HK Instruments DPI Series User manual

Copyright HK Instruments, Inc. 2017 www.hkinstrumentsinc.com Installation version 2.0 2017

INSTALLATION

INSTRUCTIONS

DIFFERENTIAL PRESSURE SWITCHES

DPI Series

• READ THESE INSTRUCTIONS CAREFULLY BEFORE ATTEMPTING TO

INSTALL, OPERATE OR SERVICE THIS DEVICE.

• Failure to observe safety information and comply with instructions can result in

PERSONAL INJURY, DEATH AND/OR PROPERTY DAMAGE.

• To avoid electrical shock or damage to equipment, disconnect power before

installing or servicing and use only wiring with insulation rated for full device

operating voltage.

• To avoid potential fire and/or explosion do not use in potentially flammable or

explosive atmospheres.

• Retain these instructions for future reference.

• This product, when installed, will be part of an engineered system whose

specifications and performance characteristics are not designed or controlled

by HK Instruments. Review applications and national and local codes to assure

that the installation will be functional and safe. Use only experienced and

knowledgeable technicians to install this device.

Thank you for choosing an HK Instruments DPI Series electronic

differential pressure switch. The DPI Series is intended for use

in commercial environments. It combines the advantages of an

electronic differential pressure switch (on-off relay) and a multi-

functional differential pressure transmitter to meet your job re-

quirements.

The DPI Series is comprised of the DPI1 with bi-directional meas-

urement ranges from ±0.4 to ±2.01 inWC, the DPI10 with meas-

urement ranges from 0.4 to 10.0 inWC.

All DPI Series devices include one relay, display, manual pushbut-

ton auto-zero and span point calibration. Optional features include

a second relay, and NIST standard calibration certificates.

SPECIFICATIONS

Performance

Accuracy (at applied pressure):

±0.7 % (±1.5 % initial)

%/FS from highest pressure range including:

general accuracy, temperature drift, linearity, hysteresis,

and repetition error).

Long term stability:

Typical 1 year

With : ± 0.004 inWC

Without : ± 0.032 inWC

Overpressure:

Proof pressure: 100 inWC

Burst pressure: 120 inWC

Zero point calibration:

Automatic with (-eZ) circuit or

manual via menu

Response time:

0.5–10 sec, selectable via menu

Technical Specifications

Media compatibility:

Dry air or non-aggressive gases

Measuring units:

Pa, kPa, mmWC, inWC, mbar selectable via menu

Measuring element:

Piezoresistive

Environment:

Operating temperature:

Without : 14–122 °F (-10–50 °C)

With : 23−122 °F (-5−50 °C)

Storage temperature: -4–158 °F (-20–70 °C)

Humidity: 0 to 95 % rH, non condensing

Physical

Case:

Dimensions: 3.5” x 3.4” x 1.46”

(89 x 86.5 x 37.1 mm)

Weight: 5.3 oz (150 g)

Mounting: Case: 2 each 3/16” (4.3 mm) holes

Lid: 2 each 3/16” (4.3 mm) holes

Materials: Case: ABS (UL 94 V-0 Approved)

Lid: PC (UL 94 V-1 Approved)

Protection standard: IP54 / NEMA3

Touch sensitive buttons on the lid:

Menu, Back, OK, down arrow, up arrow

Display:

3 1/2 digit LCD backlit display

2-line display (12 characters/line)

Line 1: Active measurement

Line 2: Units

Size: 1.81” W x 0.57” H

(46.0 W x 14.5 H mm)

Electrical connections:

n/Out:

Terminal block (24 V, GND, 0–10 V)

Wire: 12–24 AWG (0.2–1.5 mm2)

Relay 1:

Terminal block (NC, COM, NO)

Wire: 12–24 AWG (0.2–1.5 mm2)

Relay 2:

Terminal block (NC, COM, NO)

Wire: 12–24 AWG (0.2–1.5 mm2)

Cable entries:

Strain relief: M16 & M20

Knockout ø: 0.625” (16 mm)

Knockout ø: 0.787” (20 mm)

Pressure fittings:

3/16” ø (5.2 mm) barbed brass

+ High pressure

– Low pressure

Electrical

Circuit: 3-wire (24 V, GND, 0–10)

Input:

Without : 21–35 VDC/ 24 VAC, ±10 %

With : 24 VAC or VDC, ±10 %

Output:

DPI: 0–10 V

Relay 1: 250 VAC / 30 VDC / 6 A

Relay 2: 250 VAC / 30 VDC / 6 A

Resistance minimum: 1 kΩ

Current consumption:

35 mA + relays (7 mA each) + eZ circuit (20 mA)

+0–10 V output (10 mA)

Conformance

Meets requirements for CE marking:

EMC Directive 2014/30/EU

RoHS Directive 2011/65/EU

Meets safety requirements for electrical equipment for

measurement, control, and laboratory use:

ETL marking, standard IEC61010-1.

