HIOS BLT-AY-61 User manual

Driver Controller for Automatic

BLF Brushless Screwdriver

BLT-AY-61

BLT-AY-71

Operation Manual

(As of September of 2017)

HIOS Inc.

1-16-5 Akiyama, Matsudo City, Chiba Pref., Japan 270-2223

Phone: 81-47-392-2001 FAX: 81-47-392-7773

No. ET-A048

17B

- 2 -

Contents

■ Introduction ........................................................................................................................................... 3

■ Outline ...................................................................................................................................................... 4

■ Precautions ............................................................................................................................................. 5

■ BLT-AY-61/BLT-AY-71 Specications ............................................................................................ 6

■ Exterior Drawings ................................................................................................................................ 7

■ Main Functions ..................................................................................................................................... 8

■ Main Terminology ............................................................................................................................... 9

■ Front Panel ............................................................................................................................................. 10

■ Rear Panel Input / Output ................................................................................................................ 11

■ Display When the Power is ON with the Default Settings ................................................... 12

■ How to switch between Reading Start/Pulse Start ................................................................ 13

■ MODE Settings 1 .................................................................................................................................. 14

■ MODE Settings 2 .................................................................................................................................. 15

■ Torque Up Settings ............................................................................................................................. 16

■ Clutch Mechanism ............................................................................................................................... 17

■ Input / Output Connections ............................................................................................................ 18

■ Relationship between RPM and Torque ..................................................................................... 19

BLF-2000, BLF-5000

■ Relationship between RPM and Torque ..................................................................................... 20

BLF-7000 Series

■ Timing Chart Table .............................................................................................................................. 21

■ Timing Chart 01-18 ............................................................................................................................. 22-39

■ After-sale service .................................................................................................................................. 40

- 3 -

■ Introduction

Thank you for purchasing the BLT-AY-61 and BLT-AY-71 Driver controller. Please read this

instruction manual thoroughly before use to ensure proper operation. Store this instruction

manual in a safe place for future reference.

BLT-AY-71 is only up to 120V ac for warranty more then 120V ac, HIOS can not take any respon-

sibility.

BLF-2000 BLF-5000 BLF-7000 Series

BLT-AY-61 BLT-AY-71

- 4 -

■ Outline

Conventional automatic screw drivers of CLF Series, αF Series, and CL-A Series use motors with

carbon brushes that require periodic replacement. Wear in the carbon brushes as well as in the

commentator aects the operating life of the driver, requiring the motor to be replaced peri-

odically.

The BLT-AY-61 and BLT-AY-71 Driver controller uses a brushless motor and not use consumable

parts such as carbon brush. That saves much of maintenance eorts for this driver.

Features such as 2WS* (2-way speed) and REV (reverse rotation), which are available as option-

al for CLT-AY-61/CLT-AY-81, are now included as standard.

A torque protection circuit is used during low speed 2WS operation to vastly improve bit stop-

ping when re-tightening screws.

There is a main power switch, and the primary input voltage ranges from 100 V to 240 V allow-

ing worldwide use.

* With conventional Driver controller CLT-AY-61/CLT-AY-81, similar function is called "2WV", but with these new

automatic drivers, it is called "2WS".

<Notes>

① BLT-AY-61 is a power supply dedicated to BLF-2000 and BLF-5000.

② BLT-AY-71 is a power supply dedicated to BLF-7000 series. Up to

120V ac only.

③ Any other power supply or counter, such as T-70BL or BLOP-STC3,

cannot be used for automatic screwdrivers.

Such misuse might cause an accident or other problem.

(Notice)

We can specially provide you with a screwdriver for left-handed threads on request.

- 5 -

■ Precautions

Please read this instruction manual thoroughly before use to ensure proper operation.

● On any commercial power source, install a ground-fault interrupt breaker and safety circuit

breaker.

● Connect the unit to ground and use only the rated voltage.

● Do not exceed the rated loads for the output connections on the rear panel. Exceeding the

rated load will cause the unit to malfunction.

● If the unit may be subjected to inductive loads from a relay or solenoid valve coil in auxiliary

equipment connected to the input/output connections on the rear panel, install a reverse

polarity diode to suppress electrical noise. The unit may malfunction if noise suppression is

not installed.

● The overload protection will be activated when the driver is locked or has become over-

loaded. If the driver is overloaded repeatedly, the maximum ratings of the unit or attached

electric driver may be exceeded. If the driver becomes overloaded during Forward operation

or begins to malfunction due to developing excessive heat, stop the ongoing operation im-

mediately, turn the main power switch o, remove the power cable, and contact our service

department for repairs.

● When tightening screws on work pieces constructed of plastics susceptible to static electric-

ity build-up, tightening should be performed after static electricity has been discharged. If

working on pieces that have not been properly discharged, static electricity may flow up

through the end of the bit, causing malfunctions.

● A common GND should be used if the unit is connected to auxiliary equipment that is pow-

ered separately. The unit may malfunction if a common GND is not used.

● Do not apply voltage to the inputs or outputs. This may cause malfunctions.

● Extending input/output connection cables longer than necessary or bundling power cables

together can cause malfunctions.

● Choose an installation area with no vibrations. If the unit is installed in a high location, en-

sure that it is properly secured.

● Do not install the unit near high voltage equipment or in an electrically noisy environment.

● Do not place heavy items on top of the unit, or stack the units on top of one another.

● Do not install the unit in an area where it may be subjected to dust or metal fragments.

● Do not use the unit with anything other than HIOS drivers as this will cause the unit to mal-

function.

● Do not disassemble or modify the unit in any way, as doing so may cause the unit to mal-

function. Such malfunctions are not covered by the HIOS warranty and repairs to the unit

may be refused.

● The operating environment for the driver should be between 5C and 40C with relative hu-

midity of 80% or less (there should be no possibility of condensation).

● Do not drop the unit or subject it to mechanical shocks.

● Always hold the plug when inserting or removing power cables or driver cords into or from

sockets.

● Do not drag cords or cables, subject them to oil or to sharp edges, or place them under

heavy objects.

● If the unit will not be used for a long period of time, turn the main power switch OFF and

unplug it from the service outlet.

