Back page 2

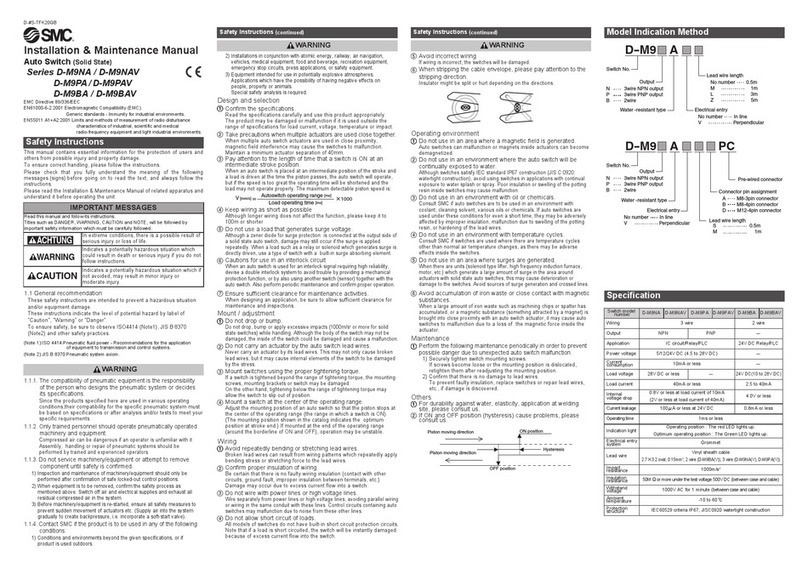

Trimmer Auto Switch Precautions 1

Be sure to read this before handling. For Auto Switch Common Precautions,

refer to “Precautions for Handling Pneumatic Devices” (M-03-E3A).

1. Confirm the specifications.

Read the specifications carefully and use this product appro-

priately. The product may be damaged or malfunction if it is

used outside the range of specifications of current load, volt-

age, temperature or impact.

2. Take precautions when multiple cylinders

are used close together.

When multiple auto switch cylinders are used in close proximi-

ty, magnetic field interference may cause the switches to mal-

function. Maintain a minimum cylinder separation of 40 mm.

(When the allowable separation is indicated for each cylinder

series, use the specified value.)

3. Keep the wiring as short as possible.

Use a wire 3 m or shorter between the sensor and amplifier.

Although wire length of power supply/output cable should not

affect switch function, use a wire 100 m or shorter.

4. Take precautions for the internal voltage

drop of the switch.

5. Pay attention to leakage current.

Although a varistor for surge protection is connected at the

output side of a trimmer auto switch, damage may still occur if

the surge is applied repeatedly. When a load, such as a relay,

solenoid, which generates surge is directly driven, use a type

of switch with a built-in surge absorbing element.

6. Cautions for use in an interlock circuit.

When an auto switch is used for an interlock signal requiring high

reliability, devise a double interlock system to avoid trouble by

providing a mechanical protection function, or by also using an-

other switch (sensor) together with the trimmer auto switch. Also

perform periodic maintenance and confirm proper operation.

7. Ensure sufficient clearance for maintenance

activities.

When designing an application, be sure to allow sufficient

clearance for maintenance and inspections.

Design and Selection

Warning

1. Do not drop or bump.

Do not drop, bump or apply excessive impacts (980 m/s2or

more for sensor unit and 98 m/s2or more for amplifier unit)

while handling.

Although the body of the switch may not be damaged, the in-

side of the switch could be damaged and cause a malfunction.

2. Do not carry a cylinder by the auto switch

lead wires.

Never carry a cylinder by its lead wires. This may not only

break the lead wires, but it may cause internal elements of the

switch to be damaged by the stress.

3. Mount switches using the proper tightening

torque.

When a switch is tightened beyond the range of tightening tor-

que, the mounting screws, mounting bracket or switch may be

damaged. On the other hand, tightening below the range of

tightening torque may allow the switch to slip out of position.

Mounting and Adjustment

Warning

1. Avoid repeatedly bending or stretching lead

wires.

Broken lead wires will result from applying bending stress or

stretching forces to the lead wires.

2. Be sure to connect the connector for sensor

to the amplifier before power is applied.

3. Confirm proper insulation of wiring.

Be certain that there is no faulty wiring insulation (contact with

other circuits, ground fault, improper insulation between termi-

nals, etc.). Damage may occur due to excess current flow into

a switch.

4. Do not wire with power lines or high voltage

lines.

Wire separately from power lines or high voltage lines, avoid-

ing parallel wiring or wiring in the same conduit with these

lines. Control circuits, including auto switches, may malfunc-

tion due to noise from these other lines.

5. Do not allow short circuit of loads.

Output is automatically stopped when the protection circuit is

working, as the output unit registers any excess current flow,

if loads are short circuited. Should this occur, shut off the

power supply, remove the cause of this excess current flow

and switch on the power again. Take special care to avoid re-

verse wiring between the power supply line (brown) and the

output line (black, white).

6. Avoid incorrect wiring.

If the connections are reversed (power supply line + and pow-

er supply line –), the switch will be protected by a protection

circuit. However, if the power supply line (–) is connected to

the black, white wire, the switch will be damaged.

Wiring

Warning

Operating Environment

1. Never use in an atmosphere with explosive

gases.

The structure of trimmer auto switches is not designed to pre-

vent explosion. Never use in an atmosphere with an explosive

gas since this may cause a serious explosion.

2. Do not use in an area where a magnetic field

is generated.

Trimmer auto switches will malfunction or magnets inside cyl-

inders will become demagnetized.

3. Do not use in an environment where the

trimmer auto switch will be continually ex-

posed to water.

Although the sensor units of trimmer auto switches satisfy the

IEC standard IP67 structure (JIS C0920: waterproof con-

struction), do not use trimmer auto switches in applications

where continually exposed to water splash or spray. Poor in-

sulation or swelling of the potting resin inside switches may

cause malfunction.

(Amplifier part D-RNK and RPK: IP40)

Warning