the tower and the generating

set that compose it, must be carried out by specialized personnel, with experience

in Diesel engines and mechanical installations as well as in generation of

electricity. This handbook and all the other reference documentation are

indispensable in order to prepare these specialists.

At Himoinsa we think of you, that’s why its essential that you thoroughly read all

safety regulations and warnings before you start the lighting tower, only by doing

this we can assure you an optimal service in perfect reliability and safety

conditions.

HIMOINSA advises that the validity of the information in this handbook refers to

the date that it was issued, as several aspects such as the technological

developments, new regulations or updates and improvements of the models

oblige us to make changes without notice, which may not appear in the current

manual.

This Handbook and the rest of the reference documentation, form part of the

lighting tower that you have purchased and must be kept and protected against

any agent that may damage them. This documentation must accompany the

equipment whenever it is leased to any other user or new owner. Although all the

information in this handbook has been thoroughly veried, HIMOINSA refuses any

responsibility for any spelling typographic or transcription errors.

In accordance with Directive CEE 85/374 and subsequent modication 99/34,

HIMOINSA will not be deemed responsible due to defective installations,

improper uses of the machine and non fullment of the regulations of this

manual.

RAMIRENT

SAFETY REGULATIONS | PAG. 4

2. SAFETY REGULATIONS

Before working on the machine carefully read the following safety regulations,

and nd out about the local requirements in safety.

The installation, operation, maintenance and repairs must be carried out only

authorized and competent personnel.

The owner is responsible for the maintenance of the Lighting Tower in good safety

conditions. The parts and accessories must be replaced if they are not in good

functioning conditions.

2.1 GENERAL SAFETY PRECAUTIONS

•Do not allow non-authorized people to be close to the Lighting Tower.

•Do not allow people with pacemakers to get close to the tower as it

may cause electromagnetic interferences on these devices.

•Do not get close to the Tower wearing loose clothes or objects that

may be attracted by the airow or by the mobile parts of the engine.

•lt is forbidden to dismount or disable any safety device.

•lt is forbidden to lean on the Lighting Tower or leave objects on it.

•Lower the mast when wind speed exceeds 80km/h.

•Do not tow the lighting tower trailer on the highway at speeds

exceeding 90km/h.

lf the Lighting Tower is driven by automatic driving sets, it is necessary to:

•Place a red light that switches on when the unit is working, in a

visible place.

•Place a warning sign warning of the possibility that and automatic

unexpected start up of the machine may occur.

•Place an obligations sign stating: “All maintenance operations must

be carried out with the genset in the LOCK position”.

•For the emergency stop of the group, press “emergency stop” push

button, located in the group or the emergency push button to be

installed outside the engine room.

RAMIRENT

SAFETY REGULATIONS | PAG. 5

Once the pole is totally opened, verify the following points:

•The mast must be totally perpendicular to the ground.

•The feet must be in touch with the ground.

•All xings must be locked.

•Do not move the tower when the ood lights are on. The high

temperatures that the laments of the lights reach, make them very

vulnerable to small vibrations, therefore we recommend switching off

the oodlights 1O minutes before moving the equipment.

•Do not fold the mast of the unit without having lowered it.

•Do not open the pressure control valve at the bottom of the mast

when it is opened.

2.3 SAFETY DURING INSTALLATION AND FIRST START UP

•For provisional installations, it will just be enough to place the unit on

a well levelled surface, for installations for a longer period of time, its

advisable to build foundations. The installation of the Generating set

and all its accessories must be carried out by specialized personnel.

lf any difculty, consult the Himoinsa Technical Department.

•You must know all the emergency procedures related to the

installation to be done.

•Always use a protective hard hat, safety boots and gloves, safety

goggles and tight clothes.

•Do not change the original protections, located on the rotary exposed

parts, over the hot surfaces, air intakes, belts and parts in tension.

•Do not leave dismounted parts, tools or any other accessory on top

of the engine or nearby or at the premises of the genset.

•Never leave ammable liquids or cloths soaked with ammable

liquids near the generating set, near electrical devices or parts of the

electrical installation (including lamps).

•Take all precautions possible in order to avoid are risks; check that

there is a grounds installation and that has been made according to

Regulations.

•Place a sign “NO MANOEUVRING” in all the sectioning organs that

insulate the parts of the installation on which you must work.

•lnsulate all disconnected links and wires. Do not leave uncovered the

voltage terminals of the generator.

•Connect the grounds installation to all the connexion relative points

prepared in the unit and its accessories.

2.2 SAFETY AT DELIVERY, STORAGE AND UNPACKING

•Once you receive the lighting tower check that the goods received

correspond to those on the delivery note and that all the goods are in

perfect conditions.

•To lift and transport the Tower, lifting machines the appropriate

capacity must be used. All loose and pivoting parts must be safely

xed before lifting it.

•When moving the lighting Tower and specially when lifting it , it is

recommended to use the available points for its safe and easy

movement.

