stertil-KONI ST 1085-FWA User manual

STERTIL

SUPERIOR SOLUTIONS

Capacity 18,500 lbs.

or 22,000 lbs.

MOBILE COLUMN LIFT

ST 1085 - ST 1100

Superior

Solutions

The Stertil Group provides customized

and technically advanced lifting solutions

for heavy-duty customers worldwide,

as well as the best possible after-sales

service from factory trained local

partners. These superior solutions

are conceived, developed and

implemented by a team of specialized

professionals with unique experience.

Thanks to its quality people, its total

in-house production process and its

international organization, Stertil-Koni

is the world leader in the eld of

heavy-duty vehicle lifting systems.

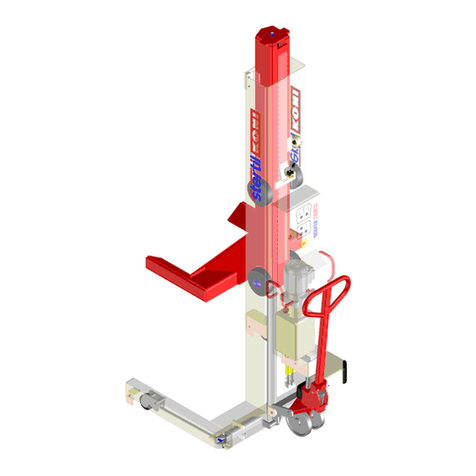

Wireless…

Our wireless mobile column lifts with the ebright Smart

Control System represent the latest in mobile column lifting

technology. Using the innovative ID key, you can connect

up to 32 columns in a single lift set. In most cases, the

special deep cycle batteries only need to be recharged

every two weeks. No time is wasted connecting up cables

and the mechanic has maximum access to the vehicle,

without any tripping hazards.

Full color touch screen control

The revolutionary ebright Smart Control System

combines intuitive ease of use with maximum visual

information about the lifting process. The main advantages:

•

7" full color touch screen, works even when wearing gloves

•User-configured options, such as choice of language,

safety warnings and scheduled maintenance notifications

•All relevant information available at a glance

•Customizable ID-Key to prevent unauthorized operation

•Wireless Mesh network for optimal connectivity

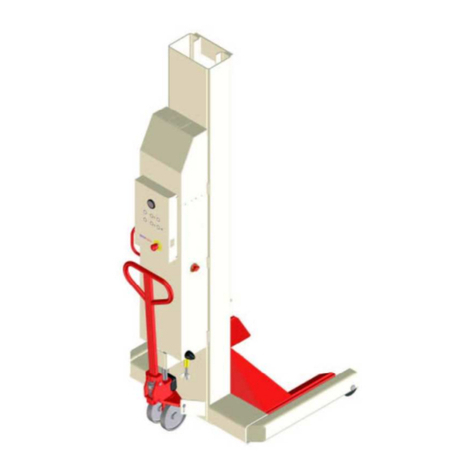

… or cabled, it’s up to you

If you predominantly work in a fixed location the cabled

mobile column lifts could be the best solution for you.

This setup offers the possibility to connect up to 32 columns

in a single lift set. All interconnection cables are equipped

with heavy-duty plugs at both ends.

Both the wireless and the cabled column lifts are equipped

with a control panel on each individual column. Columns

can be operated individually, in pairs or simultaneously as

a complete set with the touch of a button. Each column

can therefore be used at any given location.

Wireless mobile

column lifts

with ebright Smart

Control System

TOUCH SCREEN WIRELESS

Power supply

The Stertil-Koni wireless mobile column lifts operate on

24 VDC and are easily recharged by means of a 110 VAC

wall receptacle. The Stertil-Koni cabled mobile column lifts

operate on three phase at 208/230, 460/480 and

575 VAC, as well as single phase at 220 VAC.

Fast lifting and lowering

The ST 1085 and ST 1100 only take 94 seconds to reach

its maximum lifting height of 73". This makes them one of

the fastest mobile column lifts in the world.

Reliable hydraulic technology

•Extended column life and minimal maintenance

thanks to low-friction design

•Stringent testing before leaving the factory

•Manual lowering in case of a power outage

•Maximum protection of the cylinder and

seal against damage

Adjustable pick-up forks

ST 1085 mobile column lifts have a fork length of 14",

ideal for picking up a variety of vehicles, including vehicles

with super single tires in a safe and secure manner.