- 6 -

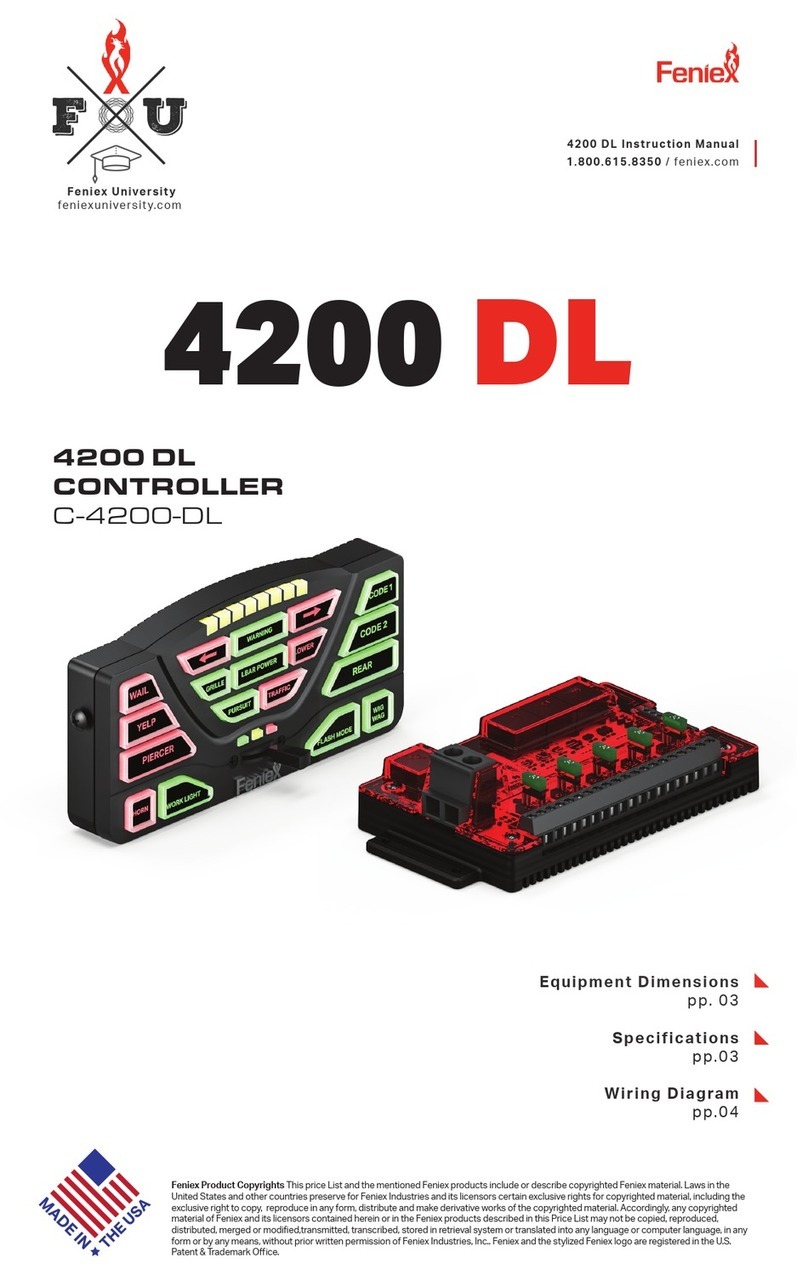

■ BLT-AY-61/BLT-AY-71 Specications

BLT-AY-61 BLT-AY-71

Input Voltage AC100-240V (47-63Hz)

Power 100W

Fuse Rating 3A/250V (spare fuse included)

Dimensions See p.7 for Exterior Drawings.

Weight Approximately 1.75kg (main unit only)

Driver (See p19, 20)

Compatible Drivers BLF-2000 or BLF-5000 BLF-7000 or BLF-7000X and

BLF-7025X

Rotation Control Direction Forward / Reverse

Driver rpm Settings LOW/HIGH

(2WS)

Low side 05 - 15 (11 steps)

High side 20 - 30 (11 steps)

Power cord length 1.8m

Accessories Power supply connector 1 piece (See p.11)

Note: The RPM may vary between forward and reverse rotation. The above gures are to be used as a guide only.

● Tightening check (impact number) 1 – 4 / Continuous

● Torque up trigger selection

・Forward / Reverse rotation by UP trigger; Forward / Reverse rotation by DOWN trigger

Standard automatic screwdriver does not Torque-up for Reverse.

・If you want to fasten the screw of counter-clock-wise, please ask for the special screwdriver

for it.

・HIGH reverse rotation impact number or LOW reverse rotation impact number should be

set at U0 or d0 to use the driver for removing screws.

● Overtime Protection (Restored by turning power OFF / ON)

10 steps t0 – t9

t1: approximately 10 seconds – t9: approximately 90 seconds, t0: approximately 2550 sec-

onds

Caution!!

This is a protection feature for the controller and driver, and is normally set within the program

on the system side of the sequencer.

● Overload Protection (Recovery by turning power OFF / ON)

"OL" is displayed on the front panel when the protection circuit is activated.

* Caution!!

This setting protects the controller and driver. If the protection circuit is being activated often,

the load on the motor is excessively high. Stop any tightening operations that exceed the rating

of the unit.