•lt is totally forbidden to use any other lifting points located over the

engine, alternator or other components.

•lf the lighting Tower is damaged for any reason during its

transportation, storage, and/or mounting, it mustn’t be started up

before it is veried by our specialized personnel.

•lf you want to store the Tower until its utilization, it is highly

recommendable to have a warehouse properly protected against any

chemical agent that may damage its components.

•Unpacking must be carried out carefully, avoid causing any damages

to the goods during such operation, especially when using levers,

saws or any other metallic tools.

WARNING

Do not place the mast in vertical position, before opening the levelling feet or

before stabilizing the mast over a rm and regular surface. The Tower could

overturn causing serious physical and / or material damages.

RAMIRENT

SAFETY REGULATIONS | PAG. 6

•Verify and check that the voltage connections as well as the auxiliary

services have been made properly.

•When installing the battery, rst connect the positive terminal and

after the negative one. Negative pole to the engine block.

•Check the cyclical direction of the phases is according to the mains.

•lndividualize the position of the emergency stop button pushers, the

quick fuel interception valves, the switches and any other emergency

systems present in the installation.

•lsolate all the connections and disconnected threads. Don’t leave

open the terminals of power of the generator.

RAMIRENT

LIGHTING TOWER: COMPOSITION AND LOCATION OF ITS COMPONENTS | PAG. 7

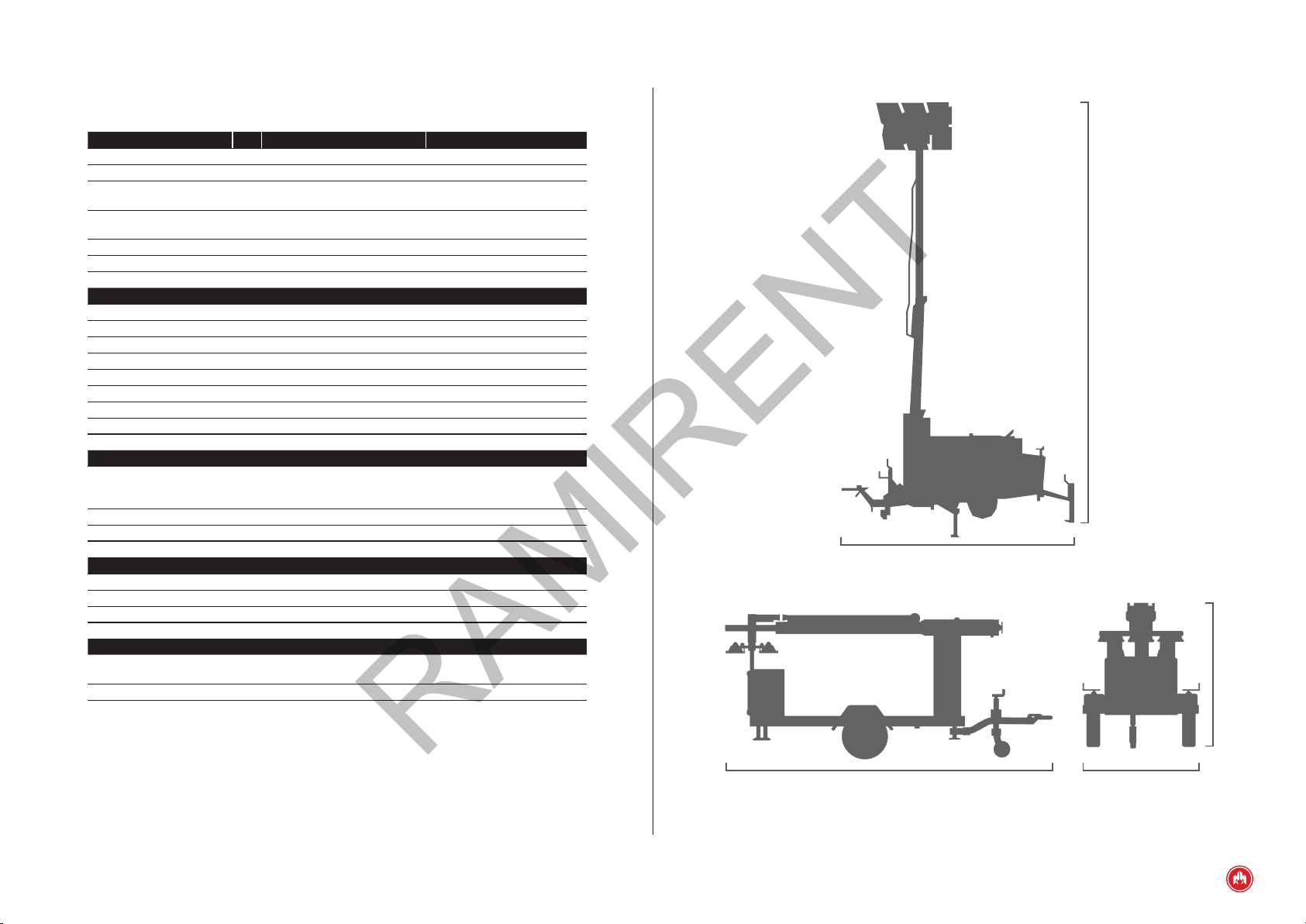

3. LIGHTING TOWER: COMPOSITION AND

LOCATION OF ITS COMPONENTS

3.1 COMPOSITION

The KT8000 and KT12000 lighting towers are basically composed of:

•Mobile kit with automatically extendible mast.

