Hirschmann EAGLE mGuard Series Manual

Description and operating instruction

Industrial ETHERNET Firewall/VPN System

EAGLE mGuard

The industrial firewall/VPN system

– EAGLE mGuard TX/TX

– EAGLE mGuard TX/MM SC

– EAGLE mGuard TX/SM SC

– EAGLE mGuard TX/LH SC

– EAGLE mGuard MM SC/TX

– EAGLE mGuard MM SC/MM SC

– EAGLE mGuard MM SC/SM SC

– EAGLE mGuard MM SC/LH SC

– EAGLE mGuard FW TX/TX

– EAGLE mGuard FW TX/MM SC

– EAGLE mGuard FW TX/SM SC

– EAGLE mGuard FW TX/LH SC

– EAGLE mGuard FW MM SC/TX

– EAGLE mGuard FW MM SC/MM SC

– EAGLE mGuard FW MM SC/SM SC

– EAGLE mGuard FW MM SC/LH SC

in the following called EAGLE mGuard,

authenticates, validates and ensures that

the communication within the production

networks remains confidential, also beyond

the boundaries of the company.

– Interfaces:

depending on the type up to two 10/100

MBit/s twisted pair (TP/TX) ports (RJ45

socket) and/or up to two 100 MBit/s FX

ports (multimode, singlemode or

longhaul) with DSC connectors and addi-

tionally one V.24 interface for external

management or modem connection and a

USB interface.

– Network modes:

• Multi Client Transparent Mode

(MCT Mode), default setting

• Single Client Transparent Mode

(SCT Mode)

• Router Mode

– Firewall (FW)

– ARP Limiter

– Redundancy support

– ACA 11 and ACA 21-USB support

– Management: HTTPS, SNMPv3, SSH

– Redundant power supply

– Temperature range: 0°C – 60°C, no fan

– Housing: can be mounted on DIN rail, IP20

The VPN versions (EAGLE mGuard TX…/

EAGLE mGuard MM…) in addition support

Virtual Private Network (VPN) functions.

In the „Manual EAGLE mGuard Manage-

ment – Industrial ETHERNET Firewall/VPN

System“ you will find a detailed description

on the EAGLE mGuard.

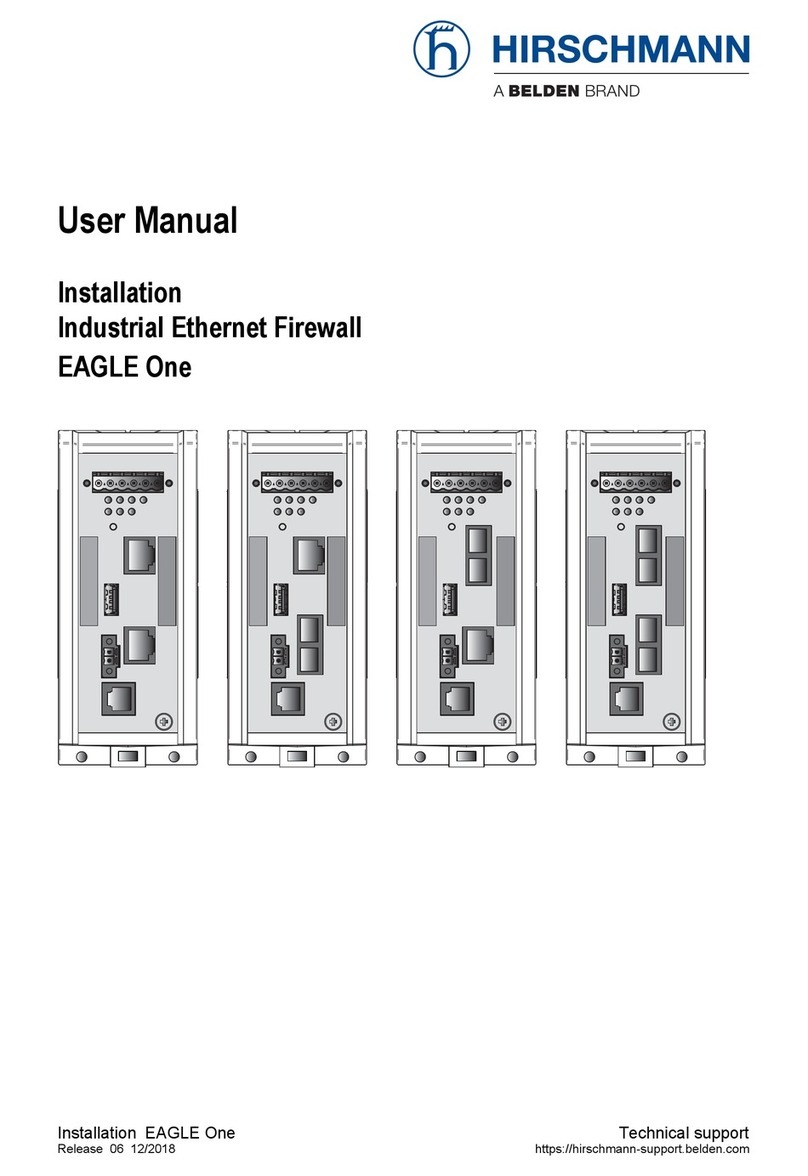

EAGLE mGuard TX/TX

EAGLE mGuard FW TX/TX

EAGLE mGuard MM SC/TX

EAGLE mGuard FW MM SC/TX

EAGLE mGuard TX/MM SC

EAGLE mGuard TX/SM SC

EAGLE mGuard TX/LH SC

EAGLE mGuard FW TX/MM SC

EAGLE mGuard FW TX/SM SC

EAGLE mGuard FW TX/LH SC

EAGLE mGuard MM SC/MM SC

EAGLE mGuard MM SC/SM SC

EAGLE mGuard MM SC/LH SC

EAGLE mGuard FW MM SC/MM SC

EAGLE mGuard FW MM SC/SM SC

EAGLE mGuard FW MM SC/LH SC

Hirschmann. Simply a good Connection.

1

STATUS

P21

LS/DA

21

+24V (P1)

FAULT

+24V (P2)

0V

0V

V.24

Aufkleber MAC-Adresse

IP-ADDRESS

k

FAULT

R

V.24

2

g

USB

x

2

1

STATUS

P21

LS/DA

21

+24V (P1)

FAULT

+24V (P2)

0V

0V

V.24

Aufkleber MAC-Adresse

IP-ADDRESS

g

k

FAULT

R

V.24

USB

x

RS2-4R

h

1

2

RM

P

01

RM

21 FAULT

+24V (P1)

FAULT

+24V (P2)

0V

0V

V.24

DA

LS

DA

LS

DA

LS

DA

LS

3

4

Aufkleber MAC-Adresse

IP-ADDRESS

RING

2

1

STATUS

P21

LS/DA

21

+24V (P1)

FAULT

+24V (P2)

0V

0V

V.24

Aufkleber MAC-Adresse

IP-ADDRESS

g

k

FAULT

R

V.24

USB

x

2

1

STATUS

P21

LS/DA

21

+24V (P1)

FAULT

+24V (P2)

0V

0V

V.24

Aufkleber MAC-Adresse

IP-ADDRESS

g

k

x

FAULT

R

V.24

USB

2

The performance features described here

are binding only if they have been expressly

guaranteed in the contract. We have

checked that the contents of the technical

publication agree with the hardware and

software described. However, it is not possi-

ble to rule out deviations completely, so we

are unable to guarantee complete agree-

ment. However, the details in the technical

publication are checked regularly. Any cor-

rections which prove necessary are contai-

ned in subsequent editions. We are grateful

for suggestions for improvement.

