Hiniker DB-5245-1 User manual

HINIKER V-PLOW

DB-5245-1 STONE

HYDRAULIC UNIT

SERVICE MANUAL

DO NOT USE OR OPERATE THIS EQUIPMENT UNTIL THIS MANUAL

HAS BEEN READ AND THOROUGHLY UNDERSTOOD

PART NUMBER 25012796

TITLE

Introduction

POWER UNIT OPERATION

GENERAL

The hydraulic power unit consists of a 12 VDC

motor, a hydraulic pump rated at 1.9 GPM @

1600 PSI, and a valve body containing six nor-

mally closed electric solenoid valves and three

adjustable pressure relief valves. The uid sup-

ply line for the pump is submerged in a 2.5 quart

capacity reservoir and is ltered by a 149 micron

screen.

The valve body directs hydraulic uid to operate

six hydraulic circuits, raise, lower, angle left, an-

gle right, vee and scoop. The raise, angle, vee

and scoop circuits receive uid under pressure,

and the lower circuit does not, however, pressure

is generated as uid returns to the reservoir.

RAISE MODE OF OPERATION

Operating the Raise switch energizes the 12

VDC motor, the S5 solenoid valve and de-en-

ergizes the S6 solenoid valve. Hydraulic uid

under pressure is then directed through the S5

solenoid valve and a one way check valve (CV1)

to the lift cylinder.

Releasing the Raise switch de-energizes the

12 VDC motor and the S5 solenoid valve. The

one way check valve (CV1) maintains hydraulic

pressure in the lift cylinder.

The raise circuit is protected by a pressure relief

valve (SYSRV) set to relieve system pressure at

2250 PSI.. Typically, pressure is relieved when

the lift cylinder reaches the full up position.

LOWER MODE OF OPERATION

Operating the Lower switch energizes the S6 so-

lenoid valve, lowers the blade and establishes a

oat circuit. The oat circuit allows uid to enter

or exit the lift cylinder allowing the blade to fol-

low the contour of the ground.

ANGLE LEFT MODE OF OPERATION

Operating theAngle Left switch energizes the 12

VDC motor, the S2 solenoid valve and the S3

solenoid valve. Hydraulic uid under pressure is

then directed through the S2 solenoid valve to

the right wing cylinder. Hydraulic uid, not under

pressure, is directed from the left wing cylinder

through the S4 solenoid valve back to the reser-

voir as the cylinder retracts.

The right wing circuit is protected by a crossover

relief valve (RV2) set to relieve system pressure

at 2700 PSI. It is also protected by a retraction

relief (RV5) set at 3000 PSI.

ANGLE RIGHT MODE OF OPERATION

Operating the Angle Right switch energizes the

12 VDC motor, the S1 solenoid valve and the S4

solenoid valve. Hydraulic uid under pressure is

then directed through the S1 solenoid valve to

the left wing cylinder. Hydraulic uid, not under

pressure, is directed from the right wing cylinder

through the S2 solenoid valve back to the reser-

voir as the cylinder retracts.

The left wing circuit is protected by a crossover

relief valve (RV3) set to relieve system pressure

at 2700 PSI. Typically, pressure is relieved when

the left wing cylinder reaches its fully extended

position. It is also protected by a retraction relief

(RV4) set at 3000 PSI.