Product is tested and meets the NRTL product approval

requirements.

INTRODUCTION WARNING

AVERTISSEMENT

• LISEZ ATTENTIVEMENT CES INSTRUCTIONS AVANT DE PROCÉDER À

L’INSTALLATION, LA MISE EN SERVICE OU L’ENTRETIEN DE CET APPAREIL.

• Le non-respect des informations et instructions de sécurité peut entraîner DES

DOMMAGES CORPORELS, LA MORT ET/OU DES DÉGÂTS MATÉRIELS.

• Afin d’éviter les chocs électriques et les dommages matériels, déconnectez

l’alimentation électrique avant l’installation ou l’entretien, et utilisez uniquement du

câblage avec isolement assigné pour une tension d’alimentation optimale.

• Afin de prévenir les risques d’incendie et/ou d’explosion, n’utilisez pas l’appareil

dans des environnements potentiellement inflammables ou explosifs.

• Conservez ces instructions à titre de référence.

• Une fois installé, ce produit fera partie d’un système technique dont les

spécifications et les caractéristiques de performance ne sont ni conçues ni

contrôlées par HK Instruments. Consultez les applications et les codes nationaux

et locaux pour garantir le fonctionnement correct et sûr de l’installation. Ne faites

appel qu’à des techniciens expérimentés et compétents pour installer cet appareil.

APPLICATIONS

DPI series devices are commonly used in HVAC/R systems for:

• fan, blower and filter monitoring

• staircase pressure monitoring and alarm

• pressure monitoring in cleanrooms

• boiler pressure monitoring and alarm

RoHS 2

2011/65/EU

4002576

Conforms to ANSI/UL Std 61010

Certified to CAN/CSA Std C22.2 No 61010

COMPANY WITH

MANAGEMENT SYSTEM

CERTIFIED BY DNV GL

= ISO 9001 = ISO 14001 =

Copyright HK Instruments, Inc. 2017 www.hkinstrumentsinc.com Installation version 2.0 2017

SCHEMATICS

DIMENSIONAL DRAWINGS

Figure 1a - Surface mounting

Figure 1b - Mounting orientation

Figure 1c - Application connections

24 V GND 0–10 V

Terminal block Terminal block(s) for relay(s)

NC COM NO NC COM NO

1.46 (37.1)

3.5 (89.0)

3.4 (86.5)

2.93 (74.5)

2.54 (64.5)

2.07 (52.5)

0.169 (4.3)

inch (mm)

YES NO NO

Static pressure Filter/Damper

monitoring

Fan/Blower

monitoring

Not

connected

INSTALLATION

1) Mount the device in the desired location (see step 1).

2) Open the lid and route the cable(s) through the strain relief(s) and

connect the wires to the terminal block(s) (see step 2).

3) The device is now ready for configuration.

WARNING! Apply power only after the device is properly wired.

STEP 1: MOUNTING THE DEVICE

1) Select the mounting location (duct, wall, panel).

2) Use the device as a template and mark the screw holes.

3) Mount with appropriate screws.

INSTALLATION

Copyright HK Instruments, Inc. 2017 www.hkinstrumentsinc.com Installation version 2.0 2017

STEP 3: CONFIGURATION

1) Select the desired measurement unit.

2) Select the desired measurement range.

3) Select the desired response time.

4) Configure the relay(s).

5) Zero the device.

6) Calibrate the span point.

7) Connect the pressure tubes. Connect positive pressure to port

labeled “+” and negative pressure to port “-”.

The device is now ready to be used.

Figure 2b - Wiring diagram relay(s)

NC

COM

NO

Relay 1

NC

COM

NO

Relay 2

CONFIGURATION CONTINUED

WIRING DIAGRAMS CONTINUED

STEP 2: WIRING DIAGRAMS

For CE compliance, a properly grounded shielding cable is required.

1) Unscrew the strain relief and route the cable(s). Use separate

strain relief for the 0–10 V output cable and the relay cable(s).

