HISEER GSWW60 Instruction manual

GEOTHERMAL HEAT PUMP

Installation ,Operation &Maintenance Manual

The Installation of this unit is to adhere to all Local

Building Codes and Standards

1

Pre-Installation

Important Site Instructions

The installation, commissioning, inspection, maintenance and repairs must only be carried out by

a ualified person.

All electrical wiring must be completed by a licensed electrical contractor in accordance with the

appropriate standards.

The drilling work re uires a permit from your local council.

The heating system and heat source must be properly designed and dimensioned to ensure an

efficient operation. It is particularly important to keep water flow temperatures as low as possible.

The minimum heating water flow rate through the heat pump must be assured in all operating

states of the heating system.

Movement and storage

The unit must not be transported, moved or stored at greater than a 30° angle from the upright

position. Install and store the unit in a dry area. They are not rated for outdoor use.

Safety

If a refrigerant leak occurs, remove the complete charge using a recovery unit and store the

refrigerant in mobile container.

Note: care is to be taken as the refrigerant can breakdown due to high temperature, these

refrigerants by-products are dangerous.

Once the leak has been repaired recharge the unit with the correct filling weight and the type

found on the unit’s nameplate.

Note: ensure the correct refrigerant gas is used to recharge the unit as an incorrect gas can cause

damage beyond repair to the compressor.

Do not use oxygen to purge lines or to pressurize a unit for any purpose.

Oxygen gas reacts violently with oil, grease and other common substances.

Use only refrigerant or dry nitrogen for testing.

Never exceed the specified maximum operating pressures.

Do not un-weld or flame cut the refrigerant lines including any refrigerant circuit components

until the entire refrigerant (li uid and vapour) has been removed from unit. Traces of vapour

should be displaced with dry nitrogen.

Refrigerant in contact with an open flame will produces toxic gases.

Ensure that the necessary safety protection e uipment is available when servicing. Have the

appropriate fire extinguishers for that system.

Do not siphon refrigerant.

Avoid spilling li uid refrigerant onto the skin or splashing it into the eyes. Use safety goggles.

Wash any spills from the skin with soap and water. If li uid refrigerant enters the eyes,

immediately and abundantly flush the eyes with water and consult medical advice.

Note: Never apply an open flame or live stream to a refrigerant container. This can dangerously

overpressure and cause an explosion.

Pre-Installation

2

Installation Location and Positioning

The unit must be installed in a protected area that is free from rain and water penetration.

The unit must be installed on a solid level surface, preferably on a concrete pad not connected to

the main house slab foundation.

Allowances for good ventilation around the installation must be provided.

In normal operations to prevent condensation collecting on cold pipes the thermal insulation of

any cold components should be to a high level.

The unit will produce noise that is above the minimum 45 decibel rating. Therefore the unit should

be located so that it is well away from bedrooms, offices, living areas or noise sensitive areas

including neighbour’s bedrooms.

There must be suitable distances between the unit and the building to ensure normal operation and

enough room for maintenance re uirements.

Installation Location and Positioning

3

Buffer Tank

A buffer tank is recommended to ensure a trouble free heat pump operation. A suitable buffer tank

can avoid excessive heat pump cycling (switching on and off).

The buffer tank provides a hydraulic separation from the volume flow in the heat pump and

heating circuits. The volume flow in the heat pump circuit remains constant, even if the heating

circuit volume flow is reduced by thermostatic valves.

If the total of the systems water volume is less than 12L/KW then a buffer tank should be added to

reduce the compressor from ON/OFF cycling. This will prolong the compressor life span.

When a buffer tank is installed, the heating system will absorb energy from the buffer tank first.

To save energy consumption ,install the indoor pump P1 that is switched on only when compressor

is on. This is by changing EV01 to “1”.

RT sensor should be taken out of the unit and put into buffer tank’s sensor pocket. The RT sensor

is located at lower submerged sensor pocket of the plate heat exchanger. The RT sensor in the

buffer tank will control the tank temperature by starting and stopping the compressor and pump

together as re uired.

If RT sensor has not been changed to buffer tank’s sensor pocket when EV01 has been change to

“1”, when the unit reaches its set temperature ,the compressor will stop, pump P1 will also stop

accordingly due to EV01 being set to “1”. When this occurs ,there is no water circulation between

the heat pump and buffer tank. RT will keep its stopped temperature ,not the buffer tank water

temperature. RT then can not switch on compressor and pump P1 even when buffer tank water is

getting cold. Changing the RT sensor into the buffer tank will avoid this problem.