VEE MODE OF OPERATION

Operating the Vee switch energizes the 12 VDC

motor and the SI and S3 solenoids pumping uid

through hosesAand C to the rod end of the wing

cylinders. Fluid from the butt end of the cylinders

returns to the tank through hoses B and D and

valves S2 and S4

SCOOP MODE OF OPERATION

Operating the Scoop switch energizes the 12

VDC motor, the S2 solenoid valve and the S4

solenoid valve pumping uid through hoses B

and D to the butt end of the wing cylinders. Fluid

from the rod end of the cylinders returns to the

tank through hoses A and C and valves S1 and

S3

Power Unit - Hydraulic

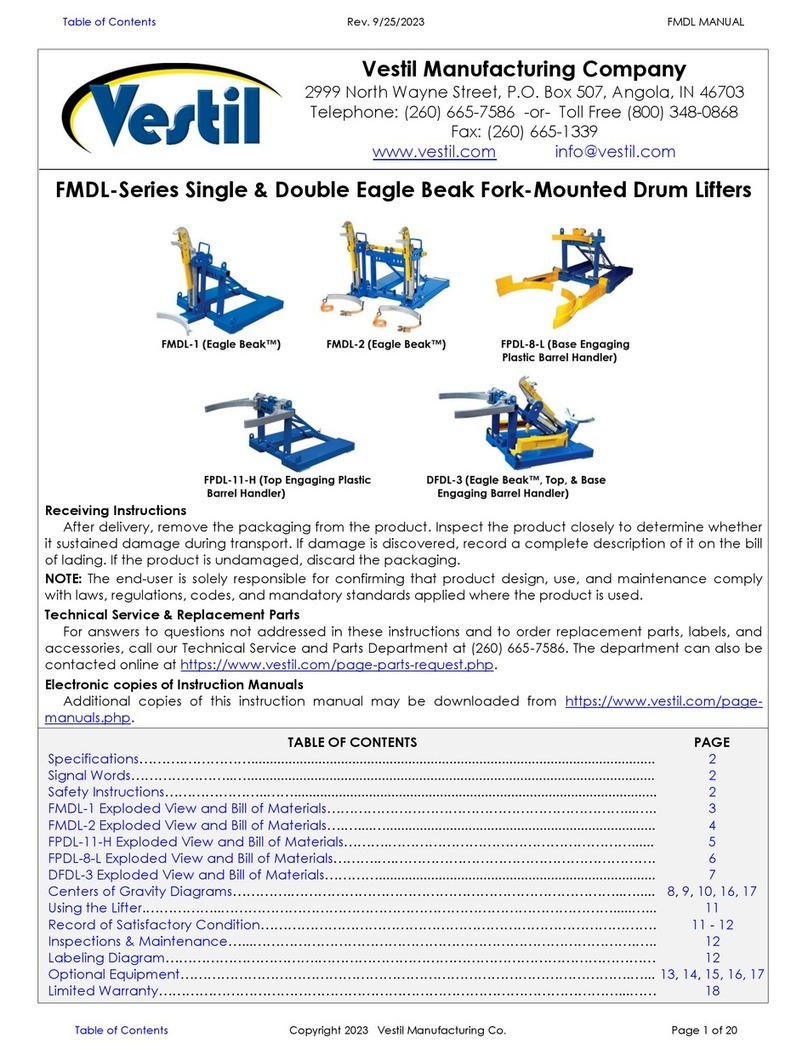

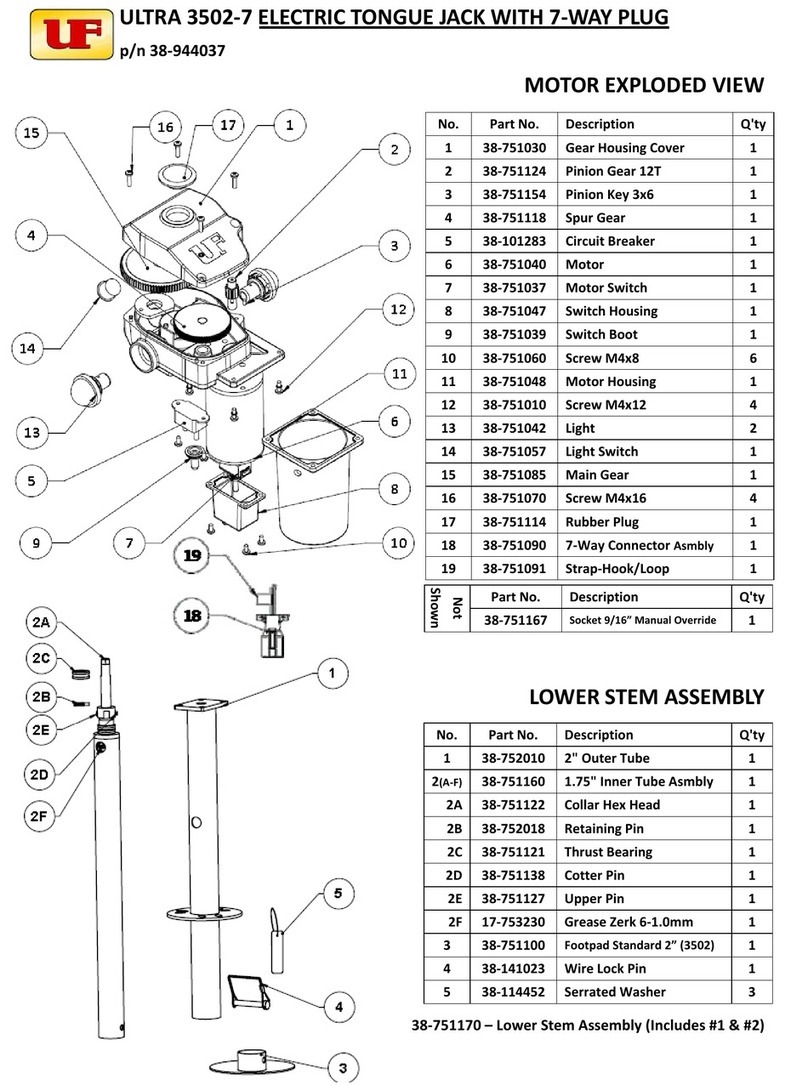

POWER UNIT - SPX MODEL DB-5245-1

REF.

NO. PART

NUMBER DESCRIPTION QTY. REF.

