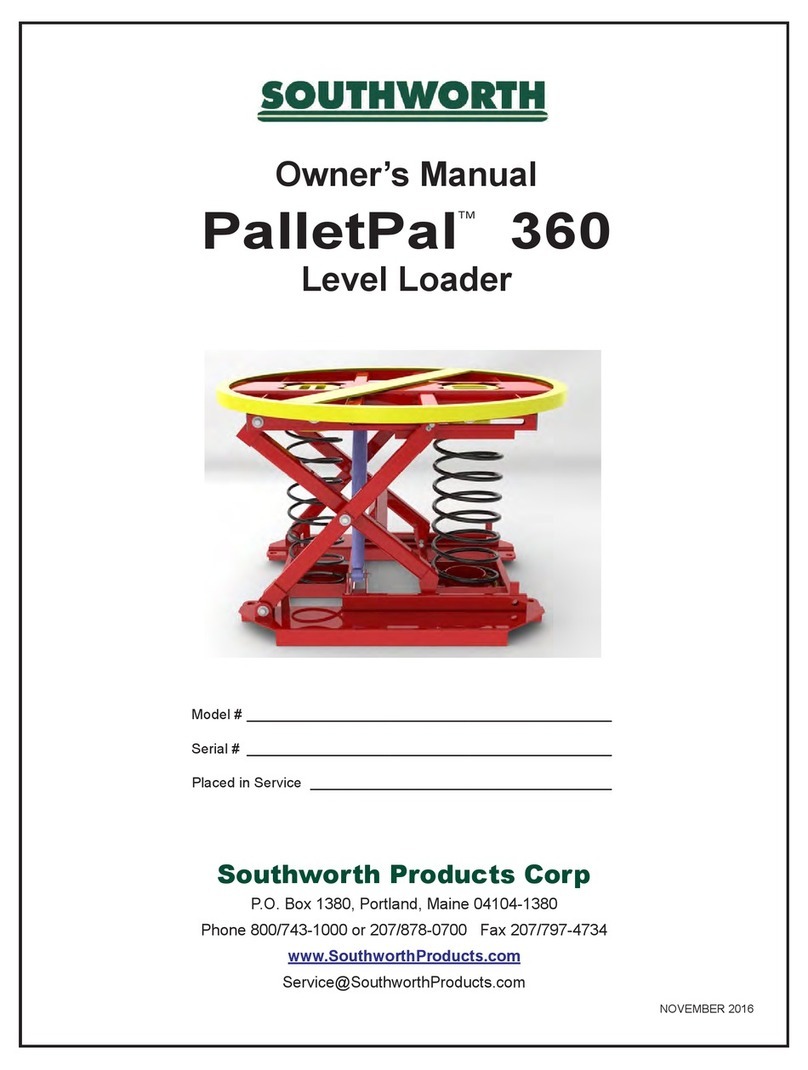

Southworth PPA User manual

SOUTHWORTH PRODUCTS CORP

PO Box 1380, Portland, ME 04104-1380

August 2017

Owner’s Manual

Air Bag Lift Tables

Airbag Lift Manual for PPA, GTA, GLSA & GLTA Models

Distributed by Ergonomic Partners

Email: [email protected]

Web: www.ergonomicpartners.com

PH: 314-884-8884 | FAX: 800-570-5584

2 Southworth Air Bag Lift Tables

Please note: This manual was current at the time of printing. To obtain the latest, most updated version, please

contact Southworth’s Customer Service Department or go to our website: www.SouthworthProducts.com, under

Parts & Service you will nd a complete list of current owner’s manuals to print.

