HANMEY Power Harrow User manual

Instruction

m

a

nu

a

l

P

owe

r

H

a

rr

ow

1

1.

P

r

ef

a

ce

:

Dear

c

u

s

t

o

m

e

r

!

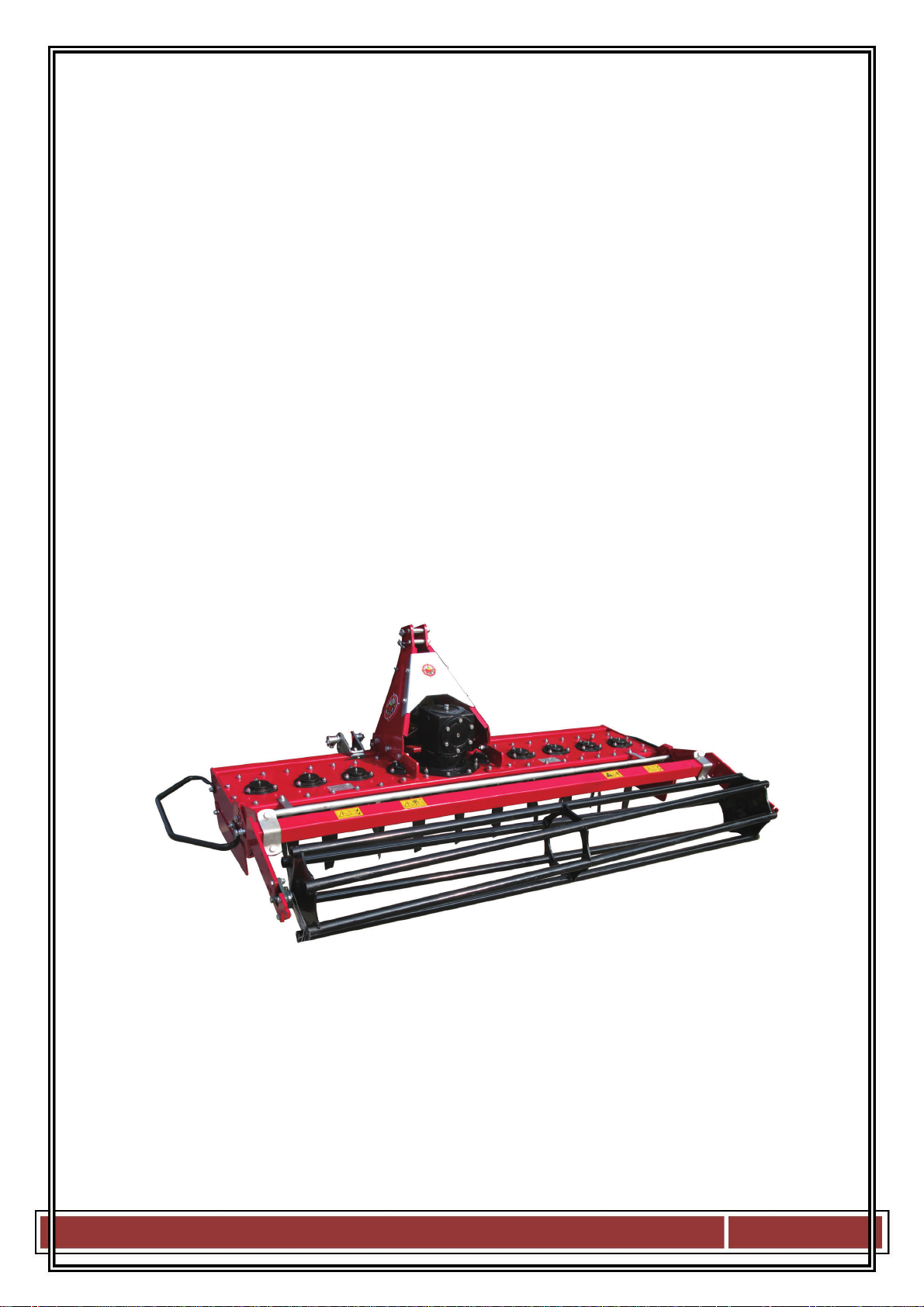

With its five tine units, the rotary power harrow type power harrow is an ideal implement for tilling

the soil and preparing seed-beds on farms and in vineyards or orchards, as well as for row crops and

specialty crops.

Please read these Operating Instructions through carefully before using the rotary power harrow and

strictly follow all the instructions so that the rotary harrow can be used safely and correctly, for its

intended purpose.

The power harrow may only be used by

p

e

r

so

n

s

who have the

required p

r

ofessio

na

l

know-how

and

who have also

read

and

understood

these

Operating

I

n

s

t

r

u

c

t

io

n

s.