We reserve the right to make technical

modifications.

Permission is not given for the circulation

or reproduction of this document, its use or

the passing on of its contents unless gran-

ted expressly. Contravention renders the

perpetrator liable for compensation for

damages. All rights reserved, in particular

in the case of patent grant or registration of

a utility or design.

Copyright

© Hirschmann

Automation and Control GmbH 2006

All Rights Reserved

Note

We would point out that the content of

these operating instructions is not part of,

nor is it intended to amend an earlier or exi-

sting agreement, permit or legal relation-

ship. All obligations on Hirschmann arise

from the respective purchasing agreement

which also contains the full warranty condi-

tions which have sole applicability. These

contractual warranty conditions are neither

extended nor restricted by comments in

these operating instructions.

We would furthermore point out that for

reasons of simplicity, these operating

instructions cannot describe every

conceivable problem associated with the

use of this equipment. Should you require

further information or should particular

problems occur which are not treated in

sufficient detail in the operating instruc-

tions, you can request the necessary infor-

mation from your local Hirschmann sales

partner or directly from the Hirschmann

office (address: refer to chapter entitled

„Notes on CE identification“).

Safety Instructions

This manual contains instructions which

must be observed to ensure your own per-

sonal safety and to avoid

damage to devices and machinery. The

instructions are highlighted with a warning

triangle and are shown as

follows according to the degree of endan-

germent:

zDanger!

means that death, serious injury or

considerable damage to property

will result if the appropriate safety

measures are not taken.

zWarning!

means that death, serious injury or

considerable damage to property

can result if the appropriate safety

measures are not taken.

zCaution!

means that light injury or damage to

property can result if the appropria-

te safety measures are not taken.

Note: is an important piece of information

about the product, how to use the product,

or the relevant section of the documentati-

on to which particular attention is to be

drawn.

Certified usage

Please observe the following:

zWarning

The device may only be employed

for the purposes described in the

catalog and technical description,

and only in conjunction with external

devices and components recommen-

ded or approved by Hirschmann.

The product can only be operated

correctly and safely if it is transpor-

ted, stored, installed and assembled

properly and correctly. Furthermore,

it must be operated and serviced

carefully.

Safety Guideline Password

This device is a safety technological pro-

duct. In the interest of your own safety we

recommend strongly to change the

password immediately.

Safety Guidelines

Power Supply

䡺Switch the basic devices on only when

the case is closed.

zWarning!

The devices may only be connected

to the supply voltage shown on the

type plate.

The devices are designed for

operation with a safety extra-low

voltage.Thus, they may only be

connected to the supply voltage

connections and to the signal

contact with PELV circuits or

alternatively SELV circuits with the

voltage restrictions in accordance

with IEC/EN 60950.

䡺For the case where the module is opera-

ted with external power supply: Use only a

safety extra-low voltage in accordance with

IEC/EN 60950 to power the system.

䡺Relevant for North America:

The subject unit is to be suppplied by a

Class 2 power source complying with the

requirements of the National Electrical

Code, table 11(b). If power is redundant

supplied (two individual power sources) the

power sources together should comply with

the requirements of the National Electrical

Code, table 11 (b).

䡺Relevant for North America:

Use 60/75°C or 75°C copper(CU)wire only.

For use in Class 2 circuits.

Safety Guidelines

Shielding Ground

Note: The shielding ground of the connec-

table twisted pairs lines is connected to the

front panel as a conductor.

䡺Beware of possible short circuits when

connecting a cable section with conductive

shielding braiding.

Safety Guidelines Housing

zWarning!

Only technicians authorized by Hir-

schmann are permitted to open the

housing.

Note: The device is grounded via the sepa-

rated ground screw. It is located on the left

under the front panel.

䡺Make sure that the electrical installation

meets local or nationally applicable safety

regulations.

zWarning!

The ventilation slits must not be

covered so as to ensure free air cir-

culation.

The distance to the ventilation slots

of the housing has to be a minimum

of 10 cm.

Never insert pointed objects (thin

screwdrivers, wires, etc.) into the

inside of the subrack! Failure to

observe this point may result in inju-

ries caused by electric shocks.

Note: If installed in a living area or office

environment, the device must be operated

exclusively in switch cabinets with fire pro-

tection characteristics according to EN

60950.

Note: The housing has to be mounted in

upright position.

Safety Guidelines Environment

zWarning!

The device may only be operated in

the listed maximum surrounding air

temperature range at the listed

relative air humidity range (non-

condensing).

䡺The installation location is to be selec-

ted so as to ensure compliance with the cli-

matic limits listed in the Technical Data.

䡺To be used in an up to Pollution Degree

2 environment only (IEC 60664-1).

3

Based specifications and

standards:

The devices fulfil the following specificati-

ons and standards:

– EN 61000-6-2:2001 Generic standards –

Immunity for industrial environments

– EN 55022:1998 + A1 2000 + A2 2003 –

Information technology equipment –

Radio disturbance characteristics

– EN 60950:1:2001 – Safety of Information

Technology Equipment (ITE)

– EN 61131-2:2003 – Programmable

Controllers

– CFR-47 Part 15:2003 – Code of Federal

Regulations

– UL 508:1998 – Underwriters Labratories

Inc. Safety for Industrial Control

Equipment.

– UL 1604 Electrical Equipment for Use in

Class I and Class II, Div. 2 and Class III

Hazardous (Classified).

– Germanischer Lloyd VI-7-3 Part1 Ed.2003 –

Test Requirements for Electronic

Equipment

Certified devices are marked with a

certification identifier.

7Notes on CE

identification

The devices comply with the regula-

tions of the following European

directive:

89/336/EEC

Council Directive on the harmoniza-

tion of the legal regulations of mem-

ber states on electromagnetic com-

patibility (amended by Directives

91/263/EEC, 92/31/EEC and

93/68/EEC).

The EU declaration of conformity is

kept available for the responsible

authorities in accordance with the

above-mentioned EU directives at:

Hirschmann

Automation and Control GmbH

Stuttgarter Straße 45-51

D-72654 Neckartenzlingen

Telephone ++49-1805-14-1538

The product can be used in the resi-

dential sphere (residential sphere,

business and trade sphere and small

companies) and in the industrial

sphere.

– Interference proof:

EN 61000-6-2:2001

– Emitted immunity:

EN 55022:1998 + A1 2000

+ A2 2003, Class A

zWarning!

This is a Class A device. This equip-

ment may cause radio interference if

used in a residential area; in this

case it is the operator´s responsibili-

ty to take appropriate measures.

The precondition for compliance

with EMC limit values is strict adhe-

rence to the construction guidelines

specified in this description and

operating instructions.

Staff qualification

requirements

Note: Qualified personnel, as understood

in this manual and in the warning signs, are

persons who are familiar with the setup,

assembly, startup, and operation of this

product and are appropriately qualified for

their job. This includes, for example, those

persons who have been:

– trained or directed or authorized to

switch on and off, to ground and to label

power circuits and devices or systems in

accordance with current safety enginee-

ring standards

– trained or directed in the care and use of

appropriate safety equipment in accor-

dance with the current standards of safety

engineering

– trained in providing first aid.

General Safety Instructions

䡺This device is electrically operated.