Buffer Tank

4

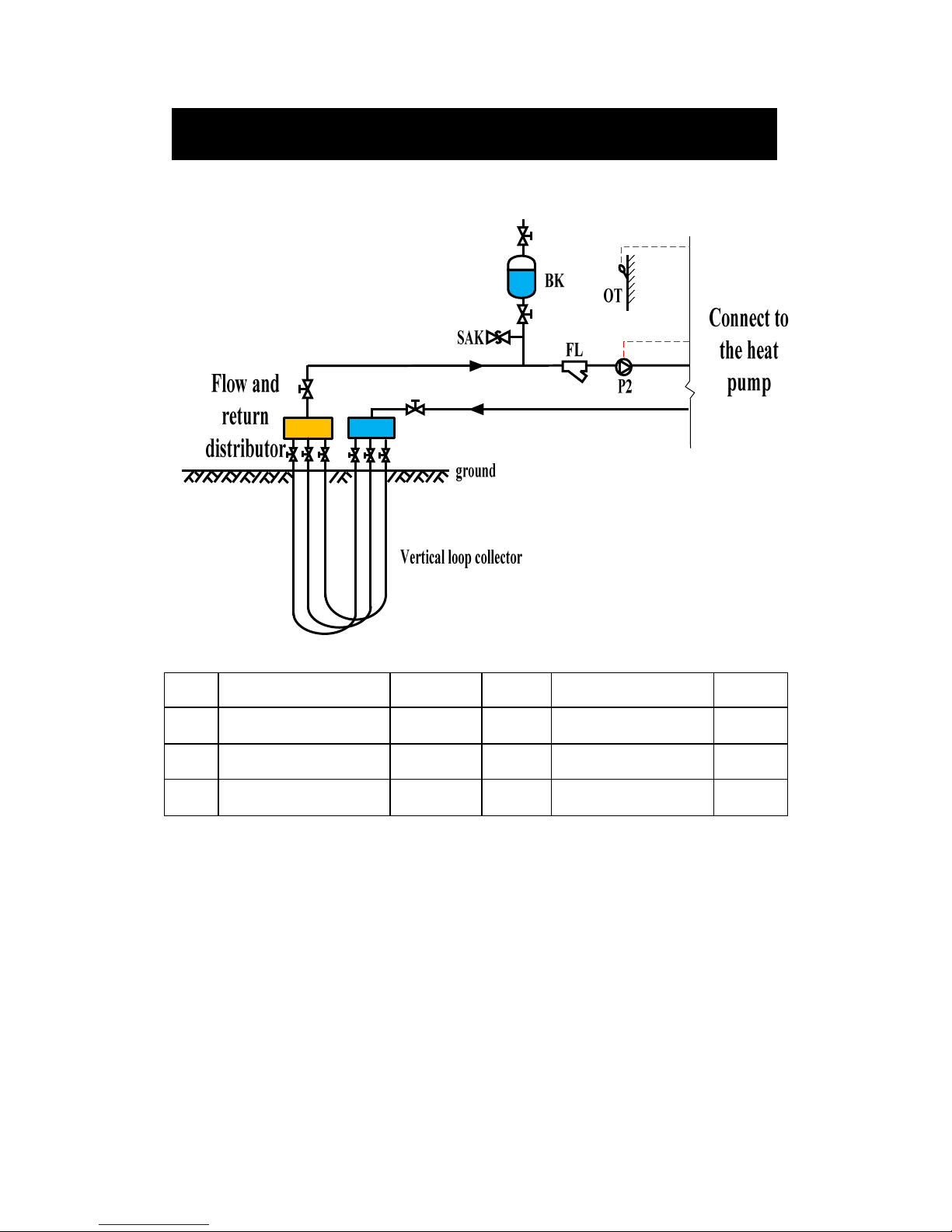

System Overview Vertical Ground Loop System

Name

Description Location

Name Description

Location

P2 Outdoor side water

pump External OT Outdoor temperature

sensor Internal

SAK

Safety valve External FL Particle filter External

BK Brine tank/expansion

tank External

Systems Overview Outdoor side)

5

System Overview Horizontal Ground Loop System

Name

Description Location

Name Description

Location

P2 Outdoor side water

pump External OT Outdoor temperature

sensor Internal

SAK

Safety valve External FL Particle filter External

BK Brine tank/expansion

tank External

Systems Overview Outdoor side)

6

System Overview Ground Water with Intermediate Heat Exchanger

System

Name

Description Location

Name Description Location

P2 Outdoor side water pump

External OT Outdoor temperature

sensor Internal

P3 Ground water pump External FL Particle filter External

BK Brine tank/expansion

tank External SAK Safety valve External

FW Water flow switch External FI filter External

DP Intermediate heat

exchanger External

Principle of Operation:

An intermediate heat exchanger (DP) should be installed to prevent ground water damaging or

contaminating the unit’s internal heat exchanger. A plate heat exchanger that is able to be cleaned

is recommended for this situation that can be disassembled for cleaning and repair or any damage

plates can be replaced. Anti-freezing measurement must be adopted to protect the ground water

circuit.

Systems Overview Outdoor side)