- 7 -

7.5

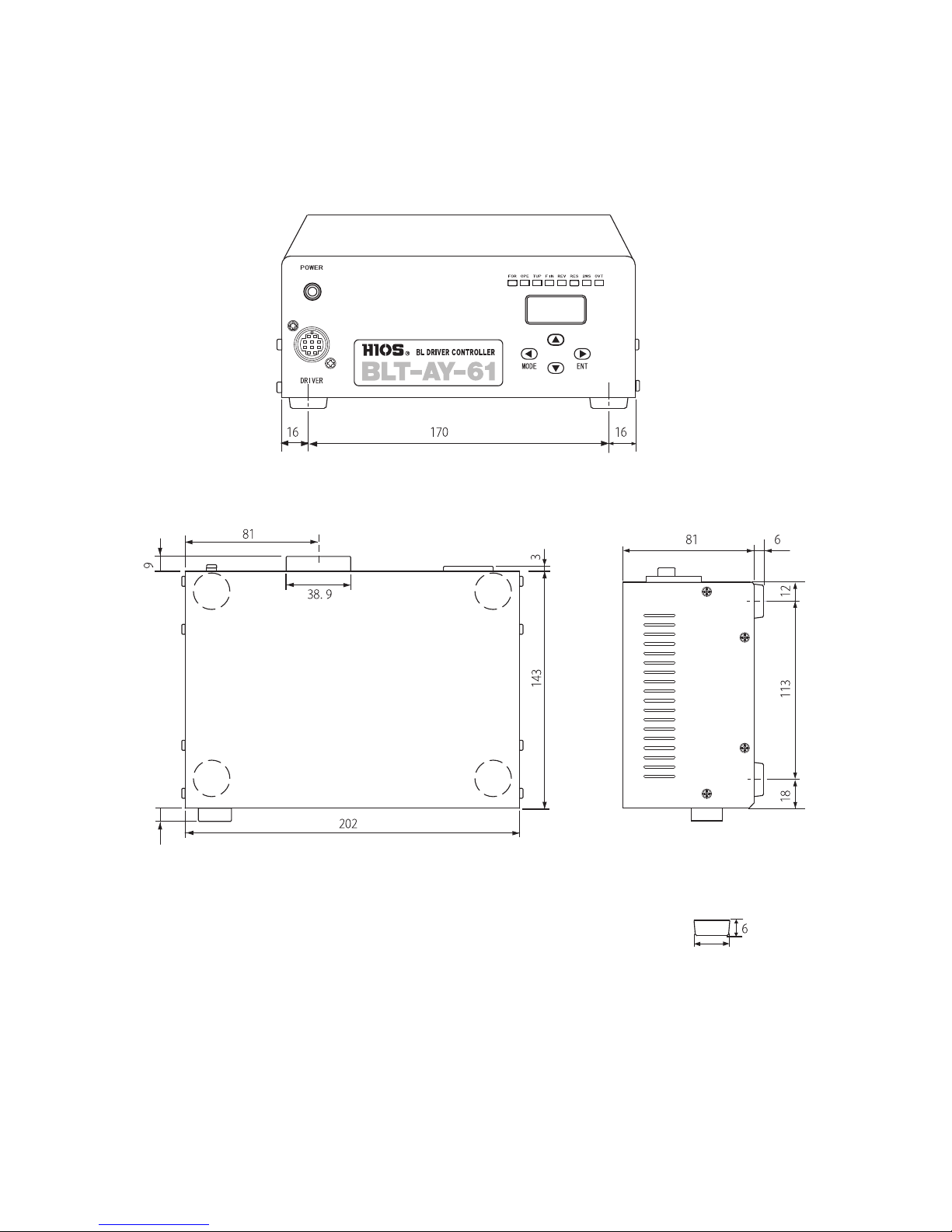

■ Exterior Drawings

BLT-AY-61 and BLT-AY-71 have common exterior drawings.

FrontFront

(Caution) The above exterior drawing of the power supply for brushless screwdrivers Not to

scale.

(Front View)

(Overhead View)

Input terminal block

(Right Side View)

Footing size 4-∅22

Unit: mm

- 8 -

■ Main Functions

1. The motor control circuitry is incorporated into the BLT-AY-61/ BLT-AY-71, giving the driver

a simpler construction.

2. The internal buzzer can be turned o (internal SW 6-1).

3. The FOR input for forward rotation from an external source can be switched between pulse

and reading (internal SW 6-2).

4. Forward / Reverse driver rotation High speed / low speed driver rotation can be controlled

externally.

5. The rpm can be set in 11 steps comprising 20 – 30 for high speed, and 11 steps comprising

5 – 15 for low speed.

6. The shape of the input signal can be selected to suit the movement of the cam during

torque up operations. Torque up can also be set for reverse rotation (for tightening counter

screws).

Eg 1: Set to U1 when tightening with high rpm and one impact (one UP trigger edge)

Eg 2: Set to d3 when tightening with low rpm and three impacts (three DOWN trigger)

7. If the driver keeps rotating and the overtime setting is set on the controller, the driver will

stop automatically and a buzzer will sound (recovery by turning power OFF / ON).

8. If the driver is overloaded, the overload protection circuit will be activated, the driver will

stop and a buzzer will sound (recovery by turning power OFF / ON).

9. Operation display indicators are installed on the front panel to monitor driver operation.

10. Simple settings are available with the combination of four buttons (Mode, ↓ , ↑ and ENT)

and the 2-digit seven segment display.

11. The internal power supply has a power selector switch and can be used with voltages of

any country.

12. The power unit has been made compact and lighter compared to other power units for au-

tomatic drivers.

13. The rear terminal block is removable, making installation and replacement simple.

- 9 -

■ Main Terminology

1. Tightening Check (setting the impact number)

To check that the screw has been tightened properly or to tighten the screw further, the

screw is tightened two or three times after the initial tightening. A tightening check can also

be referred to as a second tightening or re-tightening.

2. Torque Up

After the screw has been tightened and the tightening torque reaches the set torque, the

electric driver clutch disengages.

3. UP Trigger

Used when the clutch signal is received on the upslope of the cam when the bit is rotating at

high speed.

4. DOWN Trigger

Used when the clutch signal is received on the down slope of the cam when the bit is rotat-

ing at low speed.

5. Input Method

Signal input to the unit is through a photo coupler with a maximum current of 10 mA.

If an open collector connection is used, connect the emitter to GND and the input to the col-

lector.

(Caution)

Do not apply any voltage to the inputs. Install a diode that absorbs reverse voltages to the

relay coil on the input connections. If any auxiliary equipment is used, include electrical

noise suppression.

6. Output Method

The output signal of the unit is through a dry contact output internal common GND on one

side with a maximum rated load of DC 24 V / 500 mA. A common GND for connections with

auxiliary equipment should be used.

(Caution)

Do not apply voltage to the inputs. Install a diode that absorbs reverse voltages to the relay

coil on the input connections. If an auxiliary unit is used, carry out electrical noise suppres-

sion.

7. Overload Protection

The overload protection circuit stops output to protect the unit and electric driver from ex-

cess current if the driver is operated into overload.

