Hisstema NP-1 User manual

© 2020 ... Hisstema AB

System NP-1

Version 1.66.09 2020-05-04

Introduktion

A brief introduction to Hisstema System NP-1

Developed by Nils Bj örkman

Congratulations!

You have j ust been given the opportunity to work with Hisstema AB's control

system NP-1

A high-tech, modern high performance product.

System NP-1 has been developed by Hisstema AB to meet the increasing

need for flexibility, user-friendliness, security, connectivity (data

communication) and reliability in the 21st century.

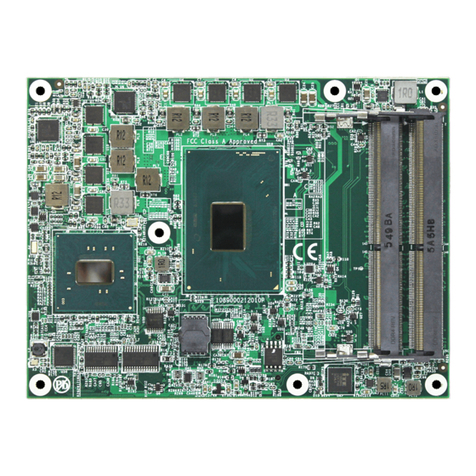

The system is built around the latest single chip computer technology with a

high performance processor and plenty of memory.

The program written in the modern language C / C ++ is based on a real-time

operating system to get maximum performance, maximum reliability and

simplest software maintenance.

System NP-1 has a 1/4 VGA graphical display with very good readability to

present information to you as a user in the best way.

A "real" keyboard with all digits makes entering all values easy. To enter text,

just like on the mobile phone, each digit key corresponds to three letters

except the digit.

Development work has been ongoing since 2003 under the leadership of Per

Holmberg and has been practically carried out by Nils Björkman.

Hisstema AB hopes that you will appreciate your new control system NP-1.

If you need support, simply call Hisstema AB +46 (0)8 554 230 70 during office

hours. For contact at other times see the chapter "Support".

All rights to this manual belong to Hisstema AB.

It is not allowed in any form, graphic, electronic etc. to copy, distribute or publish all or part of this manual without

written permission from Hisstema AB.

The products described in this manual are all copyright Hisstema AB.

Although every effort has been made to make this manual as accurate and complete as possible, Hisstema AB

accepts no responsibility for errors in its content, discomfort, damage or costs arising from what is written or omitted

in this manual. Hisstema AB cannot be held liable for any damage that has occurred directly or indirectly through

this manual.

This manual is entirely aimed at competent and competent personnel. (Trained elevator installer or similar)

Hisstema System NP-1

© 2020 ... Hisstema AB

All the people who have provided tips, ideas, views and advice

regarding the development of system NP-1.

The suppliers who in every way put up material and knowledge.

Hisstema´s staff who have endured all the experiments and tests

that have taken both time and place.

And last but not least, To YOU who have shown Hisstema AB your

confidence by purchasing this product.

Publisher

Editor

Technical review

Design and Photo

Hisstema AB

Nils Björkman

Juha Drougge

Nils Björkman

Copy / Print

***

Per Holmberg

IContent

I

© 2020 ... Hisstema AB

Content

0

Chapter I General 1

Chapter II Warranties 3

................................................................................................................................... 41 Warranty

................................................................................................................................... 42 Storage

Chapter III Getting started 5

................................................................................................................................... 61 Display and Keyboard

.......................................................................................................................................................... 7PIN-code

.......................................................................................................................................................... 8Main page

.......................................................................................................................................................... 12Status

.......................................................................................................................................................... 13Menus

.......................................................................................................................................................... 16Data input

Chapter IV System overview 17

................................................................................................................................... 181 Description of the system's functions

.......................................................................................................................................................... 23Overview image

Chapter V Installation 24

................................................................................................................................... 251 Choice of installation location

Chapter VI Wiring 26

Chapter VII Start up 28

................................................................................................................................... 291 Basic settings

