PRZYKŁADOWE SCHEMATY APLIKACYJNE

Step Position "L"

- hot medium from le side

Position "R"

- hot medium from right side Action to be taken

Orientation

of the valve in

installation

R

Determine the orientation

of the valve in the system

and remove the knob and

blue limiting ring.

Position of

the closing

element (view

from the front

of the valve)

Position the closing

element midway between

the hot water inlet and

the cold water inlet to the

valve. The closing element

moves ° range between

these connections.

Application

of the blue

limiting ring

Position the limiting ring

so that the indicator is

midway between the hot

water inlet and the cold

water inlet to the valve.

Application of

the knob

Position the knob onto the

white adapter. The knob

only fits in one position.

Scale selection

L

R

Select the appropriate

side and place the lid

with the scale. on the

scale means the valve is

fully closed (no hot water

supply) and fully open

(no cold water supply).

Kvs lever

position (in

maximum

setting) (view

from the

underside of

the valve)

Unscrew the screw which

is holding the red lever on

the underside of the valve,

and then replace the lever

so that the black coding

pin is in the "L" or "R"

position. Tighten the lever

with the screw.

Selecting

and reading

the correct

Kvs value

(example)

Manually set the

appropriate Kvs value

for the installation.

See section "VALVE

SELECTION AND Kvs

Setting" for guidelines.

Installation

of the valve in

the system

Install the valve in

the system using

a appropriate seal.

INSTRUCTION MANUAL ..

-way rotary mixing valves

ARV Vario ProClick

Art. Nr: 13 362 20, 13 382 20, 13 384 20,

13 385 20, 13 386 20, 13 387 20

AFRISO Sp. z o.o. Customer Service Team

Szałsza, ul. Kościelna tel.

- Czekanów fax

www.afriso.pl zok@afriso.pl

NOTE

The product may only be used if you have fully read and understood these operating instructions. The manual is

also available on the AFRISO websites in the Internet.

WARNING!

The ARV Vario ProClick mixing valve may only be installed, commissioned, and dismantled by trained

personnel.

Changes and modifications carried out by unauthorised persons may cause danger and are prohi-

bited for safety reasons.

Risk of burns from hot medium! All installation and maintenance work must be carried out aer

the system has cooled down.

APPLICATION

ARV Vario ProClick -way mixing valves are designed for heating and cooling installations. They are usually installed

on the system feed or return to the heat source. They mix the medium flow in the right proportions to obtain the

required temperature of the medium. They can also act as switching valves between two parts of the system.

DESCRIPTION

ARV Vario ProClick -way rotary mixing valves have a body made of brass. The closing element and internal

components are made of plastic. It is possible to adjust the Kvs coeicient value on each valve. A dedicated lever

on the underside of the valve is used to change this parameter. The connections on internal threaded models are

octagonal. The valves are equipped with knobs for manual adjustment and angle limiters. The rotating scale on

one side is printed with the graduation " to " and the symbol "L", while the other side has the graduation "

to " and the symbol "R". This allows the valve to operate in dierent mounting positions. The knob is made of

non-slip material. For the connection of ARV ProClick valves to ProClick actuators or controllers, there are plastic

parts under the knob. With these parts, ProClick actuators and controllers are mounted without using any tools.

KVS VARIO FUNCTION

ARV Vario ProClick -way rotary mixing valves enable to select the optimum Kvs coeicient value for a particular

installation and subsequently changed. The correct Kvs value is a key aspect to the correct operation of the mixing

valve. If the Kvs value is too low, this will result in increased pressure losses through the valve and thus throttle the

flow in the system. This may result in underheating of rooms. Too high value of the Kvs coeicient will result in too

small pressure drop across the mixing valve and thus large fluctuations in the temperature of the medium which

feeds the installation. This is particularly unfavourable in the case of surface heating systems. Optimum selection

of the Kvs coeicient enables smooth and economical operation of the whole installation.