Adhere strictly to the safety requirements

relating to voltages applied to the device as

described in the operating instructions!

zWarning!

Failure to observe the information

given in the warnings could result in

serious injury and/or major damage.

Only personnel that have received

appropriate training should operate

this device or work in its immediate

vicinity. The personnel must be fully

familiar with all of the warnings and

maintenance measures in these

operating instructions.

Correct transport, storage, and

assembly as well as careful operati-

on and maintenance are essential in

ensuring safe and reliable operation

of this device.

Use only undamaged parts!

䡺These products are only to be used in

the manner indicated in this version of the

”Description and Operating Instructions”.

䡺Particular attention is to be paid to all

warnings and items of information relating

to safety.

zWarning!

Any work that may have to be per-

formed on the electrical installation

should be performed by fully

qualified technicians only.

zWarning!

LED- or LASER components accor-

ding to IEC 60825-1 (2001):

CLASS 1 LASER PRODUCT.

LIGHT EMITTING DIODE - CLASS 1

LED PRODUCT.

FCC Note:

This equipment has been tested and found

to comply with the limits for a Class A digi-

tal device, persuant to part 15 of the FCC

Rules. These limits are designed to provide

reasonable protection against harmful inter-

ference when the equipment is operated in

a commercial environment. This equipment

generates, uses, and can radiate radio fre-

quency energy and, if not installed and

used in accordance with the instruction

manual, may cause harmful interference to

radio communications. Operation of this

equipment in a residential area is likely to

cause harmful interference in which case

the user will be required to correct the inter-

ference at his own expense.

,Recycling Note:

After its use, this product has to be

processed as electronic scrap and

disposed of according to the prevai-

ling waste disposal regulations of

your community / district / country /

state.

4

1. Functional description

1.1 FIREWALL- AND VPN FUNCTIONS

Firewall functions

The EAGLE mGuard FW supports the

following firewall functions:

– Stateful inspection firewall

– Transparent firewall:

Single client / multi client

– Configurable firewall rules:

– Received/transmitted data travel

– Modem access

– External management access

– IP masquerading, 1-to-1 NAT

– IP spoofing protection

VPN functions

The EAGLE mGuard supports the following

virtual private network (VPN) functions:

– Multipoint VPN:

Router and single client transparent mode

– VPN protocols: IPSec, L2TP

– Encoding algorithms:

– DES-56

– 3DES-168

– AES-128, AES-192, AES-256

– Authentification:

– Pre shared key (PSK)

– X.509v3 certificates

– Hashing algorithms: MD5, SHA-1

– NAT-T support

– Firewall rules for every VPN connection

1.2 OPERATION MODES

This device protects the network which is to

be safeguarded (trusted port k) from out-

side influences (untrusted port g). This can

be intentional attacks or unauthorized

accesses as well as disturbing network

occurrences as e.g. overload.

In the state of delivery the device operates

in the multi client transparent mode (MCT

mode). In this mode there are no network

settings necessary for operation (e.g. for

subnets).

This pre-configuration of the firewall ensu-

res that every IP travel from the trusted net-

work (k) is possible, but not the other way

round: travel from the untrusted (g) to the

trusted network is not possible. Therefore

already in the state of delivery configuraion

attacks from outside into the trusted net-

work are impossible.

Multi Client Transparent Mode

(MCT mode) – Single Client

Transparent Mode (SCT mode)

The MCT/SCT mode is a transparent bridge

mode. In this mode the device operates as a

2 port bridge where only IP and ARP frames

are transmitted, in compliance with the

firewall rules.

The access to the device is possible, too,

without configuring the IP address, using

the address 1.1.1.1.

In the MCT mode several clients are suppor-

ted in the network which is to be protected,

whereas in the SCT mode only one client is

possible.

Please note that you have to carry through

the corresponding IP configurations in the

MCT mode.

Note: In the MCT mode no virtual private

networks (VPN) are supported.

Router mode

In the router mode the device operates as a

2 port router. The corresponding IP configu-

rations are to be carried through. You will

find a detailed description in the EAGLE

mGuard manual.

Note: In the router mode another network

access to the trusted network is supported

via the V.24 interface of the EAGLE mGuard,

using PPP. In this case the communication

with the EAGLE mGuard itself or with the

devices in the trusted network is possible,

in compliance with the firewall rules for the

modem connection.

PPPoE/PPTP mode

In the PPPoE/PPTP mode the EAGLE

mGuard operates the same way as in the

router mode, with the difference that on the

trusted port (k) the PPPoE/PPTP protocol is

used. Therefore internet access e.g. via a

DSL modem becomes possible.

1.3 SPECIFIC FUNCTIONS OF THE

TP/TX INTERFACE

Link control

The EAGLE mGuard monitors the connec-

ted TP/TX line segments for short-circuit or

interrupt using regular link test pulses in

accordance with IEEE standard 802.3

10/100BASE-T/TX. The EAGLE mGuard does

not transmit any data to a TP/TX segment

from which it does not receive a link test

pulse.

Note: A non-occupied interface is assessed

as a line interrupt. The TP/TX line to termi-

nal equipment which is switched off is like-

wise assessed as a line interrupt as the de-

energised bus coupler cannot transmit link

test pulses.

Auto polarity exchange

If the receive line pair is incorrectly connec-

ted (RD+ and RD- switched) polarity is auto-

matically reversed.

Autonegotiation

Autonegotiation is a procedure in which the

switch automatically selects the operating

mode of its 10/100 RJ-45 ports. When a

connection is set up for the first time, the

switch detects the speed (10 or 100 Mbit/s)

and the transmission mode of the connec-

ted network (half duplex or full duplex).

Autocrossing

If the autonegotiation function is active, the

EAGLE mGuard detects the transmit and

receive pairs (MDI, MDI-X). The EAGLE

mGuard automatically configures its port

for the correct transmit and receive pins.

Consequently it does not matter whether

you connect devices using a cross-over or

straight cable.

Fig. 1: Overview interfaces, display elements and controls of the EAGLE mGuard

2

1

STATUS

P21

LS/DA

21

+24V (P1)

FAULT

+24V (P2)

0V

0V

V.24

Aufkleber MAC-Adresse

IP-ADDRESS

g

k

x

FAULT

R

V.24

RS2-4R

h

1

2

RM

P

01

RM

21 FAULT

+24V (P1)

FAULT

+24V (P2)

0V

0V

V.24

DA

LS

DA

LS

DA

LS

DA

LS

3

4

Aufkleber MAC-Adresse

IP-ADDRESS

RING

2

1

STATUS

P21

LS/DA

21

+24V (P1)

FAULT

+24V (P2)

0V

0V

V.24

Aufkleber MAC-Adresse

IP-ADDRESS

g

k

FAULT

R

V.24

2

1

STATUS

P21

LS/DA

21

+24V (P1)

FAULT

+24V (P2)

0V

0V

V.24

Aufkleber MAC-Adresse

IP-ADDRESS

g

k

FAULT

R

V.24

1

STATUS

P21

LS/DA

21

+24V (P1)

FAULT

+24V (P2)

0V

0V

V.24

Aufkleber MAC-Adresse

IP-ADDRESS

k

FAULT

R

V.24

2

g

USB USB

x

USB

x

USB

x

MAC address field

IP address field

TX

MM

SM

LH

TX

MM

SM

LH

6pinterminal block

(screw locking

mechanism)