NO. PART

NUMBER DESCRIPTION QTY.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

25010734

950-001-327

25010332

25010244

25010221

25010334

25010214

25010236

25011654

25011667

25010544

25010992

25010230

25010337

25010746

25012736

25010330

25010518

PumpAssembly

Hex Head Cap Screw 5/16-24 x 3 Gr. 8

Inlet Plumbing Kit

Plumbing Elbow

Filter

Pump O-Ring Kit

Coupling

O-Ring

Release Valve Kit

Solenoid Coil

Cartridge Release Valve

O-Ring Kit

Motor 12V DC

Motor Brush Kit

Check Valve

Orice With O-Ring

Adjustable Relief Valve Kit

Adjustable Relief Valve O-Ring

1

2

1

1

1

1

1

1

2

6

2

1

1

1

1

1

1

1

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

25010738

950-004-071

25010436

25010217

25010220

25010762

25012678

25010985

950-004-095

952-004-080

25011525

25010935

25012737

25010745

25012673

952-001-001

951-001-003

Plastic Tank

Machine Screw #12-24 x 1/2 Hex Washer Head

Decal - Fill Line

Plastic Breather

Plumbing Magnet

Manifold O-Ring Kit

Relief Valve

Crossover Relief Valve

Socket Head Cap Screw 1/4-20 x 2 1/2

Lock Washer 1/4 Inch

Spool Valve

Return Tube

Return Tube

Return Tube Filter

Ground Stud 1/4-20

Lock Washer 1/4 Inch

Hex Nut 1/4-20

1

4

1

1

1

1

2

2

4

4

2

1

1

2

1

1

1

DWG. NO. 6526A

25012648 Power Unit - SPX Model DB-5245-1

Power Unit Hydraulic Circuit Diagram

DWG NO. 6459

Introduction

V-Plow Power Unit

DWG NO. 6457A

TITLE

TABLE OF CONTENTS

25012796 3/10 Manual/25012796

Troubleshooting Procedures....................................................................................................... 2

V-Plow Will Not Raise.................................................................................................................. 3

V-Plow Lifts Slowly ...................................................................................................................... 4

V-Plow Will Not Stay Up.............................................................................................................. 5

V-Plow Will Not Lower................................................................................................................. 6

Left Wing Will Not Extend ........................................................................................................... 7

Right Wing Will Not Extend......................................................................................................... 8

Left Wing Will Not Stay Extended............................................................................................... 9

Right Wing Will Not Stay Extended.......................................................................................... 10

Left Wing Will Not Retract..........................................................................................................11

Right Wing Will Not Retract ...................................................................................................... 12

DC Motor Removal and Replacement...................................................................................... 13

DC Motor Brush Replacement.................................................................................................. 14

Check Valve Removal, Cleaning & Replacement (CV1) ........................................................ 15

Relief Valve Removal, Cleaning & Replacement .................................................................... 16

System Relief Valve Removal, Cleaning & Replacement....................................................... 17

Solenoid Valve Removal, Cleaning and Replacement.......................................................18-19

Spool Valve Removal, Cleaning and Replacement..................................................................... 20

Valve Block Removal, Cleaning and Replacement................................................................. 21

Hydraulic Pump Removal, Cleaning and Replacement.....................................................22-23

Flow Control Valve Removal, Cleaning and Replacement..................................................... 24

System Relief Valve Testing and Adjustment.......................................................................... 25

DC Motor Current Draw (Full Load).......................................................................................... 26

DC Motor Current Draw (No Load)........................................................................................... 27

Solenoid Test ............................................................................................................................. 28

Relief Valve Testing and Adjustment ....................................................................................... 29

Hydraulic Pump Test.................................................................................................................... 30

Table of Contents 1

TITLE

TROUBLESHOOTING PROCEDURES

INTRODUCTION

This section is designed to help you troubleshoot

the hydraulic system on the Hiniker V-Plow.

Each procedure consists of a detailed problem

description followed by a step-by-step ow chart

that will direct you to do certain service or test

procedures. If each service or test procedure is

done step-by-step in the order given, the prob-

lem can usually be corrected.

INITIAL INSPECTION

1. Make sure vehicle is in park and parking

brake is set.

2. Retract wings fully and lower plow to the

ground before servicing any part of the hy-

draulic or electrical systems.

3. Inspect all wiring harness connectors for:

A. Corrosion or dirt in and/or on Pins and

Sockets.

B.Damagedor missingPinsand/or Sockets.

C. Full engagement of Pins into respective

Sockets.

4. Check Ground.

A.Makesurebatterygroundto vehicleframe

is clean, corrosion free and tight.

B. Make sure that ground connections from

the Snow Plow harness to vehicle frame

or battery are clean, corrosion free and

tight.

5. Verify the correct hydraulic uid is being

used in unit and make sure oil level is to “Fill

Line” when the plow is on the ground and

the wings retracted.

6. Check all hoses and cylinders for proper

condition and leaks.

7. Make sure battery is charged and charging

system is in good condition.

8. Check 10 AMP fuse located on the Under-

hood Wiring Harness. Replace if bad.

9. Make sure joystick controller is connected in

the cab and turned on.