7

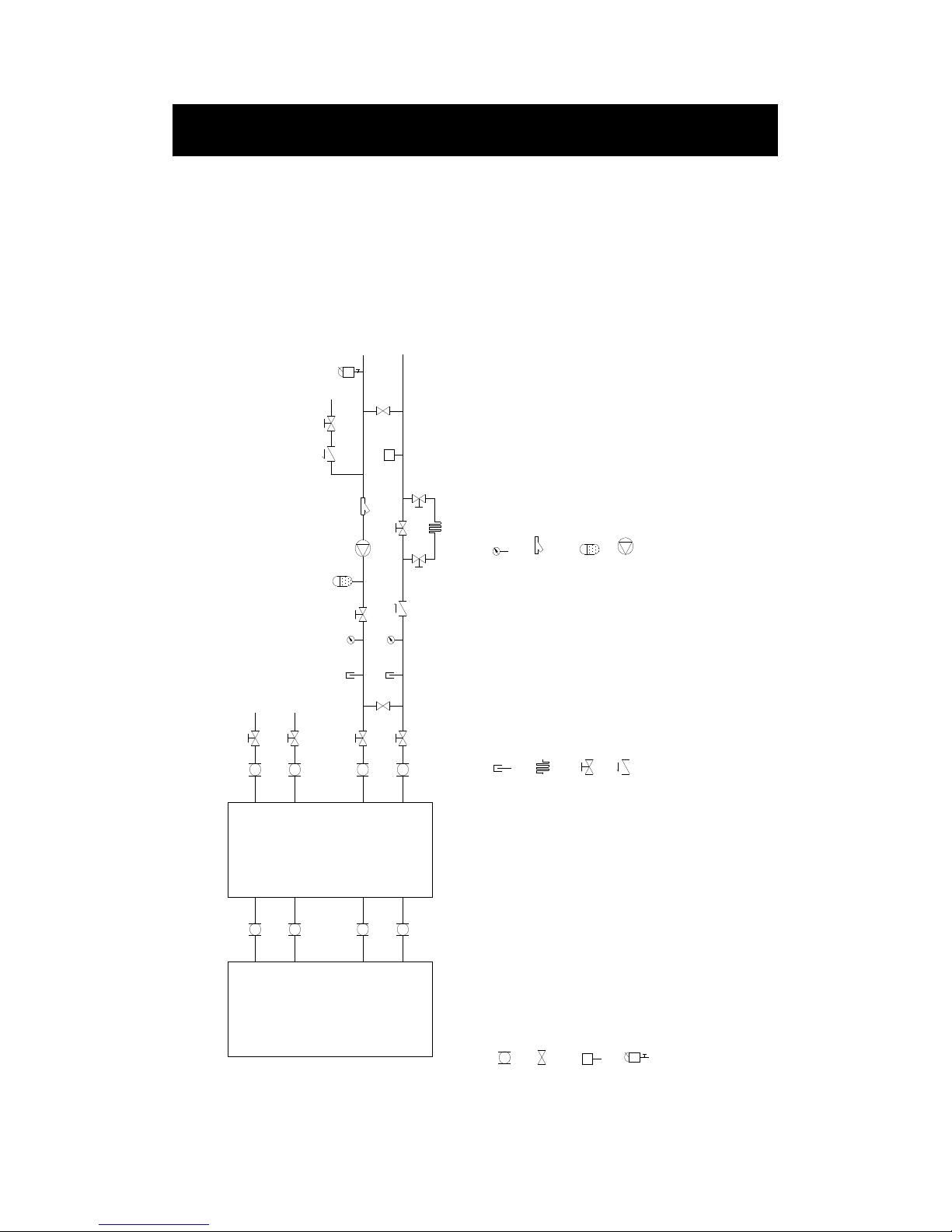

Several units could be connected together to build a large system.

Each controller is set to different cooling, heating set point (2-3 degree difference)so they will not

start at the same time to reduce start current.

All units water pump control signal connected together to A/C contactor which supply power for

water pump so the water pump can run as long as any unit is running.

GSWW60 GSWW60

Connect outdoor

system

Connect

indoor system

soft-joint for reducing vibration

between machine and system

by-pass valve

water pressure gauge

filter

automatic air vent valve

temp gauge

electronic heater

shut off valve

non-returning valve

expansion tank

water pump

water flow switch ( If it is assembled

inside the factory, no need to install)

Systems Overview Indoor side)

8

Heating working principle:

To set two units in parallel operation, set the primary unit to the re uired parameters, unit two is to

have 3~5°C difference of ST01,ST02 and ST05 to allow for energy stage control.

Switch on both units’ A/C switches one by one, if the RT parameter is lower than the set values of

both units, then the units will start to heat together. The unit with the lower ST02+ST04 value will

stop first, the other will stop as well when the RT rises above its set value. Then both units will

stop.

The unit with the higher ST02-ST04 value will start first again to heat when the buffer tank’s RT

drops. If this unit can meet the heating capacity then the RT will not drop any further, only this

unit will run as re uired. If the heating load is bigger than the capacity of one unit then the RT will

continue to drop to below the second unit ST02-ST04 value, the second unit will start increasing

the heating capacity.

Systems Overview Indoor side)

9

Installation

Installation must be carried out in accordance with current Standards and Building Codes

.

The

heat pump does not come fitted with shutoff valves and these must be fitted outside of the heat

pump to facilitate future service

.

Important

The pipe work must be flushed before the heat pump is connected so that any contaminant does

not damage the unit’s internal component parts

.

Gro nd Loops:

When dimensioning the ground collectors, consideration must be given to the geothermal location,

type of rock, soil structure and the size of the heat pump

.

When installing the collector pipe ensure it rises constantly towards the heat pump to avoid air

pockets. If this is not possible install high points to vent the air. The ground collectors must be free

of all air.

All brine pipes that enter any rooms must be insulated against condensation. The expansion tank

(BK) must be installed as the highest point in the collector system and on the incoming pipe before

the brine pump.