................................................................................................................................... 292 Frequency control

................................................................................................................................... 303 Manual operation

................................................................................................................................... 314 Shaft equipment

................................................................................................................................... 315 Shaft measurement

................................................................................................................................... 326 Floor setting

................................................................................................................................... 337 Test runs from the system

................................................................................................................................... 338 Brake value adjustment

Chapter VIII Overview 34

................................................................................................................................... 351 Limit test

................................................................................................................................... 352 Brake test

................................................................................................................................... 353 EN81-A3

................................................................................................................................... 364 Overload scale

................................................................................................................................... 365 Run time limiter test

................................................................................................................................... 376 Movement supervision

Chapter IX Support and spare parts 38

Hisstema System NP-1II

© 2020 ... Hisstema AB

................................................................................................................................... 391 Contact Hisstema

Chapter X Maintenance 40

................................................................................................................................... 411 Replacement of components

................................................................................................................................... 412 Cleaning

................................................................................................................................... 413 Inspection

Chapter XI Functions 42

................................................................................................................................... 431 Calculator

................................................................................................................................... 432 Speedlog

Chapter XII IN / OUT / BUTTON 45

................................................................................................................................... 461 Inputs

................................................................................................................................... 522 Outputs

................................................................................................................................... 583 Buttons

................................................................................................................................... 594 Roof box connectors

................................................................................................................................... 595 Panel board

................................................................................................................................... 606 Shaft board

Chapter XIII Parameters 61

................................................................................................................................... 631 Door parameters

................................................................................................................................... 682 Selector

................................................................................................................................... 693 Brake parameters

................................................................................................................................... 704 Code lock

................................................................................................................................... 715 Speed curve

................................................................................................................................... 726 Controls

................................................................................................................................... 777 Times

................................................................................................................................... 788 Run parameters

................................................................................................................................... 809 Info-Link parameters

................................................................................................................................... 8110 Priority / Fire

................................................................................................................................... 8411 System parameters

................................................................................................................................... 8812 Floor / References

................................................................................................................................... 8813 Doors and Calls

................................................................................................................................... 8914 Safety circuit

................................................................................................................................... 9015 Object

................................................................................................................................... 9116 Ethernet

................................................................................................................................... 9117 Overload scale

................................................................................................................................... 9218 Floor Display INFO-Link

................................................................................................................................... 9319 PLC

................................................................................................................................... 9420 Statistics

................................................................................................................................... 9421 Communication Frequency

................................................................................................................................... 9522 CAN-bus

................................................................................................................................... 9623 Analogue inputs

................................................................................................................................... 9724 Com Ports

IIIContent

III

© 2020 ... Hisstema AB

Chapter XIV Troubleshooting 99

................................................................................................................................... 1001 Event memory

................................................................................................................................... 1012 Service memory

................................................................................................................................... 1033 Incident number

................................................................................................................................... 1064 Error number

................................................................................................................................... 1165 View of safety chain

................................................................................................................................... 1176 Waiting for respons

Index 120

Chapter I

General 2

© 2020 ... Hisstema AB

1 General

This manual is intended to simplify the handling of your NP-1 system from Hisstema AB.

This manual is based on program 1.66.09.

Congratulations on your new control from Hisstema AB

Chapter II

Warranties 4

© 2020 ... Hisstema AB

2 Warranties

2.1 Warranty

Hisstema AB normally offers a 2-year warranty against manufacturing defects unless otherwise agreed upon

writing.

The warranty covers replacement parts for all supplied materials, but not freight, assembly, any fines for being

out of order, etc.

2.2 Storage

The warranty is valid only when a component from Hisstema AB is stored properly.

Proper storage facilities should be dry, ventilated, and should maintain an even temperature.

This prevents condensation, which could lead to moisture and oxidation damage.

The cabinet should not be exposed to excessive impact. Too many bumps may damage the electronics.

The warranty does not cover damage caused by water.