2 Troubleshooting

TITLE

V-Plow Will Not Raise 3

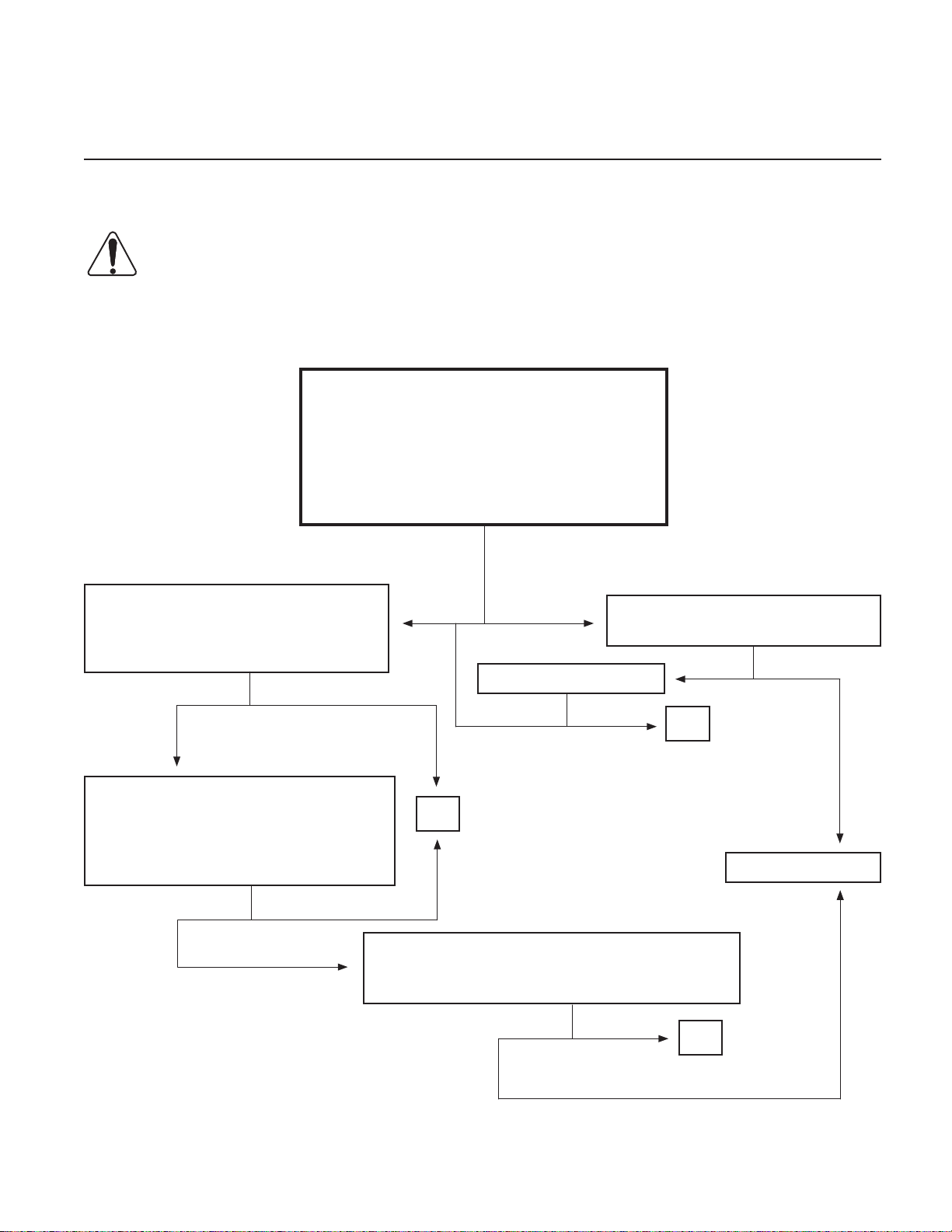

V-PLOW WILL NOT RAISE

Perform all initial inspections and checks listed on page 2 before beginning test procedure.

WARNING: Always retract wings fully, lower the plow to the ground and relieve pressure

before removing any ttings, hoses or caps. Allow the system to cool down before drain-

ing oil or handling system components. Serious burns can result from contact with hot

oil. FAILURE TO HEED CAN RESULT IN SERIOUS INJURY OR DEATH.

V-PLOW WILL NOT RAISE

ALL OTHER FUNCTIONS ARE NORMAL.

DOES PUMP MOTOR RUN?

Perform Solenoid Valve Test to S5 Solenoid

Valve. Repair or replace as necessary.

See page 28.

Does V-Plow raise?

Refer to electrical troubleshooting.

Does pump motor run?

Turn ignition switch on and momentarily ac-

tivate the RAISE switch on the joystick con-

trol box to ensure that the FLOAT mode is

OFF. Check S6 Solenoid Valve for magne-

tism by loosely holding metal end of screw-

driver within 1/8” of the nut end of the S6

Solenoid Valve Coil.

Is screwdriver attracted to nut end of coil?

Remove, inspect and clean System Relief

Valve. Repair or replace as necessary. See

page 17. Reinstall and adjust.