Note: Condensation may drip from the expansion tank. Position the expansion tank so that it isn’t

in the way of other e uipment

.

When installing the circulation pump for the brine circuit, position the electric connection at the

12 o’clock position to prevent ingress of condensate.

Ensure ade uate thermal and sound insulation of all pipes routed through wall apertures.

Thermally insulate pipes on the inside buildings and installed with a vapour seal. As the

temperature of the ground collector system can fall below 0°C, the fluid must be protected against

freezing down to –15°C. The details of the types of antifreeze used are to be left near the unit for

future servicing.

Shut-off valves should be installed as close to the heat pump as possible

.

In the case of a connection to an open ground water system, an intermediate frost-protected circuit

must be provided, due to the risk of dirt and freezing that could occur in the evaporator, this

re uires an extra exchanger.

IMPORTANT:

The recommended ground loop pipe length must be adjusted according to the local conditions.

The length of the collector pipe varies depending on the rock/soil conditions and on the heating

system, i.e. radiators or floor heating. Max length per collector should not exceed 200m.

Installation

10

Where there is more than one ground loop these must be connected in parallel with a means of

adjusting the flow. For surface soil heat, the pipe should be buried at a depth of about 1.8 meters

and the distance between the hoses should be at least 1 meter.

For bore holes the distance between the holes must be at least 15m.

Installation should be inspected before it is commissioned. The inspection must be carried out by a

suitably ualified person and should be documented. The above applies to closed loop heating

systems as well. If the heat pump is replaced the installation must be re-inspected again.

After filling the brine ,check circuit pressure. The pressure should be approx 2 bar. Minimum

system pressure 1 bar, Max pressure should not be over 3 bar.

Pipe Connections (Indoor Side):

Ensure all re uired safety devices, shut-off valves (as close to the heat pump as possible) and

particle filter are fitted

.

The safety valve must have a maximum 3 bar opening pressure and be

installed on the water outlet.

An expansion vessel that is the correct size for the system must be installed. Ensure that the

diaphragms and seals of the expansion vessel including any safety valves are suitable for the heat

transfer medium.

The entire length of the overflow water pipe from the safety valves must be inclined to prevent

water pockets and must also be frost proof if re uired.

Thoroughly flush the heating system.

Carry out a leak test.

Operating pressure: 2 bar. Max pressure must not be over 3 bar.

Installation

IMPORTANT:

When connecting to a system with thermostats on all radiators a bypass valve must be fitted,

or some of the thermostats must be removed to ensure sufficient flow through the heat pump.