The fork length for the ST 1100 mobile column lift is 12".

Both models can handle wheels with rim diameters from

R12 to R22.5 with an adjustable fork that is easy to

move manually and includes a mechanical lock.

Retractable wheels

Both the wireless and the cabled mobile column lifts are

available with retractable wheels. This unique Stertil-Koni

design is the best available on the market. This prevents

high point loading on the floor and reduces the floor

surface pressure by a factor of 10. The system is fast,

efficient, very stable and extremely reliable.

Adjustable lowering speed

If you need to lower the vehicle more slowly for precision

placement of under carriage components, this is easily

done with a single touch.

Unique synchronization

The synchronization system is activated at a height

difference of just 9/16". This ensures a safe and smooth

lifting and lowering cycle, even in cases where the

distribution of the vehicle weight is extremely uneven.

Lifetime guarantee

The innovative synthetic runner wheels within the column

come with a lifetime parts guarantee.

Easy to move

Stertil-Koni mobile column lifts are indeed mobile, thanks

to the synthetic roller wheels and hydraulic pallet jack

mechanism with patented overload protection.

Safe working space

As an extra safety feature, we have also designed ample

working space between the column and the vehicle.

This ensures that the vehicle will not come into contact with

the column in the event of sagging vehicle suspension.

MAX 32 LINKED

COLUMNS

UNIQUE

SYNCHRONIZATION

SYSTEM

MAX

32

OVERLOAD

PROTECTION

ADJUSTABLE

LOWERING SPEED

Well thought out

in all aspects

High resolution

7" touch screen

Intuitive controls

•Tracking of specific operations and

information codes

•Intuitive controls with actual data about the lift:

- Indication for Single, All or Pair operation mode

- Information about how many columns are

in the set (up to 32 columns)

- Actual lifting height displayed

- Lowering speed can be manually adjusted

on the touch screen

- Battery status information

- Customizable ID-Key to prevent unauthorized

operation

•Wireless Mesh network with continuous active

channel search offering optimal connectivity

•High resolution 7” touch screen

•Owner/User configurable system with user ID key

- Individual user settings for setting language

and units of measure

- Protection against unauthorized use, thanks to

personalized ID key

•Maintenance notifications

•Visual display of maximum programmable lifting

height

•Warning and failure information

•Operation manual available on-screen

Features

Overview of ST 1085 – ST 1100

models

ebright

wireless

ST 1085-FWA

ST 1100-F WA

ebright

wireless

ST 1085-RWA

ST 1100-RWA

ebright

cabled

ST 1085-FSA

ST 1100-FSA

ebright

cabled

ST 1085-RSA

ST 1100-RSA

ebright Smart Control System with a control box

on each individual mobile column

••••

Touch screen with important information about

the system e.g. lifting height, operation mode

••••

Wireless Mesh network with continuous active

channel search offering optimal connectivity

• •

These columns utilize a power outlet in the

workshop and communicate with each other via

interconnecting cables

• •

Adjustable lowering speed for slow or

normal lowering

••••

Hydraulic pallet truck mechanism with patented

overload protection

••••

14"-long adjustable fork, suitable for

super single tires ST 1085 ST 1085 ST 1085 ST 1085

12"-long adjustable fork S T 110 0 S T 110 0 S T 110 0 S T 110 0

Fixed synthetic wheels that reduce the floor

surface pressure

• •

Retractable synthetic wheels integrated into

the base frame, for 10x less floor pressure

• •

Everything

under

control

10”

33”

47 1/4”

14”*

44”

9 3/8”-22”

34 1/2”

49 1/4”

14”*

44”

9 3/8” - 22”

4”

143 1/2”

97”

73”

6”

10”

4”

143 1/2”

97”

73”

6”

a member of the Stertil Group

95003902 ST1085 - ST1100 USA 02-2017. Stertil is a registered trademark of Stertil B.V.. We reserve the right to make changes in specifications without notice and without making changes retroactive.

Technical specifications

Lifting capacity: 18,500 lbs. or 22,000 lbs.