See page 25. Does V-Plow raise?

Remove, inspect and clean S6 Solenoid

Valve. See page 18-19. Repair or replace

as necessary. Does V-Plow raise?

Check ttings and lift cylinder hose for ob-

structions. Remove lift cylinder and drain

oil. Check for a frozen/binding cylinder by

manually compressing and extending the

cylinder. Repair or replace as necessary.

Does V-Plow raise?

Call Hiniker Service Does V-Plow Raise?

Call Hiniker Service

Yes No

No Yes End

No Yes

No Yes End

No Yes End

YesNo End

YesNo

End

YesNo

TITLE

V-PLOW LIFTS SLOWLY

Perform all initial inspections and checks listed on page 2 before beginning test procedure.

WARNING: Always retract wings fully, lower the plow to the ground and relieve pressure

before removing any ttings, hoses or caps. Allow the system to cool down before drain-

ing oil or handling system components. Serious burns can result from contact with hot

oil. FAILURE TO HEED CAN RESULT IN SERIOUS INJURY OR DEATH.

V-PLOW LIFTS SLOWLY

ALL OTHER FUNCTIONS ARE NORMAL.

Remove, inspect and clean System Relief Valve.

See page 17.

Adjust pressure. See page 25.

DOES V-PLOW LIFT FULLY UP IN APPROXIMATELY 2 SECONDS?

Remove, inspect and clean S5 Solenoid

Valve See page 18-19.

Repair or replace as necessary. Does V-

Plow lift fully up in approximately 2 sec-

onds?

Check ttings and lift cylinder hose for ob-

structions. Remove, lift cylinder and drain

oil. Check for a binding cylinder by manu-

ally compressing and extending the cylin-

der. Repair or replace as necessary. Does

V-Plow lift fully up in approximately 2 sec-

onds?

YesNo

YesNo End

Yes

No

Note: Until pump system warms, slow functioning of the V-Plow will occur in extremely cold tempera-

tures unless a high quality oil that is appropriate for the temperatures in which you will be plow-

ing snow is used. See chart below.

Note: Ensure vehicle battery is fully charged and alternator output is 13.6 Volts minimum with engine

running and no accessories on.

End

Call Hiniker Service DWG NO. 3066

4 V-Plow Lifts Slowly

TITLE

V-PLOW WILL NOT STAY UP

Perform all initial inspections and checks listed on page 2 before beginning test procedure.

WARNING: Always retract wings fully, lower the plow to the ground and relieve pressure

before removing any ttings, hoses or caps. Allow the system to cool down before drain-

ing oil or handling system components. Serious burns can result from contact with hot

oil. FAILURE TO HEED CAN RESULT IN SERIOUS INJURY OR DEATH.

V-PLOW WILL NOT STAY UP.

ALL OTHER FUNCTIONS ARE NORMAL.

Remove, inspect and clean Check Valve 1 (CV1)

See page 15.

Repair or replace as necessary.

DOES V-PLOW STAY UP?

Momentarily activate the RAISE switch on

the joystick control box to ensure that the

oat mode is OFF. Verify that there is no

voltage at the S6 Solenoid Valve, using a

voltmeter or test light. Is voltage present?

Remove, inspect and clean S6 Solenoid

Valve.

See page 18-19.

Repair or replace as necessary.

Does V-Plow stay up?

YesNo

YesNo

End

Call Hiniker Service

Refer to electrical troubleshooting.

Does V-Plow stay up?

V-Plow Will Not Stay Up 5

YesNo End

YesNo End

TITLE

V-PLOW WILL NOT LOWER

Perform all initial inspections and checks listed on page 2 before beginning test procedure.

WARNING: Always retract wings fully, lower the plow to the ground and relieve pressure

before removing any ttings, hoses or caps. Allow the system to cool down before drain-

ing oil or handling system components. Serious burns can result from contact with hot

oil. FAILURE TO HEED CAN RESULT IN SERIOUS INJURY OR DEATH.

V-PLOW WILL NOT LOWER

ALL OTHER FUNCTIONS ARE NORMAL.

Perform Steps 1 thru 5 of the

Solenoid Valve Test to Solenoid Valve S6.

See Page 28.

DO NOT REPLACE CARTRIDGE VALVE

AT THIS TIME.

DOES V-PLOW LOWER?

Support plow blade (same as the left paragraph).

Check for plugged ttings and hydraulic hose.

Remove and drain oil from lift cylinder. Check for

frozen/binding cylinder by manually compressing

and extending the cylinder.

Repair or replace as necessary.

Does V-Plow lower?

Support plow blade with a oor Jack or

other suitable means. Relieve hydraulic

pressure by loosening hose tting on lift

cylinder. Remove, inspect and clean S6

Solenoid Valve. See page 18-19. En-

sure plunger pushes in approx. 1/16”

and springs back. If it does not, replace

cartridge valve. Remove, inspect and

clean Flow Control Valve. See page 24.