11

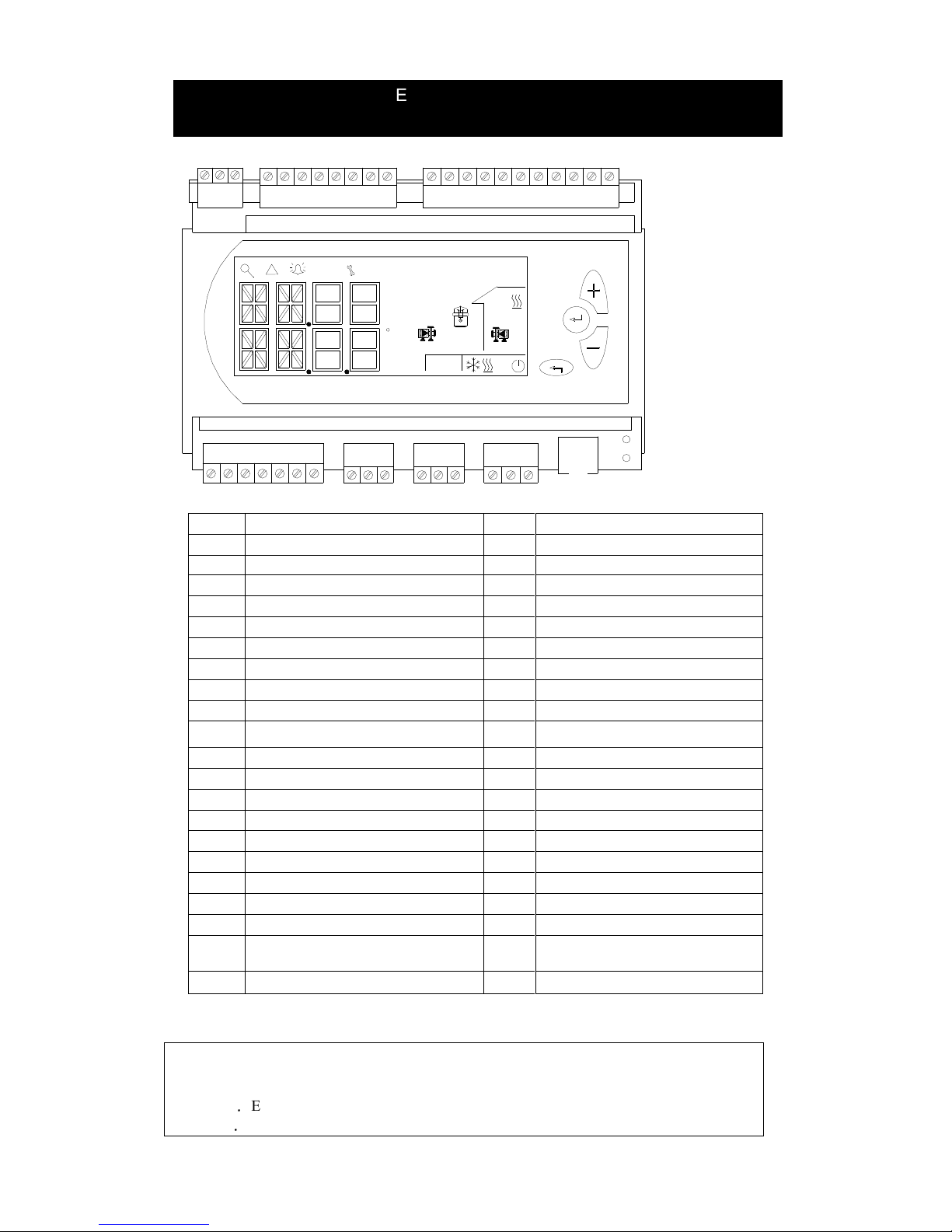

Electrical Connection

Q13 Q14 Q34Q24 Q44 Q54 Q64 Q23 Q74 Q84 Y1 G0 Y2 A+ B- GND

RJ45

G0 PE D1 M D3D2 M MD4 D5 X1 GND X3X2 X4 X5GND GND +5V

X6 +24V

RS485

!

C

G

SIEMENS

RWR470.10

Terminal Assigments Terminal Assignments

G Power supply AC/DC 24 V Q13 Supply 1 AC 24 V 230 V)

G0 Power supply ground Q14 Compressor 1

PE Saftey ground Q24 Compressor 2

Q34 Indoor water pump

X1 Inlet water temperature of indoor side Q44 Outdoor water pump

X2 Outlet water temperature of indoor side Q54 4-way valve

X3 Outdoor ambient temperature Q64 Electric heater or boiler

X4 Hot water temperature

X5 Outlet water temperature of outdoor side Q23 Supply 2 AC 24 V 230 V)

X6 Exhaust gas temperature/return gas

temperature

Q74 Hot water pump or revert valve

GND Common reference point for analog input Q84 Alarm

+5 V DC 5 V power output for active sensor Y1 Analog output 2, 0...10 V

+24 V DC 24 V power output for active sensor GND Common reference point

Y2 Analog output 2, 0...10 V

D1 Water flow switch

D2 Low pressure switch A+ A+ connector for RS485

D3 high pressure switch B- B- connector for RS485

D4 Air conditioner switch GND Optional for RS485 communication

D5 Hot water switch RJ45 Service interface for parameters

uploading and downloading

M Common reference point for digital input

Warning:

Electrical connections and servicing must be carried out under the supervision of a ualified

electrician

.

Electrical installation and wiring must be carried out in accordance with Local

Standards

.

Electrical Connection

12

Power Connection:

Before connecting the power supply please confirm the unit suits the power supply as unit

nameplate.

Breaker protection must be installed according to the max value stated in the nameplate attached

to the unit inside of front panel.

The e uipment must be installed via an isolator switch with a minimum breaking gap of 3 mm

.

Disconnect the heat pump before insulation testing the house wiring

.

The unit is three phase, the power supply must conform to the specification on the unit’s

nameplate.

The supply voltage must be within the range specified in the electrical data table. For wiring

connection, refer to the electric wiring diagram on the inside panel of the unit.

When the building is e uipped with an earth-fault breaker the heat pump should be e uipped with

a separated one

.

WARNING:

Disconnect the main power supply switch before servicing the system or handling any internal

parts of the unit.

In case of any major malfunction turn the unit off, disconnect the mains power supply and contact

a ualified service engineer.

Electrical Connection

13

Outdoor Ambient Temperature Sensor:

The outdoor temperature sensor (OT) is a standard part placed inside the electric box. One

terminal is connected with the PC board X3 and GND, the other terminal must be installed

outdoors. It should be mounted on a wall that has the mean outdoor temperature which can

accurately measure the outdoor temperature and not to be exposed the rain, sun and snow.

If the outdoor ambient temperature sensor cable runs close to power cables a shielded cable should

be used. If a conduit is used, it should be sealed to avoid condensation in the outdoor temperature

sensor probe.

Indoor Side Inlet Water Temperature Sensor:

The indoor side inlet water sensor (RT) from factory is placed in the submerged pocket of the plate

heat exchanger.

If a buffer tank is installed, the RT sensor can be moved to the buffer tank temperature sensor inlet

pocket and EV01 parameter value can be set to “1”. This stops the pump running when

compressor is OFF.

If the RT sensor can not be moved to the buffer tank temperature sensor inlet, the EV01 parameter

value must be set to “0” (factory default setting). This allows the pump to continue to run so RT

measured the same as butter tank water temperature.

Important:

All temperature sensor must be separated (min 200 mm) from high voltage power cables to avoid

interference which will cause measured temperature fluctuating and the heat pump may operate

incorrectly.