Please ensure that you know how to handle and operate the power harrow before using it!

General i

n

fo

r

m

a

t

io

n

:

•

The rotar

yp

ower harrow ma

y

onl

y

be used for the s

p

ecified

p

ur

p

ose: mechanical soil

tillage and seed-bed preparation.

•

The power harrow may only be started and stopped from the tractor driver’s seat. No-

one may remain within a distance of less than 10 meters around the rotary harrow during

its operation.

•

The power harrow may only be operated in full daylight.

•

The power harrow may only be operated when all guards and safety mechanisms are

installed and fully functional.

•

Malfunctions impairing safety must immediately be remedied by specialist personnel.

•

The accident prevention regulations issued by the employers’ liability insurance association

must be observed.

•

The traffic regulations must be observed when driving on public roads.

•

ThePTOshaftmustbedisengagedfromthetractor during all maintenance and repair

work on the power harrow in order to prevent inadvertent start-up.

•

Repairs should only be undertaken by specialist repair shops or the customer service

center. The rotary power harrow should never be modified without authorization.

•

The power harrow may only be operated with a

PTO

shaft with

f

r

ic

t

io

n

cl

u

t

c

h

.

2

2. Desc

r

i

p

t

io

n

of the

m

a

c

h

i

n

e

:

The rotary power harrow must be used for mechanical soil tillage and seed-bed preparation on

farms and in vineyards and orchards, as well as for row crops and specialty crops.

Moisture remains in the soil and the water balance of the soil is maintained since the soil is not

turned up as it is tilled. The vertically rotating cutters also prevent compaction of the soil, thus

resulting in optimum preparation of the seed-beds.

The power harrow is mounted on the tractor by means of a three-point suspension. It has five tine

units; the tine pick-up is rigidly mounted. The gear mechanism is driven via a PTO shaft and drives

the cutters in the housing via gear wheels.

The working depth is set by means of a hand spindle in combination with the support roller. The

friction clutch mounted on the PTO shaft protects both the harrow and the tractor from damage if

overloaded. An additional machine, such as a seeder, can be connected to the rotary harrow via a

further three-point suspension on the basic unit and a p.t.o. shaft on the main gear unit. In this way,

the seed-bed can be prepared and the seed sown in a single pass.

The working depth should be adjusted in line with the prevailing ground conditions in order to

obtain the best possible results. Large objects should be removed from the ground beforehand so

that the soil can be tilled correctly and to prevent premature wear on the tines.

The housing accommodates the various components making up the rotary power harrow. The

support roller, three-point frame, angular gear and tine units are bolted onto the housing.

The

three-point frame

is made of robust sheet metal and bolted onto the housing. The bolts of the

lowe

r

links

support

can be undone and the three-point frame displaced sideways on the rectangular

profile of the housing for off-center operation.

The

angular gear

which is mounted on the housing diverts the tractor’s rotary motion through 90°

and drives the tine units via gear wheels.

Each tine unit comprises a tine flange, guard plate, two tines, bearing housing, bearing and

connecting elements. The tines are mounted underneath the guard plate and serve to loosen the soil.

They are secured by means of special bushings, washers, bolts and lock nuts.

3

3.

Start-up

and

operation

of

the

m

a

c

h

i

n

e

:

*Befo

r

e using the machine

for

the

first

t

i

m

e

- Read through the

operating instructions for

the rotary power harrow

and additional attachments

and ensure that you are fully

familiar with the mode of

operation of all units.

- Check that the length of

the PTO shaft fits your

tractor. The PTO shaft

should include an

appropriate protective

mechanism!

*

Attachment

to the

t

r

a

c

t

o

r

- Examine tools (tines)

and tine carriers for

signs of wear and

ensure they are

secured correctly.

- Check that the support roller

and three-point frame are

correctly secured to the housing.

- Now connect the

power harrow to the

tractor by means of

the three-point

suspension. Secure the

bolts of the upper and

lower links with

spring pins. Park the

tractor on level

ground and adjust the

upper link so that the

rotary power harrow is

horizontal.

- Now adjust the length of the

PTO shaft to match your

tractor. For this purpose,

hold

the two halves of the

PTO shaft side-by-

side in the shortest

lift-out position and

mark it accordingly.

Shorten the inner and

outer protective tube

by equal amounts.

Then shorten the

inner and outer

sliding profile by the

same amount as the

protective tube.

Finally round

off the

cut edges and

carefully remove all

chips. Grease the

sliding profiles.

- Before engaging the

PTO shaft, carefully

clean and grease the

p.t.o. shaft of the

tractor and power

harrow. Then slide

the PTO shaft over

the p.t.o. shaft until

the locking

pin

engages completely.

The friction clutch

of the PTO shaft

must be mounted at

the machine end.