Chapter III

Getting started 6

© 2020 ... Hisstema AB

3 Getting started

3.1 Display and Keyboard

The NP-1 system has a high definition (320x240 pixels) 1/4 VGA STN blue negative screen with white backlight.

Press F1 (or any button) to turn on the back light.

The display turns off automatically (screen saver) after a few minutes.

If you are in any of the menus, the display does not shut off.

When the display shuts off, you are automatically logged out if you where logged in.

Key functions:

F1

Overload device (If Hisstema brand).

F2-F3

Switches functions depending on which menu you are in. The text over the button (in the display) shows the

current operation . They are normally used for next/previous.

F4

Enter the menu system. Go back to the main page. When you return with F4, you can choose to save all

parameters.

ESC

Leave the current page or current input. Everything you changed will still be active, but WILL NOT be saved.

After restarting the computer it will no longer be there! If you want to save your changes later, you

press F4, F4 and Enter.

ENTER (Yellow angled arrow).

Confirm the selected function or entered value.

LEFT-ARROW

On the main page; CLOSE AUTOMATIC DOOR .

When inputting values; Delete incorrect values.

In Speed log: Move left after zooming in.

RIGHT-ARROW

On the main page; OPEN AUTOMATIC DOOR.

In Speed log: Move right after zooming in.

UP-ARROW

On the main page; Run lift to the top.

In the menu: Choose menu option on the top line. If the cursor is on the top row, the one under will be

selected.

In Speed log: Zoom in.

DOWN-ARROW

On the main page; Run lift to the bottom.

In the menu; Choose the menu option on the row below. If the cursor is on the last row, the first row will be

selected.

In Speed log: Zoom out.

0-9

On the main page; Enter the floor you want the lift to travel to. Confirm by pressing ENTER.

In the menu; Choose a menu alternative with a number.

Hisstema System NP-17

© 2020 ... Hisstema AB

At input; Enter the value wanted.

,

Decimal point. Used to enter decimals (e.g. 3.4) when inputting data.

-

Minus sign. Used to enter a negative number during input.

In Edit Connectors; it is used to go to a specific connector. For example: "-, 4, Enter" go directly to

connector 4.

CALL (Hand).

Turns on and off call (call buttons on each floor).

When the yellow LED lights are lit, call is on.

ALARM

Resets the emergency alarm from the lift car.

When the red LED lights are lit the emergency alarm has been triggered.

This is only used when there is no emergency telephone installed. .

LEDs

GREEN Flashes 1 time per second to show that the system functions correctly.

YELLOW Lit when the external buttons (call) are active (activated).

RED Lit when the emergency car alarm has been set off.

3.1.1 PIN-code

A personal password (PIN code) is required to access all pages except for STATUS and HELP.

STANDARD PIN CODE for level 1, 2 and 3 is available in the drawing binder!

A PIN-code is normally 4 digits.

There are 6 access levels:

Level

PIN Code

Description

0

No code needed

Main page, MANUAL and the HELP page are the only accessible

functions

1

PIN-1

"Building maintenance level"

Standard code = 1111; ALL parameters are readable

2

PIN-2

"Service level"

Everything as level 0-1. All parameters that normally may need to be

changed for service and troubleshooting can be changed

3

PIN-3

"Installation level"

Everything as level 0-2. All parameters that normally may need to be

changed during installation and commissioning of the lift can be

changed

4

PIN-4

"OEM level"

Intended for other suppliers you buy system in bulk. Permits some

configuration, disconnection of safety functions etc.

5

PIN-5

"Hisstema level"

Getting started 8

© 2020 ... Hisstema AB

Everything as level 0-4. Completely unlocked. All parameters may be

edited

6

PIN-6

"Special level" (Also called "Expert level")

This level is solely intended for system developers.

When you log in to a level, you can change the PIN for that level as well as all lower levels.

When the screen saver is activated, you are automatically logged out.

Before the lift is SHAFT MEASURED, you are always logged into level 3.