•Generating set.

3.2 LOCATION OF ITS COMPONENTS

3.2.1 TELESCOPIC MAST

Consisting of 3 expansions made in extruded aluminium T6 and anodized with a

15 microns layer.

3.2.2 SUPPORT FOR SIX PROJECTORS

•KT8000: Made of quartz iodine with 1.500W power and a ow of

33.100 lumens each. The tower has a lighting capacity of 198.000

lumens, covering a surface area of 16,500 square metres.

•KT12000: Made of metal halide with 2.000W power and a ow

of 220.000 lumens each. The tower has a lighting capacity of

1.320.000 lumens, covering a surface area fo 110.000 square

metres.

3.2.3 MAST SUPPORT

Among other functions, houses and protects the electrical motor that drives all

the hydraulic system of the mast.

RAMIRENT

LIGHTING TOWER: COMPOSITION AND LOCATION OF ITS COMPONENTS | PAG. 8

3.2.5 REAR CABINET

With manual lock with key and foam protection, designed in order to keep the 6

projectors during transportation.

3.2.6 MOBILE KIT

Composed of a rigid shaft, articulated nozzle (optional) (1), hooking on eye (2),

hiding jockey wheel (3), 4 extensible legs protected with nylon in all their surface

(4), on the chassis it has 4 lifting eyes clearly indicated (5).

1 2 3 4 5

23 5 4 5 4

1

3.2.4 WATERPROOF CONTROL AND MANEUVERING SHELTER

Houses and protects in its interior the mast control automatic central, the

maneuvering panel and the generator set- tower connection hose.

RAMIRENT

TECHNICAL INFORMATION | PAG. 9

4. TECHNICAL INFORMATION

Ligthing tower KT8000 KT12000

Tower Model KT8000 T5/T6 KT12000 T5/T6

Voltage (3P + N + T) V 400 - 220 400 - 220

Maximum dimensions (wor-

king mode)

mm 4254 (L) x 3262 (W) x 9408 (H) 4254 (L) x 3262 (W) x 9675 (H)

Minimum dimensions (trans-

port mode) mm 4524 (L) x 1578 (W) x 2146 (H) 4524 (L) x 1578 (W) x 2146 (H)

Dry Weight Kg 970 1345

Consumption Diesel Diesel

Mast

Mast type Hydraulic Hydraulic

Mast sections 3 3

Rotation 360º manual 360º manual

Double safety block Standard Standard

Lamps nº 6 x 1500 W 6 x 2000 W

Lamps type Quartz Iodine Metal Halide

Total lumnes 6 x 33.000W = 198.000 6 x 220.000W = 1.320.000

Illuminated surface 16.500 m2110.000 m2

Waterproof control and maneuvering shelter

Control press buttons

protection, panel and

connection hose with genset

Standard Standard

Protection level IP66 IP66

Maneuver press buttons 2 (1 x rising, 1 x descending) 2 (1 x rising, 1 x descending)

Features

Wheels Jockey wheel Jockey wheel

Stabilisers 4 4

Lifting eyes

4

4

Generating set

Canopy (Standard Fuel Tank:

100L) B10 B10

Trailer kit xation Safety bolts Safety bolts

Safety bolts 1578 mm

4254 mm

9408 mm (KT8000)

9675 mm (KT12000)

