hivolt HC52 Series User manual

HC52 Series

© 2019 hivolt.de - Subject to change without notice, errors expected HC52_E 08/2019 Page 1 of 7

hivolt.de GmbH & Co. KG

Oehleckerring 40 ∙D-22419 Hamburg ∙Germany ∙+49 40 537122-0 ∙+49 40 537122-99 ∙[email protected] ∙www.hivolt.de

20kV - STRAIGHT COAXIAL CONNECTOR SERIES

FEATURES

−Rated Voltage 20kVDC

−Recessed contacts

−Coaxial design

−Bayonet Coupling

−Intermateable with industry standard

20kV coaxial connectors

−Completed cable assemblies available

−RoHS compliant

APPLICATIONS

−Instrument High Voltage Connections

−High voltage power supplies / amplifiers

−Medical electronics

−Nuclear instrumentation

−Test and measurement equipment

−High voltage laboratory wiring

−General high voltage testing

20kV reverse polarity coaxial high voltage connectors designed to

minimize the risk of electrical shock to personnel through the use of

recessed contacts. Both the cable connectors and the bulkhead

receptacles have recessed contacts and will stand off the rated voltage in

unmated condition.

The front mount receptacles are hermetically sealed.

The straight crimp cable plug HC52P and the rear mount crimp

receptacles HC52RB are compatible with RG 213 or RG 214 coaxial cable.

The straight cable plug HC52P-HTV30S is compatible with our 30kV rated

HTV-30S-22-2 coaxial cable.

A suitable crimping tool is available on request.

The connectors are RoHS compliant.

The connectors should never be mated or unmated when energized.

Please see the HC51 series for 10kVDC models.

HC52 series connectors are not intermateable with SHV or HC51 series

connectors.

SPECIFICATIONS

Operating voltage: max. 20kVDC (at sea level)

Test voltage: 30kVDC

Impedance: non constant

Insulation resistance: 1000GΩ

Center contact resistance: ≤3mΩ

Outer contact resistance: ≤2mΩ

Operating temperature: -55 to +85°C

Leak rate < 1x10-6 mbar*l/s @ 1bar differential

pressure

(applies to front mount bulkhead

receptacles only)

Ratings listed above apply to clean mated connector pairs in standard atmospheric conditions. When connectors are used

in an adverse environment (such as high temperature, humidity, pollution content, extreme mechanical exposure, etc.) the

connector should be derated. The fitness for use must be proved by extended operational tests.

HC52 Series

© 2019 hivolt.de - Subject to change without notice, errors expected HC52_E 08/2019 Page 2 of 7

hivolt.de GmbH & Co. KG

Oehleckerring 40 ∙D-22419 Hamburg ∙Germany ∙+49 40 537122-0 ∙+49 40 537122-99 ∙[email protected] ∙www.hivolt.de

MODEL OVERVIEW - PLUGS

Part Number

Description

Termination

Center

Contact

Contact Pin

Material/

Plating

Insulator

Material Body

Material/

Plating

Gasket

Material Weight

HC52P-213 /-214

Straight Crimp Cable Plug

Crimp

Beryllium

Copper/

Au over Ni

over Cu

High Density

PE Brass/

Ni over Cu Silicone 51.2g

HC52P-HTV30S

Straight Crimp Cable Plug

Crimp Beryllium

Copper/

Au over Ni

over Cu

High Density

PE Brass/

Ni over Cu Silicone 51.2g

MODEL OVERVIEW - RECEPTACLES

Part Number

Description

Termination

Center

Contact

Contact Pin

Material/

Plating

Insulator

Material Body

Material/

Plating

Gasket

Material Weight

HC52RB-213

Rear Mount Bulkhead

Crimp Receptacle

Crimp Brass/

Au over Ni

over Cu

High Density

PE Brass/

Sn-Zn-Cu

Alloy over

Cu

Silicone

HC52RB-A

Front Mount Bulkhead

Receptacle (long insulator)

Solder Brass/

Au over Ni

over Cu

High Density

PE Brass/

Sn-Zn-Cu

Alloy over

Cu

Silicone 58g

HC52RB-B

Front Mount Bulkhead

Receptacle (short insul.)