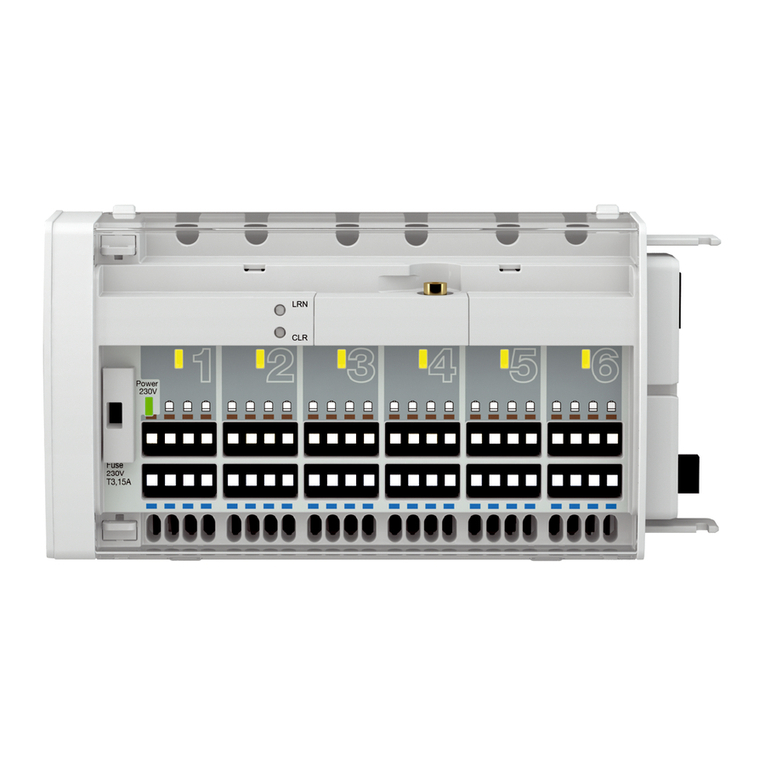

CONSTRUCTION

Knob

Valve body with plastic part for mounting ProClick actuator/controller

Fatening on the valve spindle

Adapter screw

Limiting ring with indicator

Adapter with fatening, for ProClick actuator/controller

Double-sided scale

Kvs value adjustment lever

Kvs lever coding pin

Lever fastening screw

Fig.1 Construction of 3-way valves ARV Vario ProClick

BEFORE INSTALLATION

Caution! Pay attention to the position of the closing element, which is on the opposite side to the flattening on

the adapter and on the valve spindle.

!

Fig. 2 Position of the closing element respect to the flattening on the adapter and valve spindle

The ARV Vario ProClick mixing valve is supplied with a fitted plastic knob. In order to prevent plastic components

from damage, we recommend that lid with the scale, the knob and the blue limiting ring should be removed from

valve before mounting the valve in installation. These elements are mounted with a snap. If you have problems

removing the knob, you can gently lever it o with a flathead screwdriver.

VALVE SELECTIONS AND KVS SETTINGS

Caution! The correct Kvs coeicient of the valve must be set before the first start of the installation.

Subsequent change is possible but may be diicult due to lack of free access to the valve.

The size and value of the Kvs coeicient of the mixing valve should be specified in the design of the installation.

In the absence of a design, the valve and the Kvs coeicient can be based on simplified selection charts. The Kvs

selection charts for each valve are included in the appendix to this manual.

The simplified selection procedure goes as follows:

. Determine the heat demand of the installation in kW.

. Select the value for the temperature dierence ∆T between supply and return (e.g. ∆T=K for underfloor

heating; ∆T=K or ∆T=K for radiator heating).

. Run a vertical line from the selected power in kW to the selected temperature dierence ∆T.

. Guide the horizontal line to the end of the coloured box in the diagram on the right.

. Select the smallest Kvs value from those with which the horizontal line in the coloured area intersects. The

coloured field defines the optimal pressure drop in the valve. In typical installations this should be between

and kPa.

. Select the appropriate valve size that enable setting selected value.

The selected valve may be equal or smaller compared to diameter of pipes used in the system. The valve on the

system feed may be two diameters smaller, and on the return to the solid fuel boiler, one diameter smaller than

the nominal diameter of pipes used.

Example: pipe diameter DN is used in the system, so the valve in the system feed should be sized in range of

DN-DN and on the return to the heat source DN-DN.

VALVE IN SWITCHING/DIVERTING FUNCTION

When using the valve in a switching or diverting function, there is no need to change the factory (maximum) Kvs

coeicient setting.

EXAMPLE APPLICATION SCHEMES

Mixing function

L

L

R

1 2

43

page