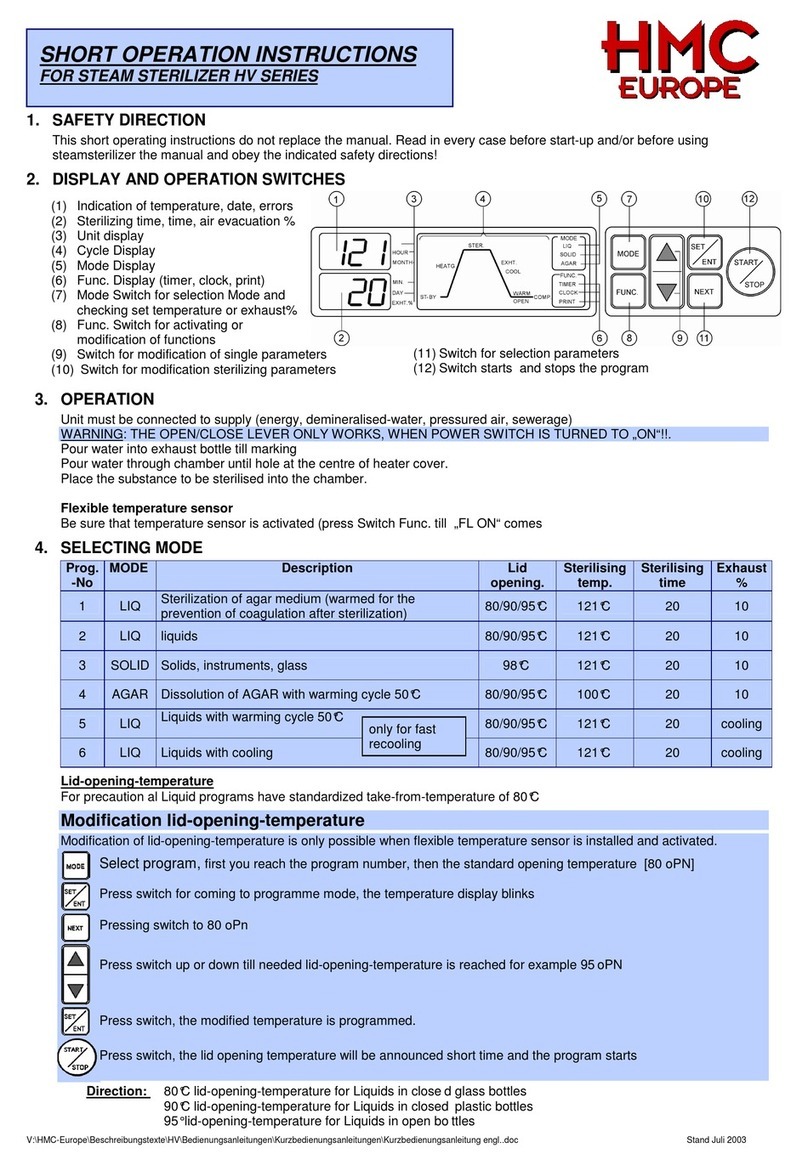

HMC HG-50 User manual

This manual suits for next models

1

Table of contents

Other HMC Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

Harvard Bioscience

Harvard Bioscience DSI Buxco E-cigarette, Vapor, & Tobacco (EVT) Smoke... Application guide