Solder Brass/

Au over Ni

over Cu

High Density

PE Brass/

Ni over Cu Silicone 61g

HC52 Series

© 2019 hivolt.de - Subject to change without notice, errors expected HC52_E 08/2019 Page 3 of 7

hivolt.de GmbH & Co. KG

Oehleckerring 40 ∙D-22419 Hamburg ∙Germany ∙+49 40 537122-0 ∙+49 40 537122-99 ∙[email protected] ∙www.hivolt.de

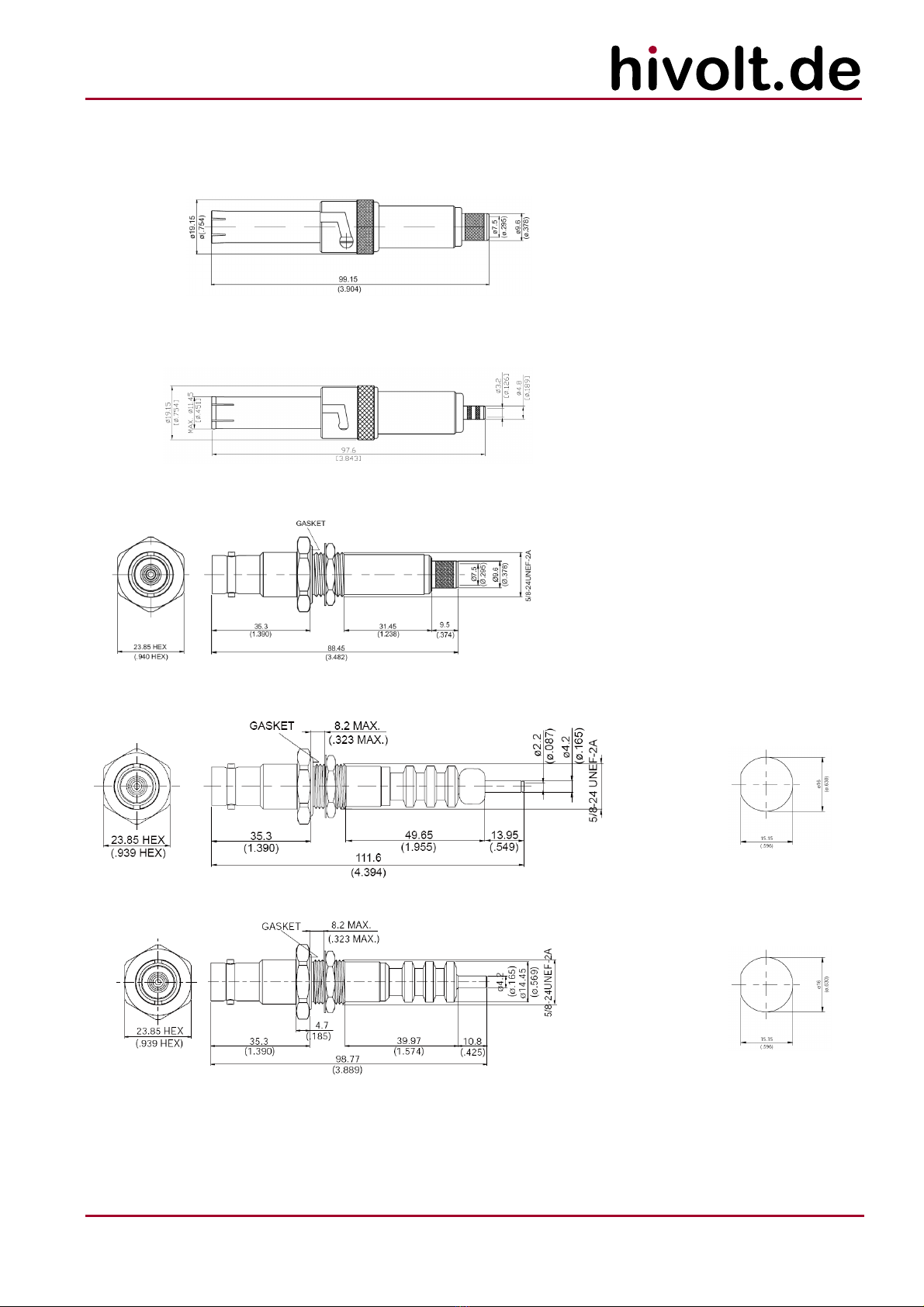

DIMENSIONS

HC52P-213 /-214

HC52P-HTV30S

HC52RB-213

HC52RB-A

PANEL CUT-OUT

HC52RB-B

PANEL CUT-OUT

−All dimensions are in mm (inch); drawings not to scale.

−All values and dimensions without given tolerances are nominal.

HC52 Series

© 2019 hivolt.de - Subject to change without notice, errors expected HC52_E 08/2019 Page 4 of 7

hivolt.de GmbH & Co. KG

Oehleckerring 40 ∙D-22419 Hamburg ∙Germany ∙+49 40 537122-0 ∙+49 40 537122-99 ∙[email protected] ∙www.hivolt.de

ORDERING INFORMATION

20kV Straight Crimp Cable Plug (female) for RG 213 HC52P-213

20kV Straight Crimp Cable Plug (female) for RG 214 HC52P-214

20kV Straight Crimp Cable Plug (female) for HTV-30S-22-2 HC52P-HTV30S

20kV Rear Mount Bulkhead Crimp Receptacle (male) for RG 213 HC52RB-213

20kV Front Mount Bulkhead Receptacle (male, long insulator) HC52RB-A

20kV Front Mount Bulkhead Receptacle (male, short insulator) HC52RB-B