Does V-Plow lower?

YesNo

YesNo

End

Call Hiniker Service

YesNo End

6 V-Plow Will Not Lower

End

TITLE

Left Wing Will Not Extend 7

LEFT WING WILL NOT EXTEND

Perform all initial inspections and checks listed on page 2 before beginning test procedure.

WARNING: Always retract wings fully, lower the plow to the ground and relieve pressure

before removing any ttings, hoses or caps. Allow the system to cool down before drain-

ing oil or handling system components. Serious burns can result from contact with hot

oil. FAILURE TO HEED CAN RESULT IN SERIOUS INJURY OR DEATH.

LEFT WING WILL NOT EXTEND

ALL OTHER FUNCTIONS ARE NORMAL.

Move joystick on controller to

“Right” position.

DOES PUMP MOTOR RUN?

Remove, inspect and clean S3 - S4 Spool Valve.

Repair or replace as necessary. See page 20.

Does Left Wing Extend?

Perform Solenoid Valve Test to S4 So-

lenoid Valve. Repair or replace as nec-

essary. See page 28.

Does Left Wing Extend?

Yes No

YesNo

Call Hiniker Service

YesNo

End

End

Refer to electrical troubleshooting.

Does pump motor run?

Remove, inspect and clean Relief Valve

3 (RV3). Repair or replace as neces-

sary. See page 16. Reinstall and adjust.

See page 29.

Does Left Wing Extend?

YesNo

NoYes

Does Left Wing Extend?

YesNo End

TITLE

RIGHT WING WILL NOT EXTEND

Perform all initial inspections and checks listed on page 2 before beginning test procedure.

WARNING: Always retract wings fully, lower the plow to the ground and relieve pressure

before removing any ttings, hoses or caps. Allow the system to cool down before drain-

ing oil or handling system components. Serious burns can result from contact with hot

oil. FAILURE TO HEED CAN RESULT IN SERIOUS INJURY OR DEATH.

RIGHT WING WILL NOT EXTEND

ALL OTHER FUNCTIONS ARE NORMAL.

Move joystick on controller to

“Left” position.

DOES PUMP MOTOR RUN?

Remove, inspect and clean S1 - S2 Spool Valve.

Repair or replace as necessary. See page 20.

Does Right Wing Extend?

Perform Solenoid Valve Test to S2 So-

lenoid Valve. Repair or replace as nec-

essary. See page 28.

Does Right Wing Extend?

Yes No

YesNo

Call Hiniker Service

YesNo

End

End

Refer to electrical troubleshooting.

Does pump motor run?

Remove, inspect and clean Relief Valve

2 (RV2). Repair or replace as neces-

sary. See page 16. Reinstall and adjust.

See page 29.

Does Right Wing Extend?

YesNo

NoYes

Does Right Wing Extend?

YesNo End

8 Right Wing Will Not Extend

TITLE

LEFT WING WILL NOT STAY EXTENDED

Perform all initial inspections and checks listed on page 2 before beginning test procedure.

WARNING: Always retract wings fully, lower the plow to the ground and relieve pressure

before removing any ttings, hoses or caps. Allow the system to cool down before drain-

ing oil or handling system components. Serious burns can result from contact with hot

oil. FAILURE TO HEED CAN RESULT IN SERIOUS INJURY OR DEATH.

LEFT WING WILL NOT STAY EXTENDED

ALL OTHER FUNCTIONS ARE NORMAL.

Remove, inspect and clean Relief Valve 3 (RV3).

See page 16.

Repair or replace as necessary.

DOES LEFT WING STAY EXTENDED?

Remove, inspect and clean

S3 - S4 Spool Valve. See page 20.

Repair or replace as necessary.

Does Left Wing Stay Extended?

YesNo

Call Hiniker Service

YesNo End

End

Left Wing Will Not Stay Extended 9

TITLE

RIGHT WING WILL NOT STAY EXTENDED

Perform all initial inspections and checks listed on page 2 before beginning test procedure.

WARNING: Always retract wings fully, lower the plow to the ground and relieve pressure

before removing any ttings, hoses or caps. Allow the system to cool down before drain-

ing oil or handling system components. Serious burns can result from contact with hot

oil. FAILURE TO HEED CAN RESULT IN SERIOUS INJURY OR DEATH.

RIGHT WING WILL NOT STAY EXTENDED

ALL OTHER FUNCTIONS ARE NORMAL.

Remove, inspect and clean Relief Valve 2 (RV2).

See page 16.

Repair or replace as necessary.

DOES RIGHT WING STAY EXTENDED?

Remove, inspect and clean

S1 - S2 Spool Valve. See page 20.

Repair or replace as necessary.

Does Right Wing Stay Extended?

YesNo

Call Hiniker Service

YesNo End

End

10 Right Wing Will Not Extend

TITLE

Left Wing Will Not Retract 11

LEFT WING WILL NOT RETRACT

Perform all initial inspections and checks listed on page 2 before beginning test procedure.