The overload protection is activated, turn o the control unit and let it sit idle for at least one

minute. The driver may be operated after turning the unit back on.

(Caution)

Please note that if the driver is repeatedly overloaded, activating overload protection, the cur-

rent rating of the unit or the electric driver may be exceeded.

- 10 -

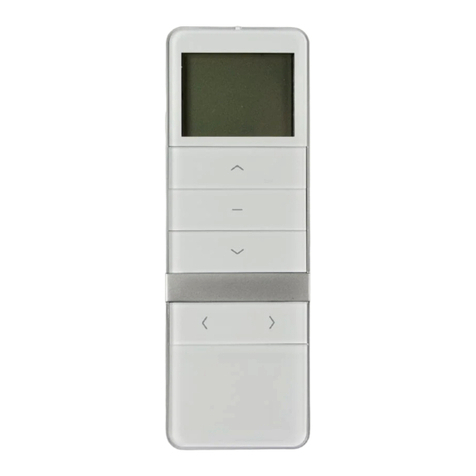

■ Front Panel

2. Driver Connector

5. Function Button

▲ UP Button

▼ DOWN Button

ENT Button

3. Operation Display LED 4. Setting Value

Segment Display

1. Main SW

A green LED will light up when the power is turned ON, and the operation display LEDs and

all segments of the value display will light up for 1 second.

2. Driver Connector

Attach the automatic BL driver cable.

3. Operation Display LEDs

The state of auxiliary inputs and outputs as well as the driver’s operation can be monitored

with this LED array.

4. Setting Value Segment Display

Displays the settings for torque up rpm for Forward driver rotation / torque up rpm for re-

verse rotation / 2WS HIGH side rpm / 2WS LOW side rpm / 2WS HIGH side overtime / 2WS

LOW side overtime.

5. Function Button / UP Button / DOWN Button / ENT Button

Driver operating settings should be changed after a reset signal has been input. Other

inputs such as 2WS should also be disabled so that there are no LEDs lit up. Pressing the

Function Button will result in a short beeping buzzer sound. Holding the button down lon-

ger will result in a short beeping buzzer sound, and the operation display LED and setting

value segment display will turn on. Pressing the ENT button will switch between the opera-

tion display LED and setting value segment. The UP/DOWN buttons are used to change the

value of the settings.

After the settings are complete and the Function Button is pressed again, a short beep

buzzer will sound. On holding the button down longer, a two-second beeping buzzer will

sound one second from the start of pressing the button and the setting value segment dis-

play will turn o, indicating that settings are complete.

● Refer to page * for more information on how to change each setting.

- 11 -

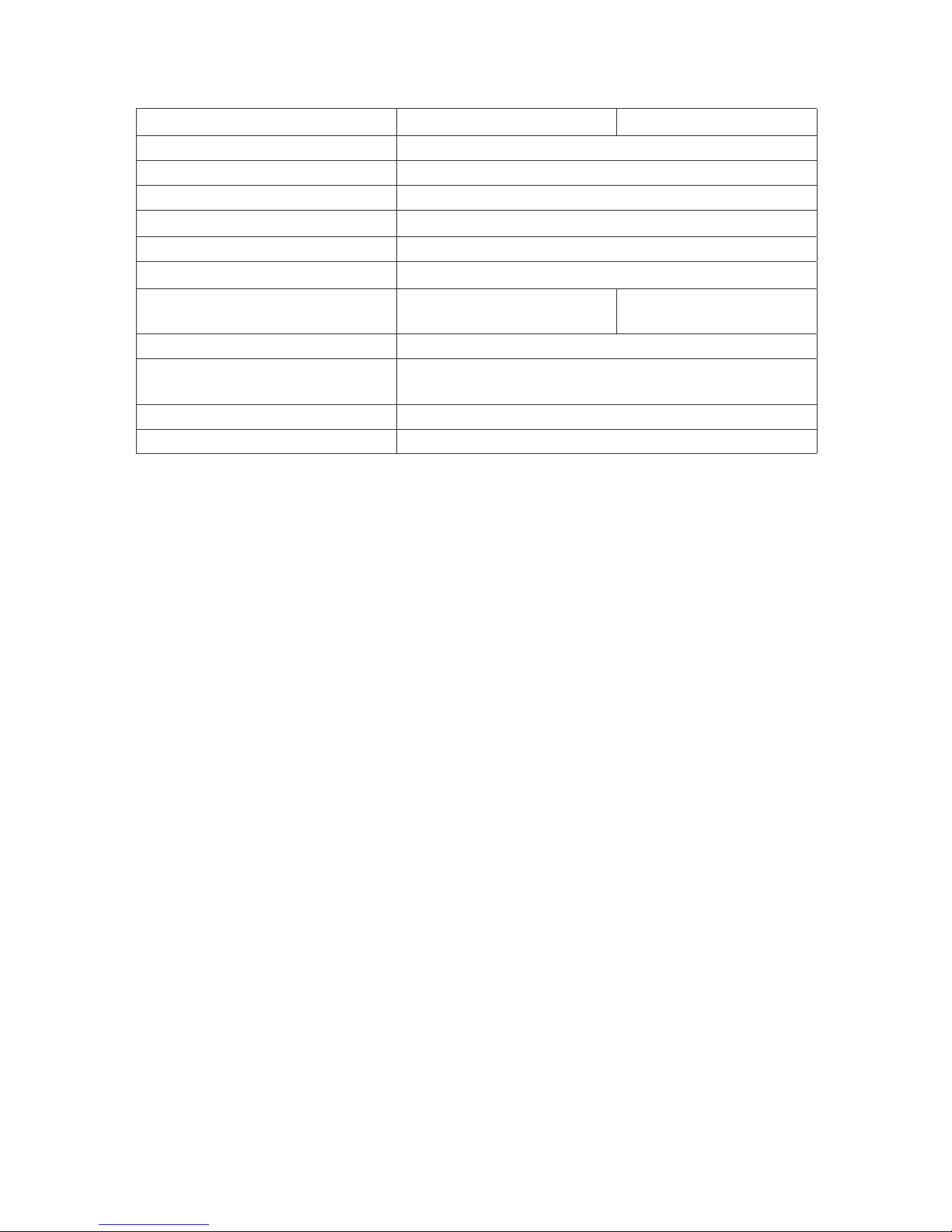

■ Rear Panel Input / Output

No Input /

Output Signal Name Outline

1 External Output FINISH Output

Output is present on this terminal when screw tight-

ening is complete. Output ceases when either the

next FOR or REV input is received or when the RESET

input is used.

