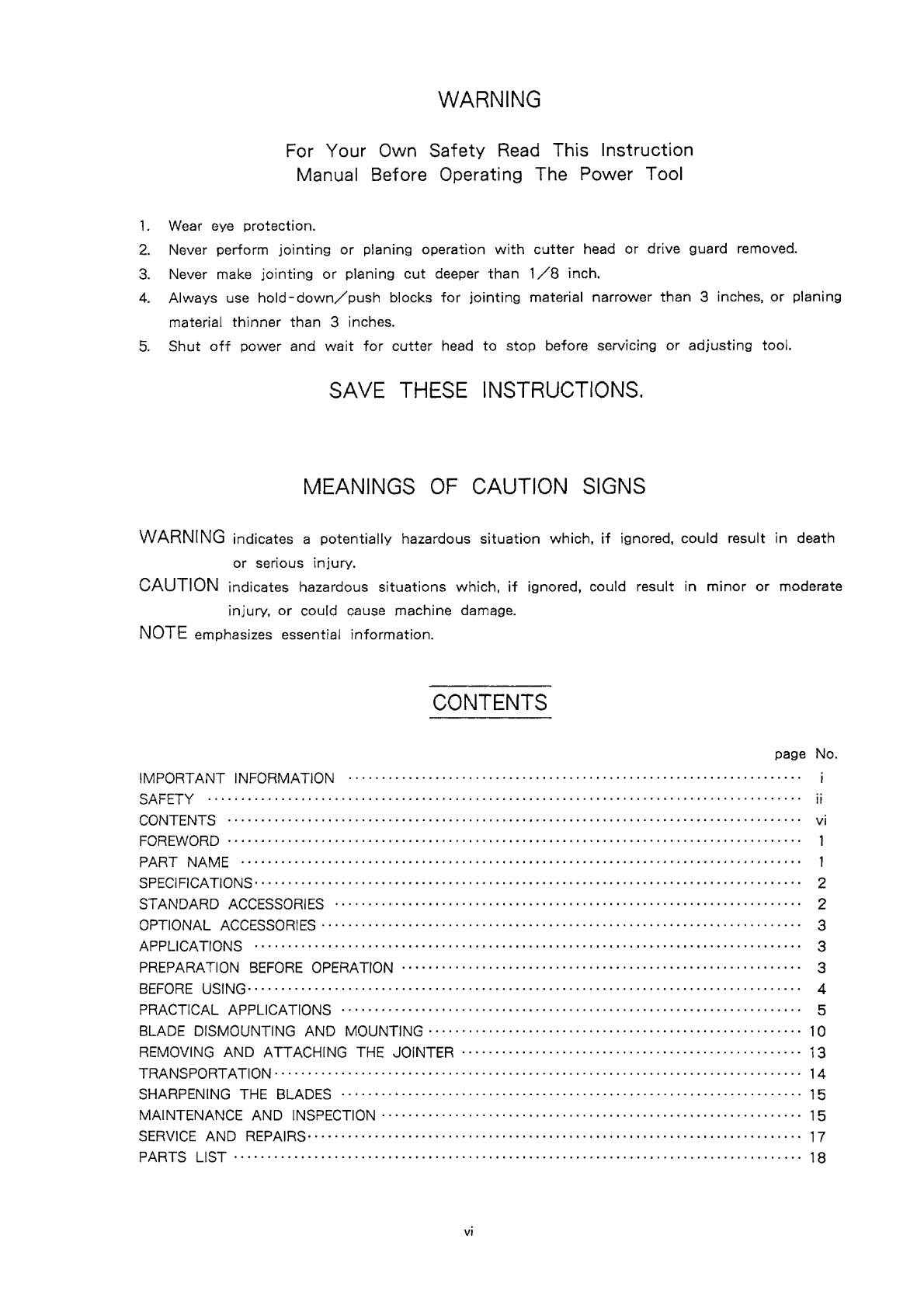

Hitachi P 12RA User manual

Other Hitachi Planer manuals

Hitachi

Hitachi F-30A User manual

Hitachi

Hitachi P 20SF User manual

Hitachi

Hitachi P13F Operator's manual

Hitachi

Hitachi P 20SA2 User manual

Hitachi

Hitachi P14DSL User manual

Hitachi

Hitachi P 20SB User manual

Hitachi

Hitachi P 20DA Manual

Hitachi

Hitachi P 20SA2 User manual

Hitachi

Hitachi F-30A User manual

Hitachi

Hitachi P14DSL User manual

Hitachi

Hitachi P 20SB User manual

Hitachi

Hitachi P 12RA Datasheet

Hitachi

Hitachi P 20SB User manual

Hitachi

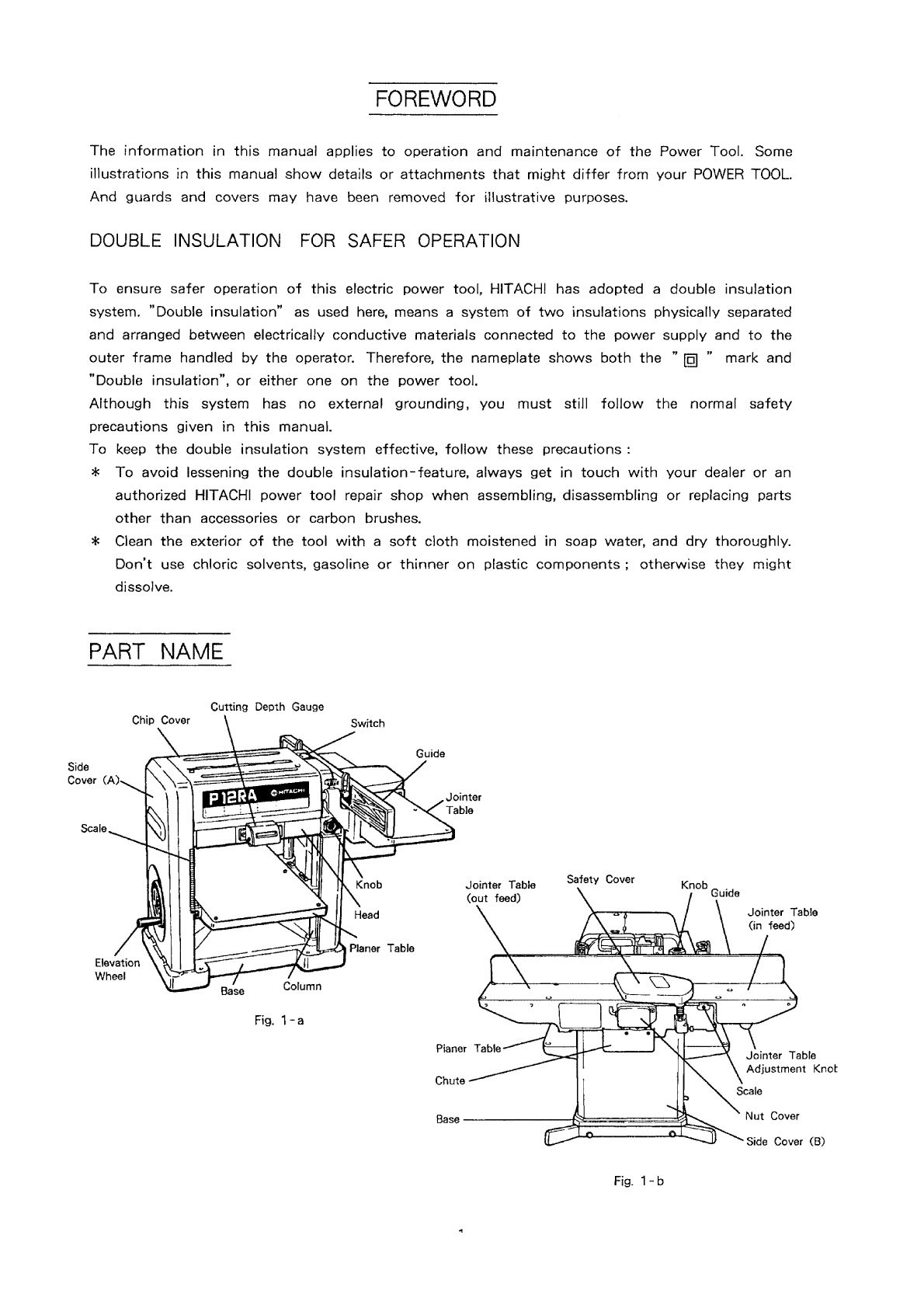

Hitachi P 20SD User manual

Hitachi

Hitachi P 20DA Operator's manual

Hitachi

Hitachi P14DSL User manual

Hitachi

Hitachi P 20SF User manual

Hitachi

Hitachi P 20SB Operator's manual

Hitachi

Hitachi P13F Operator's manual

Hitachi

Hitachi P 20SE User manual

Popular Planer manuals by other brands

Felisatti

Felisatti PF180/1500 operating instructions

DeWalt

DeWalt DW 1150 Operation, adjustmants, maintenance, spare parts

Triton

Triton TRP UL Operating and safety instructions

Melbourne

Melbourne MTC-49407 owner's manual

VARO

VARO POWERplus POW1520 manual

Powermatic

Powermatic 209 Operating instructions and parts manual