2) Connect the wires as shown in figure 2a and 2b.

3) Tighten the strain relief.

Figure 2a - Wiring diagram 0–10 V output

24 V

GND

Pout

Power supply

24 VDC / 24 VAC

+

Output 0...10 V

V

+

With the MENU button you can enter the menu by pressing the button for

3 seconds. You can exit the menu without making any

changes.

With the BACK button you can return without making changes.

With the OK button you can open new options or conrm changes and return

to previous display.

With the buttons you can scroll the menus.

/

Pa, kPa, mmH2O, inchWC, mbar

Pressure range selection

Response time

Relay menu(s)

Zero point calibration

Response time

High point calibration menu

High point calibration

Reset high point calibration

Relay activation menu

Relay setpoint

Relay hysteresis 0–5 % of range

Relay activation on increasing pressure

Relay activation on decreasing pressure

Copyright HK Instruments, Inc. 2017 www.hkinstrumentsinc.com Installation version 2.0 2017

HK Instruments, Inc. (HK)

(a) WARRANTY COVERAGE: HK warrants to the original end user of the Products that

the Products will, at the date of initial purchase, meet the applicable specification for

such Products (as described by HK in its product literature) and, under normal use and

service, will be free from any defects in materials or manufacture for (a) one (1) year

from date of sale to end user for electromechanical Products and (b) five (5) years from

date of manufacture for electronic Products.

(b) NO WARRANTY OF PRODUCT SUITABILITY: Neither HK nor the manufacturer of

the Products to be sold hereunder (“Manufacturer”) makes any warranty that Products

are suitable for a particular purpose, application or design. Many states and localities

have differing codes or regulations governing the installation and/or use of HK

products. HK does not guarantee compliance with such codes or regulations; the end

user is solely responsible for safe and correct installation and use of the Products and

for compliance with such codes and regulations.

(c) EXCLUSION OF IMPLIED WARRANTIES: THE WARRANTY HEREIN IS THE

ONLY WARRANTY APPLICABLE TO THE PRODUCTS AND EXCLUDES ALL OTHER

WARRANTIES, INCLUDING ANY WARRANTY OF MERCHANTABILITY OR FITNESS

FOR A PARTICULAR PURPOSE, AND ANY IMPLIED WARRANTY ARISING FROM

COURSE OF DEALING OR USAGE OF TRADE.

(d) REMEDIES FOR NON-CONFORMITY OR BREACH OF WARRANTY: If the Product

purchased does not conform to the applicable warranty, HK will provide, at its

option, one of the following remedies: (1) repair of the non-conforming Product, (2)

replacement with a conforming Product, or (3) refund of the original purchase price.

THESE REMEDIES SHALL BE THE EXCLUSIVE AND SOLE REMEDY for any breach

of warranty. HK and Manufacturer have no other responsibility or liability for breach of

warranty or otherwise.

(e) LIMITATION OF LIABILITY: NEITHER HK NOR MANUFACTURER WILL BE LIABLE

FOR ANY INCIDENTAL, SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES

UNDER ANY CIRCUMSTANCE, INCLUDING WITHOUT LIMITATION ANY DEFECT IN

THE PRODUCT PURCHASED.

(f) FURTHER LIMITATIONS: The warranty herein does not cover damage caused

by lightning, flood or other natural phenomenon; normal wear and tear; accident,

improper or careless handling, abnormal use, overloading, improper storage or abuse;

incorrect installation, care or reconstruction; or alteration, calibration, reconfiguration,

maintenance or installation work done by unqualified personnel. Should Manufacturer

alter the structure of any Product in the future, HK and Manufacturer shall not be

obligated to make comparable changes to Products already purchased. HK will give

a new warranty for Products being replaced or repaired within the warranty period,

however only to the expiration of the original Product’s warranty period. The warranty

includes the repair of a defective part or device, or if needed, a new part or device, but

no other costs except as otherwise stated in the HK Distributor Terms and Conditions.

The parts left over from installation should be

recycled according to your local instructions.

Decommissioned devices should be taken to

a recycling site that specializes in electronic

waste.

RECYCLING/DISPOSAL

WARRANTY POLICY

STEP 4: ZEROING THE DEVICE

To zero the device two options are available:

1) Manual zero point calibration

2) function

Does my transmitter have an function? See the product label.

If it shows -eZ in the model number, then you have the func-

tion.