LED display

elements

Recovery button

V.24 interface

external

management

and modem

Port 1 and 2

TX (RJ45 connector, autonegotiaton

+ autopolarity + autocrossing)

or FX (SC connector; multimode,

singlemode, longhaul)

kg

EAGLE mGuard TX/TX

EAGLE mGuard TX/MM SC

EAGLE mGuard TX/SM SC

EAGLE mGuard TX/LH SC

EAGLE mGuard MM SC/TX

EAGLE mGuard MM SC/MM SC

EAGLE mGuard MM SC/SM SC

EAGLE mGuard MM SC/LH SC

EAGLE mGuard FW TX/TX

EAGLE mGuard FW TX/MM SC

EAGLE mGuard FW TX/SM SC

EAGLE mGuard FW TX/LH SC

EAGLE mGuard FW MM SC/TX

EAGLE mGuard FW MM SC/MM SC

EAGLE mGuard FW MM SC/SM SC

EAGLE mGuard FW MM SC/LH SC

Port 1 Port 2

(trusted) (untrusted)

x x

x x

x x

x x

x x

x x

x x

x x

x x

x x

x x

x x

x x

x x

x x

x x

5

1.7 CONTROLS

R – Recovery button

The Recovery button is used to set the devi-

ce into the following states:

– Restart

To produce a restart, press the recovery

button longer than 1,5 and shorter than 7

seconds, until the STATUS LED goes out

and the FAULT LED lits red.

– Flashing the firmware

To produce the flashing of the firmware,

press the recovery button longer than 7

seconds, until all port LEDs (LS/DA) lit

green.

– Recovery procedure

To produce the recovery procedure, press

the recovery button 6 times shortly. The

EAGLE mGuard answers flashing 6 times

yellow with the STATUS LED. Press the

button again 6 times.

In the „Manual EAGLE mGuard Manage-

ment – Industrial ETHERNET Firewall/VPN

System“ you will find detailed information

how to carry through the recovery actions.

1.8 INTERFACES

10/100 MBit/s connection

10/100 Mbit Ports (8-pin R45 sockets) allow

terminal equipment or independent net-

work segments complying with the stan-

dards IEEE 802.3 100BASE-TX / 10BASE-T to

be connected. These ports support autone-

gotiation, autocrossing and the autopolarity

function.

Factory settings: autonegotiation active.

The socket casings are electrically connec-

ted to the front panel of the EAGLE

mGuard. The pin configuration complies

with MDI-X.

– Pin configuration of the RJ45 socket:

– TD+: pin 3, TD-: pin 6

– RD+: pin 1, RD-: pin 2

– remaining pins: not used.

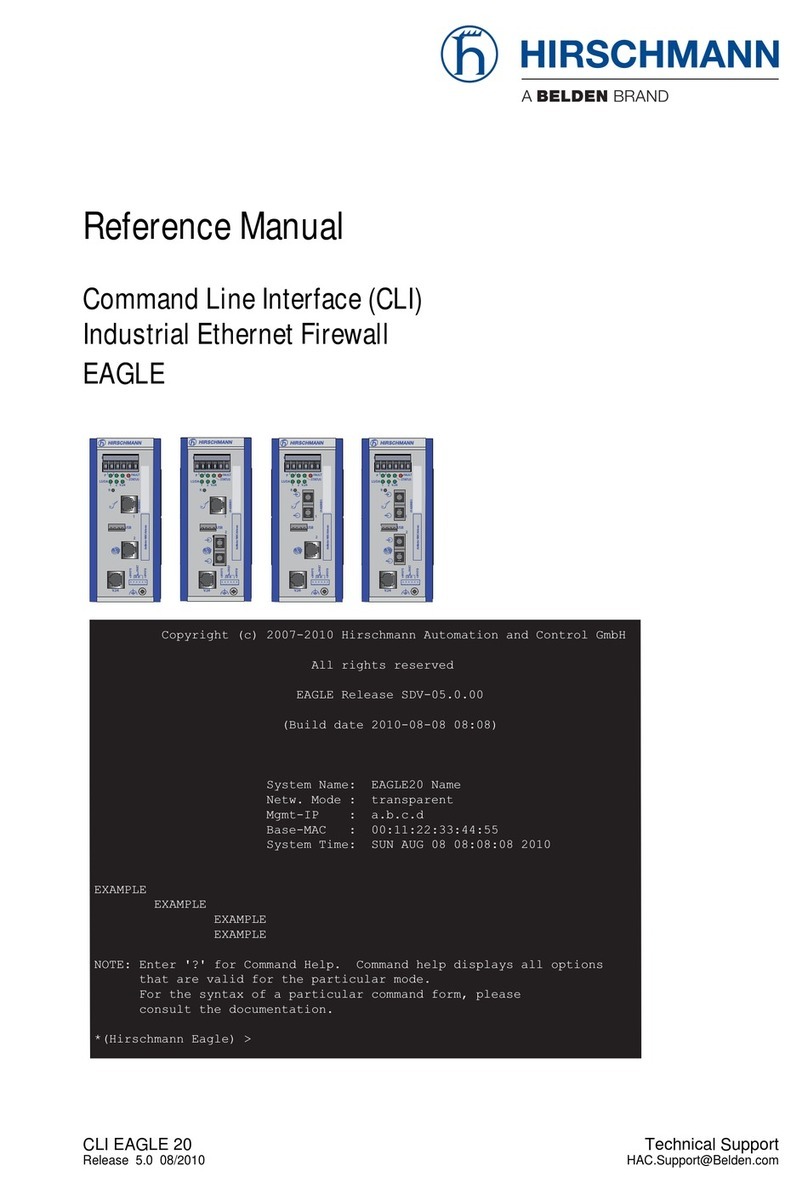

Fig. 2: Pin configuration of an TP/TX

interface

100 Mbit/s connection

100 MBit/s F/O ports (DSC sockets) allow

terminal equipment or independent

network segments complying with the

standard IEEE 802.3 100BASE-FX to be

connected.

State on delivery: full duplex.

Note: Make sure, that you conncet LH ports

only to LH ports, SM ports only to SM ports

and MM ports only to MM ports.

V.24 interface

(external management, modem)

A serial interface for local connection of

– an external management station (VT100

terminal or a PC with corresponding ter-

minal emulation) is available via the RJ11

socket (V.24 interface). A link can thus be

established with the User Interface UI.

– an AutoConfiguration Adapter ACA 11 is

available via the RJ11 socket (V.24 interfa-

ce).

– an analog modem is available.

n.c.

Pi

n

8

n.c. Pin 7

TD- Pin 6

n.c. Pin 5

n.c. Pin 4

Pin 3TD+

Pin 2RD-

Pin 1RD+

1.4 SPECIFIC FUNCTIONS OF THE

F/O INTERFACE

Link control

According to IEEE 802.3 standard 100BASE-

FX an EAGLE mGuard monitors the atta-

ched F/O lines for open circuit conditions.

1.5 FURTHER FUNCTIONS

AND FEATURES

Diagnosis

In case of a reset the EAGLE mGuard runs a

hardware self test. During operation an inte-

grated watch dog (monitoring unit) moni-

tors the function of the software.

Reset

The EAGLE mGuard will be reset by the

following actions:

– management

– input voltages fall below a threshold

– watchdog

– switching between transparent mode and

router mode

After a reset the following actions are car-

ried through:

– self test

– initialization

1.6 DISPLAY ELEMENTS

Equipment status

These LEDs provide information about sta-

tuses which affect the function of the entire

EAGLE mGuard.