2146 mm

RAMIRENT

START UP | PAG. 10

5. START UP

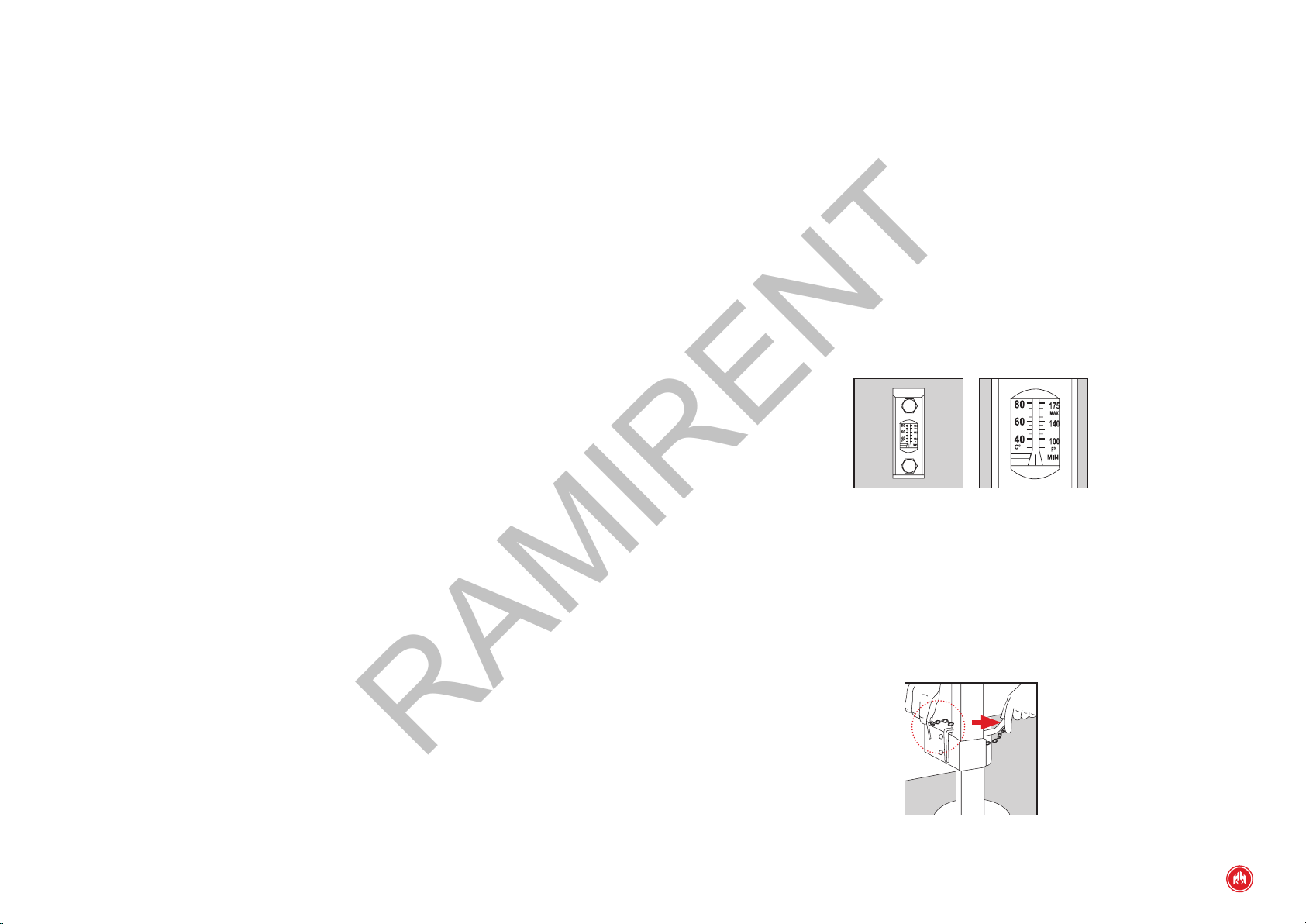

5.1 LEVELS

Check all levels of the equipment.

Hydraulic oil level: it can be checked by looking at the indicator that is on the

front side of the oil tank (under the motor). lt must be done when the tower is

resting and it has to be at least % of the total.(

Hydraulic oil temperature: this level also incorporates a Mercury temperature

meter in the center thereof so that the customer can respect working properties

of the oil. Some oils can lose properties above or below certain temperatures.

For water, oil and diesel levels of the genset, see generating set manual.

Fig.1

5.2 ANCHORAGE

As described in the safety chapter, do not raise the mast before opening the

levelling feet and stabilizing the tower on a rm and regular surface, in order to

do so, follow the steps bellow:

•Take out the safety brackets of the pins. (Fig. 2)

•Pull out the pins vertically. (Fig. 2)