CRIMP TOOLS

Ergonomic blank crimp tool frame HC-CR-2

suitable for crimp inserts HC-CR-DIE-A, HC-CR-DIE-B, HC-CR-DIE-C

Crimp Insert Hex 5.5mm, 5.9mm, Square 0.98mm, 1.6mm, 2.4mm HC-CR-DIE-B

Crimp Insert Hex 2.55mm, 3.3mm, 10.7mm, Square 1.6mm, 2.4mm HC-CR-DIE-C

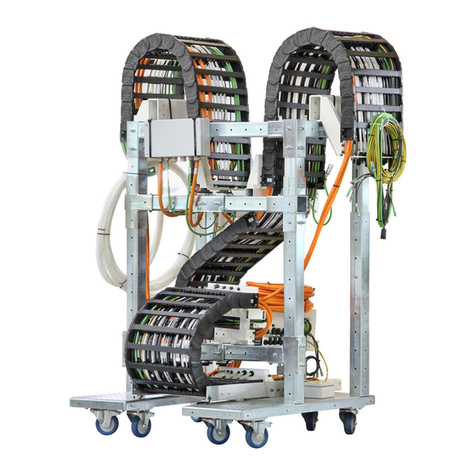

Bespoke ready-to-use high voltage cable assemblies based on different high voltage cable types are available. The cable

assemblies are fully tested. Please contact hivolt.de for details.

Examples:

Cable: HTV-30S-22-2; Length: 2m; HC52P-HTV30S plug assembled on both ends HCA-020-H52C-002-H52C-T

Cable: RG 213; Length: 10m; HC52P-213 plug assembled on one end, HCA-020-H52A-010-H52R-X

HC52RB-213 receptacle on the other end

Disclaimer

The information given in this data sheet is technical data, not assured product characteristics. It has been carefully checked and is believed to be accurate; however, no responsibility is

assumed for inaccuracies. The user has to ensure by adequate tests that the product is suitable for his application regarding safety and technical aspects.

hivolt.de GmbH & Co. KG does not assume any liability arising out of the application or use of any product described.