2 Common COM Common for input and output. This is connected to

the internal controller GND.

3 External Input REV Input

Apply input to this terminal when you wish to operate

the driver in reverse rotation. The driver will operate

in reverse while the signal is present.

4 External Input 2WS Input Driver rotation SPEED can switch between two stages.

2WS will be the LOW side while the signal is ON.

5 External Input RESET Input Used when the driver operation is to be stopped by

an external source.

6 External Input FOR Input

Apply input to this terminal when you wish to oper-

ate the driver in forward rotation. The method can be

selected between pulse and reading. *1

*1 When the input method is set to pulse, the driver will operate in forward rotation when a FOR input pulse of

100 ms or more is received.

To stop rotation, apply input to the RESET terminal.

The reading input for the start method means that the driver rotates FOR while FOR is input.

To stop the rotation, turn the FOR input OFF or use the RESET input.

Pulse or reading can be switched with the DIP SW on the internal board.

Inlet with Fuse Holder 3 A / 250 V

External I/O terminal

Terminal block connector

on the main body

Model number: XW4A-10B1-V1

Accessories:

Power supply side

Terminal block connector

1. Main SW

- 12 -

p.12

MODE

ENT

DRIVER

POWER

FOR OPE TUP FIN REV RES 2WS OVT

The BLT-AY-61 and BLT-AY-71 can be switched between 2WS HIGH (20 – 30) and 2WS LOW

(5 – 15) by turning 2WS ON / OFF. The bit can be rotated in reverse by turning REV (reverse

rotation input) ON / OFF.

The torque up number can be set regardless of whether the rotation is forward / reverse

or HIGH / LOW.

Change the number by following the steps in the MODE settings (pages 14 – 15).

In order to prevent the driver from rotating in the case of an accident, the built-in over-

time timer can also be set in the same way regardless of whether the rotation is forward /

reverse or HIGH / LOW.

Change the number by following the steps in the MODE settings (pages 14 – 15).

The factory settings are as follows.

● 2WS HIGH forward rotation impact number U1

● 2WS HIGH reverse rotation impact number U0

● 2WS HIGH setting speed 30

● 2WS HIGH overtime setting value t0 (approximately 42 minutes)

● 2WS LOW forward rotation impact number d1

● 2WS LOW reverse rotation impact number d0

● 2WS LOW setting speed 15

● 2WS LOW overtime setting value t0 (approximately 42 minutes)

● Overload protection function Front panel OL display

* For the impact number setting, if you set U0 or d0, torque up does not happen and the impact is contin-

ued (setting without torque up).

When the main SW is turned ON, the green

SW LED light up.

All operation LEDs and the setting value seg-

ment display will turn on for one second.

Display When the Power is ON with the Default Settings

(Note)

HIGH reverse rotation impact number or LOW reverse rotation impact number should be set at

U0 or d0 to use the driver for removing screws.

- 13 -

■ How to switch between Reading Start/Pulse Start

1) Turn the power to the BLT-AY-61 or BLT-AY-71 off and remove the power cable from the

power outlet.

2) Remove the driver cable from the plug on the main unit.

3) Remove the cover of the main unit. Take care not to lose the screws.

4) Switch between reading start/pulse start using No. 2 of SW6 on the circuit board within the

main unit.

Pulse start is enabled with No. 2 ON, and Reading Start with No. 2 OFF.

5) After the settings have been changed, replace the cover of the main unit and attach with

the eight screws.

* Take care to prevent foreign particles entering the main unit while the cover is o.

No Function

1Buzzer (ON -> buzzer beeps / OFF -> buzzer does not

beep

2Switching between Reading Start/Pulse Start

ON -> Pulse Start / OFF -> Reading Start

BLT-AY-61/BLT-AY-71

(with the cover removed)

(removing the eight

screws on each side)