-The

wo

r

k

i

n

g

depth

is now adjusted with

the aid of the hand

spindle in

accordance with

ground condition on

a firm and level

substrate or by

lifting the unit

completely.

The power harrow with

fitted tools and attachments

is now ready for use.

4

*

Working

with the

power

ha

rr

ow

- The tractor p.t.o. shaft must not be switched on until it is certain that the shaft will rotate

at not more than 540 rpm at maximum engine speed.

- The p.t.o. drive must not be engaged when the tractor drives running at full load.

-The

p

owe

r

harrow

may only be

started

and stopped

from

the

t

r

a

c

t

o

r

driver’s

se

a

t

.

- The power harrow may only be switched on when there is no-one within its range of

operation and hazard area (radius of 10 m from the rotary harrow) due to the risk of

objects,

such as

stones, being hurled away from the machine. The duly prepared machine

must be lowered to the working position before it is switched on. The rotary power

harrow can then be switched on.

- The machine must be lowered slowly in order to avoid damage to the tools and

attachments.

- During the work, the machine must be lowered to the working depth and left with the set

control hydraulics. The horizontal position of the rotary power harrow can be

corrected by

means of the upper link.

- The areas to be tilled should be inspected for visible large obstacles before staring so that

they can be removed from the harrow’s range and thus prevent damage to the tines and

drive elements.

- If a reversing manoeuvre is required at the end of the row being tilled, the tractor p.t.o.

must be switched off and the rotary harrow allowed to come to a complete standstill

before it is lifted out of the ground for the manoeuvre (risk of clods of earth being hurled

off by the tines).

- If the frame has been fully fitted with tools, its stability will be assured even without

support wheels.

- Dust clouds may form when operating the power harrow at higher speeds on dry ground.

Light respiratory protection should therefore be worn when using a tractor without

closed driver’s cab.

5

4.

Maintenance, care

and

t

r

an

s

p

o

r

t:

The

PTO

shaft must always be disengaged and the ignition key

r

e

m

ove

db

efo

r

es

t

a

r

t

i

n

g

any

maintenance

and

repair work

on the

power

ha

rr

ow!

Maintenance or repair work must never be performed underneath the rotary power harrow

without appropriate supports. Precautions must always be taken to prevent the machine from

dropping inadvertently, for instance by using hoisting gear.

The rotary power harrow should always be placed on firm, level ground.

The power harrow type LXG is designed and built to require as little maintenance and care as

possible.

H

oweve

r

,

the following points should be o

b

se

r

ve

dn

eve

r

t

h

eless

:

- All nuts, bolts and screws must be examined after the first five hours of operation and

then always before using the machine in order to ensure that they are secure.

They

must

be retightened if necessary.

- The PTO shaft must be lubricated with sufficient sulphur-free grease every eight hours

of operation so that it can always be extended and retracted without difficulty. The

bearing points on the cutter unit, the spindle for setting the working depth and the

roller mount must be lubricated every 30 hours of operation via the corresponding

grease nipples.

- The oil must be checked every 20 hours of operation.

- Gear oil must be changed after approx. 200 hours of operation. A container must be

placed under the machine to collect the escaping oil and prevent contamination of the

ground. Waste oil must be disposed of in accordance with the regulations.

- The rotary power harrow should be stored in a dry place, on firm, level ground. It

should be secured with chocks or similar objects to prevent inadvertent tilting.

- The machine must be thoroughly cleaned before prolonged storage. Those parts which

are in contact with the ground during operation should be sprayed with corrosion

inhibitor.

- Particular attention must be paid to the condition of the tines in order to ensure

maximum occupational safety and high-quality results. Before starting work, the tine

must therefore be examined to ensure they are correctly secured and wear down

evenly. Bent tines must be replaced immediately.

- Vibrations in the rotary power harrow are usually due to imbalances in the tine unit

and may damage the machine. Switch off the rotary power harrow and the tractor if

the vibrations increase significantly during operation or if the machine’s running noise

changes suddenly. The cause must be located and remedied before resuming work.

6

- When cleaning the machine with a high-pressure cleaner, care must be taken not to

direct the high-pressure jet against bearings and seals, as this can result in

malfunctions and premature failure of the machine.

- The screw connections between tines and tine flange / guard plate must be checked

regularly. Always fit new lock nuts and new washers whenever the screw connections

have been removed. The condition and degree of wear on the tines and tine pick-up

must be checked regularly.

- When transporting the machine, care must be taken to ensure that there is no one and

nothing in the immediate vicinity when sluing outwards with the tractor.

- The power harrow should only be repaired by a specialist repair shop or a authorized

customer service center.