Southworth Air Bag Lift Tables 3

Contents

INTRODUCTION............................................................................................ 4

Things to Know .................................................................................. 4

As a General Rule ............................................................................. 4

RESPONSIBILITY OF OWNERS AND USERS............................................. 5

SAFETY ALERT SYMBOLS AND SIGNAL WORDS...................................... 6

RISE TIMES .................................................................................................. 7

AIR BAG REFERENCE CHART .................................................................... 7

SAFETY.......................................................................................................... 8

Safety Considerations ........................................................................ 8

Signal Words ...................................................................................... 8

Safe Servicing of the Lift .................................................................... 9

INSTALLATION INSTRUCTIONS ................................................................ 10

MAINTENANCE ............................................................................................11

TROUBLESHOOTING ................................................................................. 12

ORDERING REPLACEMENT PARTS.......................................................... 13

WARRANTY ................................................................................................. 19

List of Figures

Figure 1: Safe Servicing of Lift ...................................................................... 9

Figure 2: Lift Assembly - 2,000 .................................................................... 14

Figure 3: Tilt Assembly - 2,000 ..................................................................... 15

Figure 4: Lift/Tilt Assembly- 2,000 ................................................................ 16

Figure 6: Foot Control Schematic................................................................. 17

4 Southworth Air Bag Lift Tables

INTRODUCTION

This manual contains information to acquint you with the safe and proper installation, use and upkeep

of the machine. You should ensure that this manual is available to personnel working with the machine

and require its use by these personnel.

In the interset of safety, please read this entire manual carefully and be familiar with its contents

before you install, use or service the machine. If you have any questions about any instructions in

this manual, please contact your dealer or Southworth Products Corp.

Southworth’s product warranty is provided in the back of this manual. This instruction manual is not

intended to be or to create any other warranty, expressed or implied, including any implied warranty

of merchantability or tness for a particular purpose, all of which are hereby expressly excluded.

As set forth more specically in the product waranty, Southworth’s obligation unfder that warranty is

limited to the repair or replacement of defective components, which shall be the buyers sole remedy.

Southoworth shall not be liable for any loss, injury or damage to persons or proprrty, not for any defect,

indirect or consequential damage of any kind resulting from the lift table.

Things to Know

1.) Capacity on pneumatic lift/tilt tables is affected by plant air psi (pounds per square inch of

pressure).

2.) Plant air pressure is typically 80 to 90 psi.

3.) Speed on lift/tilt tables is affected by the cfm available (cubic feet per minute or air volume ow).

4.) The cfm is a function of the air compressor’s capacity and the pressure and the size of the lines

leading to the lift/tilt table.

5.) The cfm is best expressed as “free air.” Meaning it is measured (or calculated) as a volume

blowing out an open line.

6.) Southworth capacity ratings and speed estimates on all models are based on 80 psi at 80 cfm,

free air.

As a General Rule

1.) Increasing cfm will increase up speed.

2.) Increasing psi will increase capacity and up speed.

3.) Capacity and speed are a function of the air compressor and the associated airline network, not

the equipment.

4.) If a pneumatic lift/tilt is not fully raised or lowered and a load is removed from the unit, the unit will

raise slightly as the pressure on the air inside the airbag is reduced.

5.) If a pneumatic lift/tilt is not fully raised or lowered and a load is put on the unit, the unit will lower

slightly as the air is compressed inside the airbag.

Southworth Air Bag Lift Tables 5

Responsibility of Owners and Users

Inspection and Maintenance

The device shall be inspected and maintained in proper working order in accordance with

Southworth’s owner’s manual.

Removal from Service

Any device not in safe operating condition such as, but not limited to, excessive leakage, miss-

ing rollers, pins, or fasteners, any bent or cracked structural members, cut or frayed electric,

hydraulic, or pneumatic lines, damaged or malfunctioning controls or safety devices, etc. shall

be removed from service until it is repaired to the original manufacturer’s standards.

Deection

It is the responsibility of the user/purchaser to advise the manufacturer where deection may

be critical to the application.

Repairs

All repairs shall be made by qualied personnel in conformance with Southworth’s instructions.

Operators

Only trained personnel and authorized personnel shall be permitted to operate the lift.