WARNING: Always retract wings fully, lower the plow to the ground and relieve pressure

before removing any ttings, hoses or caps. Allow the system to cool down before drain-

ing oil or handling system components. Serious burns can result from contact with hot

oil. FAILURE TO HEED CAN RESULT IN SERIOUS INJURY OR DEATH.

LEFT WING WILL NOT RETRACT

ALL OTHER FUNCTIONS ARE NORMAL.

Perform Steps 1 thru 5 of the Solenoid Test to

S3 Solenoid. See page 28.

DO NOT REPLACE CARTRIDGE VALVE AT THIS TIME.

DOES LEFT WING RETRACT?

NOTE: Pay special attention to

above warnings.

Remove, inspect and clean S3 - S4

Spool Valve. See page 20. Repair

or replace as necessary.

Does Left Wing Retract?

YesNo

Call Hiniker Service

YesNo End

NOTE: Pay special attention to above

warnings.

Check left wing cylinder hose and t-

tings for obstructions. Remove left wing

cylinder from plow and drain oil. Check

for frozen/binding cylinder by manually

compressing and extending the cylinder.

Repair or replace as necessary.

Does Left Wing Retract?

YesNo

End

WARNING: If wing can not be retracted, then it must be secured and the pressure re-

lieved before performing any tests and/or procedures.

FAILURE TO HEED CAN RESULT IN SERIOUS INJURY OR DEATH.

TITLE

12 Right Wing Will Not Retract

RIGHT WING WILL NOT RETRACT

Perform all initial inspections and checks listed on page 2 before beginning test procedure.

WARNING: Always retract wings fully, lower the plow to the ground and relieve pressure

before removing any ttings, hoses or caps. Allow the system to cool down before drain-

ing oil or handling system components. Serious burns can result from contact with hot

oil. FAILURE TO HEED CAN RESULT IN SERIOUS INJURY OR DEATH.

RIGHT WING WILL NOT RETRACT

ALL OTHER FUNCTIONS ARE NORMAL.

Perform Steps 1 thru 5 of the Solenoid Test to

Solenoid S1. See page 28.

DO NOT REPLACE CARTRIDGE VALVE AT THIS TIME.

DOES RIGHT WING RETRACT?

NOTE: Pay special attention to

above warnings.

Remove, inspect and clean S1 - S2

Spool Valve. See page 20. Repair

or replace as necessary.

Does Right Wing Retract?

YesNo

Call Hiniker Service

YesNo End

NOTE: Pay special attention to above

warnings.

Check left wing cylinder hose and t-

tings for obstructions. Remove left wing

cylinder from plow and drain oil. Check

for frozen/binding cylinder by manually

compressing and extending the cylinder.

Repair or replace as necessary.

Does Right Wing Retract?

YesNo

End

WARNING: If wing can not be retracted, then it must be secured and the pressure re-

lieved before performing any tests and/or procedures.

FAILURE TO HEED CAN RESULT IN SERIOUS INJURY OR DEATH.

