CommPro

Limited Warranty

CommPro warrants its CommPro-Series Reverse Osmosis system to be free from defects in

materials and workmanship under normal use within the operating parameters

listed below. For a period of one year from the date of purchase CommPro will repair or replace

any part of the Reverse Osmosis System with the exception of the lters, membrane and

battery.

Conditions of Warranty

The above warranty shall not apply to any part of the CommPro Reverse Osmosis System that

is damaged because of neglect, misuse, alteration, accident, misapplication, physical damage,

fouling, and/or scaling of the membrane by minerals, bacterial attack, sediment or damage

caused by re, freezing, hot water, or an Act of God.

CommPro assumes no warranty liability in connection with this Reverse Osmosis System other

than as specied herein. CommPro shall not be liable for consequential damages of any kind or

nature due to the use of CommPro products.

Warranty Service

Warranty service will be provided by CommPro under the following conditions:

1) Contact your local CommPro dealer who will obtain return authorization instructions from

CommPro.

2) Ship the unit or part freight prepaid to CommPro for warranty evaluation or service. Unit

must be returned in the original carton or packaged to prevent possible damage. Systems or

parts covered under the warranty shall be repaired (or, at our option replaced) and returned

without charge.

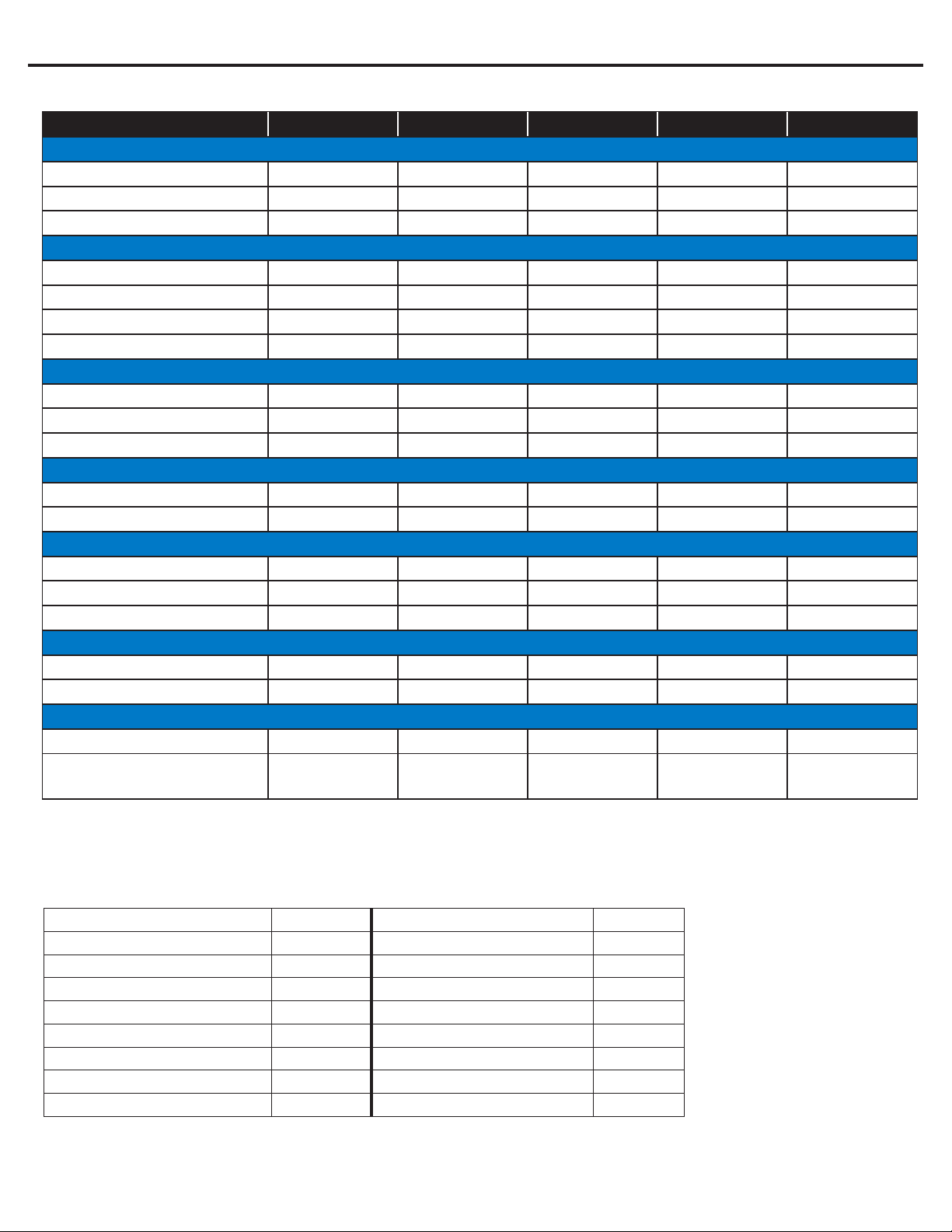

Turbidity < 1.0 net turbidity (NTU)

Conditions for Operation of TFC - Thin Film Composite Membrane

Used in the CommPro-Series

Source Water Supply - TFC Chemical Parameters - TFC

Community / Private Bacteriologically Safe Hardness (CaCo3)< 1 GPG

45 / 85 psiSystem Pressure min/max Iron (Fe) < 0.1 mg/L

Temperature 40º / 85º F Manganese (Mn) < 0.05 mg/L

pH Range 3.0 to 11.0 Hydrogen Sulde (H2S) 0.00 mg/L

Maximum supply TDS level 2000 mg/L Operating Limits

Maximum Pressure 150 PSI

(16)

Water Industries warrants its CommPro-Series Reverse Osmosis system to be free from

defects in materials and workmanship under normal use within the operating parameters

listed below. For a period of one year from the date of purchase, Water Industries will

repair or replace any part of the Reverse Osmosis System except the filters, membrane,

or battery.

Conditions of Warranty

The above warranty shall not apply to any part of the CommPro Reverse Osmosis System

that is damaged because of neglect, misuse, alteration, accident, misapplication, physical

damage, fouling, and/or scaling of the membrane by minerals, bacterial attack, sediment

or damage caused by fire, freezing, hot water, or an Act of God.

CommPro assumes no warranty liability in connection with this Reverse Osmosis System

other than as specified herein. Water Industries shall not be liable for consequential dam-

ages due to the use of CommPro products.

Warranty Service

Warranty service will be provided CommPro under the following conditions:

1. Contact your local Water Industries dealer, who will obtain return authorization instruc-

tions from CommPro.

2. Ship the unit or part freight prepaid to Water Industries Warehouse for warranty eval-

uation or service. The unit must be returned in the original carton or packaged to

prevent possible damage. Systems or parts covered under warranty shall be repaired

(or, at our option, replaced) and returned without charge.