Before Operation

Before using the device, the operator shall have:

• Read and/or had explained, and understood, the manufacturer’s operating instructions

and safety rules.

• Inspected the device for proper operation and condition. Any suspect item shall be care-

fully examined and a determination made by a qualied person as to whether it con-

stitutes a hazard. All items not in conformance with Southworth’s specication shall be

corrected before further use of the equipment.

During Operation

The device shall only be used in accordance with this owner’s manual.

• Do not overload.

• Ensure that all safety devices are operational and in place.

Modications or Alterations

Modications or alterations to any Southworth industrial positioning equipment shall be made

only with written permission from Southworth.

6 Southworth Air Bag Lift Tables

SAFETY ALERT SYMBOLS AND SIGNAL WORDS

The safety of all persons operating, maintaining, repairing, or in the vicinity of this equipment is of paramount con-

cern. This is a powerful machine with moving parts, and is capable of causing personal injury if proper precautions are not

taken. Therefore, throughout this manual, certain hazards have been identied which may occur in the use of the machine,

and there are appropriate instructions or precautions which should be taken to avoid these hazards. In some cases, there

are consequences which may occur if instructions or precautions are not followed. Below are the symbols and signal words

along with their denitions referenced from ANSI Z535.4 - Product Safety Signs and Labels.

4.11 Safety Alert Symbols: A symbol that indicates a hazard. It is composed of an equilateral triangle surrounding

an exclamation mark. The safety alert symbol is only used on hazard alerting signs. It is not used on safety notice and safety

instructions signs.

4.14 Signal Words: The words used in the signal word panel. The signal words for hazard alerting signs are “DANGER,”

“WARNING,” and “CAUTION.” Safety notice signs use the signal word “NOTICE.” Safety instruction signs use signal words that

are specic to the situation.

DANGER indicates a hazardous situation which, if not avoided, will result

in death or serious injury.

WARNING indicates a hazardous situation which, if not avoided, could

result in death or serious injury.

CAUTION indicates a hazardous situation which, if not avoided, could

result in minor or moderate injury.

NOTICE is used to address practices not related to physical injury.

SAFETY INSTRUCTIONS (or equivalent) signs indicate specic safety-

related instructions or procedures.

NOTE: DANGER, WARNING or CAUTION should not be considered for property damage accidents unless personal injury risk

appropriate to these levels is involved.

A): for use with DANGER signal word; (safety white triangle, safety red exclamation mark, safety red background)

B): for use with WARNING signal word; (safety black triangle, safety orange exclamation mark)

C): for use with CAUTION signal word; (safety black triangle, safety yellow exclamation mark)

D) and E): for use with DANGER, WARNING, or CAUTION signal word; (D: is a safety yellow triangle with a

black border and safety black exclamation mark; E: is a safety yellow triangle with a safety black exclamation mark and a

safety yellow border around a safety black band)

NOTE: D and E are provided to allow for consistency with certain ISO standards such as ISO 3864-1 and ISO 3864-2.

Southworth Air Bag Lift Tables 7

Air Bag

Reference Chart

RISE TIMES

Pneumatic lifts/tilts are directly affected by weight that is on the platform.

Pressure compensation, such as we use on hydraulic machines is not applicable.

The following chart should be helpful. These speeds are all approximate.

CONDITION LIFT TILTER

RAISE-LOADED 30 SECONDS 20 SECONDS

LOWER-EMPTY 30 SECONDS 30 SECONDS

RAISE-EMPTY 15 SECONDS 15 SECONDS

LOWER-LOADED 15 SECONDS 20 SECONDS

8 Southworth Air Bag Lift Tables

SAFETY

The safety of all persons operating, maintaining, repairing or in the vicinity of the machine is of

paramount concern to Southworth. This is a powerful machine with moving parts and is capable

of causing personal injury if proper precautions are not taken. Therefore, throughout this manual,

Southworth has identied certain hazards that may occur in the use of this machine and provided

appropriate instruction or precautions that should be taken to avoid these hazards. In some cases,

Southworth has also pointed out the consequences that may occur if Southworth’s instructions or

precautions are not followed. Southworth uses the following system of identifying the severity of the

hazards associated with its products.