Safety Advice

Design, installation and inspection of machinery and devices carrying high voltage require accordingly trained and qualified personnel. Appropriate safety rules and directives must be

complied with.

Improper handling of high voltage can mean severe injuries or death and may cause serious collateral damage!

HC52 Series

© 2019 hivolt.de - Subject to change without notice, errors expected HC52_E 08/2019 Page 5 of 7

hivolt.de GmbH & Co. KG

Oehleckerring 40 ∙D-22419 Hamburg ∙Germany ∙+49 40 537122-0 ∙+49 40 537122-99 ∙[email protected] ∙www.hivolt.de

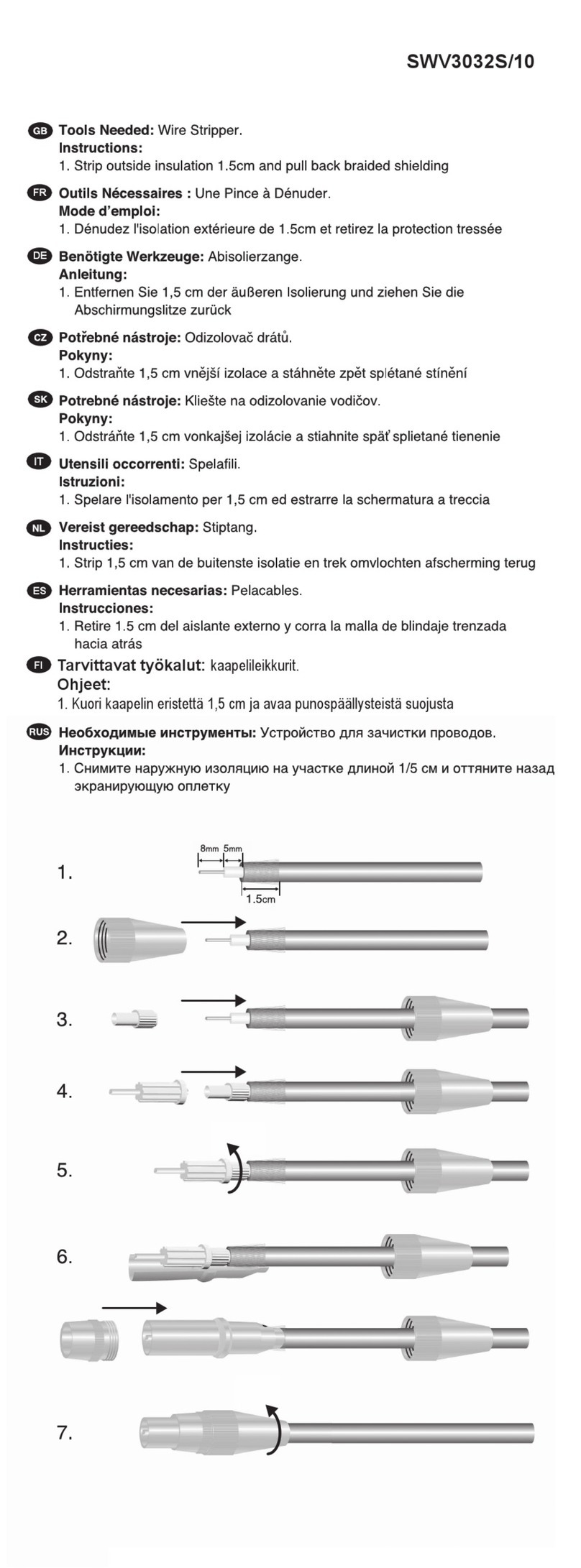

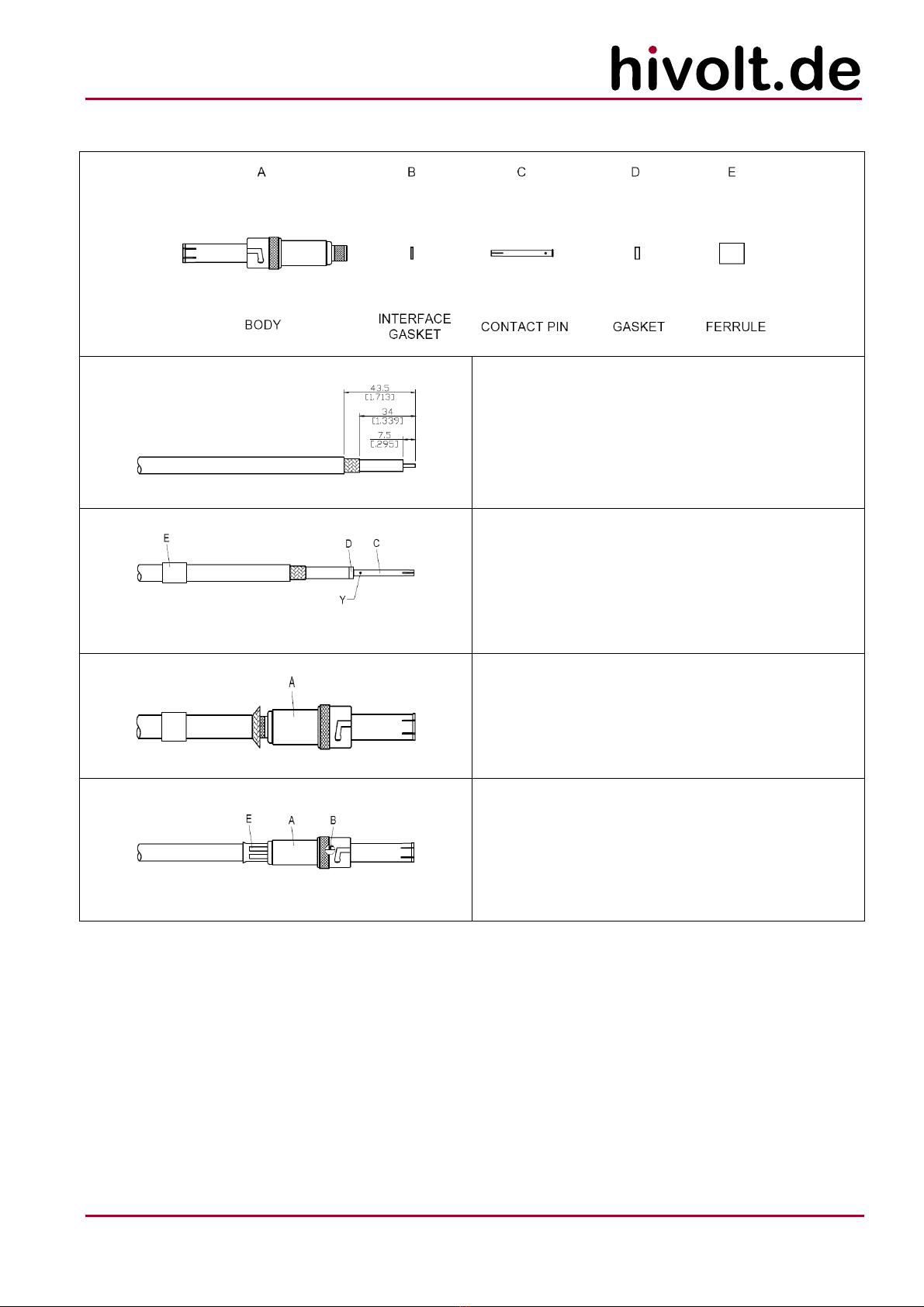

CABLE ASSEMBLY INSTRUCTIONS HC52P-213 AND HC52P-214

Step 1: strip as shown.

Make sure not to scratch the isolation!

Step 2: slide ferrule “E” over cable.

Step 3: put gasket "D" and pin "C" on center conductor and

solder in "Y".

Gasket must be under compression after soldering

is completed.

Step 4: loosen braiding and slide connector "A" in place.