Changing and

regrinding

t

i

n

es

:

Tines should only be

reground

and changed by

your dealer,

since

co

n

si

d

e

r

ab

le

hazards

c

an

arise

if they

are

fitted

i

n

co

rr

ec

t

ly.

Removal of the

t

i

n

es

:

- First switch off the tractor and remove the ignition key.

- Disengage the PTO shaft and then the rotary power harrow from the tractor.

Remember

to

support

it so that it cannot tip ove

r

i

nad

ve

r

t

e

n

t

ly.

- Turn the power harrow over with the aid of hoisting gear so that the tines can be

reached without difficulty.

- Remove the fastening bolt and nut with a suitable wrench.

•

Im

p

ortant:

For safet

y

reasons, new self-lockin

g

nuts and new washers must alwa

y

sbe

used whenever the tints are changed.

Ensure

that the tines

are

fitted co

rr

ec

t

ly

in the

direction

of

r

o

t

a

t

io

n

.

Installation

of the

t

i

n

es

:

- Fit the tines in the correct order.

- Fit the fastening bolt, washers and nut.

- Tighten the self-locking nut twice.

R

eg

r

i

nd

i

n

g

the

t

i

n

es

:

If the tines have to be reground, care must be taken to ensure that each pair of tines in the

tine unit is reground. This prevents the tine unit concerned becoming imbalanced.

Use the

transport

aids

or three-point

hitch

provided

on the housing to

transport

and

handle the

p

owe

r

ha

rr

ow.

7

5. Safety i

n

s

t

r

u

c

t

io

n

s

:

- The Implements may only be used when all safety mechanisms are in place and

fully functional.

- All faults capable of impairing safety must immediately be remedied by specialist

personnel.

- The operating instructions of any additional attachments installed must be read

through carefully and observed.

- Never climb onto the tractor or leave it unattended when the p.t.o. shaft is running.

- Never allow anyone who is not familiar with the safety and operating instructions to

use the machine.

- Remove all visible large objects which may be picked up and hurled aside by the

rotary power harrow. Particular attention must be paid to loose wires on the ground.

- Adjust your driving speed in line with the ground conditions and prevailing

circumstances.

- No one may remain within 10 meters of the power harrow during operation of the

machine. High

risk

of

injury

due to moving machine parts and objects being hurled

away from the machine, such as stones, etc.

- Never climb or reach in between the power harrow and the tractor with your arms or

legs during operation of the machine – high

risk

of

injury!

(This is only permitted

when the machine has been lowered to the ground and the tractor switched off.)

- The machine should only be operated in full daylight . Traffic regulations must be

observed when driving on public roads. Adequate illumination must be ensured when

driving in twilight or darkness (A detachable set of lights is recommended.)

- Never climb or reach in between the support roller and cutter unit with your arms or

legs – high

risk

of

i

n

j

u

r

y.

- Always wear tightly fitting clothes so that these cannot be caught between rotating

parts of the machine.

- Safety stickers must be kept clean and observed!

- Never open or remove the guard elements during operation. Worn or defective parts

must immediately be replaced by new parts.

8

- The cutter unit must never be operated when the power harrow is lifted off the ground.

- Driving a tractor on steep slopes can be dangerous. If work on steep slopes is

unavoidable, great care should be exercised. Do not take bends too tightly.

- No one may ever ride on the machine either during operations or while it is being

transported, not even over short distances.

- Always examine the rotary power harrow for signs of damage following a collision

with any objects. Such damage must always be repaired before resuming work.

- Maintenance and repair work may only be carried out when the PTO shaft and

machine have been disengaged form the tractor.

- Never crawl under a rotary power harrow which is still connected to the tractor, as the

machine may be lowered at any time – high

risk

of

i

n

j

u

r

y.

- The accident prevention regulations of the employers’ liability insurance association

must be observed when using the machine.

- When traveling round bends, take account of the larger width / length (turning circle)

and considerable weight of the rotary power harrow.

- Ensure that the PTO shaft halves and protective tubes overlap as prescribed, both in

the transport position and in the working position. Read the operating instructions for

the PTO shaft in this context.

- The PTO shaft should only be engaged and disengaged when the tractor engine is

switched off and the ignition key has been removed.