Southworth pneumatic lift/tilt tables are equipped with a pressure safety relief valve so overloading

will not “burst” the air bag.

Southworth pneumatic lift/tilt tables have a safety orice speed control. This regulates the down speed.

Should an air line rupture, the unit will descent at about the normal rate. This orice is not adjustable.

All Southworth pneumatic lift/tilt tables can be tted (optional) with industrial, high quality dampers to

provice smooth movement even when loads are abruptly introduced to the platform.

Southworth units are also equipped with safe, reliable Firestone air spring actuators rather than vinyl

air bags.

All Southworth models are designed with a generous safety factor of three to one.

Safety Considerations

Southworth pneumatic lift/tilt tables are designed and manufactured to meet the safety requirements

of the ANSI Standard MH29. Southworth pneumatic lift/tilt tables are equipped with a pressure safety

relief valve so overloading will not “burst” the air bag.

Southworth pneumatic lift/tilt tables have a safety orice speed control. This regulates the down speed.

Should an air line rupture, the unit will descent at about the normal rate. This orice is not adjustable.

All Southworth pneumatic lift/tilt tables can be tted (optional) with industrial, high quality dampers to

provice smooth movement even when loads are abruptly introduced to the platform. Southworth units

are also equipped with safe, reliable Firestone air spring actuators rather than vinyl air bags.

All Southworth models are designed with a generous safety factor of three to one.

SIGNAL WORD

The word or words that designates a degree or level of hazard seriousness. The signal words for

product safety signs are “DANGER, WARNING and CAUTION.”

“DANGER” Immediate hazard which will result in severe personal injury or death.

“WARNING” Hazardous or unsafe practice which could result in severe personal injury or death.

“CAUTION” Hazardous or unsafe practice that could result in minor personal injury or property

damage.

Please read and follow the instructions in this manual, including all safety instructions and

precautions carefully and completely.

Southworth Air Bag Lift Tables 9

WARNING !

Only authorized personnel should perform inspection or maintenance and service procedures.

Unauthorized personnel attempting these procedures do so at the risk of severe

injury or death.

Failure to properly adhere to lift blocking procedures is to risk the sudden and uncontrolled de-

scent of the lift during maintenance or inspection. A falling lift can cause severe injury or death.

This procedure describes the only factory-approved

method of working under a lift. Follow these instruc-

tions EVERY time you plan to reach or crawl beneath

the lift to perform service or maintenance – no matter

how momentary that might be.

If the factory-provided maintenance device is dam-

aged or missing, stop immediately and consult the

factory for assistance. The manufacturer is not liable

for your failure to use the approved maintenance

device(s) and procedures that have been provided.

1. Any load must be removed from the lift prior

to engaging the maintenance device(s). These

devices are designed to support an unloaded

lift only. Failure to remove the load from the lift

prior to blocking could cause the failure of the

maintenance device(s) and allow the lift to fall

unexpectedly. This can result in personal injury or death, or permanent damage to the maintenance

device(s) and/or the lift.

2. Raise the lift to its fully raised position. If you do not, the maintenance device(s) may not be able

to be placed properly in its/their designed blocking position.

3. Remove the maintenance device(s) from its/their storage location and place it/them into the

engaged position as shown in Figure 1. (Note: further information may be useful here to provide

additional instructions as to the location and method of storage and engaged positions).

4. Lower the lift until it makes complete contact with the maintenance device(s). Re-check to ensure

that all provided devices are fully and securely engaged. If the device(s) is/are not fully engaged

the lift could fall unexpectedly, resulting in permanent damage to the device(s) or the lift.

DANGER !

