SAFETY PRECAUTIONS....................................................................................................................................................... 2

PARTS IDENTIFICATION.......................................................................................................................................................3

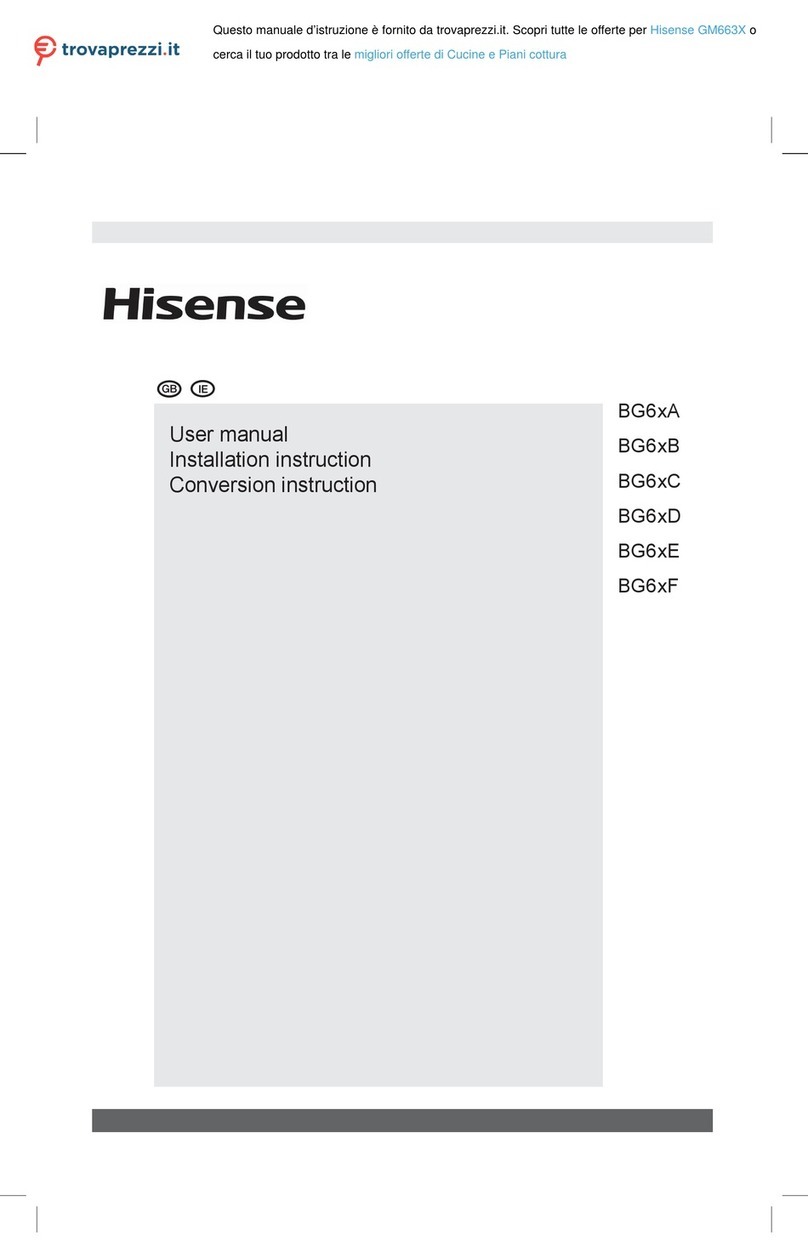

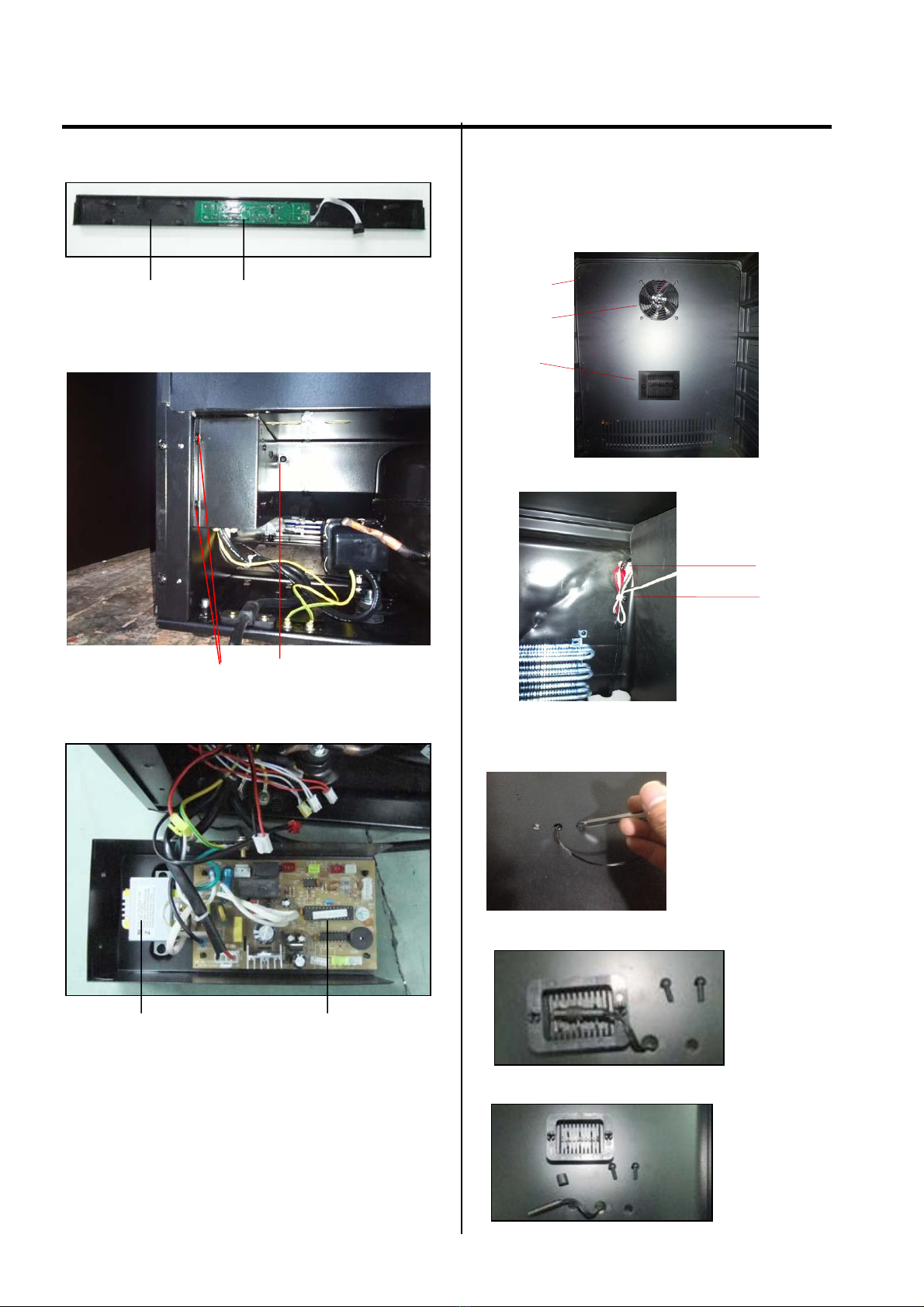

DISASSEMBLY................................................................................................................................................................... 4-8

DOOR................................................................................................................................................................................... 4

SHELVES.............................................................................................................................................................................. 4

LAMP…………..................................................................................................................................................................... 4

MAGNETIC SWITCHE..................................................................................................................................................... 4-5

DISPLAY BOARD BOX ASSEMBLY ................................................................................................................................5-6

CONTROL BOARD & TRANSFORMER.............................................................................................................................. 6

SENSOR & FAN............................................................................................................................................................... 6-8

TROUBLESHOOTING....................................................................................................................................................... 9-12

COMPRESSOR COMPONENTS ....................................................................................................................................... 9

ANOTHER ELECTRIC COMPONENT ............................................................................................................................ …10

SERVICE DIAGNOSIS CHART.......................................................................................................................................... 11

REFRIGERATING CYCLE.................................................................................................................................................. 12

DESCRIPTION OF CONTROL PCB .....................................................................................................................................13

SAFETY PRECAUTIONS

Please read the followings beforeservicingyour appliance.

1. Check if an electric leakage occurs in the set.

2. To prevent electric shock, unplug prior to servicing.

3. In case of testing with power on, wear rubber gloves

to prevent electric shock.

4. If you use any appliances, check regular current,

voltage and capacity.

5. Don't touch metal products in cold freezer with wet

hand. It may cause frostbite.

6. Prevent water flowing to electric elements in

mechanical parts.

7. When sloping the set, remove any materials on the

set, especially thin plate type. (ex.: glass shelf or

books.)

8. When servicing evaporator part, wear cotton gloves

without fail. It is to prevent wound by sharp fin of

evaporator.

9. Leave a breakage of refrigerating cycle to a heavy

service center. The gas in cycle inside may soil

ambient air.