TITLE

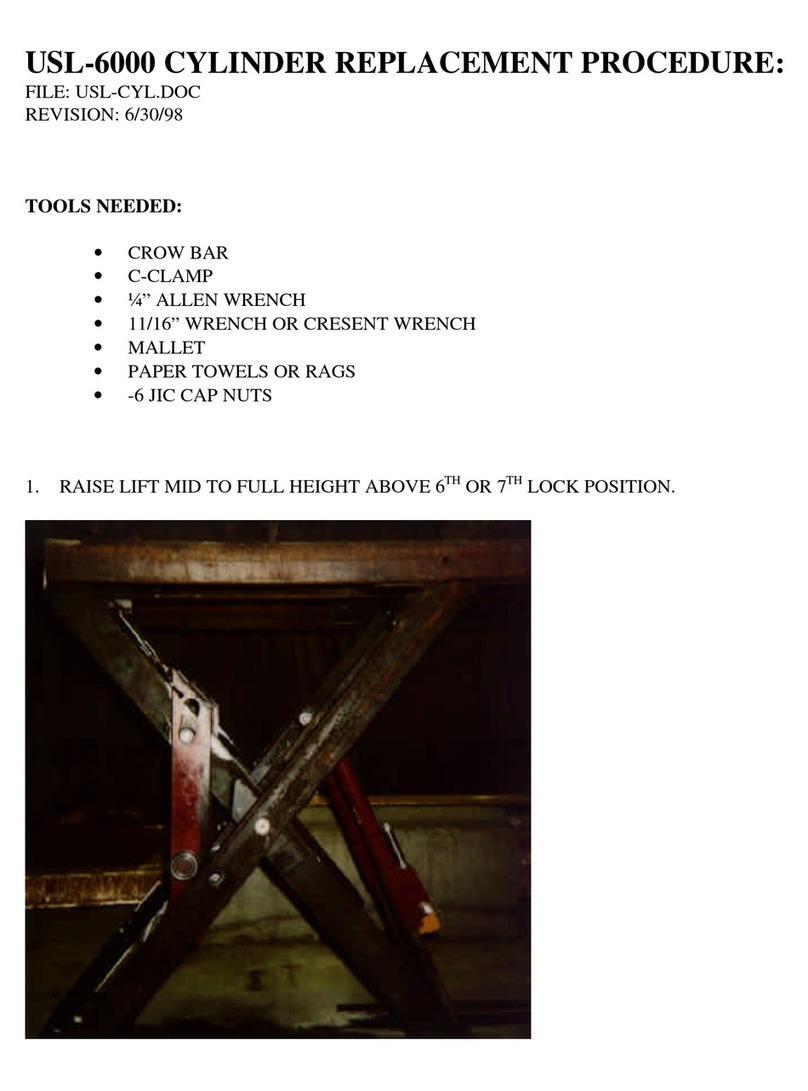

DC MOTOR REMOVAL AND REPLACEMENT

DC Motor Removal and Replacement 13

WARNING: Disconnect Vehicle Bat-

tery prior to performing this procedure

to avoid electrical shock or burns.

1

2

PHOTO NO. 1000263

Disconnect the black wire of the battery power

cable at location 2. Disconnect the red (or red

striped) wire of the battery power cable from the

motor terminal at location 1.

MOUNT BOLTS

PHILLIPS HEAD SCREWS

MOTOR CAP MOTOR

DWG NO. 3512

Remove the two Phillips head screws from the

motor cap. Using a 3/8” wrench loosen the two

motor mounting bolts. Do not remove bolts.

NOTE: Use care when removing the motor from

the endhead, the motor can separate into three

pieces and will require additional time to reas-

semble.

Hold motor together while removing it from the

end head.

NOTE: If oil is found in the cavity of the valve

passage where the coupling is located, replace-

ment of the oil pump shaft seal is necessary be-

fore the unit can be put back into service. See

page 22.

PHILLIPS HEAD SCREWS

MOTOR CAP MOTOR

MOTOR TERMINAL

(POS)

GROUND SCREW

(NEG) COUPLING

PUMP SHAFT

VALVE PASSAGE

SHIPPING NUTS

(REMOVE)

DWG NO. 3513

Remove shipping nuts from new motor, align

splined shaft of motor with coupler and position

motor onto the locating pins on the end head.

Torque the two motor mounting bolts to 5-8 ft.

lbs. with a 3/8” wrench. Reattach motor cap.

Reconnect the black wire of the battery power

cable at location 2 and the red (or red striped)

wire of the battery power cable to motor termi-

nal at location 1. See photo 1000263.

TITLE

WARNING: Disconnect Vehicle Battery

prior to performing this procedure to

avoid electrical shock or burns.

1

2

PHOTO NO. 1000263

Disconnect the black wire of the battery power ca-

ble at location 2. Disconnect the red (or red striped)

wire of the battery power cable from the motor ter-

minal at location 1.

PHILLIPS HEAD SCREWS

MOTOR CAP

MOTOR

DWG NO. 3514

Remove the two Phillips head screws from the mo-

tor cap. Remove motor cap.

PHOTO NO. 3747

NOTE: If your motor is equipped with two (2)

brushes with bare wires (Ground brushes) and

two (2) brushes with insulated wires (POS brush-

es), make sure that you note location of the two

types and replace them with like type brushes.

WARNING: Failure to replace Brushes

correctly will severely damage Motor

and may cause electrical res. FAIL-

URE TO HEED CAN RESULT IN SERIOUS IN-

JURY OR DEATH.

PHOTO NO. 3749

Remove screws from brush leads. Carefully

pry back the tension spring with a straight slot

screwdriver and remove brush. Replace brush if

it is 1/4” or less in length. (P/N 25010337)

IMPORTANT: Brushes should be replaced as

a set. DO NOT replace one Brush only.

Clean the motor commutator with a spray electri-

cal contact cleaner before installing brushes.

To install new brushes reverse the procedure.

14 DC Motor Brush Removal and Replacement

DC MOTOR BRUSH REPLACEMENT

Table of contents

Other Hiniker Lifting System manuals

Popular Lifting System manuals by other brands

Rotary

Rotary SPO55E Operation & maintenance manual

Aquatec

Aquatec orca Assembly instructions

Dhollandia

Dhollandia DH-CH1 Series installation manual

ARKSEN

ARKSEN 018-HO-18040 owner's manual

CLASSIC LIFT

CLASSIC LIFT CL4500XH Installation and service manual

PFlow Industries

PFlow Industries 21 Series Hydraulic VRC owner's manual

Mec

Mec Mast Series Service & parts manual

Ultra-Fab

Ultra-Fab ULTRA 3502-7 Installation & operation

Mohawk

Mohawk USL-600 Replacement Instruction

Future Automation

Future Automation TSLM-MO-3 Technical sheet

KI

KI Genesis Desking Repair & Replacement Instructions

HOMCOM

HOMCOM 713-087 Assembly & instruction manual