- 14 -

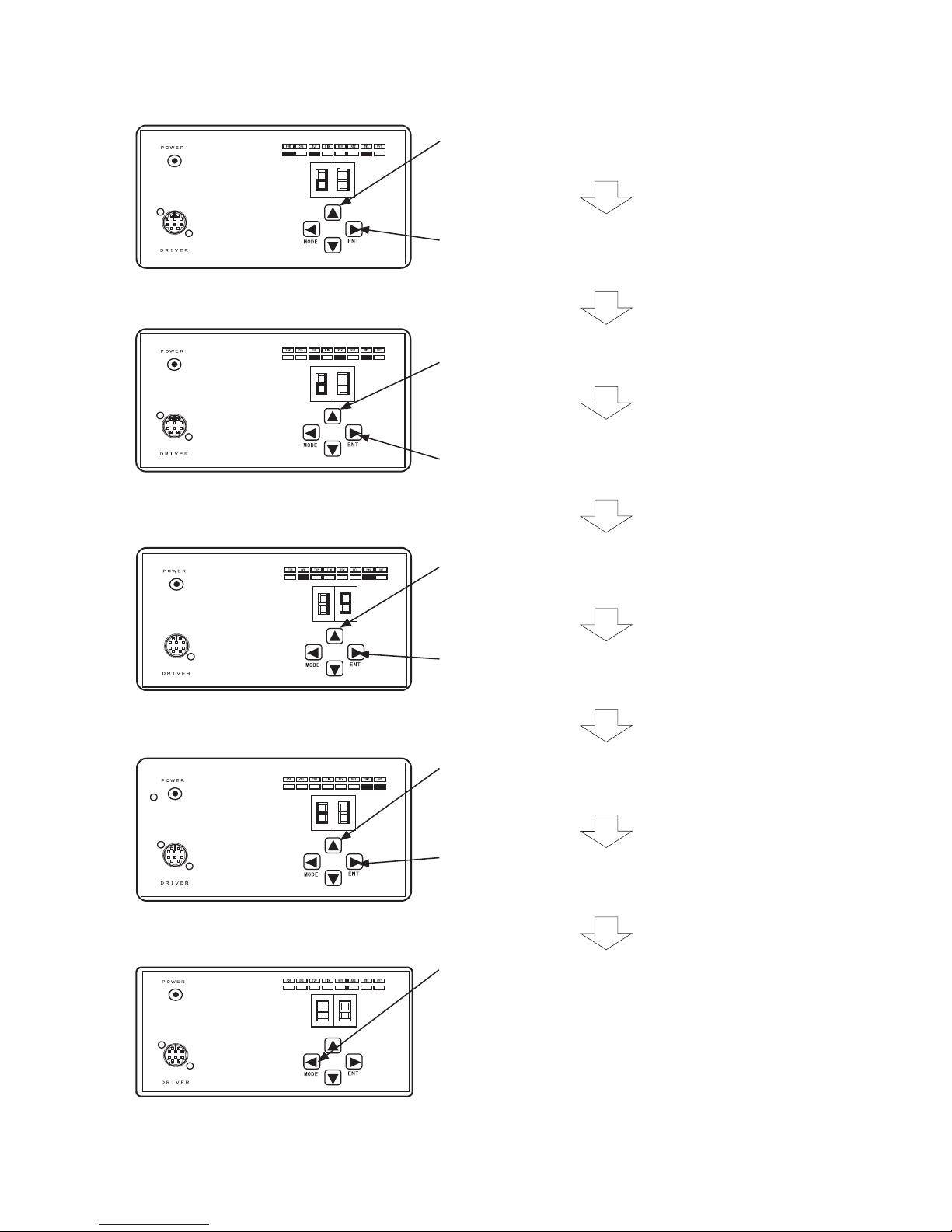

(1) Hold down the Function Button

"Beep (2 seconds) beep beep"

(2) Forward rotation (2WS – HIGH) torque up settings

Use ▲ / ▼ to change the settings (U0 to U4 and

d0 to d4)

Always check the changes with ENT. If changes

to other settings are not required, hold down the

Function Button to complete the setting process.

(3)

Reverse rotation (2WS – HIGH) torque up settings

※

Use ▲ / ▼ to change the settings (U0 to U4 and

d0 to d4)

Always check the changes with ENT. If changes

to other settings are not required, hold down the

Function Button to complete the setting process.

(4) Forward / reverse rotation (2WS – HIGH) speed

settings

Use ▲ / ▼ to change the settings (20 to 30)

Always check the changes with ENT. If changes

to other settings are not required, hold down the

Function Button to complete the setting process.

(5) Forward / reverse rotation (2WS – HIGH) overtime

settings

Use ▲ / ▼ to change the settings (t0 to t9)

Always check the changes with ENT. If changes

to other settings are not required, hold down the

Function Button to complete the setting process.

MODE Settings 1

- 15 -

MODE Settings 2

(6) Forward rotation (2WS – LOW) torque up settings

Use ▲ / ▼ to change the settings (U0 to U4 and

d0 to d4)

Always check the changes with ENT. If changes

to other settings are not required, hold down the

Function Button to complete the setting process.

(7)

Reverse rotation (2WS – LOW) torque up settings

※

Use ▲ / ▼ to change the settings (U0 to U4 and

d0 to d4)

Always check the changes with ENT. If changes

to other settings are not required, hold down the

Function Button to complete the setting process.

(8) Forward / reverse rotation (2WS – LOW) speed

settings

Use ▲ / ▼ to change the settings (05 to 15)

Always check the changes with ENT. If changes

to other settings are not required, hold down the

Function Button to complete the setting process.

(9) Forward / reverse rotation (2WS – LOW) over-

time settings

Use ▲ / ▼ to change the settings (t0 to t9)

Always check the changes with ENT. If changes

to other settings are not required, hold down the

Function Button to complete the setting process.

(10) Hold down the Function Button

"Beep (1 second) beeeep (2 seconds)"

All displays will turn o

(Note)

HIGH reverse rotation impact number or LOW reverse

rotation impact number should be set at U0 or d0 to

use the driver for removing screws.