Fig.2

RAMIRENT

START UP | PAG. 11

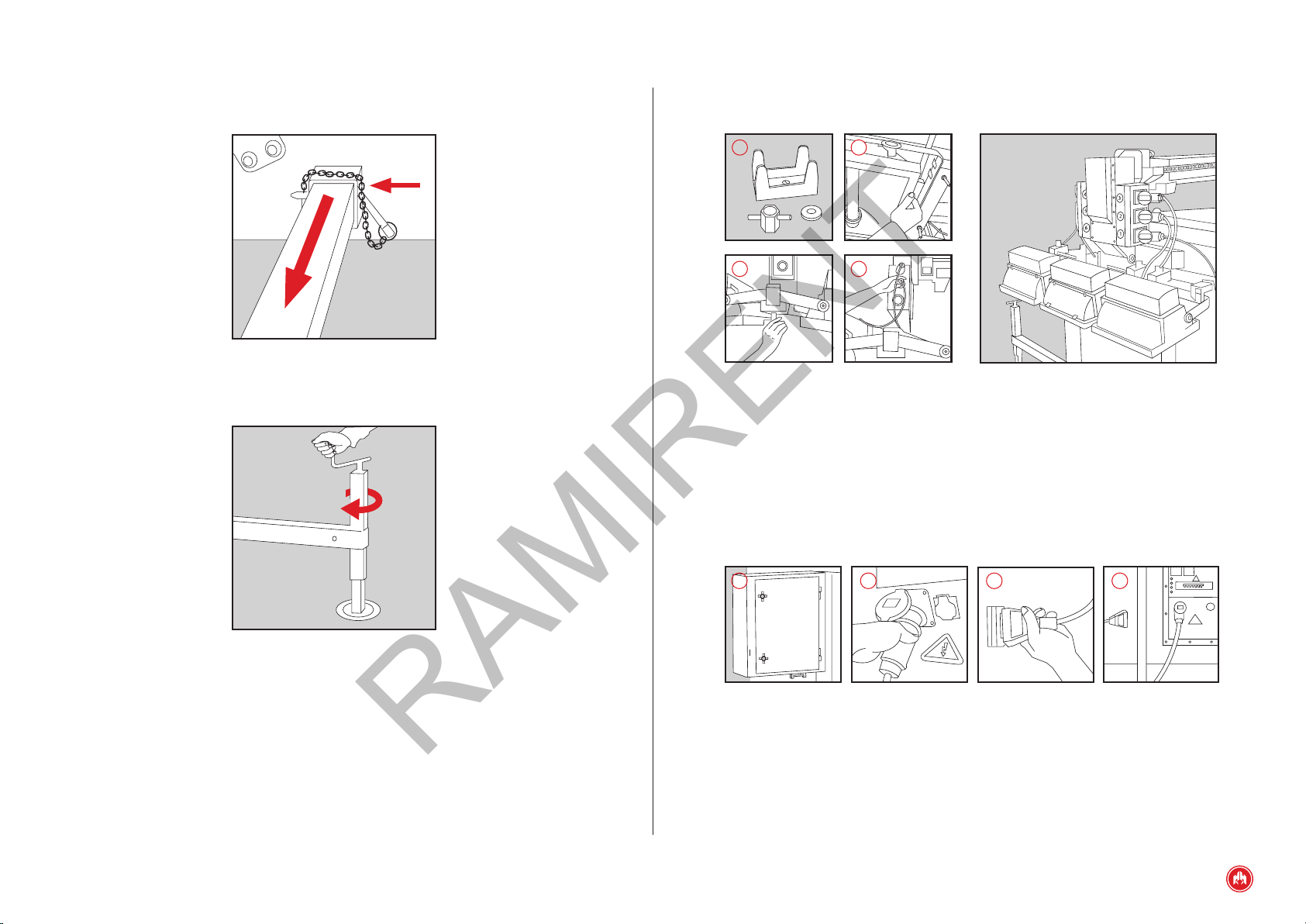

Once all spotlights are in place connect each one to its corresponding socket

(Fig. 4).

43

1 2

5.4 CONNECTING THE GENERATING SET TO TOWER

Once you have veried the connexion and the proper xing of the spotlights, we

will connect the generating set to the lighting tower. (Fig. 4).

In order to carry out this operation, get the extension cable that is in one of the

side compartments (Fig. 1) and connect one of the ends to the corresponding

power output located in the generating set (Fig. 2) control panel and the other

end to the lighting tower (Fig. 3).

1 2 3 4

5.5 STARTING UP THE GENERATING SET.

As shown in the start up procedure described in the instructions of the generating

set. (See Genset manual).

•Extract the legs. (Fig. 3)

•Put the safety brackets back in again. (Fig. 3)

Fig.3

•Turn the uppermost handle on the telescopic spindle bearings until it

grips there is a certain resistance. In this way one can balance and

x the tower to the chosen work surface. (Fig. 4)

Fig.4

5.3 INSTALING THE SPOTLIGHTS

Place the supplied spotlights in their corresponding slots, xing them with the

wingnuts located at the end of the mast.

In order to carry out this operation, unscrew the wingnut and remove the

supporting bracket (Fig. 1). Fit the spotlights (Fig. 2) with the glass upwards,

place the supporting bracket which grips the spotlight mounting, then the wingnut

and tighten it rmly (Fig. 3).