If you, for any reason, need access to a level higher than that for which you now have access, you must contact

Hisstema AB.

You can then get a temporary code for a higher level. This is valid only ONCE and for ONE system. Each new

login requires a new temporary code.

3.1.2 Main page

The first image you see when the system is switched on is shown below.

This image provides most of the information you need to assess the lift's status

.

Description of the Main Page

Top:

To left: Lift number in group and status:

Single = Solitary lift that cannot communicate with another lift

Master = Lift with lowest number in a lift group. This controls all acknowledgments.

Slave = Lift with an higher number in a lift group. This only accepts calls on trunk that are unique for

this lift.

In the Center: Object number (F-number) and program version

To the Right: During traffic control, the current status is shown. See further, under traffic control in the

advanced manual.

2nd row left: The lift's position in 1/10 floor. KV.3 means approximately one-third of a floor above KV

2nd row right: The lift's destination. If the lift is standing still, the clock is shown here.

3rd row left: The lift's current speed. If the lift is standing still, the floor error in mm is shown here.

3rd row right: Remaining expected door time. If no door time is displayed, you will see your Access Level

here.

4th row: Current errors. All errors regarding safety violations, etc. are shown here

5th row: Information texts

Left box Same information as row 4 but in graphic form. Thumbs up means EVERYTHING is OK.

Right box The 4 automatic doors' status is shown.

Right edge : Lift shaft showing the destinations that have been entered.

Hisstema System NP-19

© 2020 ... Hisstema AB

Middle row shows lift car and the right row call.

A lit symbol indicates that the message has been received and is now on the waiting

list.

Up Arrow: Up Call.

Down Arrow: Down Call.

Double Arrow: Here (Directionless call) or special call.

P1: Priority 1 Emergency operation.

P2: Priority 2 Bed transport.

P3: Priority 3.

Side Arrow: Another lift in the group has a call of some kind.

Lower edge F1 No function, F2 provides Manual operation, F3 shows Status and F4 goes to Menu

Mode.

Door status

Status of each automatic door (The order that is sent from the system to the door) is shown by a symbol.

Door A Closed Off Door A Closed Door A Open

Door A Opening Door A Closing Door A Parked Open

Photocell Door A Broken Compressive Edge Door A Broken Door Button

Door A Not Active Radar

Status Symbols

Most of the alarms have a symbol describing what the lift is waiting for

Fire alarm 1 Overload Full load

Getting started 10

© 2020 ... Hisstema AB

Speed governor Button Stuck Limitswitch open

Emergency alarm Inspection run Excess speed

Car door A Shaft door A Automatic door A

Blocking Free Safety 1 Wrong direction

Frequency inverter fault Combined hydraulics Limit, SG or Machine room

Pit safety Delay Contactor supervision

Fire figheter mode Lift car safety Lift car safety

Hisstema System NP-111

© 2020 ... Hisstema AB

Lock / Shoulder Machine room Lift car priority

All OK Sabotage Overtemp Motor

Pekab Photocell Prioroty 1 Reference error

Emerggency power Run Emergency power block Call buttons off

Swing door Warning Out of Order

Waiting for acknowledgment Voltage error Time Controlled

NOTE! Make a note of the number! Inspection Run

Getting started 12

© 2020 ... Hisstema AB

Overspeed

3.1.3 Status

If you press F3 STATUS, you come to the status menu.

1. Voltmeter: Digital voltmeter for troubleshooting. The measurement pin is connected to connection 9 pin 10

(Furthest to right on bottom row)

2. Safety circuit: Displays the safety circuit in graphic format. Here you can see if any safety is open or similar

3. System status: Display showing all the system's input voltages, battery status, cabinet temperature, etc.

4. Speed log: Displays the latest run in graphic format as a speed curve

5. GSM/GPRS: Display of selected GSM modems, Operator, Signal strength (good for antenna placement), etc

6. Lift / Lift Car: Displays all inputs/outputs on shaft node / lift car node

oSHAFT-Bus Status

The first 32 nodes are shown. Each node has 8 positions. A number over each position indicates which row

is which.