- 16 -

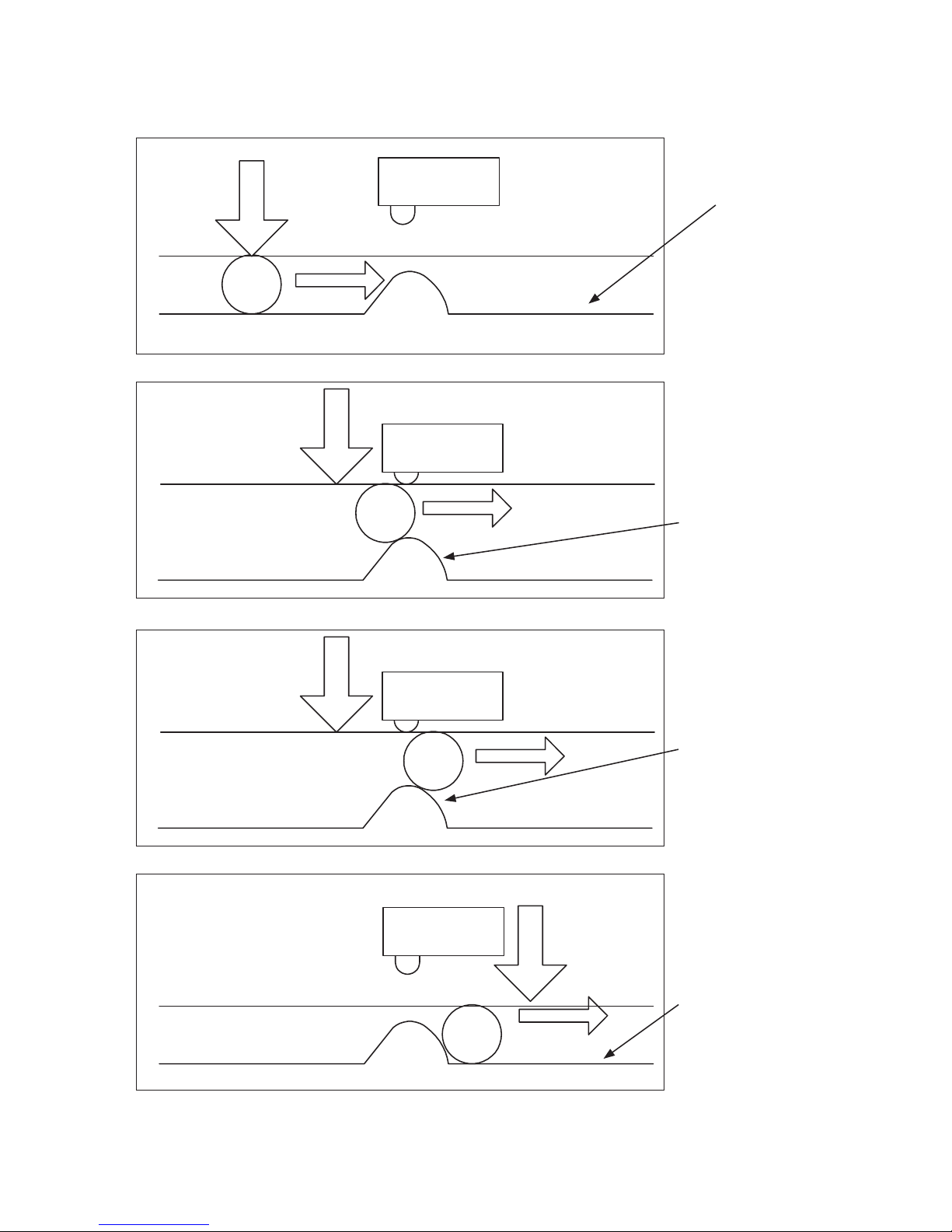

■ Torque Up Settings

Most customers are undoubtedly experienced in driving a car, and are aware that cars travel-

ing up a slope at a high speed will end up going over the mountain even when the brakes are

applied, while cars traveling at a low speed will come to a stop before reaching the top of the

mountain when the brakes are applied.

The automatic brushless screwdriver BLF-series uses a system that traverses the lobe of a me-

chanical cam to apply torque to screws. To ensure that torque is applied to the bit accurately, a

clutch is used when traversing the cam. The timing of the application of the brake when the bit

is rotating at high speeds and low speeds is required to be adjusted to traverse the lobe of the

cam.

The BLT-AY-61/BLT-AY-71 controller is designed to control the rotational speed of the driver

over a large range of speeds from low to high, as well as to allow settings for torque up with

DOWN trigger at low speeds and UP trigger at high speeds.

Applying the brakes here at a high

speed will result in the car stopping

past the top of the mountain.

The brakes are applied at a low speed

here.

- 17 -

■ Clutch Mechanism

The clutch mechanism is described below.

Detection SW

"OFF"

Cam

Roller

Roller

Torque adjustment

pressure

Torque adjustment

pressure

Torque adjustment

pressure

Torque adjustment

pressure

Movement to

traverse cam

Movement to

traverse cam

Movement to

traverse cam

Movement to

traverse cam

Roller

Roller

Cam

Cam

Cam

Detection SW

"ON"

Detection SW

"ON"

Detection SW

"ON"

1

2

3

4

Diagram of the

mechanism that

allows the driver to

detect torque.

If the speed when

traversing the cam is

high, the detection

SW turns ON (before

traversing the cam)

and the brake is ap-

plied to the motor.

If the speed when

traversing the cam is

low, the detection SW

turns OFF (after tra-

versing the cam) and

the brake is applied to

the motor.

By traversing the cam,

torque is transferred

accurately and

the screw is com-

pletely tightened.

- 18 -

■ Input/Output Connections

FOR input terminal

Input/Output circuit layout

The input circuit consists

of a photo coupler. Drop

the input terminal to GND

level using an open col-

lector.

The output circuit uses a dry con-

tact; however, one side has a com-

mon GND.