Lift system: hydraulic lifting system with

microprocessor-controlled

synchronization

Lifting height: maximum 73", automatic stop at

the highest position

Lifting time: 94 seconds

Motor rating: 3 hp / 4 hp per column

(Cabled/Wireless)

Weight: 1,350 lbs per column (Wireless)

Column lift height: 97"

Highest safety requirements

• ANSI/ALI-ALCTV certified (USA), CSA certified

(Canada), CE certified (Europe)

• Independent mechanical locking system engages

at 5" above finished floor. Locking pawl engaged by

gravity. The locking system is always active, even

when the column is turned off

• Locking profile with locking increments of just 1 3/8"

• Synchronization between the mobile lifting columns

starts at a height difference of 9/16"

• Automatic overload protection

• Low voltage control panel with emergency stop

• Each column is equipped with hold-to-run

push buttons

• Each individual mobile lifting column is tested prior to

leaving the factory

• Splash-proof electrical system (IP 65).

Accessories & options

Stertil-Koni offers an extensive package of accessories

& options tailored to fit your specific needs. More information?

For more information about the ST 1085, ST 1100,

or any of Stertil-Koni's other top products, please

do not hesitate to contact us. We will be pleased

to assist you.

Fixed front wheels Adjustable forks

Adjustable forksRetractable front wheels

* For the ST 1100: 12"

Stertil-Koni U.S.A. Inc.

200 Log Canoe Circle

Stevensville, Maryland 21666

Tel. 410-643-9001

Toll free 800-336-6637

Fax 410-643-8901

www.stertil-koni.com

StertilKoniUSA @StertilKoniUSA

14 45 00-1

DIVISION 14 45 00

VEHICLE LIFTS(ST 1085 FWA ebright)

PART 1 GENERAL

1.1 SECTION INCLUDES

A. Mobile column lifts.

1.2 RELATED SECTIONS

A. Section 03 30 00 - Concrete: Footings and foundations.

B. Section 26 05 00 - Common Work Results for Electrical.

1.3 SUBMITTALS

A. Submit under provisions of Section 01 30 00 - Administrative Requirements.

B. Product Data: Manufacturer's data sheets on each product to be used, including:

1. Preparation instructions and recommendations.

2. Storage/handling requirements and recommendations.

3. Installation methods.

C. Shop Drawings: Submit drawings showing full layout of all lifts with dimensions

D. Operation and Maintenance Manual: Submit Operation and Maintenance manual to

include system operation, maintenance and troubleshooting, spare part numbers,

drawings and schematics.

1.4 QUALITY ASSURANCE

A. Manufacturer Qualifications: The lift company selling the product shall have

ISO-9001 certification and the proof of current certification shall accompany the bid.

B. Installer Qualifications: For warranty validation, installation shall be performed by

qualified factory authorized and trained personnel.

C. Product Requirements:

1. Design Standards and Certification: The lift shall be certified by ETL/Intertek

to the ANSI/ALI ALCTV-current edition Standard for Automotive Lifts: Safety

Requirements for Construction, Testing and Validation.

2. The drive system shall permit lifting without any pulsation, jerks, or unsteady

lifting. Lifting shall be smooth. System shall be comprised of an electrically

powered pump, flow control valves, and a fluid reservoir. An

electronic/hydraulic synchronization system shall ensure smooth alignment of

each lifting assembly based on variances in vehicle weight. A microprocessor

shall control all lift movement for ultimate operator safety and convenience.

Troubleshooting codes shall facilitate service and repair.

14 45 00-2

1.5 DELIVERY, STORAGE, AND HANDLING

A. Store products in manufacturer's unopened packaging until ready for installation.

B. Store and dispose of solvent-based materials, and materials used with

solvent-based materials, in accordance with requirements of local authorities having

jurisdiction.

1.6 PROJECT CONDITIONS

A. Maintain environmental conditions (temperature, humidity, and ventilation) within

limits recommended by manufacturer for optimum results. Do not install products

under environmental conditions outside manufacturer's absolute limits.

1.7 WARRANTY

A. Manufacturer's Warranty: Lift system shall be warranted for a minimum period of 2

years for parts and 1 year for labor. Hydraulic cylinder shall have a parts only

warranty of an additional four years. Guide rollers shall have a lifetime warranty; this

extended warranty covers parts only.

PART 2 PRODUCTS

2.1 MANUFACTURERS

A. Acceptable manufacturer: Stertil-Koni USA, Inc., which is located at: 200 Log Canoe

Circle; Stevensville, MD 21666; Toll Free Tel: 800-336-6637; Tel: 410-643-9001;

Email: request info (lifts@stertil-koni.com); Web: www.stertil-koni.com

B. Requests for substitutions will be considered in accordance with provisions of

Section 00 26 00.