1. = Down call A side

2. = Up call A side.

3. = Down call B side.

4. = Up call B side.

5. = Hidden Door Switch (For low top / pit).

6. = Safety 1.

7. = Safety 2.

8. = Relay output, e.g. for door opener .

A "1" indicates activated, a "0" indicates not activated and a "-" indicates that the system does not have

contact with the node

F2, toggles between Shaft and Car bus status

oLift Car Bus Status

The first 8 panel boards are shown together with the roof box node.

Each node has 14 positions. One / two digits above each position indicated the respective connector's

status.

Roof box node shows connector 1, 2 and 9. Each position indicates the connector's status.

A "1" indicates activated, a "0" indicates not activated and a "-" indicates that the system does not have

contact with the board.

If you press F2, who change to Shaft Bus Status.

Hisstema System NP-113

© 2020 ... Hisstema AB

7.Frequency: View all normally interesting variables for frequency inverter (Only YASKAWA). You can also send

a RESET to the control this way. All error messages from the frequency control are shown here. This presumes

that series communication with the frequency inverter is activated.

8.Destination: No function yet

9.Expansion board:

Shows all inputs/outputs etc. on expansion board.

Currently, type A and B boards are available.

A = 16 in/out/button NPN or PNP

B = Overload scale

If there is no board, the text "No Board" is shown.

A1: shows status for board A with unit number 1. 16 positions are shown. Each position corresponds to

a connection on the board. 1-8 the inner connectors, 9-16 the outer.

A2: shows status for board A with unit number 2. 16 positions are shown. Each position

corresponds to a connection on the board. 1-8 the inner connectors, 9-16 the outer.

B1: Shows status for overload unit with unit number 1. This only shows if the unit is active or not.

B2: Shows status for overload unit with unit number 2. This only shows if the unit is active or not. It

is NOT possible to have 2 overload units (B) at the same time!

Should it say "HAS TO BE PNP !" on a row, it means that the system is set up for low top/pit with

expansion board A, but the board is missing or is set up as NPN.

10. Communication: No function yet

3.1.4 Menus

When you press F4 MENU you access all menus.

1. User:

1. Menu level:You can choose here between three menu levels.

§

BASIC - You only see the most common parameters.

§

MEDIUM - You see all the parameters you are authorised to change.

§

ADVANCED - You see ALL of the parameters.

2. Log out: If you want to log out manually, you choose this function. If you leave the system until the

screen saver is activated you are logged out automatically!

3. Deliver cabinet Save all settings as DELIVERY. Resets the cabinet to a basic mode that is suitable

for restarting the commissioning. Only works if you are logged on at level 5! NOTE! After this the lift

is NOT COMMISSIONED!!

2. Calculator: Here you have a completely normal, standard calculator

3. DCP4 Frequency:

1. If you have a frequency inverter connected by DCP protocol you can see a copy of its display and use

simulated buttons to control it.