RESET input terminal Same as above circuit layout

2WS input terminal Same as above circuit layout

REV input terminal Same as above circuit layout

COM input terminal

FINISH output terminal

Internal

circuit

Internal Power / DC 24V

Internal

circuit

GND

- 19 -

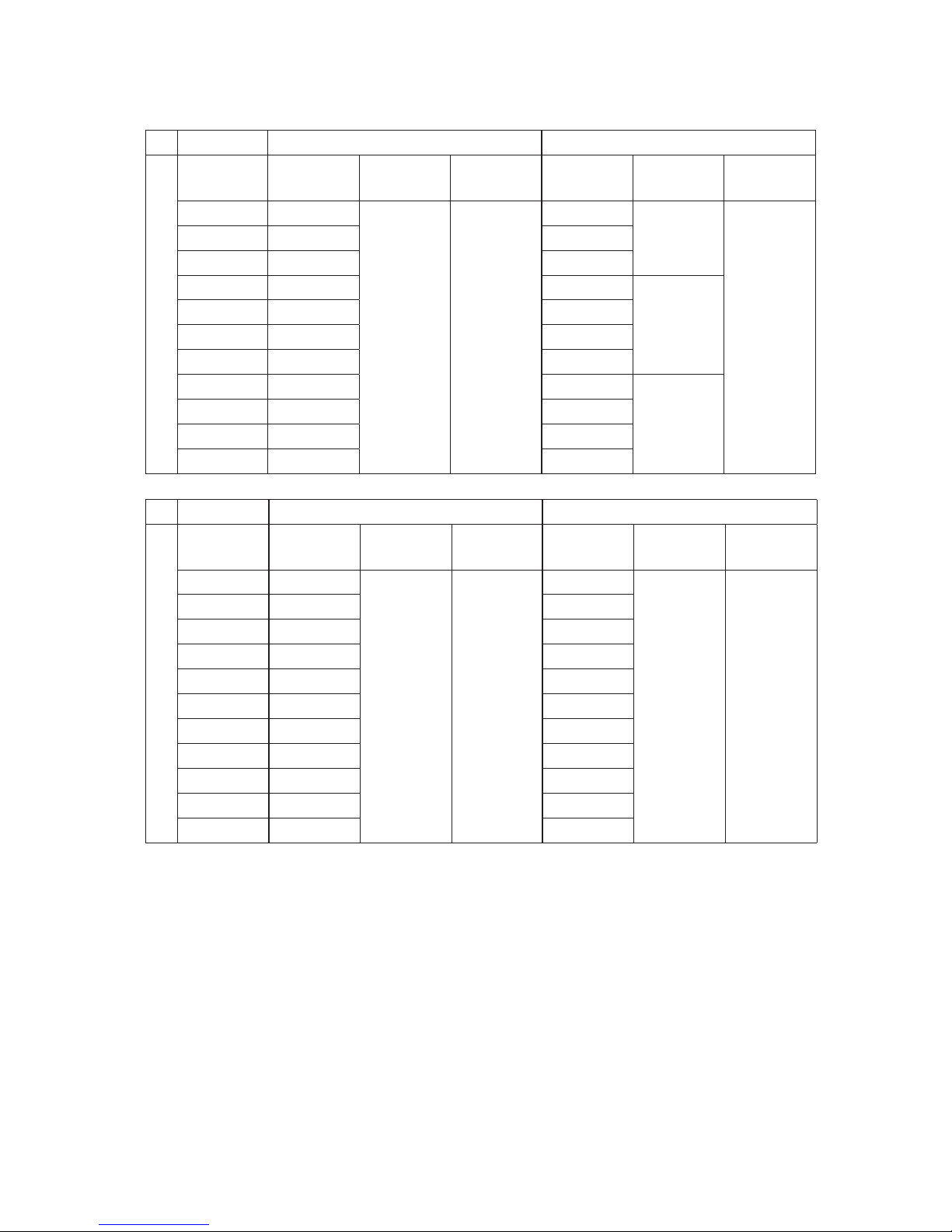

■ Relationship between RPM and Torque (BLF-2000 / BLF-5000)

For the unloaded rotation speed, consider the value in the chart with the range of ± 10%.

Screwdriver BLF-2000* BLF-5000

LOW 11 steps switching

Speed Set-

ting RPM Max Torque Min Torque RPM Max Torque Min Torque

05 120 r.p.m

0.35 N・m 0.03 N・m

115 r.p.m

0.6 N・m

0.3 N・m

06 150 r.p.m 135 r.p.m

07 165 r.p.m 150 r.p.m

08 187 r.p.m 180 r.p.m

0.8 N・m

09 210 r.p.m 195 r.p.m

10 232 r.p.m 210 r.p.m

11 270 r.p.m 240 r.p.m

12 285 r.p.m 255 r.p.m

1 N・m

13 300 r.p.m 285 r.p.m

14 315 r.p.m 300 r.p.m

15 345 r.p.m 320 r.p.m

Screwdriver BLF-2000* BLF-5000

HIGH 11 steps switching

Speed Set-

ting RPM Max Torque Min Torque RPM Max Torque Min Torque

20 690 r.p.m

0.35 N・m 0.03 N・m

660 r.p.m

1 N・m 0.3 N・m

21 720 r.p.m 690 r.p.m

22 750 r.p.m 720 r.p.m

23 780 r.p.m 750 r.p.m

24 810 r.p.m 780 r.p.m

25 825 r.p.m 810 r.p.m

26 870 r.p.m 840 r.p.m

27 975 r.p.m 940 r.p.m

28 975 r.p.m 940 r.p.m

29 975 r.p.m 940 r.p.m

30 975 r.p.m 940 r.p.m

* BLF-2000 includes two torque control springs. The silver spring accessory is used for high torque measure-

ment while the black spring attached to the main body is used for low torque measurement.

Please refer to the reference table of output torque in the "Instruction Manual" for the screwdriver for auto-

matic BLF brushless screwdriver.

(Cautions)

1. RPM may vary due to dierences between forward rotation and reverse rotation. The reference

value is a rough guideline.

2. The listed RPMs were measured without load. In case Speed Setting is 27 or more, the actual

RPMs may dier from the values in the table according to the loads.

The torques were measured with our Torque meter (HP) and Fidaptor.

3. The values in above table may dier from the values observed in your environment. Please use

the above values as a rough guideline.

- 20 -

■ Relationship between RPM and Torque (BLF-7000 Series)

For the unloaded rotation speed, consider the value in the chart with the range of ± 10%.

Screwdriver BLF-7000 / BLF-7000X BLF-7025X

LOW 11 steps switching

Speed Set-

ting RPM Max Torque Min Torque RPM Max Torque Min Torque

05 150 r.p.m

1.1 N・m

0.7 N・m

120 r.p.m

1.4 N・m

1.2 N・m

06 180 r.p.m 140 r.p.m

07 210 r.p.m 160 r.p.m

08 240 r.p.m 180 r.p.m

09 270 r.p.m 210 r.p.m

10 300 r.p.m

1.5 N・m

230 r.p.m

11 330 r.p.m 250 r.p.m

12 360 r.p.m 280 r.p.m

2 N・m

13 390 r.p.m 300 r.p.m

14 420 r.p.m 320 r.p.m

15 450 r.p.m 350 r.p.m

Screwdriver BLF-7000 / BLF-7000X BLF-7025X

HIGH 11 steps switching

Speed Set-

ting RPM Max Torque Min Torque RPM Max Torque Min Torque

20 495 r.p.m

2 N・m 0.7 N・m

400 r.p.m

2.5 N・m 1.2 N・m

21 510 r.p.m 420 r.p.m

22 540 r.p.m 440 r.p.m

23 570 r.p.m 470 r.p.m

24 600 r.p.m 490 r.p.m

25 615 r.p.m 510 r.p.m

26 645 r.p.m 540 r.p.m

27 735 r.p.m 600 r.p.m

28 735 r.p.m 600 r.p.m

29 735 r.p.m 600 r.p.m

30 735 r.p.m 600 r.p.m

(Cautions)

1. RPM may vary due to dierences between forward rotation and reverse rotation. The reference

value is a rough guideline.

2. The listed RPMs were measured without load. In case Speed Setting is 27 or more, the actual

RPMs may dier from the values in the table according to the loads

The torques were measured with our Torque meter (HP) and Fidaptor.

3. The values in above table may dier from the values observed in your environment. Please use

the above values as a rough guideline.

This manual suits for next models

1

Table of contents