If for any reason you are unable to lower the lift completely onto the maintenance device(s), stop

immediately and consult the factory. Failure to properly use the factory approved maintenance

device(s) could result in severe injury or death.

5. Once the maintenance device(s) is/are properly and securely engaged, continue to press the down

valve for an additional 5-10 seconds to relieve all pressure in the operating system.

warning

Failure to relieve operating system pressure could result in the sudden and unexpected release

of air during maintenance and/or repair of the lift and may result in severe injury or death.

6. Follow OSHA lock-out/tag-out procedures. Disconnect and tag all power sources to prevent an un-

planned or unexpected actuation of the lift.

7. Once inspection or work is complete, reverse the performance of the steps above to raise the lift off

the maintenance device(s) and place the device(s) back into its/their designated storage position(s).

Safe Servicing of the Lift

10 Southworth Air Bag Lift Tables

INSTALLATION INSTRUCTIONS

Preparations:

1. Before you start to install the lift, check for local codes and ordinances which may apply in your area. It

is your responsibility to obtain any necessary permits.

2. Read all of these installation instructions carefully. Be sure to read and understand all of the warnings!

3. Prepare air supply to have lter regular that provides psi.

Positioning the lift:

1. Remove the shipping material and unskid the lift.

2. Move the lift into position, supporting the base frame of the lift. Mount the lift on a rm level surface and,

if necessary, insert shims to level the lift. Install lag bolts to hold the lift in place. Make sure to shim or

grout under the base frame to prevent any exing.

NOTICE

Machine base lag anchors need to be sized for a minimum of 5000# pull-out force for each lag.

WARNING

If the lift is mounted on an unstable surface, it may tip over when in use. You may be hurt

and the lift and/or load may be damaged.

Air Line (if equipped): Connect airline between actuator device and supply lines.

WARNING!

Be sure the air line will not be pinched by the lift during operation. If you allow the line to be

pinched, the lift may not work properly. A hose may break, the lift may drop suddenly and

someone may be hurt.

Testing

1. Check all connections and make sure that they are tight and do not leak air.

2. Clear the area around the lift. Remove any loose wires, lumber or other material which might get in the

way of the lift as it is in use.

3. Operate the lift through its full range of travel. The lift should rise and lower smoothly and quietly. Raise

and lower the lift a few times to check the clearances around the lift table.

WARNING!

As the lift moves, “pinch points” are created. If you are standing too close to the lift when

it is moving, your arm or leg may be caught in the moving parts and you may be hurt. Stay

away from the pinch points when the lift is moving.

Complete Installation

1. Test the lift with the rated load. If the lift does not move contact Southworth for instructions.

WARNING!

Do not continue to use the lift if this happens. This can cause the lift to fail suddenly and you

may be hurt.

Southworth Air Bag Lift Tables 11

MAINTENANCE

All service should be done by qualied personnel. Qualied personnel should be able to read and

understand wiring and pneumatic diagrams. They should be able to troubleshoot live pneumatic circuits

safely and in accordance with accepted practice. FOR SAFETY’S SAKE, if in doubt, please contact

your dealer or Southworth Products Corporation Customer Service Department at (207)878-0700 or

(800)743-1000.

Before servicing the lift, read and understand this entire section and the section entitled “Operating

Instructions.”

Hazards

There are several hazards you should be aware of as you service the lift:

Before working on the lift be sure to insert and all maintenance devices.

WARNING!

As the lift moves, “pinch points” are created. Keep hands, feet and loose clothing

away from these pinch points. If your arms, hands or your clothing is caught, you

may be hurt.

CAUTION!

The warning labels on the lift are there for the safety of the operator. If the labels are

worn or missing, replace them

Routine Periodic Maintenance

Every month:

Visually inspect the leg rollers, center pivot bushings and the upper and lower hinge pins and

bushings.

Apply oil or WD-40 to all parts listed above.

Note: Although the bearings are “lifetime lubricated,” their performance may be extended by

additional periodic lubrication (WD-40).