9

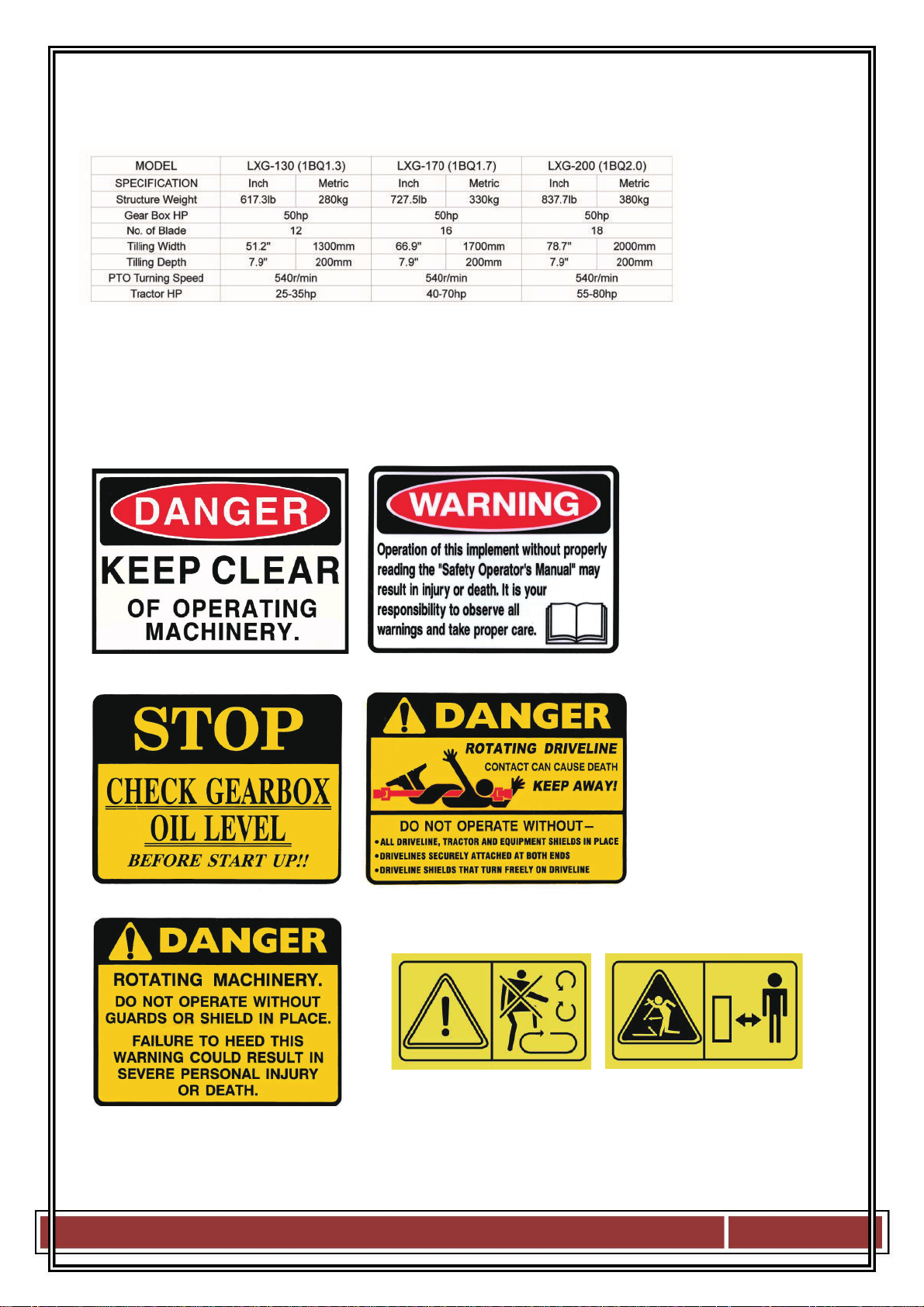

6. Technical data

:

7. Safety Decals

:

10

11

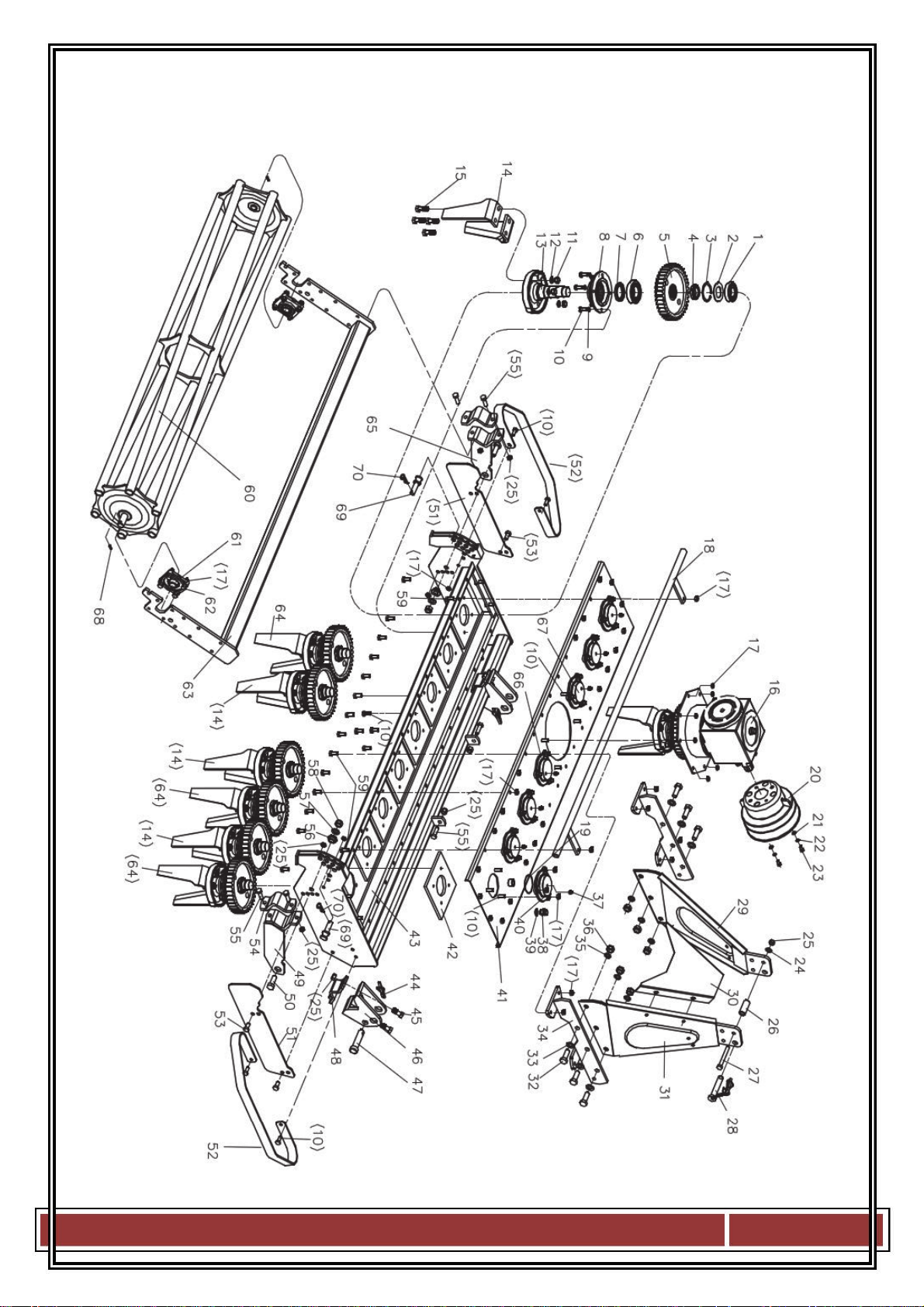

NO.

Part NO. Name & Specifications Quantity

Remark

1 GB276-6207 511022613

Bearing 6207 7

2 LXG170.115 706590024

Big washer 7

3 GB893.1-72 506060188

Seeger ring 72 7

4 LXG170.116-1 706590025

Self locking nut M39x1.5 7

5 LXG170.118 706590026

Export gear 7

6 GB276-6209 511022615

Bearing 6209 7

7 GB13871-FB-50X68X10

510020641

Oil seal FB -50X68X10 7

8 LXG170.112 706590023

Rotor support down panel 7

9 GB93-10 506030036

Washer 10 32

10 GB5783-M10X35 501011114

Bolt M10 x 35 32

11 GB6170-M14 503010048

Nut M14 32

12 GB93-14 506030038

Washer 14 32

13 LXG170.110 706590022

Colter fixing seat 7

14 LXG170.109 706590021

Colter 8

15 GB5782-M14X60 501010768

Bolt M14x60 32

16 LXG130.011 805680006

Gear case assembly 1

17 DIN985-M10 503010762

Six corner locknut M10 77

18 LXG130.018-1 805680002

Staff guage jointing 1 LXG130

LXG170.018-1 806590006

Staff guage jointing 2 LXG170

LXG210.018-1 805700003

Staff guage jointing 3 LXG210

19 GB3452.1-G-90X3.55 510013257

O-ring 1

20 FM120.00.199 703400008

PTO shaft cover 1

21 GB97.1-8 506010055

Washer 8 2

22 GB93-8 506030035

Washer 8 2

23 GB5783-M8X16 501011098

Bolt M8x16 2

24 GB97.1-12 506010057

Washer 12 2

25 DIN985-M12 503010763

Six corner locknut M12 2

26 MZ105.130 703140006

Bushing 2

27 GB5782-M12X100 501010763

Bolt M12x100 2

28 EF100.00.019-1 703740002

Above append pin 1

29 LXG170.029 806590014

Sx 3rd point 1

30 LXG170.104 706590017

Reinforcement 1

31 LXG170.028 806590013

Dx 3rd point 1

32 GB5782-M16X45 501014760

Bolt M16x45 6

33 GB97.1-16 506010059

Washer 16 6

34 LXG170.012 806590002

Impendend connect fixing

jointing 2

35 GB93-16 506030039

Washer 16 6

36 GB6170-M16 503010049

Nut M16 6

37 GB1152-M10X1 509010009

Frank press oiling cup M10x1

8

38 CBW-00-011 703070084

Aerate bolt discreteness 2

39 JB982-16 510015240

Combined oil seal 16 2

12

NO.