P1 – Power 1 (green LED)

– lit: – supply voltage 1 present

– not lit: –

supply voltage 1 is less than 9.6 V

P2 – Power 2 (green LED)

– lit: – supply voltage 2 present

– not lit: –

supply voltage 2 is less than 9.6 V

FAULT – Failure (red LED)

– lit: – The indicator contact is

open, i.e. it indicates an

error.

– not lit: – The indicator contact is

closed, i.e. it does not

indicate an error.

STATUS – Device status

(yellow/green LED)

– flashes green: – Initialization of the device

– lit green: – Device is operational

– flashes yellow slowly:

– Device is in router re-

dundancy backup mode

Port Status

These LEDs display port-related informati-

on.

LS/DA 1 to 2, V.24 – Data, Link status

(three green LEDs)

– not lit: – no valid link

– lit green: – valid link

– blinking green (3 blinks per period)

– port is disabled

– flashes yellow:– receiving data

– running light: – initialization phase after a

reset

Display of ACA function

The LEDs “STATUS” and “V.24” together

display information on the functionality of

the AutoConfiguration Adapter (ACA).

STATUS and V.24 – ACA activity

(two green LEDs)

– both LEDs flash simultaneously (slow):

– ACA writing process

– both LEDs flash simultaneously (fast):

– ACA reading process

– both LEDs flash alternated fast (about 5

sec.): – ACA error

Note: If necessary, the modem access is to

be activated via PPP. For the modem access

you need an adapter connector (not inclu-

ded in the state of delivery).

VT100 terminal settings:

– Speed: 9,600 Baud

– Data: 8 bit

– Stopbit: 1 bit

– Handshake: off

– Parity: none

The V.24 interface baud rate can be configu-

red to 9,600 up to 56,800 baud. The factory

default is 9,600 baud.

The socket casing is galvanically connected

to the front panel of the device.

Note: In chapter 6 „Technical data“ you

find the order number for the terminal

access cable which is to be ordered

separately.

Fig. 3: Pin configuration of the V.24

interface for the management access

USB interface

The USB socket offers an interface for the

local connection of an AutoConfiguration

Adapters ACA 21-USB. It is a device for

saving/loading the configuration and for

loading the software.

– Pin configuration of the USB interface:

– pin 1: VCC

– pin 2: - data

– pin 3: + data

– pin 4: ground

– AutoConfiguration Adapter ACA:

The ACA is a device for saving the confi-

guration data of a MICE, EAGLE mGuard,

RS2.../... or MACH switch. If one device

should fail, the ACA facilitates a conceiva-

ble simple assumption of the configurati-

on data by an alternative device of the

same type.

In case of a reset the EAGLE mGuard

compares the contents of the ACA with its

own configuration data. If the configura-

tion data do not correspond, the EAGLE

mGuard takes over the configuration data

of the ACA.

The function of the ACA is displayed by

the LEDs “STATUS” and “V.24” (refer to

chapter 1.6 display elements).

The configuration data is saved on the

ACA via the web based management.

6pin terminal block

The supply voltage and the indicator

contact are connected via a 6pin terminal

block with screw locking mechanism.

Pin 1

Pin 1

Pin 8

Pin 5

Pin 6

RJ11 DB9-Buchse

2

3

5

7

8

1

2

3

4

5

6

CTS

n.c.

TX

GND

RX

RTS

Pin 7

6

zWarning!

The EAGLE mGuard equipments are

designed for operation with a safety

extra-low voltage.Thus, they may

only be connected to the supply vol-

tage connections and to the signal

contact with PELV circuits or

alternatively SELV circuits with the

voltage restrictions in accordance

with IEC/EN 60950.

– Voltage supply: Redundant voltage sup-

plies are supported. Both inputs are

decoupled. There is no load distribution.

With redundant supply, the power pack

supplies the EAGLE mGuard only with the

higher output voltage. The supply voltage

is electrically isolated from the housing.

You can choose between DC or AC vol-

tage when connecting the supply voltage.

You use the +24V und 0V pins to connect

the AC voltage (see Fig. 4 and 5).

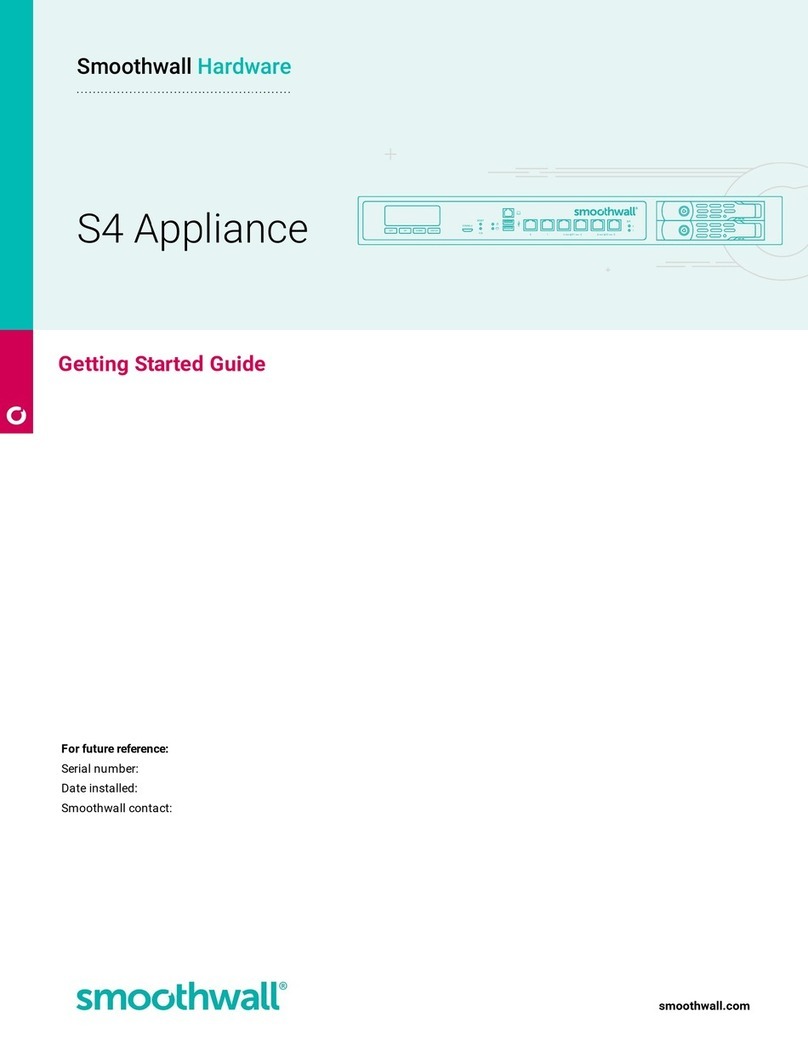

Fig. 4: Pin configuration of 6pin terminal

block, connecting DC voltage

Fig. 5: Pin configuration of 6pin terminal

block, connecting AC voltage

– Indicator contact:

The indicator contact is used to supervise

the functions of the EAGLE mGuard and

thus facilitates remote diagnosis.

Contact interrupt indicates the following

by means of a potential-free indicator

contact (relay contact, closed circuit):

– the failure of at least one of the two

supply voltages.

– a permanent fault in the EAGLE mGuard

(internal 3,3 V DC voltage, supply vol-

tage 1 or 2 < 9.6 V, ...).