1) Manual zero point calibration

NOTE: Supply voltage must be connected at least one hour prior to

zero point adjustment.

a) Disconnect both pressure tubes from the pressure ports labeled

+ and –.

b) Push both arrow buttons on top of the lid shortly or go to

configuration menu and select “Zero”.

c) The zeroing of the device will proceed automatically when the

green led on top of the lid turns off and “Zero” text followed by

a counter from 3 to 0 seconds appears on the display. The

zeroing is complete when the green led turns on again.

d) Reinstall the pressure tubes ensuring that the High pressure tube

is connected to the port labeled +, and the Low pressure tube is

connected to the port labeled −.

NOTE: The zero point should be calibrated via manual autozero, one

hour after installation and at least every 12 months during normal

operations.

2) function

If the device includes the optional circuit, no action is re-

quired.

(-eZ) is an autozero function in the form of an automatic zero-

ing circuit built into the PCB board. The function electronically

adjusts the transmitter zero at predetermined time intervals (every 10

minutes). The function eliminates all output signal drift due to thermal,

electronic or mechanical effects, as well as the need for technicians

to remove high and low pressure tubes when performing initial or pe-

riodic transmitter zero point calibration. The adjustment takes

4 seconds after which the device returns to its normal measuring

mode. During the 4 second adjustment period, the output and display

values will freeze to the latest measured value.

Transmitters equipped with the function are virtually mainte-

nance free.