Step 5: slide ferrule "E" towards the connector "A" and

crimp.

Use 10.7mm/0.421" hex crimp die insert

HC-CR-DIE-C.

Step 6: Install interface gasket B over contact pin.

All dimensions are in mm [inch]; drawings not to scale

HC52 Series

© 2019 hivolt.de - Subject to change without notice, errors expected HC52_E 08/2019 Page 6 of 7

hivolt.de GmbH & Co. KG

Oehleckerring 40 ∙D-22419 Hamburg ∙Germany ∙+49 40 537122-0 ∙+49 40 537122-99 ∙[email protected] ∙www.hivolt.de

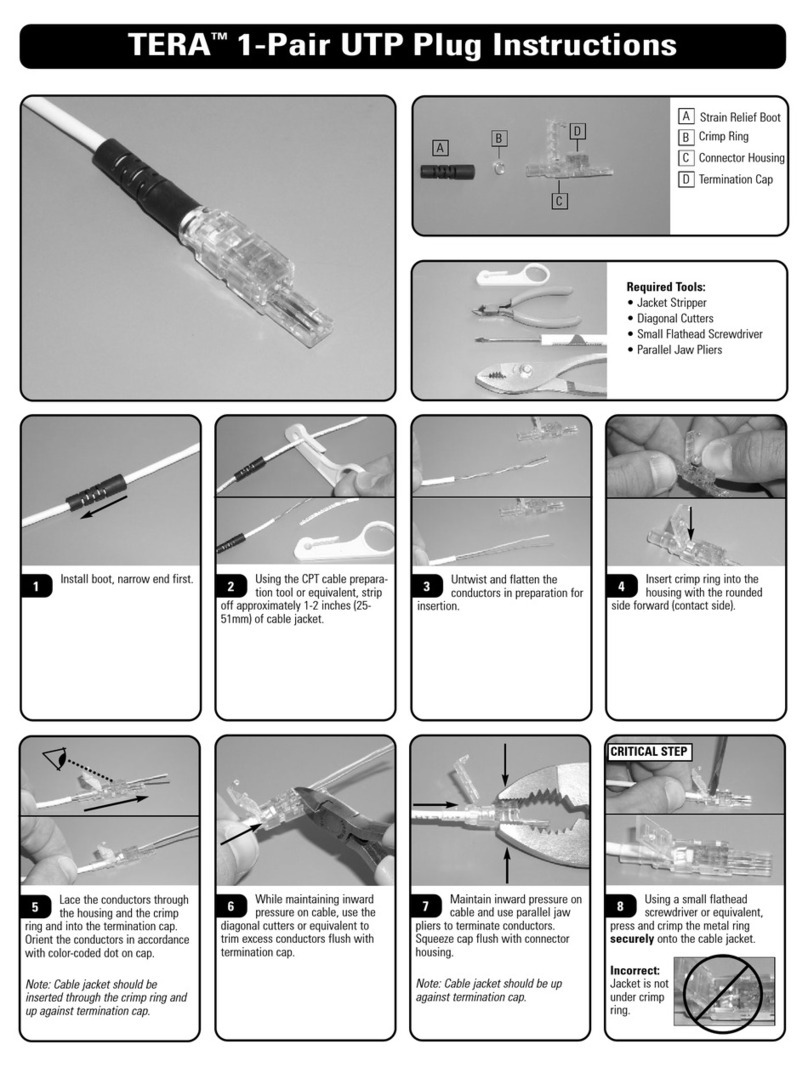

CABLE ASSEMBLY INSTRUCTIONS HC52P-HTV30S

Step 1: strip as shown.

Make sure not to scratch the isolation!

Step 2: slide ferrule "C" over cable.

Step 3: put pin "B" on center conductor and solder in "Y".

Step 4: loosen braiding and slide connector "A" in place.

Step 5: slide ferrule "C" towards the connector "A" and

crimp.

Use 5.9mm/0.232inch hex crimp die insert

HC-CR-DIE-B.