– the faulty link status of at least one port.

The indication of the link state on the

EAGLE mGuard can be masked on a

port-by-port basis using the manage-

ment software.

State of delivery: there is no link test.

– self test error

Note: In the case of the voltage supply

being routed without redundancy, the

EAGLE mGuard indicates the failure of a

supply voltage. You can prevent this

message by feeding in the supply voltage

through both inputs.

Ground connection

The EAGLE mGuard is grounded via a sepa-

rate screw connection.

FAULT

G

18...30 VAC

G

18...30 VAC

+

24V(P1) 0V 0V +24V(P2)

FAULT

9,6...60 VDC9,6...60 VDC

+24V(P1) 0V 0V +24V(P2)

+-

-+

2. Configuration

To get access to the EAGLE mGuard, you

act as follows (device in the state of

delivery):

䡺To configure the EAGLE mGuard, start a

web browser with https capability on

the PC connected to the trusted port (k)

(e. g. MS Internet Explorer V. 5.0 or

higher).

䡺Connect the untrusted port (g) to your

network.

䡺In the address field of the web browser

you enter the following address:

https://1.1.1.1/

Result: The configuration connection to the

EAGLE mGuard is being built up. A security

note is displayed.

䡺Quit the security note with “Yes”.

䡺For login you enter:

– Login: admin

– Password: private

(Observe the use of small and capital

letters!)

Result: The administrator website of the

EAGLE mGuard is displayed.

䡺Configure the device.

Alternatively you can carry through the IP

configuration for the MCT mode via the

HiDiscovery protocol. You will find the

HiDiscovery software on the CD ROM which

is included in the scope of delivery.

Note: If the configuration connection to the

EAGLE mGuard is not built up, you will find

detailed information in the „Manual EAGLE

mGuard Management – Industrial ETHER-

NET Firewall/VPN System“.

3. Assembly, startup procedure

and dismantling

Before installation and startup please pay

attention to the security notes on the pages

2 and 3. With the following steps you set

the EAGLE mGuard into operation:

3.1 UNPACKING, CHECKING

䡺Check whether the package was deliver-

ed complete (see scope of delivery).

䡺Check the individual parts for transport

damage.

zWarning!

Use only undamaged parts!

3.2 ASSEMBLY

The equipment is delivered in a ready-to-

operate condition. The following procedure

is appropriate for assembly:

䡺Pull the terminal block off the EAGLE

mGuard and wire up the supply voltage and

indicator lines.

䡺Fit the EAGLE mGuard on a 35 mm

standard bar to DIN EN 50 022.

䡺Attach the upper snap-on slide bar of

the EAGLE mGuard to the standard bar and

press it down until it locks in position.

䡺Connect the device to the local network

or the local PC which is to be protected

(k).

䡺Connect the socket for connection to the

external network (g), e. g. the Internet.

(Via this network the connctions to the

remote device or the remote network

are realized.)

Notes:

– The front panel of the EAGLE mGuard is

grounded via a separate ground connec-

tion.

– Do not open the housing.

– The shielding ground of the twisted pair

lines which can be connected is electrical-

ly connected to the front panel.

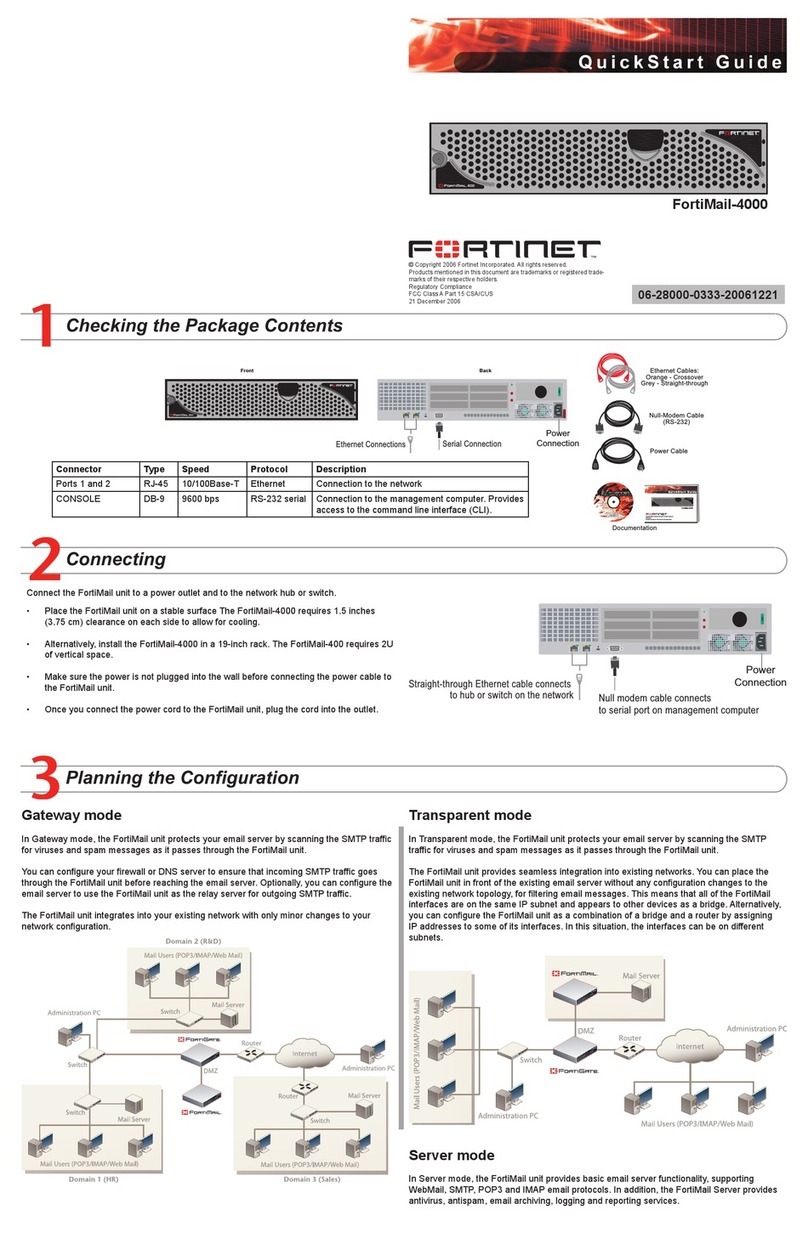

Fig. 8: Assembling the EAGLE mGuard

3.3 STARTUP PROCEDURE

You start up the EAGLE mGuard by connec-

ting the supply voltage via the 6-pin termi-

nal block. Lock the terminal block with the

locking screw at the side.

3.4 DISMANTLING

䡺To take the EAGLE mGuard off the

ISO/DIN rail, insert a screwdriver horizontal-

ly under the housing into the locking slide,

pull it (without tipping the screwdriver)

downwards and lift the EAGLE mGuard

upwards.

EAGLE

2

1

STATUS

P21

LS/DA

21

+24V(P1)

FAULT

+24V(P2)

0V

0V

V.24

AufkleberMAC-Adresse

IP-ADDRESS

g

k

x

FAULT

R

V.24

Fig. 6: Configuration before installing the

EAGLE mGuard (example)

Fig. 7: Configuration with firewall after

installing the EAGLE mGuard (example)

7

5. Technical data

General data

Operating voltage 9.6 to 60 V DC safety extra-low voltage (SELV/PELV), redundant inputs decoupled.