1. Requests for changes by the contractor on products, materials, equipment

and methods of construction required by the contract documents, after the

award, shall be considered requests for "substitutions", and shall follow the

procedures outlined within the bid documents for substitutions.

2. Any substitution of the specified lift requiring modifications of foundation

system detailed will be the responsibility of the contractor.

3. The contractor shall provide for any and all engineering and redesign of

foundation system as a result of substitution.

4. Under no circumstances will extra payment be permitted as a result of

additional work to accommodate any equipment substitution.

2.2 MOBILE COLUMN LIFTS

A. Mobile Column Lifts Model ST-1085-FWA(ebright) as manufactured by Stertil-Koni

USA, Inc.

1. General Description:

a. A lifting system or set (consisting of up to 32 columns) for vehicles

shall be composed of interchangeable columns. The size of the set

shall be able to be configured by the operator at time of set up without

the need to modify the operating system. It shall be possible to operate

up to 480 columns within any facility. With a set of up to 32 columns, it

shall be possible to operate any single column, a pair of columns, or all

columns together, at the same time.

b. Each column shall contain its own power supply which consists of two

deep cycle (group 31) 12 VDC batteries combined to provide a stable

24 VDC power supply.

14 45 00-3

c. The main power shall be fused between the primary power switch and

the motor/control circuits to protect against overload.

d. When fully charged, the on board battery power system shall be

capable of 19 lifting/lowering cycles at 100% of lifting capacity and 28

lifting/lowering cycles at 50% of lfiting capacity .

e. The 24 VDC on board power supply shall incorporate a built in

recharging systems with a pictograph on the display so the operator

can visually verify charging status.

1) The recharging system shall be a built in 110 VAC battery

charger with indicator lamps. The battery charger shall be

enclosed within a steel cabinet for protection from damage. The

charger indicator lamp shall be easily visible through a sight glass

mounted externally in the control cabinet. The indicator lamp shall

be illuminated steady red when the system is recharging, green

when batteries are fully recharged, and flashing green when the

charger is providing a trickle charge. It shall be possible to

operate the lifting column while the battery charger is actively

charging the batteries.

f. The base frame of the lifting column shall be of a rectangular design.

The contact pattern to the foundation under the column shall be

triangular in design to ensure uniform contact with the lifting foundation.

2. Lifting Capacity:

a. Each individual column shall have a nominal rated capacity of 18,500

lbs. (8,500 kg).

3. Dimensions:

a. The achieved lifting height of the column shall be no less than 73

inches (1,854 mm) when measured from the foundation on which the

column rests to the top of the lifting fork.

b. Column height shall not be greater than 97 inches (2,464 mm) when

fully lowered and 143.5 inches (3,645 mm) when the carriage has

achieved maximum height.

c. Column lifting fork shall be 14 inches in length.

4. Tire Size:

a. Wheel contact forks shall be adjustable by hand and freely accept tires

with rim diameters between R10 and R22.5. The adjustable forks shall

incorporate a mechanical locking device to ensure the fork cannot

relocate/adjust during use.

5. Pallet Jack Mechanism:

a. The pallet jack mechanism shall have a gas shock incorporated into its

design which shall serve two purposes. The primary purpose of the

pallet jack gas shock shall be to serve as a safety mechanism to

ensure that the mobile column is not lifting, while the pallet jack is

extended. If the operator fails to lower the pallet jack after column

positioning, as soon as the column experiences load during a lifting

cycle, the gas shock will retract to lower the column to its foundation for

stable lifting. The second purpose of the pallet jack gas shock shall be

to dampen the impact of floor imperfections experienced while the

column is relocated.

6. Wheels:

a. The column shall be fitted with fixed front roller wheels fabricated from

oil impregnated nylon so as to be non-destructive to the foundation on

which the column rests.

b. Floor pressure at the front roller wheel location shall be no greater than

7,200 lbs.

7. Drive Mechanism:

a. The drive system shall be hydraulic and shall permit lifting without any

14 45 00-4

pulsation, jerks, or unsteady lifting. Lifting shall be smooth. The

hydraulic power unit shall be an electrically-powered pump, flow control

valves, and a fluid reservoir.

b. Lifting carriage shall ride on durable, oil filled nylon guide rollers. Guide

rollers shall require no lubrication and no maintenance.

c. Each hydraulic cylinder shall be equipped with a hose burst check

valve to prevent decent in the event of a major fluid leak.