Part NO. Name & Specifications Quantity

Remark

40 LXG170.102 706590015

Rotor support above panel 6

41 LXG130.015 805680001

Above cover boart jointing 1 LXG130

LXG170.015 806590003

Above cover boart jointing 1 LXG170

LXG210.015 805700001

Above cover boart jointing 1 LXG210

42 LXG170.132 706590034

Mat 8

43 LXG170.016 806590004

Engine rack jointing 1

44 200.56.011 700080010

Snap pin chain 2

45 GB5783-M12X40 501011128

Bolt M12x40 4

46 LXG170.130 706590032

Stirrup 2

47 LXG170.106 706590019

Pin 2

48 LXG170.131 706590033

Stirrup 2

49 LXG170.021 806590007

Unknit rack right connect

jointing 1

50 GB5783-M16X45 501011159

Bolt M16x45 2

51 LXG170.122 706590027

Shield 2

52 LXG170.101 706590014

Shield rack 2

53 GB5783-M12X30 501011126

Bolt M12x30 4

54 RT150.107 706590008

U bolt 2

55 GB5783-M12X40 501011128

Six corner bolt 18

56 LXG170.108 706590020

Bush 2

57 GB97.1-16 506010059

Washer 16 2

58 DIN985-M16 503010765

Six corner locknut M16 2

59 GB5783-M10X30 501011113

Bolt M10x30 10

60 LXG130.024 805680003

Unlnit implement jointing 1 LXG130

LXG170.024 806590008

Unlnit implement jointing 1 LXG170

LXG210.024 805700004

Unlnit implement jointing 1 LXG210

61 UCF205 511040011

Squareness bearing UCF205 2

62 GB5783-M10X40 501011115

Bolt M10x40 8

63 LXG130.025 805680004

Unlnit implement connect

rack jointing 1 LXG130

LXG170.025 806590011

Unlnit implement connect

rack jointing 1 LXG170

LXG210.025 805700005

Unlnit implement connect

rack jointing 1 LXG210

64 LXG170.123 706590028

Colter 8

65 LXG170.017 806590005

Unknit rack left connect

jointing 1

66 LXG170.102 706590015

Rotor support above panel 1

67 LXG170.102 706590015

Rotor support above panel 1

68 GB879.1-8X35 508011565

pin 8x36 2

69 LXG170.250 706590072

pin 2

70 ZL-25.104 703340017

pin 2

13

14

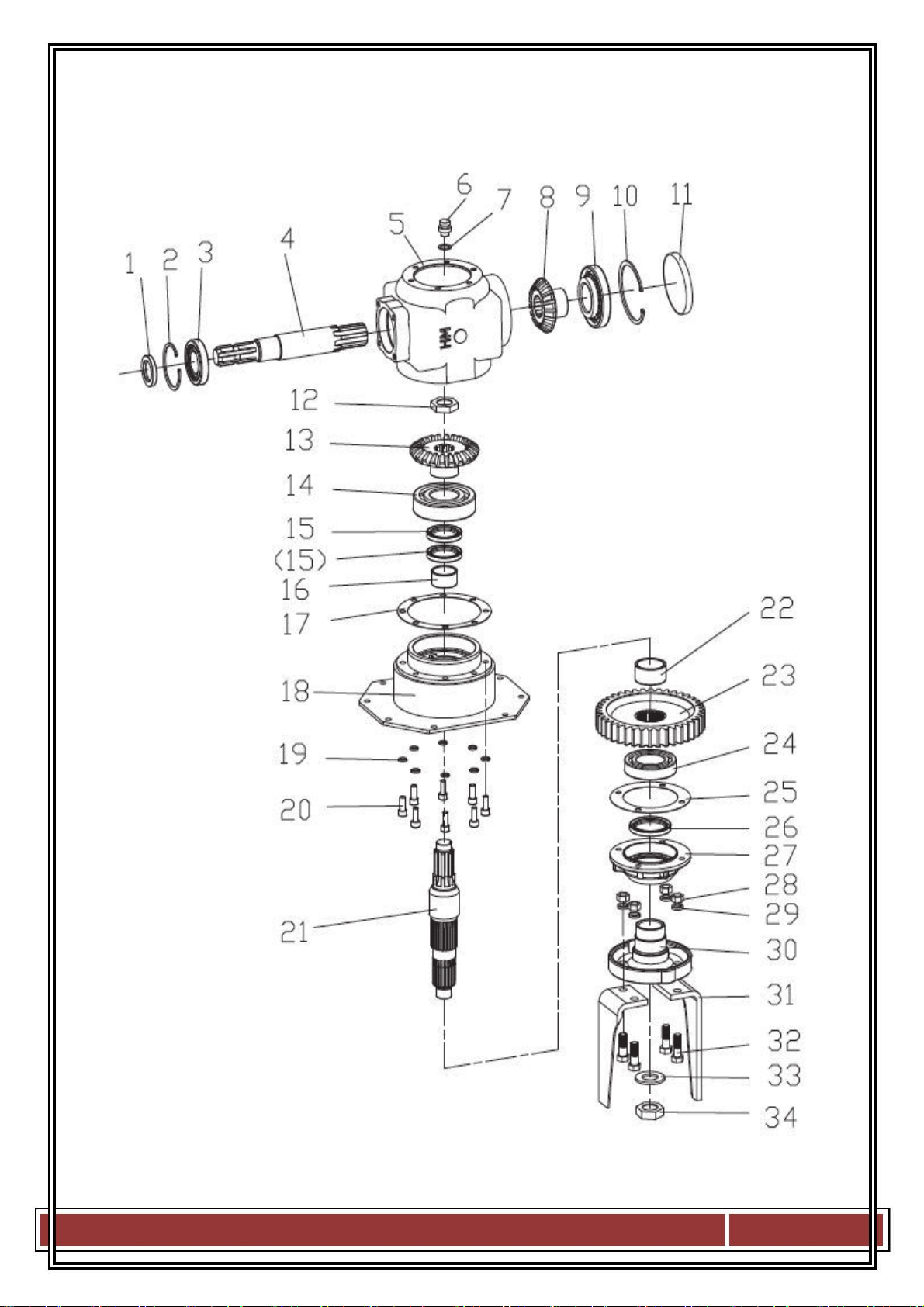

NO. Part NO. Name & Specifications Quantity