Relevant for North America: Nec Class 2 power source 5 A maximum.

or 18 to 30 V AC

Buffer time min. 10 ms at 24 VDC

Potential difference between input Potential difference to input voltage, +24 VDC: 32 VDC

voltage and housing Potential difference to input voltage, ground: -32 VDC

Power consumption at 24 V DC at 24 V AC

EAGLE mGuard (with 2 TX ports) 6.9 W max.; 23.5 Btu (IT)/h 7.2 W max.; 24.6 Btu (IT)/h

EAGLE mGuard (with 1 TX and 1 FX port) 8.1 W max.; 27.6 Btu (IT)/h 8.1 W max.; 27.6 Btu (IT)/h

EAGLE mGuard (with 2 FX ports) 9.5 W max.; 32.4 Btu (IT)/h 9.6 W max.; 32.8 Btu (IT)/h

Overload current protection at input non-changeable fuse

Dimensions W x H x D 46 mm x 131 mm x 111 mm 1.8 in x 5.2 in x 4.4 in

Weight 340 g 0.8 lb

Ambient temperature Surrounding air: 0 ºC to + 60 ºC 32 °F to 140 °F

Storage temperature Surrounding air: - 40 ºC to + 70 ºC -40 °F to 158 °F

Humidity 10% to 95% (non condensing)

Atmospheric pressure Suitable for operation up to 2000 m (6561 ft), 795 hPa, higher altitudes on demand

Pollution Degree 2

Laser protection Class 1 conforming to EN 60825-1

Protection type IP 20

Interference proof

Discharge of static electricity

Contact discharge EN 61000-4-2 Test level 3

Air discharge EN 61000-4-2 Test level 3

Electromagnetic fields EN 61000-4-3 Test level 3

Fast transients EN 61000-4-4 Test level 3

Surge voltage symmetrical EN 61000-4-5 Test level 2

Surge voltage asymmetrical EN 61000-4-5 Test level 3

Cable-based RF faults EN 61000-4-6 Test level 3

EMC emitted immunity

EN 55022 Class A

FCC 47 CFR Part 15 Class A

Germanischer Lloyd Rules for Classification and Construction VI - 7 - 3 Part 1, Ed. 2003

Stability

Vibration IEC 60068-2-6 Test FC, testing level in line with IEC 61131-2:2003

Germanischer Lloyd Guidelines for the Performance of Type Tests Part 1

Shock IEC 60068-2-27 Test Ea, testing level in line with IEC 61131-2:2003

Certifications

cUL 508 / CSA 22.2 No.142 complies with

cUL 1604 / CSA 22.2 No.213 pending

Germanischer Lloyd complies with

Network size

TX port 10BASE-T/100BASE-TX

Length of a twisted pair segment 100 m approx.

F/O port 100BASE-FX

According to IEEE 802.3u 100BASE-FX

System attenuation

50/125 µm fiber (multimode) (MM) 0 to 8 dB

62.5/125 µm fiber (multimode) (MM) 0 to 11 dB

9/125 µm fiber (singlemode) 0 to 16 dB

Wave length (SM) 1300 nm

9/125 µm fiber (singlemode), Longhaul 7 to 29 dB

Wave length (LH) 1550 nm

F/O line length (example)

50/125 µm fiber (MM) 5 km approx. (data of fiber: 1.0 dB/km, 800 MHz*km)

62.5/125 µm fiber (MM) 4 km approx. (data of fiber: 1.0 dB/km, 500 MHz*km)

9/125 µm fiber (SM) 30 km approx. (data of fiber: 1300 nm, 0.4 dB/km)

9/125 µm fiber Longhoul (LH) 24 to 86.6 km (data of fiber: 1550 nm, 0.3 dB/km)

4. Further support

In the event of technical queries, please talk

to the Hirschmann contract partner respon-

sible for looking after your account or

directly to the Hirschmann office. You can

find the addresses of our contract partners

– on the Internet

(http://www.hirschmann.de).

Our support line is also at your disposal:

Tel. +49(1805) 14-1538

Fax +49(7127) 14-1551

Answers to Frequently Asked Questions can

be found on the Hirschmann product site

www.hirschmann-ac.de

The FAQs are located in the Automation

and Network Solutions section.

www.hicomcenter.com gives you an up-to-

date overview of training courses about

technology and products.

Hirschmann Automation and Control GmbH

Stuttgarter Straße 45-51

D-72654 Neckartenzlingen

Germany

Tel.: ++49 / 1805 / 14-1538

Fax: ++49 / 7127 / 14-1551

E-Mail: [email protected]

Internet: http://www.hirschmann-ac.com

Printed in Germany

Subject to alterations

Interfaces

EAGLE mGuard V.24 port external management, modem, ACA

Indicator contact 1 A maximum, 24 V

USB interface

in addition 2 type depending ports each:

kPort 1 (trusted) gPort 2 (untrusted)

– EAGLE mGuard TX/TX TX port with RJ-45 socket (10/100 MBit/s) TX port with RJ-45 socket (10/100 MBit/s)

– EAGLE mGuard TX/MM SC TX port with RJ-45 socket (10/100 MBit/s) FX port (multimode / MM)

– EAGLE mGuard TX/SM SC TX port with RJ-45 socket (10/100 MBit/s) FX port (singlemode 1300 nm / SM)

– EAGLE mGuard TX/LH SC TX port with RJ-45 socket (10/100 MBit/s) FX port (singlemode 1550 nm / LH)

– EAGLE mGuard MM SC/TX FX port (multimode / MM) TX port with RJ-45 socket (10/100 MBit/s)

– EAGLE mGuard MM SC/MM SC FX port (multimode / MM) FX port (multimode / MM)

– EAGLE mGuard MM SC/SM SC FX port (multimode / MM) FX port (singlemode 1300 nm / SM)

– EAGLE mGuard MM SC/LH SC FX port (multimode / MM) FX port (singlemode 1550 nm / LH)

– EAGLE mGuard FW TX/TX TX port with RJ-45 socket (10/100 MBit/s) TX port with RJ-45 socket (10/100 MBit/s)

– EAGLE mGuard FW TX/MM SC TX port with RJ-45 socket (10/100 MBit/s) FX port (multimode / MM)

– EAGLE mGuard FW TX/SM SC TX port with RJ-45 socket (10/100 MBit/s) FX port (singlemode 1300 nm / SM)

– EAGLE mGuard FW TX/LH SC TX port with RJ-45 socket (10/100 MBit/s) FX port (singlemode 1550 nm / LH)

– EAGLE mGuard FW MM SC/TX FX port (multimode / MM) TX port with RJ-45 socket (10/100 MBit/s)

– EAGLE mGuard FW MM SC/MM SC FX port (multimode / MM) FX port (multimode / MM)

– EAGLE mGuard FW MM SC/SM SC FX port (multimode / MM) FX port (singlemode 1300 nm / SM)

– EAGLE mGuard FW MM SC/LH SC FX port (multimode / MM) FX port (singlemode 1550 nm / LH)