Other HK Instruments Switch manuals

Popular Switch manuals by other brands

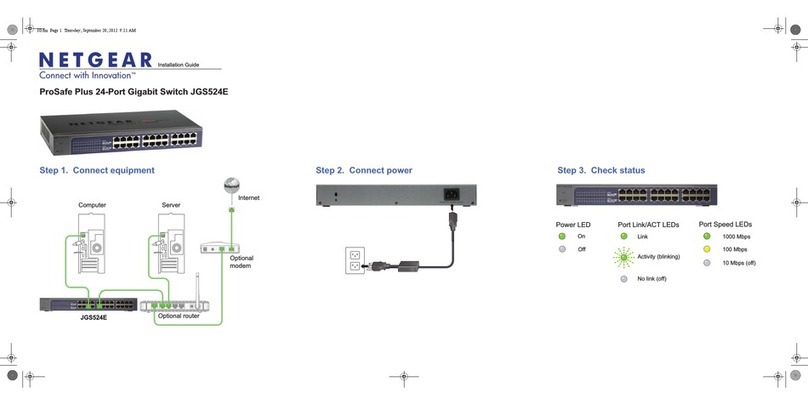

NETGEAR

NETGEAR ProSafe Plus JGS524E installation guide

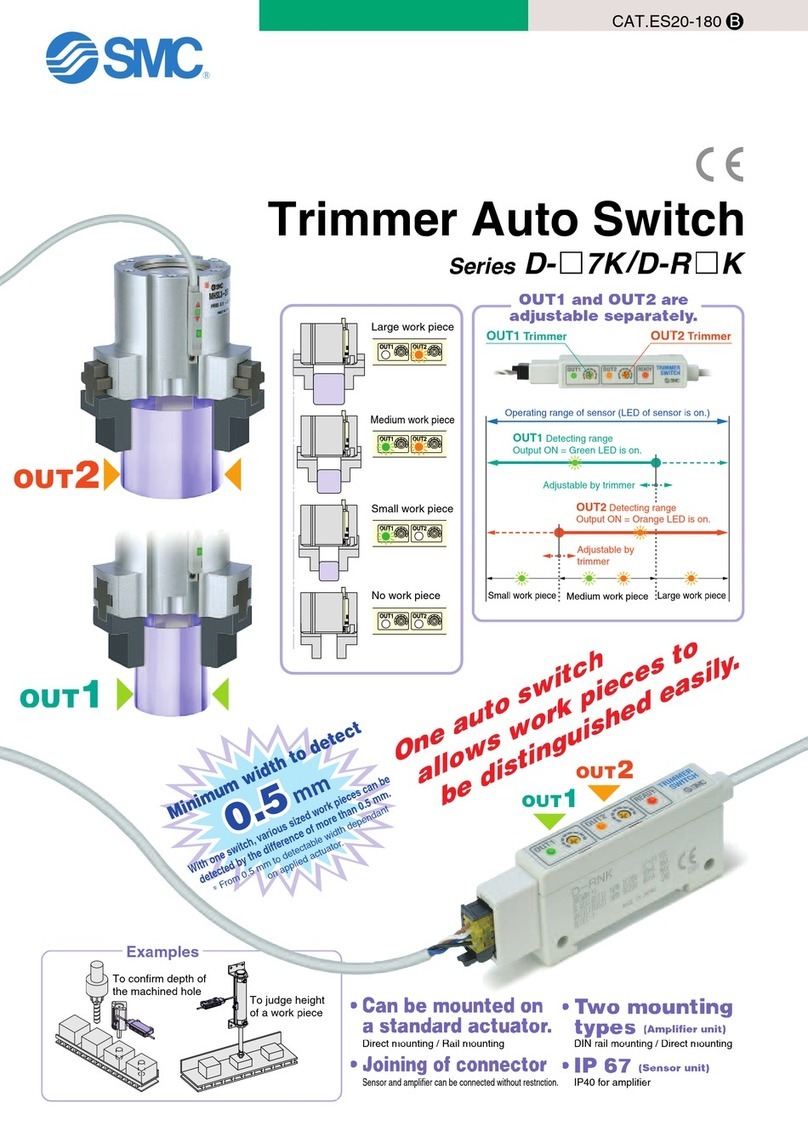

SMC Networks

SMC Networks D-F7K Safety instructions

3Com

3Com SuperStack 3C17300 Implementation guide

StarTech.com

StarTech.com STARVIEW SV431DVIUAHR user guide

Siemens

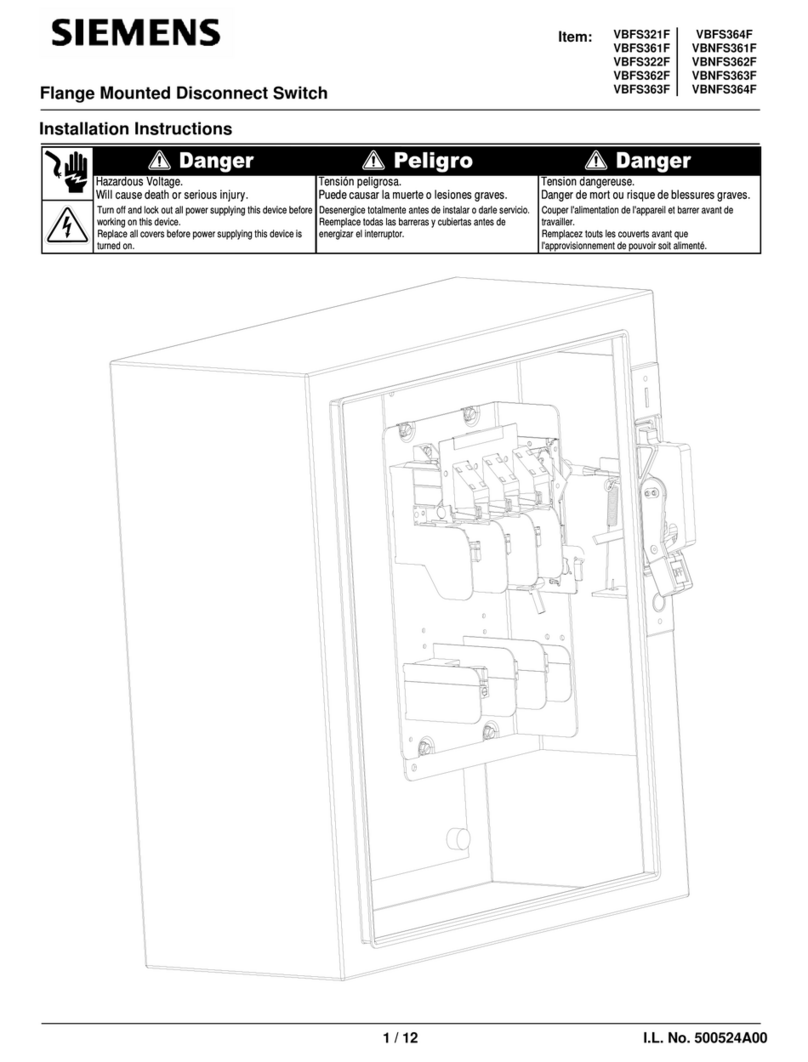

Siemens VBFS321F installation instructions

Aguilar

Aguilar aguilar OBP-3 Wiring diagram