Electrical Connection

14

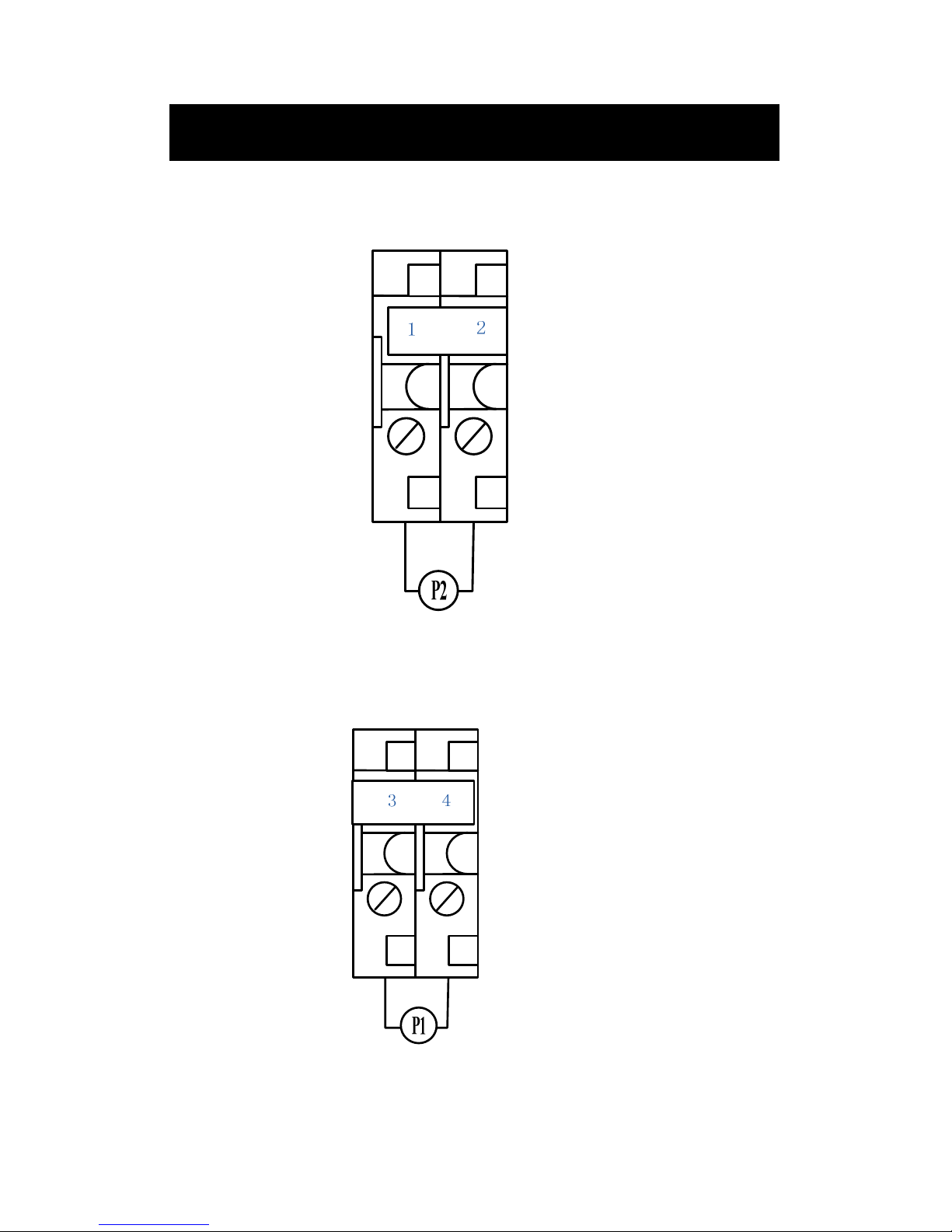

Outdoor Side Water Pump:

Outdoor side water pump is connected to terminal port (1-2). If the water pump current is over 2A,

an A/C contactor must be used to activate the water pump.

Indoor Side Water Pump:

Indoor side water pump is connected to terminal port (3-4). If the water pump current is over 2A,

an A/C contactor must be used to activate the water pump.

Electrical Connection

15

Electric Heater:

Electric heater is connected to terminal port (10-11). An A/C contactor must be used to activate the

electric heater. A thermostat T should be attached on the outer container of heater to prevent heater

from overheating.

Hot Water Pump or T ree Way Valve:

If the indoor side water pump is for both heating and

domestic hot water circulation, set SF10=0, connect a 3

way valve to terminal (7-8-9)

If another pump is used for the domestic hot water circuit,

set SF10=1, connect the hot water pump to terminal (8-9).

KM2

N

L1

PE

ELK

L2

L3

10 11

K M

K M K M

K M 2

22

2

T

(Triple phase)

Electrical Connection

16

A/C Switc :

The unit’s A/C ON/OFF cannot be operated by any button on the

controller.

When the A/C’s switch B1-B2 is bridged, the unit’s heating

/cooling function is activated. An external signal like a timer or

thermostat, etc could be connected to B1-B2 to activate or

deactivate the unit’s heating /cooling function. This external signal

must be voltage free.

Note

This is a potential free input contact only. DO NOT PUT 230VAC INTO THIS CONTACT

Hot Water Switc :

The unit’s hot water ON/OFF cannot be operated by any

button on the controller.