RAMIRENT

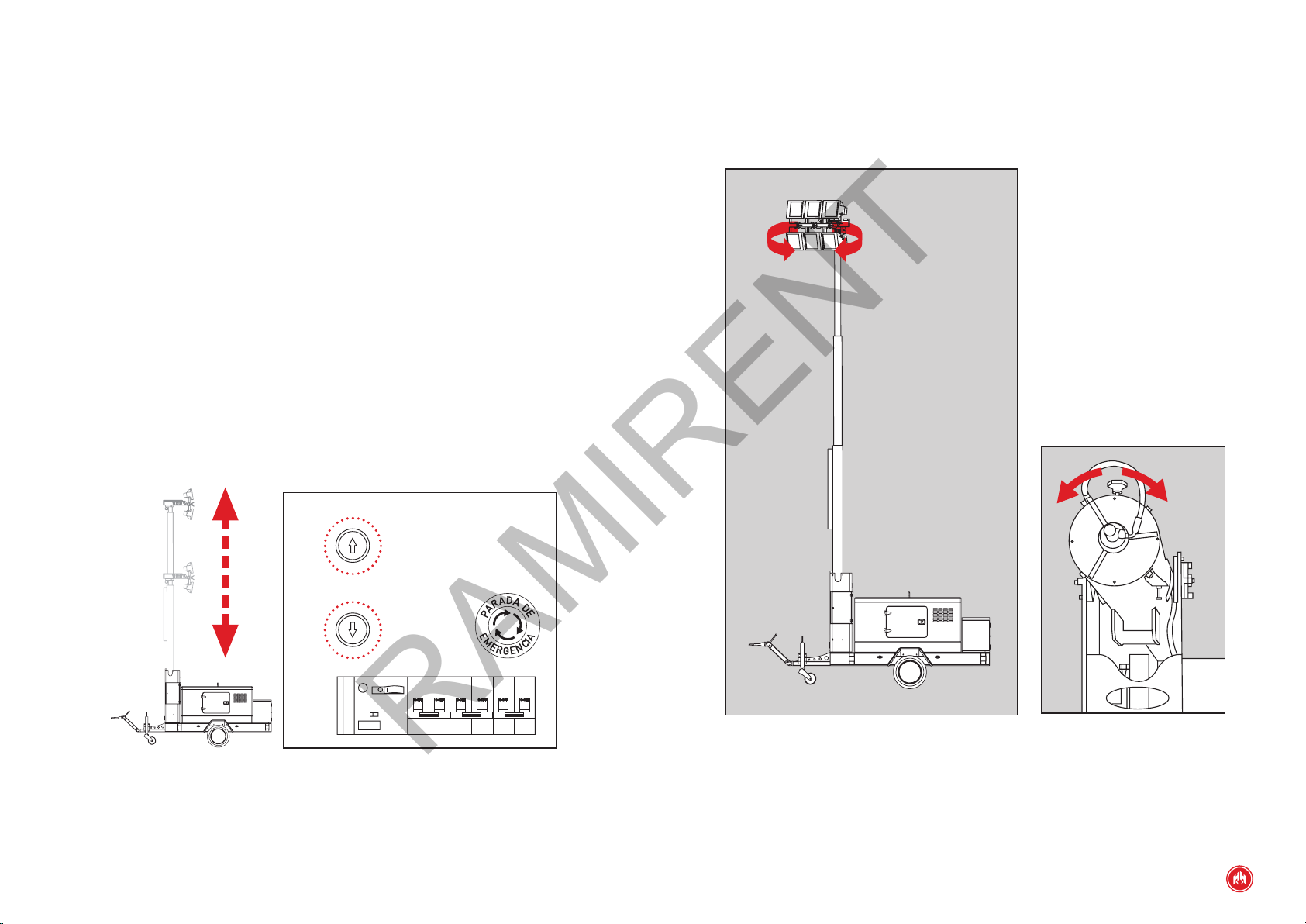

START UP | PAG. 12

•Projectors direction: To give the projectors direction we must rst

unblock the lockscrew of the mast (Fig. 2) to turn the handwheel

located on the base of the mast. This orientation allows a 355º mast

rotation and offers a 360º of lighting eld.

Fig.2

5.6 STARTING THE ELECTRICAL MOTOR

In order to raise the mast you must connect the main switch at the tower control

panel (panel located in one of the side compartments) This switch feeds the

electrical motor of the Lighting Tower which will allow raising and unfolding the

mast in its all.

5.7 MAST START CONTROL & PROJECTORS ORIENTATION/DIRECTION

•Mast start control: lt allows the control of the mast through two

simple maneuver press buttons located at the waterproof and

maneuvering shelter (Fig. 1). Before moving the mast, it is necessary

to start the electrical engine as described previously. Moreover, it is

crucial to anchor and level out the tower with the extensible side legs.

The maneuver press buttons only allows safe movements of the mast.

This means that you will not be allowed to spread out the mast until the

mast is not completely perpendicular to the oor. Therefore you will not be

allowedtopull themast downuntil theevreysectionisnotaleradycleared.

The top button controls the slope angle regarding the horizontal (Oº

transport position, 9Oº working position), and the mast raising from is

vertical startign position up to 8.9 meters.

Fig.1

RAMIRENT

START UP | PAG. 13

5.8 SAFE POSITION WHEN WORKING

For working security, we recommend that when the mast and the projectors reach

the suitable position, close the hydraulic circuit key located on the base side of

the mast (Fig. 3) in order to avoid unexpected movements and mast falls because

of a loss of load.

Fig.3

5.9 SWITCHING ON THE SPOTLIGHTS

To switch on the spotlights, it was enough with connecting the main switch (Fig.

1) located inside the tight closet of control and it maneuvers (Fig. 2), next to

work the three switches next to the main one that they light the focuses s.