8. Controls:

a. The various functions of the mobile lifting system shall be initiated from

the control panels on the columns.

b. Each control box shall include:

1) "UP" button.

2) "Down" button.

3) “Lock release” button.

4) “Confirm” button

5) Mushroom style emergency stop button

6) A high definition 7 inch LCD screen touch. The touch screen

shall be specifically designed for a harsh workshop environment.

The touch screen shall be capable of providing the following

functions:

i. Column selection indicator: This area of the touch

screen display shall inform the operator of which columns in the

set have been selected for operation.

ii. Battery charge indicator: This area of the touch

screen display shall inform the operator of the charge condition of

the battery power supply.

iii. Column height indicator: This area of the touch

screen display shall inform the operator of the height of the

individual column. The operator shall have the ability to easily

toggle between individual imperial or metric units of height

measurement (inches or mm.). The column height indicator shall

also provide on the touch screen a clear indicator if the column has

been set to stop at a restricted lifting height. This indicator shall

be displayed as a thick horizontal line in the height display region

of the touch screen. As the column rises, the screen will mimic

the column and display the lifting fork rising up towards the

horizontal restricted height indicator bar. Once the lifting fork

shown on the display arrives at the restricted height indicator bar,

the column shall stop rising.

iv. Column speed indicator: This area of the touch

screen shall inform the operator of the speed of the lifting system.

The speed indicator shall have the ability to adjust the lowering to

30% of full lowering speed.

v. Column fault code indicator: When a fault code has

been registered by the control system, the touch screen shall

inform the operator of any fault codes affecting the lifting set. The

control system shall have the ability to display 42 individual fault

codes.

vi. One-touch access to the Guide screen: This area

of the touch screen provides to the operator access to the Guide

screen. The Guide screen shall provide to all system users:

i. Calculator

vii. One-touch access to the Information screen: This

area of the touch screen provides to the operator access to:

i. Owner information

ii. Service provider information

14 45 00-5

iii. Manufacturer information

viii. One-touch access to the Settings screen which

displays 5 options which allows management of :

i. Settings screen option (1): On this screen,

operators shall have the ability to change the

language displayed on the screen as well as the

units of measure for height and weight (imperial

or metric units).

ii. Settings screen option (2): On this screen,

operators shall have the ability to retract the

mechanical locks during raising for reduced

noise, as well as to set a restricted maximum

lifting height.

iii. Area to allow for future expansion

iv. Portal to the Shop screen: access to this screen

requires a PIN with details of the Shop Screen

provide below.

v. Portal to Information screen option: access to this

screen requires a PIN with details of the

Information Screen provide below.

ix. One-touch access to the Shop screen options

(access to the Shop screen shall be generally provided to only

maintainers and system administrators). The shop configuration

screen shall allow manipulation of:

i. Edit of owner’s details: on this screen shall be

the ability to edit the information displayed on

the Owner’s field.

x. Access to the Information Screen,which displays 9

options (access to the Information screen shall be generally

provided to only maintainers and system administrators). The

maintenance configuration screen shall allow manipulation of:

Screen 1

i. Initiation of foot protection which guards

against a crushing hazard during lowering.

This safety system, when enabled, will stop

lowering as the column reaches 18 inches

above finished floor. At that time, the operator

is provided a chance to inspect and ensure that

there are no obstructions in the area of the

vehicle and lifts. After confirmation that the

vehicle and lift area is clear of obstructions, the

operator simply needs to retract the mechanical

safety locks again and compete the lowering

cycle to bring the lift completely to the floor.

ii. Ability to disable height difference monitoring to

aid in trouble shooting. Once initiated, this

control system option allows the maintainer to

operate the lifting system outside normal safety

limits. This system is only for use by the lift

system maintainer during repair procedures.

This system option will automatically be

disabled and the control system returned to

default operating parameters after 10 minutes.

iii. Ability to apply a set value to height monitoring

system to aid in troubleshooting. Once

initiated, this control system option substitutes

14 45 00-6

a fixed value for the height monitoring device in

a particular column. This system is only for

use by the lift system maintainer during repair

procedures. This system option will

automatically be disabled and the control

system returned to default operating

parameters after 2 minutes.