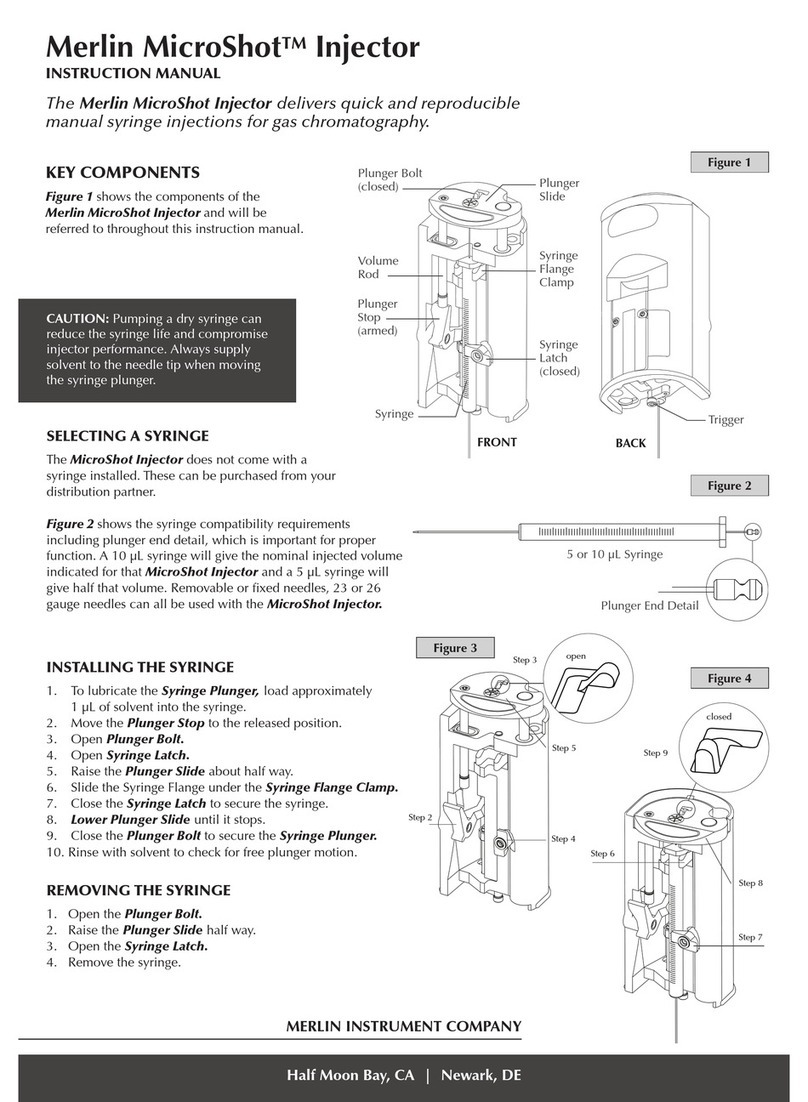

Merlin Instrument Company

Merlin Instrument Company Merlin MicroShot instruction manual

Sutter Instrument

Sutter Instrument Lambda DG-4 Operation manual

Fotric

Fotric 326 Quick start manual

Agilent Technologies

Agilent Technologies 6890 Series Site preparation and installation manual

Omni

Omni 4000 Series Operation & maintenance guide

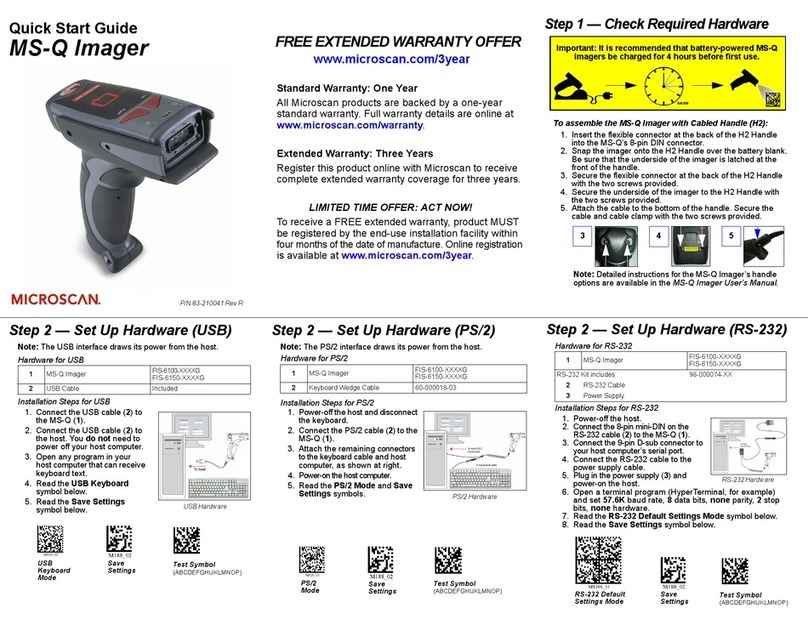

Microscan

Microscan MS-Q quick start guide

cytiva

cytiva FineLINE Pilot 35 column operating instructions

MedKlinn

MedKlinn PRO Series operating manual

Thermo Scientific

Thermo Scientific 88881-003 user manual

Olympus

Olympus SZX-RFL2 instructions

Thermo Scientific

Thermo Scientific Sorvall ST 16 instruction manual

Labnet

Labnet D0100 instruction manual

Azure

Azure Ao Absorbance user manual

ThermoFisher Scientific

ThermoFisher Scientific MiniAmp Installation, use and maintenance guide

Labnet

Labnet Spectrafuge C1301 operating instructions

Optika Italy

Optika Italy B-60 Series instruction manual

Agilent Technologies

Agilent Technologies InfinityLab LC Series user manual