21

2 spots 2 spots 2 spots

Main

interruptor ON

RAMIRENT

OPERATIONS TO CARRY OUT AFTER USE | PAG. 14

6. OPERATIONS TO CARRY OUT AFTER USE

6.1 SWITCHING OFF THE SPOTLIGHTS

In order to turn off the spotlights, you just have to disconnect the three switches

inside the control and manoeuvring waterproof cabinet (on the right side of the

main switch).

6.2 FOLDING THE MAST

View 5.7 a) Mast start control (pag. 12)

6.3 MAIN SWITCH DISCONNECTION

Disconnect the main switch in the control and manoeuvring panel.

6.4 STOPPING THE GENSET

Follow the instructions for the generating set.

6.5 DISCONNECTING THE GENSET FROM THE TOWER

Disconnect the prolongador and keep it in the rear cabinet.

6.6 DISCONNECTING THE SPOTLIGHTS

Disconnect the spotlights, dismount them and carefully put them in their

compartments.

6.7 FOLDING OF THE TELESCOPIC SPINDLE BEARINGS

Fold the telescopic spindle bearings and dismount the extensible legs.

RAMIRENT

MAINTENANCE AND FAILURES | PAG. 15

7. MAINTENANCE

It is necessary to check the hydraulic oil level every time the lighting tower is

started, and to be cleaned more frequently when working in dusty environments

and it must be relled when necessary.

The packing of the hydraulic bottles must be checked every time the lighting

tower is started.

The lubrication of the lower bolt of the hydraulic bottle has to be carried out every

time we start the lighting tower.

The hoses must be checked every time start up and be replaced when necessary.

In case of blown bulbs, it is advisable to use gloves or a cloth. Don not touch the

bulbs with the ngers. We must frequently clean and dry the lighting tower when

operating it in a humid and dusty environment

In case of doubt contact our technical service.

8. FAILURES

Due to the simplicity of the system, the number of failures is practically zero.

However, in case of any anomaly, please contact our technical service.

RAMIRENT

GUARANTEE CONDITIONS | PAG. 16

9. GUARANTEE CONDITIONS

PROFESSIONAL USE (commercial) (whichever is first)

2.000 working hours.

12 months from the date of the sale.

15 months after leaving the factory.

RESIDENTIAL USE (private) (whichever is first)

2.000 working hours.

24 months from the date of the sale.

27 months after leaving the factory.

The coverage of this warranty is ONLY applicable to the end user of the equipment

recognized by Himoinsa. In the case of Generating sets, it is only applicable to

those generating sets that operate together with an manual or automated control

panel manufactured or/and installed by HIMOINSA. The Generating sets of 3,000

rpm have a 6 months warranty or 500 hours of continuous work, or 12 months or

1,000 hours in standby or emergency, whichever period expires rst.

Except when agreed, the products sold as used will have an only 3 month

warranty. This Warranty benets only the rst purchaser and can not be tranferred

to a thrid-party (nal purchaser) without previous authorization from/of HIMOINSA.

RAMIRENT

GUARANTEE CONDITIONS | PAG. 17

9.1 COMPANY RESPONSABILITIES

•In those countries where HIMOINSA may have an authorized technical

assistance Network (information available at (www.himoinsa.

com) the warranty consists of the replacement or reparation of

the damaged parts once checked its due to defective material at

origin, manufacturing or/and assembly, therefore , it covers both

the replaced parts as well as the manpower used during the normal

working hours. The customer shall be charged with transport

expenses to the premises of the authorized distributor, where the

repairs shall be carried out.

•The warranty for the rest of the world consists of free supply on

premises San Javier (Murcia # Spain), of the non usable parts due

to defective material at origin, manufacturing or/and assembly. If the

equipment is sent to our premises, all necessary repair tasks will be

carried out free of charge.

•In this case, transport both sending and return will be chargeable to

the customer.

•The warranty will only be given after the technical study of the

defective parts. Any part sent or service carried out before the

acceptance of the warranty will be billed. All replaced parts have to

be returned to Himoinsa and will become of its property.

•In case of defects in the motor or alternator, HIMOINSA informs that

the assistance of the warranty will be provided by ofcial technical

services of the manufacturer of the alternator or motor, who will

determine the scope of the warranty.

•The defect shall appear during the normal use of the product and

within the warranty period. The company will supply the necessary

spare parts for the repair as soon as possible but shall not be

deemed responsible for any losses for not having the equipment

during this period.

•All claims made based on this warranty, must be processed through

your authorized seller or area distributor, who will process the claim

and the scope of the warranty.

•This warranty does not cover failures or defects consequence of

its normal use or wear, inappropriate use (including overload and

overvoltage), negligence, accidental damages, non authorized

modications; lack of or inappropriate maintenance or connection,

(inappropriate storage, transrportation or installing); any kind of use

of the equipment over the capacity and limits established by the

manufacturer or under conditions different from those recommended;

failures caused after the failure or defect had or should have been

detected; batteries, lamps and fuses damages; damages due of

use of parts not supplied or manufactured by the manufacturer.