Screen 2

i. Ability to select wireless operating channel to

minimize interference

ii. Ability to view total lift system run time to

properly plan for lift system maintenance.

iii. Ability to view individual column motor run time

to properly plan for lift system maintenance.

Screen 3 Area to allow for future expansion

Screen 4 (Safety Messages)-area to allow for future

expansion

Screen 5 (Maintenance Messages)-area to allow for

future expansion

Screen 6 (Back up and Restore)

I. Ability to restore control system to default

settings

Screen 7 (Software Version)

I. Ability to review system operating information

Screen 8

I. Ability to establish column type

II. Ability to establish motor type, VDC or VAC

III. Ability to establish control system

communication protocol

IV. Ability to enable or disable weight measuring

Screen 9 (Battery Settings)

i. Ability to establish at what voltage the system

will display that the battery system is WEAK

ii. Ability to establish at what voltage the system

will display that the battery system is EMPTY

c. All control panels shall have automatic synchronization through the full

stoke of the hydraulic cylinder with a maximum tolerance of 2 inches

(50 mm). Control system will actively control hydraulic correction to

maintain level synchronization, unless a column deviates more than 2.4

inches (60 mm) inches from any other column, at which point all motion

halts.

d. Each column shall be fitted with an individual analog height measuring

device. This height measuring device shall ensure that the height of

each column in the set remains synchronized at the height initiated by

the operator. The height measuring device shall also allow, through

single operation, that the operator can raise or lower any column to

alternate heights within the tolerances set by the ALI (Automotive Lift

Institute) in its manual entitled “Lifting It Right”.

e. The wireless communication system shall utilize mesh-style wireless

technology and be properly shielded from external interference in the

workshop.

f. The mobile column lift battery charger shall operate at the following

voltages: 110VAC.

g. Control panel shall be rated IP 65.

9. Safety Devices:

a. An independent and fail-safe mechanical locking system shall be

14 45 00-7

present on each column. This safety device shall be totally independent

from the lifting drive system.

b. Increments on lifting carriage locking profile shall not be greater than

1.375 inches (35 mm) and the first locking position shall engage after

no more than 5.0 inches (120 mm) of lifting.

c. A locking “pawl and ratchet” system shall be used to ensure proper and

automatic locking at any height and at all times. The locking notches

shall be integrated into the lifting carriage. The locking pawl shall be

mounted to the inside of the column and function as a wedge between

the column and the lifting carriage. The locking pawl design shall utilize

gravity, with a spring assist, to ensure the locking pawl is always

engaged into the locking ladder. The mechanical safety lock shall be

automatically engaged at all times when the lift is not operating.

PART 3 EXECUTION

3.1 EXAMINATION

A. Do not begin installation until substrates have been properly prepared.

B. If substrate preparation is the responsibility of another installer, notify architect of

unsatisfactory preparation before proceeding.

3.2 PREPARATION

A. Clean surfaces thoroughly prior to installation.

B. Prepare surfaces using the methods recommended by the manufacturer for

achieving the best result for the substrate under the project conditions.

3.3 INSTALLATION

A. Install in accordance with manufacturer's instructions. Test for proper operation, and

re-test if necessary until satisfactory results are obtained.

3.4 PROTECTION

A. Protect installed products until completion of project.

B. Touch-up, repair or replace damaged products before substantial completion.

END OF SECTION

This manual suits for next models

7

Table of contents

Other stertil-KONI Lifting System manuals

Popular Lifting System manuals by other brands

GEDA

GEDA AB 450 Assembly and operating manual

R. Beck Maschinenbau

R. Beck Maschinenbau HS 1200 FH operating manual

John Bean

John Bean 40HP210ES instruction manual

Stenhoj

Stenhoj MASCOT 1.25 Operation and maintenance instructions

Tuxedo

Tuxedo TP9KACX Installation & operation manual

Oshkosh

Oshkosh JLG 1930ES Service maintenance manual

BLUM

BLUM SERVO-DRIVE Problem Resolution

Elebia

Elebia NEO50 user manual

Rotary

Rotary SM65-51 Operation and maintenance manual

EZTRUNK

EZTRUNK 1900 0072 Assembly manual

WOOD'S POWR-GRIP

WOOD'S POWR-GRIP LJ6VH Guide to maintenance, troubleshooting, and repair

STARKE ARVID

STARKE ARVID Inlift Instructions for use