4. Troubleshooting:

Table of contents

Popular Control Unit manuals by other brands

Giacomini

Giacomini GE550Y022 Datasheet / Operating Instructions

TRAUSCH DYNAMICS

TRAUSCH DYNAMICS PoppetPLUS 3 installation guide

Ulvac

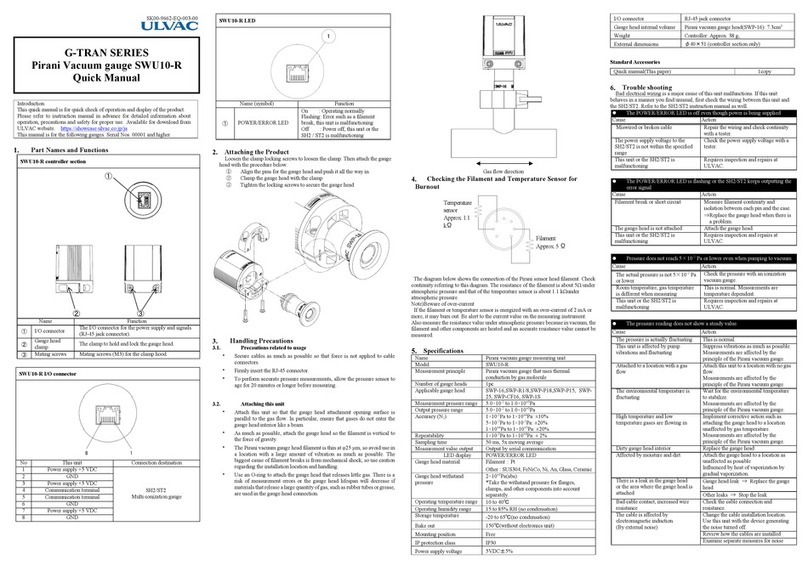

Ulvac G-Tran Series Quick manual

ICP DAS USA

ICP DAS USA I-7188XA quick start guide

Siemens

Siemens SIMATIC ET 200SP operating instructions

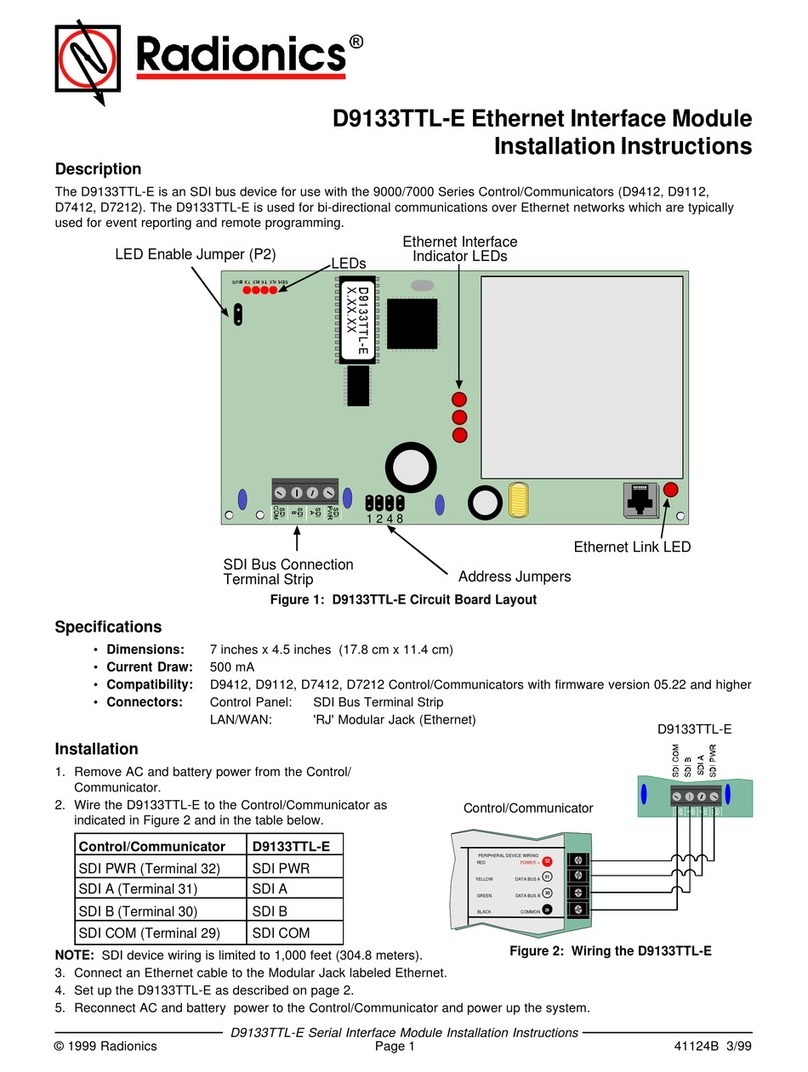

Radionics

Radionics D9133TTL-E installation instructions