Displays

Equipment status 1 x green LED P1 – power 1, supply voltage 1 present

1 x green LED P2 – power 2, supply voltage 2 present

1 x red LED FAULT – indicator contact is open and indicates error

1 x red/green LED STATUS – booting, heartbeat, system error

Port status 3 x green LED LS/DA 1 to 2, V.24 – data, link status

Controls

Recovery button R– Restart, Recovery procedure

– Flashing the firmware

Scope of delivery

EAGLE mGuard incl. terminal block for supply voltage, description and operating instructions

manual EAGLE mGuard on CD-ROM

Order number

EAGLE mGuard TX/TX 943 011-301

EAGLE mGuard TX/MM SC 943 011-302

EAGLE mGuard TX/SM SC 943 011-303

EAGLE mGuard TX/LH SC 943 011-304

EAGLE mGuard MM SC/TX 943 011-305

EAGLE mGuard MM SC/MM SC 943 011-306

EAGLE mGuard MM SC/SM SC 943 011-307

EAGLE mGuard MM SC/LH SC 943 011-308

EAGLE mGuard FW TX/TX 943 011-311

EAGLE mGuard FW TX/MM SC 943 011-312

EAGLE mGuard FW TX/SM SC 943 011-313

EAGLE mGuard FW TX/LH SC 943 011-314

EAGLE mGuard FW MM SC/TX 943 011-315

EAGLE mGuard FW MM SC/MM SC 943 011-316

EAGLE mGuard FW MM SC/SM SC 943 011-317

EAGLE mGuard FW MM SC/LH SC 943 011-318

Accessories

ETHERNET manual 943 320-011

Manual

Basics Industrial ETHERNET and TCP/IP 280 720-834

Terminal access cable 943 301-001

Rail Power Supply RPS 30 943 662-003

Rail Power Supply RPS 60 943 662-001

Rail Power Supply RPS 120 943 662-011

AutoConfiguration Adapter ACA 11 943 751-001

AutoConfiguration Adapter ACA 21-USB 943 271-001

Network Management Software HiVision 943 471-100

This manual suits for next models

16

Table of contents

Other Hirschmann Firewall manuals

Popular Firewall manuals by other brands

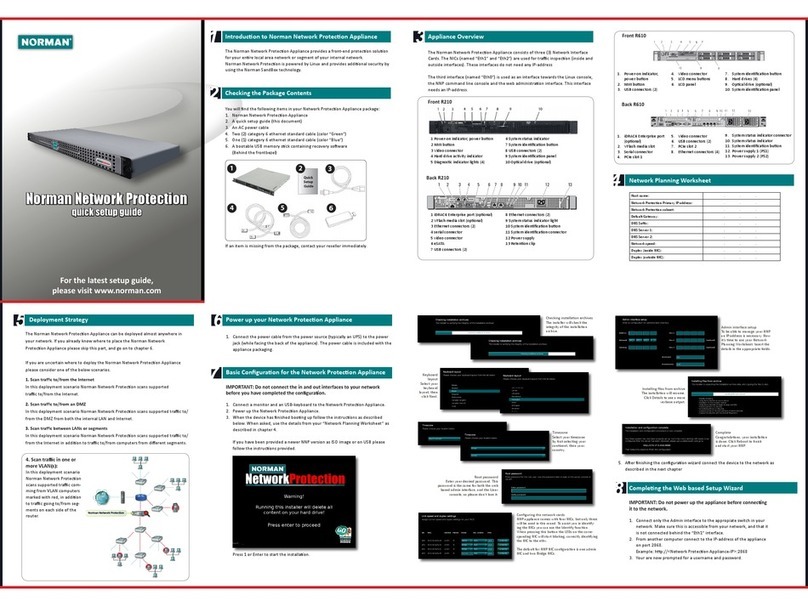

Norman

Norman NetworkProtection Administrator's guide

Lanner electronics

Lanner electronics FW-7890 Series user manual

EBLOCKER

EBLOCKER eBlocker Quick start guides

NetComm

NetComm VPN100 Technical specifications

ZyXEL Communications

ZyXEL Communications ZyWALL 1050 Support notes

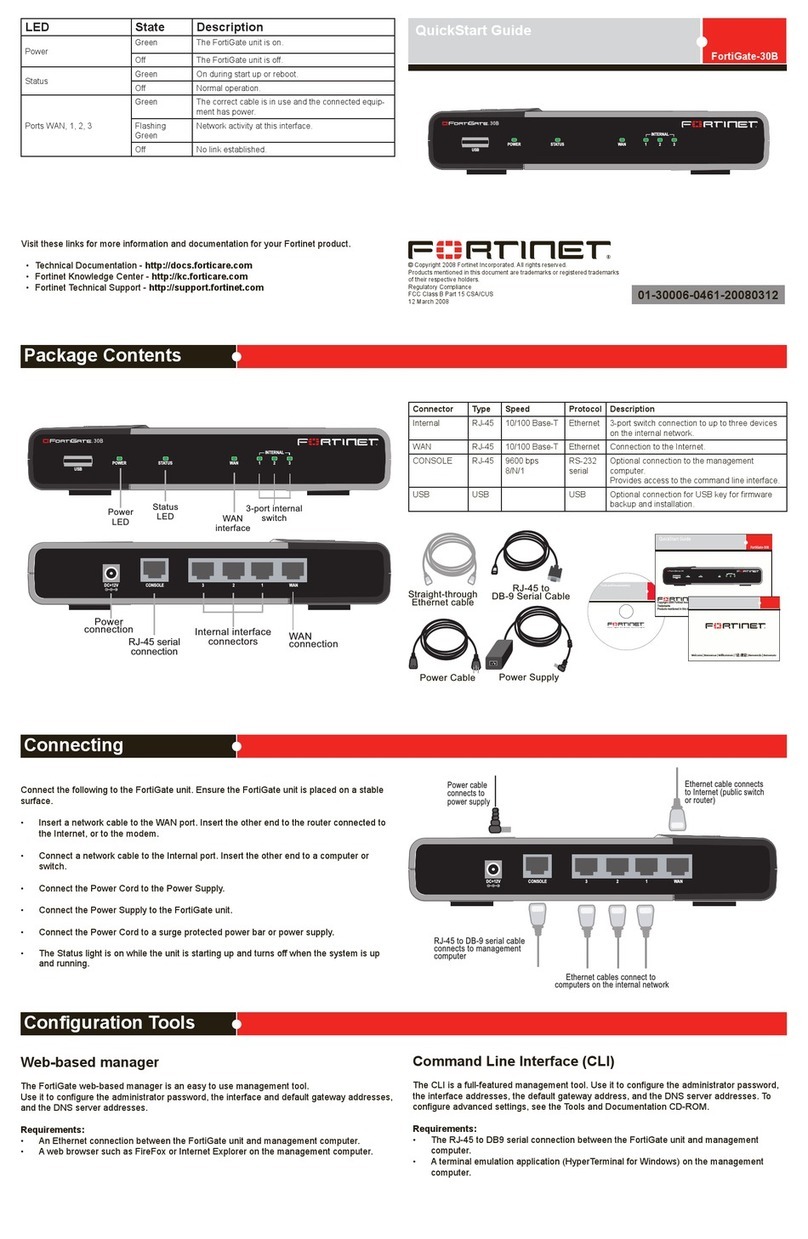

Fortinet

Fortinet FortiGate FortiGate-5005-DIST Getting started

Fortinet

Fortinet FortiGate FortiGate-30B quick start guide

PaloAlto Networks

PaloAlto Networks PA-200 Hardware reference guide

H3C

H3C SecPath F50X0-D Series Command reference

PaloAlto Networks

PaloAlto Networks PA-7000 Series Hardware reference

NetComm

NetComm VPN100 Travellers guide

Norman

Norman Network Protection Quick setup guide