The Warranty also does not cover the rental costs of substitution

equipments during repair period nor connection costs and/or

connection works of the product with other equipments of the

customer.

•The repaired or replaced parts have a (6) six month warranty, this

will not modify the warranty of the other elements.

•Equipment or components not manufactured by the company.

The company will provide a warranty equal to the one supplier,

and limited to the responsibility offered by the company for its

equipment.

•All claims to do with the fuel injection system or parts of it, will be

referred by HIMOINSA to the manufacturer of the injection system,

or to its authorized agent. The manufacturer or authorized agent’s

report ON THE FAILURE will be binding for both parties : Himoinsa

and purchaser.

9.2 USER RESPONSABILITIES

The user is responsible to:

•Install and operate the product in accordance with the operation

and instruction manual provided, and in its case with the

assistance of qualied technical personnel and in accordance with

the current regulations.

•Carry out a proper maintenance of the equipment; (including the

use of appropriate fuel, oil, antifreeze, and lubricant), as well as to

replace of the parts and components due to the normal use of the

equipment.

•Return the warranty register form properly lled in within 1O days

after the start up of the product, or a month after the date of the

sale, whichever is rst.

•Send written notication to the company or to authorized Technical

assistance service in his country, of the failures of the material

and justify them within seven days after the failure appeared and

in any case before the expiration of the warranty, otherwise the

purchaser may lose his warranty rights.

•If the repair of the defect requires the participation of other

equipments not manufactured by HIMOINSA, the purchaser will be

the only responsible for the works and costs resulted as well as to

provide full access to the products manufactured by HIMOINSA S.L.

RAMIRENT

GUARANTEE CONDITIONS | PAG. 18

•Accept the technical report about the existence or non existence of

defects in the material or the assembly.

•The manpower costs , except for those stated in the section

“COMPANY RESPONSIBILITIES”, including those ones derived from

the assembly and disassembly of the equipment .

•The costs and risks from transportation or shipping of the equipment,

and any other costs associated with the replacement of the

components.

•Any cost that may exceed the purchasing price of the product.

•Any other cost, including transport and trips, accommodation, taxes

and fees, communication expenses, extra hours among others;

except for those stated in section #Company responsibilities#

•Payment of the total price of the machine, spare parts and related

services related with the product under warranty.

•The attendance of sales or technical personnel to the #start-up#

or #functioning demonstration# of the equipment will not mean

that the present warranty may be extended to the installation or

mounting, operation expressly excluded from this warranty; it also

does not imply acceptance or understanding of the correct technical

installation, assembly or/and connexion of the machine carried out

by the purchaser or a third party unconnected with Himoinsa, neither

of the dimensioning of the equipment purchased regarding the real

power supply need of the purchaser.

The present warranty will not be applicable to the following cases:

•When the documentation (warranty, purchasing invoice, maintenance

and use manual) may have been altered in any way or may be

illegible.

•If the model and serial number of the generating set have been

altered, erased, removed or are illegible.

HIMOINSA shall not be deemed contractually or extra contractually responsible

for any material or immaterial, direct nor indirect damages; consecutive or non-

consecutive to the damage on the material covered by the warranty, such as

operating losses, expenses and costs due to not having the product, neither for

damages to third parties or to other equipment or products.

This Warranty does not limit any other rights that as a consumer, the purchaser

may have according to the current legislation. This warranty replaces any other

express or implied warranty, including, without limitation any merchantability

warranty of the equipment or its suitability for a particular purpose. All claims not

covered by the above stipulations will not be accepted by the company.

HIMOINSA Informs the user of the obligation to follow the Maintenance and use

Manual and to keep it together with the rest of the technical documentation of

the equipment in observance with the safety at work regulation as well as the

convenience of installing specic protections that may prevent overvoltage and

overload from the main electrical line, and to protect the equipment by seeking

advice of an authorized installer.

RAMIRENT

HIMOINSA se reserva el derecho de modificar cualquier característica

sin previa notificación. Las ilustraciones pueden incluir equipamiento

opcional y/o accesorios. Imágenes no contractuales. Las indicaciones

técnicas descritas en este manual se corresponden con la información

disponible en el momento de la impresión. HIMOINSA ® - 2015 ©Todos

los derechos reservados.

© HIMOINSA - October 2015

FACTORIES

SPAIN • FRANCE • INDIA • CHINA • USA • BRAZIL

SUBSIDIARIES

PORTUGAL | SINGAPORE | POLAND | UAE | PANAMA

MEXICO | GERMANY | ARGENTINA | ANGOLA | UK

HEADQUARTERS

Ctra. Murcia - San Javier, km 23.6

30730 SAN JAVIER (Murcia) SPAIN

TLF. +34 968 19 11 28 | +34 902 19 11 28

Fax +34 968 19 12 17 | Export Fax +34 968 33 43 03

www.himoinsa.com

RAMIRENT

This manual suits for next models

1

Table of contents

Other Himoinsa Lighting Equipment manuals