When hot water switch A1-A2 is bridged, the unit’s hot

water function is activated. An external signal like a

timer or thermostat, etc could be connected to A1-A2 to

activate or deactivate the unit’s hot water function. This

external signal must be voltage free.

Note

This is a potential free input contact only. DO NOT PUT 230VAC INTO THIS CONTACT

Electrical Connection

17

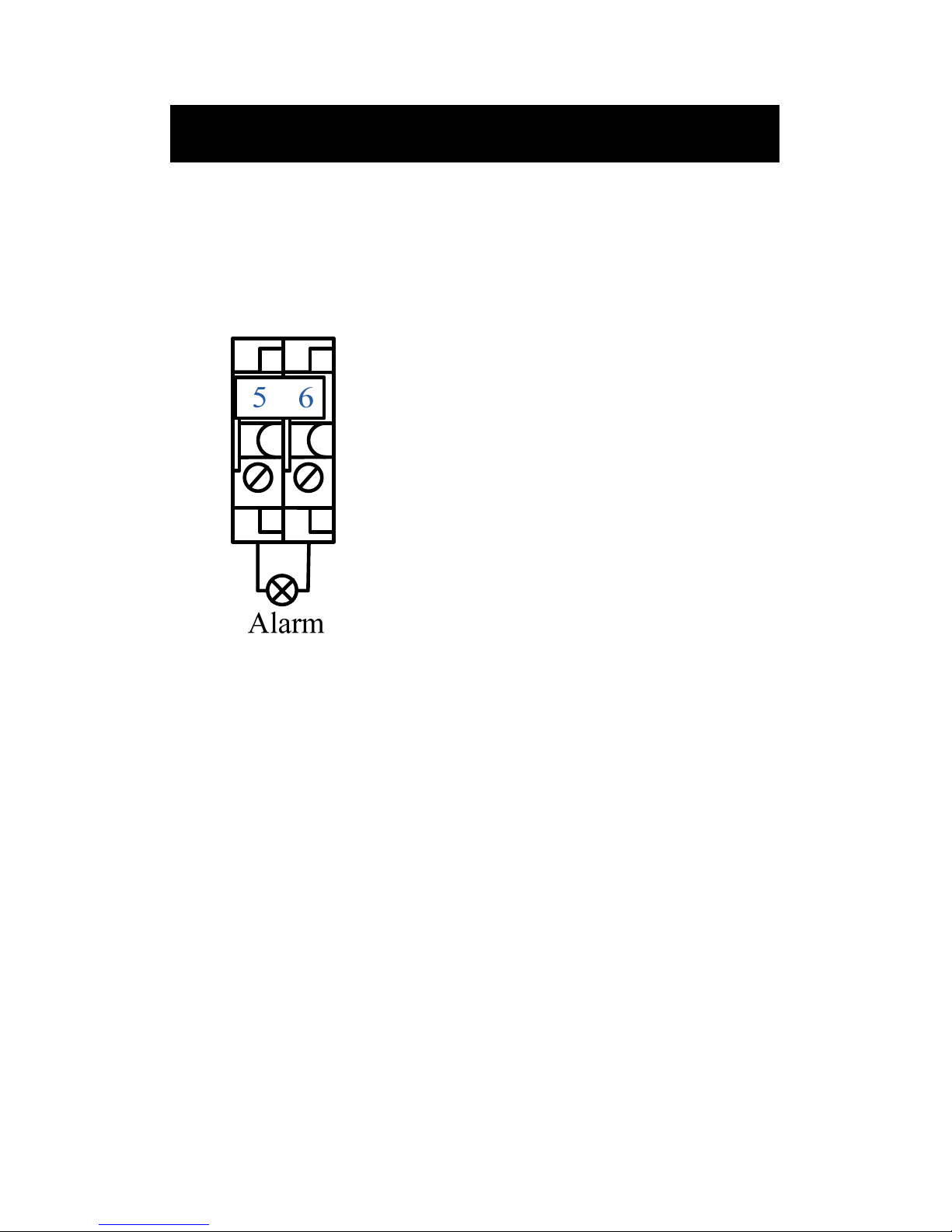

Alarm Unit’s Output:

When any alarm occurs Terminal port (5-6) will have a 230V output. It

could be connected to an alarm unit (such as indication lighter, alarm bell

etc).