Every six months:

Check all of the pneumatic ttings and hoses and repair the connections if necessary. Occasionally,

the ttings can be worked loose by vibrations from the lift.

Check all lag anchors to make sure they are tight.

WARNING!

If a pneumatic tting becomes loose or if a pneumatic hose breaks, the air will escape

from the system under pressure. If the lift is elevated when this happens, it will drop

very quickly. Someone may be hurt or the product or the lift may be damaged.

12 Southworth Air Bag Lift Tables

TROUBLESHOOTING

All service should be done by qualied personnel. Qualied personnel should be able to read and

understand wiring and hydraulic diagrams. They should be able to troubleshoot circuits safely and in

accordance with accepted practice. FOR SAFETY’S SAKE, if in doubt, please contact your dealer or

Southworth Products Corporation Customer Service Department at (207) 878-0700 or (800) 743-1000.

Before servicing the lift, read and understand this entire section and the section entitled “Operating

Instructions.”

Before working on the lift be sure to insert any and all maintenance devices. Failure to do so may

result in damage to the machine and severe personal injury!

The lift fails to elevate:

1. The machine may be overloaded. Check the actual weight of the load. The rated capacity of the

machine is shown on the table skirt.

2. Check the air supply to see if it has enough pressure. Using an external lifting mechanism, such

as a crane or a fork lift. Raise the lift and insert the maintenance devices.

3. Check the lines in the airbag for leaks.

4. If the lift raises but does not raise completely, you may have to check the psi setting on the gauge

at the supply line.

The lift elevates, but fails to hold the load:

Before working on the lift, be sure to insert any and all maintenance devices. Failure to do so may

result in damage to the lift and severe personal injury!

1. The line going between the lift and the control, (if equipped) the relief valve or up/down control

valve may be leaking. Dirt on the valve seat will prevent the valve from closing fully. Contact the local

distributor or Southoworth Products for assistance.

The lift fails to lower:

Before working on the lift, be sure to insert any and all maintenance devices. Failure to do so may

result in damage to the lift and severe personal injury!

1. Be sure lever is connected and adjusted to actuate the down (exhaust) valve (if equipped).

2. Make sure nothign is blocking the lift from lowering.

If the steps listed above do not solve the problem,

please call the Customer Service Department at

Southworth Products Corp at (207) 878-0700

or (800) 743-1000.

Southworth Air Bag Lift Tables 13

ORDERING REPLACEMENT PARTS

Southworth has carefully chosen the components in your lift to be the best available for the

purpose. Replacement parts should be identical to the original equipment. Southworth will not

be responsible for equipment failures resulting from the use of incorrect replacement parts or

from unauthorized modications of the machine.

Southworth will gladly supply you with replacement parts for your Southworth lift. With your

order, please include the model number and the serial number of the lift. You may nd these

numbers on the nameplate, which is located on the crossbar at the base of the cylinder(s).

When you are ordering parts for a cylinder, also include the cylinder number. This is stamped

on the base of the cylinder housing.

To order replacement parts, please call the Parts Department at (207)878-0700 or (800)743-

1000. Parts are shipped subject to the following terms:

• FOB factory

• Returns only with the approval of our parts department

• Payment net 30 days (except parts covered by warranty)

• Freight collect (except parts covered by warranty)

• The warranty for repair parts is 30 days from date of shipment

Parts replaced under warranty are on a “charge-credit” basis. We will invoice you when we

ship the replacement part, then credit you when you return the worn or damaged part, and we

verify that it is covered by our warranty. Labor is not covered under warranty for Parts orders.

