2

Contents

Contents ....................................................................................................................2

1. General Description..............................................................................................4

1.1. Detection principle........................................................................................................................ 4

2. Installing the detector...........................................................................................5

2.1. Siting.............................................................................................................................................. 5

2.2. Mounting and removing the detector.......................................................................................... 6

2.3. Opening the detector cover........................................................................................................... 7

2.4. Installation.................................................................................................................................... 7

2.4.1. Installation option ................................................................................................................. 7

2.4.2. Installation procedure ........................................................................................................... 8

2.5. Closing the detector cover.......................................................................................................... 11

2.6. Adjustment procedure ................................................................................................................ 11

2.6.1. Alignment adjustment......................................................................................................... 11

2.6.2 Setting the Sensitivity & Switches for Operation .............................................................. 12

2.6.3. Signal strength adjustment ................................................................................................ 13

2.7. Sensitivity check procedure ....................................................................................................... 14

3. Maintenance........................................................................................................15

3.1. General ........................................................................................................................................ 15

3.2. Visual check ................................................................................................................................ 15

3.3. Operation checks......................................................................................................................... 15

3.4. Precautions for insulation resistance checking ........................................................................15

3.5. Re-initialisation after cleaning or re-adjustment..................................................................... 15

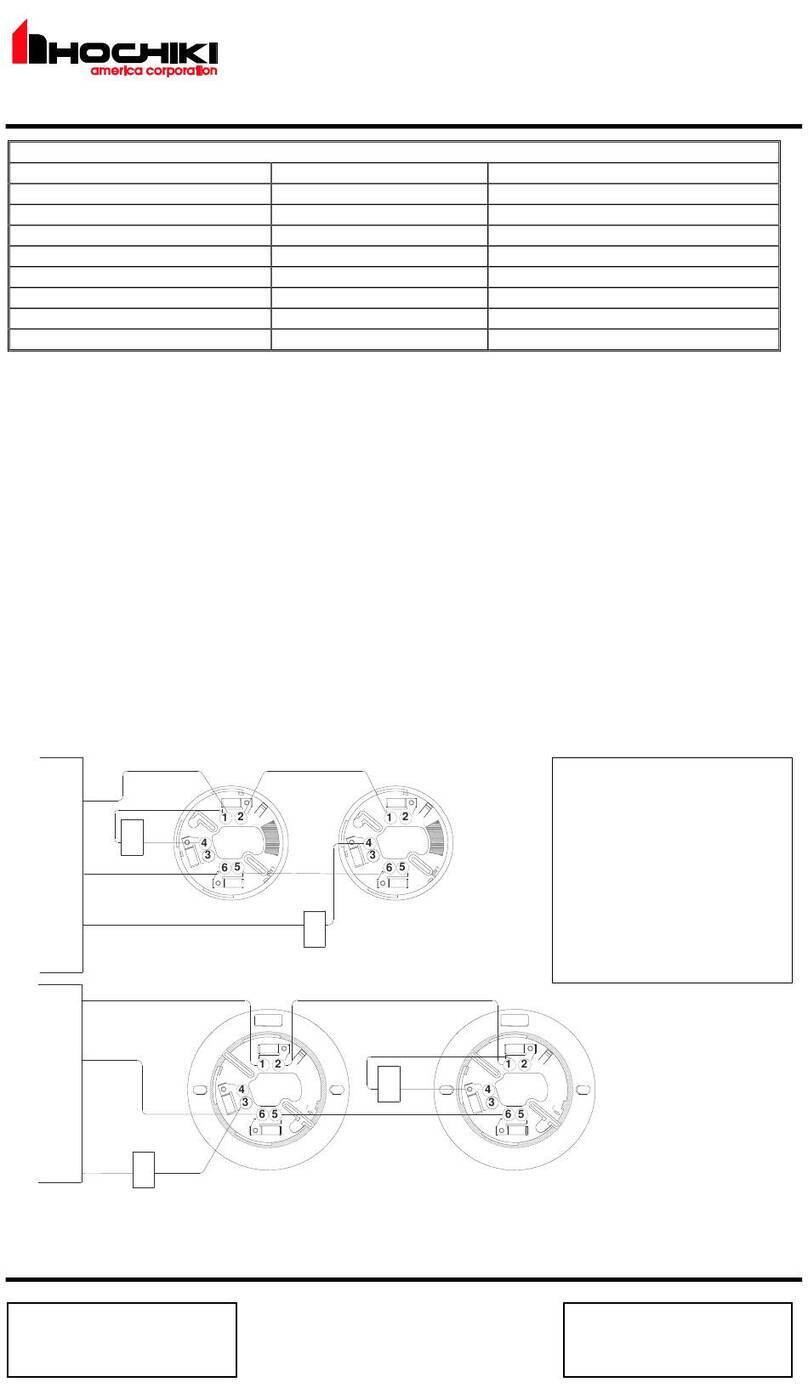

4. Terminal layout and part designation ...............................................................16

4.1. Emitter ........................................................................................................................................ 16

4.2. Receiver ....................................................................................................................................... 16

5. Summary of the SPC-24's functions...................................................................17

5.1. Alarm signal output and indicator lamp...................................................................................17

5.2. Fault signal output and indicator lamp ....................................................................................17

5.2.1. General................................................................................................................................. 17

5.2.2. After adjustment/re-initialisation.......................................................................................17

5.2.3. During normal operation..................................................................................................... 17

5.3. Indication of normal operation................................................................................................... 18