Electrical Connection

18

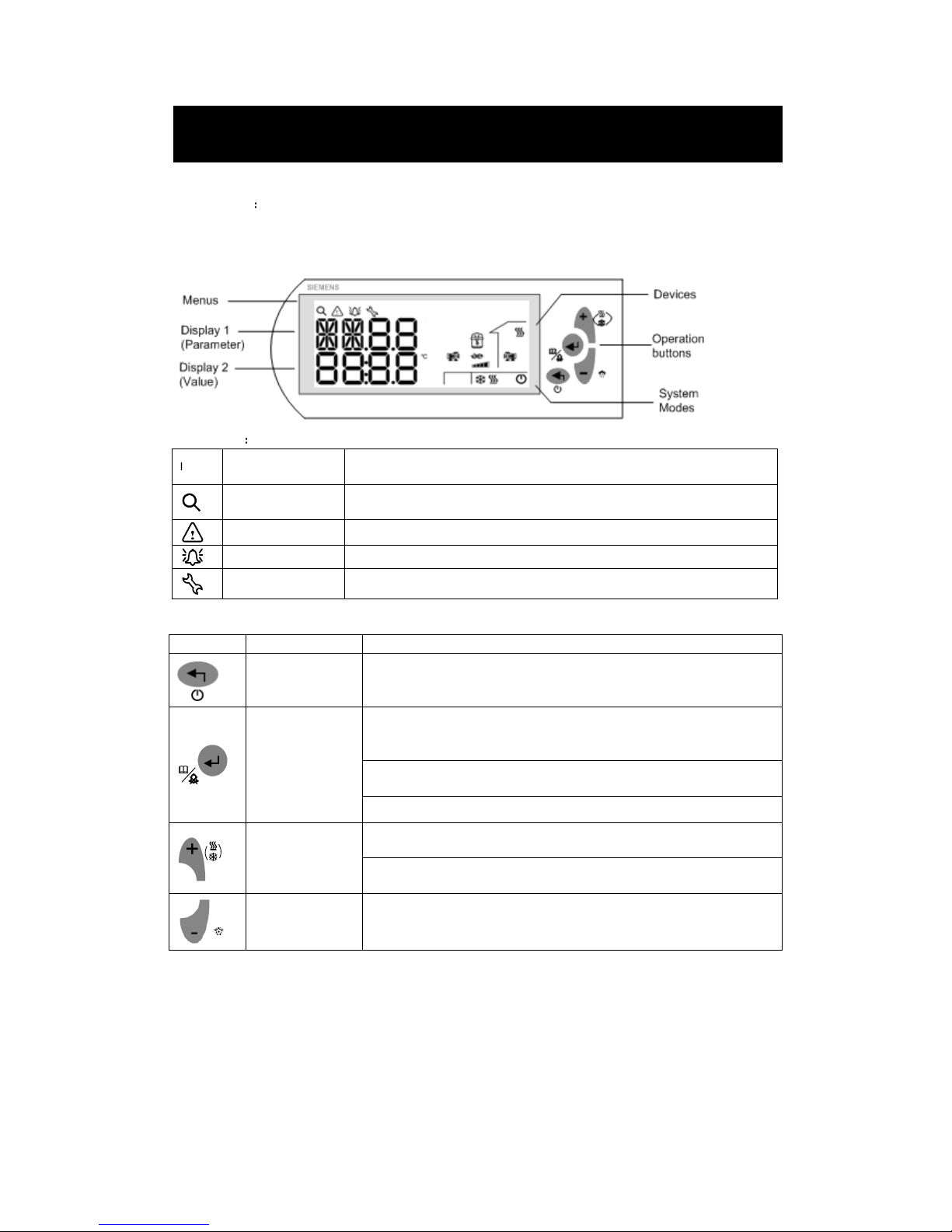

Controller

Controller Display (Display window & button area)

Display Area

:

In normal working mode: display 1 shows a parameter code, display 2 shows this code

temperature value.

In parameter setting mode: display 1 shows parameter code, display 2 shows this parameter value.

Menus area

:

Icon Meaning Function

Query/view

Actual values of all temperature

Warning Existence of warning, and the latest 10 warnings

Alarm

Existence of alarm and the

latest 20 alarms

Parameters Set parameters and values see also Menu Tree)

Operating buttons

Button Name Operation

<Esc>

In Menu /parameter setting mode, press it to return to the

previous menu level, or to cancel the value entered

<Enter>

Press down it for more than 2 seconds and release it to enter the

Menu mode when unit is at stop mode (both A/C and hot water

switch are OFF)

In Menu/parameter setting mode, press it to confirm the selected

menu level, or the value entered

Press it to acknowledge/reset warnings and alarms

<Plus>

Press it for 2 seconds to activate the System Mode in stop mode

Or, press it to select the menu level, or to increase the value in

Menu/parameter setting mode

<Minus>

Press it to select the menu level, or to decrease the value in

Menu/parameter setting mode

Controller

19

Symbol explanation

Cooling mode

Heating mode

Power

Hot water mode

Indoor side water pump

Compressor energy grade

Compressor

Water flow switch (light on represents the water flow switch alarm)

Outdoor side water pump

Controller

Table of contents

Other HISEER Heat Pump manuals

Popular Heat Pump manuals by other brands

Rheem

Rheem RKNA SERIES installation instructions

Mitsubishi Electric

Mitsubishi Electric PKA-A18HA6 Service manual

Johnson Controls

Johnson Controls Duct R-410A installation manual

CTC Union

CTC Union EcoHeat 5 Installation and Maintenance

Daikin

Daikin RKS20LVMA Service Manual Removal Procedure

Nibe

Nibe Compact Sol 300 Installation and maintenance instructions

Klimaire

Klimaire KCHD Series engineering data

Daikin

Daikin ComfortNet DX18TC Series Service instructions

evoheat

evoheat CS-i Series Installation & operation manual

flowair

flowair AURA HCS Series Installation and operating instruction

LG

LG 5BPU0-02D Engineering product data book

Energie

Energie AquaPura Split 300i Technical manual