Remark

1 CFW-40X80X12 510020412

Oil seal 40X80X12 1

2 GB893.1-80 506060191

Seeger ring 80 1

3 GB297-30208 511016412

Bearing 30208 1

4 1G-150.01.117-1 703190197

Transmission shaft 1

5 1G-150.01.118 703190198

Gearbox 1

6 CBW-00-011 703070084

Breather plug 1

7 JB982-16 510015240

Combined oil seal 16 2

8 1GN180.00.141 703210001

Smallcone-shaped gear 1

9 GB297-30310 511016492

Bearing 30310 1

10 GB893.1-110 506060203

Seeger ring 110 1

11 NFG-RCA-110X12 706230018

Back end cover 1

12 GB812-M30X1.5 503020071

Lock Nut M30x1.5 1

13 1GN180.00.146 703210002

Big cone-shaped gear 1

14 GB276-6311 511022658

Bearing 6311 1

15 CFW-50X68X8 510020390

Oil seal 50x68x8 2

16 LXG170.138 706590038

Bushing 1

17 1G-150.01.114 706590011

Casket 1

18 LXG170.026 806590012

Setting 1

19 GB93-10 506030036

Washer 10 8

20 GB70.1-M10X25 505011429

Bolt M10x25 8

21 LXG170.136 706590037

Output axles 1

22 LXG170.135 706590036

Bushing 1

23 LXG170.133 706590035

Output gear 1

24 GB276-6211 511022617

Bearing 6211 1

25 LXG170.128 706590031

Gasket 8

26 GB13871-FB-60X80X10 510020634

Oil seal PB-60X80X10 1

27 LXG170.147 706590039

Bearing seat 1

28 GB6170-M14 503010048

Nut M14 32

29 GB93-14 506030038

Washer 14 32

30 LXG170.126 706590030

Colter setting seat 1

31 LXG170.123 706590028

Colter 8

32 GB5783-M14X40 501011142

Bolt M14x40 32

33 LXG170.125 706590029

Washer 30 1

34 GB812-M30X1.5 503020071

Lock Nut M30x1.5 1

15

16

This manual suits for next models

8

Table of contents

Popular Farm Equipment manuals by other brands

Schaffert

Schaffert Rebounder Mounting instructions

Stocks AG

Stocks AG Fan Jet Pro Plus 65 Original Operating Manual and parts list

Cumberland

Cumberland Integra Feed-Link Installation and operation manual

BROWN

BROWN BDHP-1250 Owner's/operator's manual

Molon

Molon BCS operating instructions

Vaderstad

Vaderstad Rapid Series instructions