SOUTHWORTH PRODUCTS CORP

Parts Department

Telephone: (207) 878-0700

(800) 743-1000

Fax: (207) 797-4734

14 Southworth Air Bag Lift Tables

Figure 2: Lift Assembly - 2,000

ITEM QTY DESCRIPTION

1 2 AIRBAG

2 8 SCREW

3 8 SCREW

4 16 WASHER

5 2 FITTING

6 1 RELIEF VALVE

7 1 FITTING

8 1 HOSE

9 1 TEC FITTING

10 1 FITTING

11 2 CLIP

12 1 FITTING

13 2 HOSE

14 1 FITTING

Southworth Air Bag Lift Tables 15

Figure 3. Tilt Assembly -- 2,000

16 Southworth Air Bag Lift Tables

Figure 4: Lift/Tilt Assembly - 2,000

Southworth Air Bag Lift Tables 17

Figure 6.

Foot Control

Schematic

Airbag

One or Two

18 Southworth Air Bag Lift Tables

SOUTHWORTH PRODUCTS CORP

P.O. Box 1380, Portland, ME 04104-1380

Distributed by Ergonomic Partners

Email: [email protected]

Web: www.ergonomicpartners.com

PH: 314-884-8884 | FAX: 800-570-5584

Southworth Products Corp warrants this product to be free from defects in material

or workmanship for a period of 2 years of single shift usage from date of shipment,

providing claim is made in writing within that time period. This warranty shall not cover

modied designs for special applications, failure or defective operation caused by

misuse, misapplication, negligence or accident, exceeding recommended capacities,

failure to perform required maintenance or altering or repairing, unless alteration is

authorized by Southworth Products Corp. Except as set forth herein, there are no other

warranties, express or implied, including the warranties of merchantability and tness

for a particular purpose, all of which are hereby excluded.

All batteries have a 90 day parts and labor warranty, this warranty covers any

defects in material and workmanship from the date of shipment.

Southworth Products Corp makes no warranty or representation with respect to the

compliance of any product with state or local safety or product standard codes, and

any failure to comply with such codes shall not be considered a defect of material or

workmanship under this warranty. Southworth Products Corp shall not be liable for any

direct or consequential damages arising out of such noncompliance.

Southworth Products Corp’s obligation under this warranty is limited to the replace-

ment or repair of defective components at its factory or another location at Southworth

Products Corp’s discretion. The Southworth Warranty is for product sold with in North

America. For products shipped outside of North America the warranty will be for re-

placement of defective parts only. Labor is not included. This is buyer’s sole remedy.

Except as stated herein, Southworth Products Corp will not be liable for any loss, injury

or damage to persons or property, nor for direct, indirect, or consequential damage of

any kind, resulting from failure or defective operation of said product.

This warranty may be altered only in writing by Southworth Products Corp, Portland,

Maine.

2 YEAR WARRANTY

This manual suits for next models

3

Table of contents

Other Southworth Lifting System manuals

Southworth

Southworth PalletPal Walkie User manual

Southworth

Southworth PalletPal 360 User manual

Southworth

Southworth CLL05-68 User manual

Southworth

Southworth ZLS Series User manual

Southworth

Southworth UDLV-150 User manual

Southworth

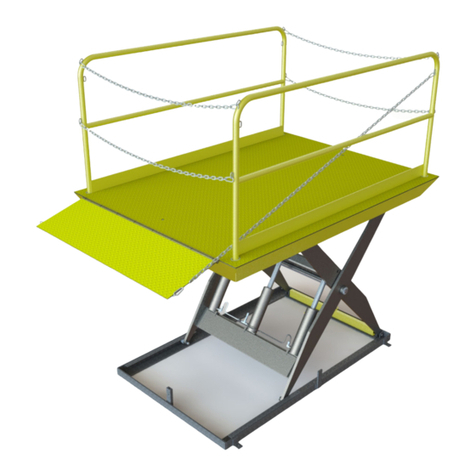

Southworth Dura-Dock Dock Lift Series User manual

Southworth

Southworth PUN Instruction manual

Southworth

Southworth Dura-Dock DDL5-59M User manual

Southworth

Southworth PLM 250 User manual

Southworth

Southworth PalletPal 360Air User manual