All dimensions are in mm [inch]; drawings not to scale

HC52 Series

© 2019 hivolt.de - Subject to change without notice, errors expected HC52_E 08/2019 Page 7 of 7

hivolt.de GmbH & Co. KG

Oehleckerring 40 ∙D-22419 Hamburg ∙Germany ∙+49 40 537122-0 ∙+49 40 537122-99 ∙[email protected] ∙www.hivolt.de

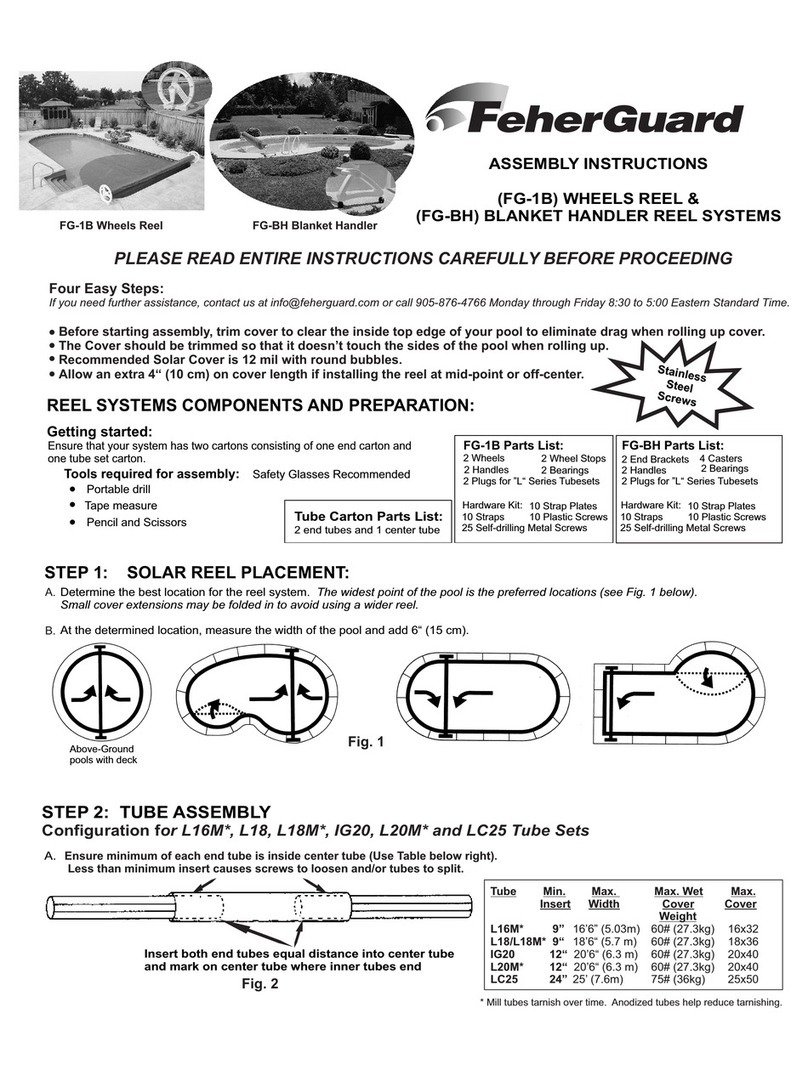

CABLE ASSEMBLY INSTRUCTIONS HC52RB-213

Step 1: strip as shown.

Make sure not to scratch the isolation!

Step 2: slide ferrule”D” over cable.

Step 3: put and gasket "C"and pin "B" on center conductor

and solder in "Y".

Gasket must be under compression after soldering

is competed.

Step 4: loosen braiding and slide connector "A" in place.

Step 5: slide ferrule "D" towards the connector "A" and

crimp.

Use 10.7mm/0.421" hex crimp die insert

HC-CR-DIE-C.

All dimensions are in mm [inch]; drawings not to scale

This manual suits for next models

6

Table of contents

Other hivolt Cables And Connectors manuals