©/TM 2023 UnityLab Corp. All rights reserved. | 21

1.0 INTRODUCTION

This manual contains the installation, operation and maintenance instructions,

troubleshooting guide, repair parts illustrations and lists for the Hoffman Electric

Steam Generators. The Steam Generators are designed and manufactured

with constant attention to quality, performance, operator safety and energy

efciency. With proper installation, operation and maintenance, the Hoffman

Electric Steam Generator will last a lifetime.

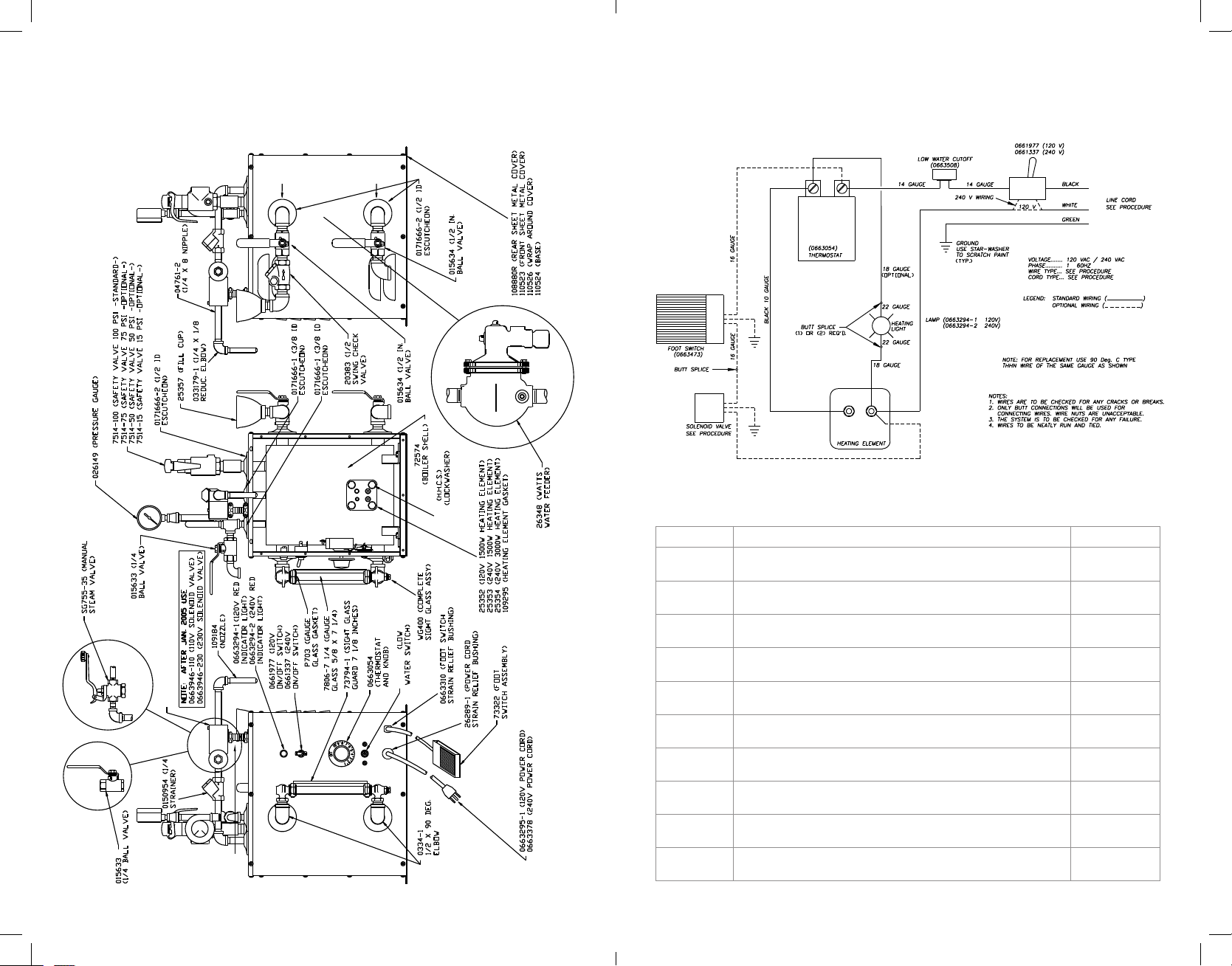

The Steam Generators are composed of a pressure vessel, a safety valve, piping,

a heating element, controls and the enclosure.

The pressure vessel is manufactured from high strength steel or cast bronze.

It is rated at 100 pounds per square inch of steam pressure. The vessel, safety

valve and piping have been designed to the standards set forth in the American

Society of Mechanical Engineers Boiler and Pressure Vessel Code. It meets or

exceeds their requirements for safety. Many Steam Generator assemblies are UL

and/or CUL listed. Consult your Hoffman distributor for their identication.

The Heating Element is a ange mounted immersion element. Immersion

elements are the most energy efcient heating elements available. This is due

to the element making contact with the working uid (water), transferring all the

energy required for heating water into steam.

Some electric steam generator models use a thermostat controller to regulate

the steam pressure. The controller senses the temperature and regulates the

current to the heating element to provide the desired output. Larger generators

are regulated with pressure switch controllers.

Steam pressure and temperature are related. The higher the steam pressure, the

higher the temperature. For a listing of pressures and corresponding temperatures

see Chapter 6, Table 6.1.1.

Hoffman also offers a wide variety of options for the steam generators. For a

listing of the options available, please contact your Hoffman Distributor.

1.1 INTENDED USE

The generators listed in this manual are intended for small steam usage

requirements. They may be used for jewelry steam cleaning, dental lab steam

cleaning, auto trim, furrier glazing of garments, or for use with steam irons, etc.

The units are capable of producing high-pressure steam. They should not be

used for applications that require low-pressure steam unless provisions are

made to limit the steam pressure (i.e. autoclaves, steam bath applications, etc.).

The machines are not intended for space heating purposes.

1.2 REGISTRATION WITH LOCAL JURISDICTION

The steam generator may need to be registered with your local or state

government. Check with your municipality for requirements.

Table of Contents

1.0 INTRODUCTION .................................................................................... 2

1.1 INTENDED USE ...........................................................................................................................2

1.2 REGISTRATION WITH LOCAL JURISDICTION .....................................................................2

1.3 PRELIMINARY DELIVERY INSPECTION ..................................................................................3

1.4 WARRANTY ACTIVATION ......................................................................................................3

1.5 SAFETY AND PRECAUTIONS..................................................................................................3

1.5.1 SAFETY NOMENCLATURE.................................................................................................3

1.5.2 SAFETY FEATURES.............................................................................................................3

1.5.3 SAFETY SUMMARY........................................................................................................... 4

2.0 INSTALLATION ..................................................................................... 5

3.0 OPERATING INSTRUCTIONS ................................................................ 6

4.0 MAINTENANCE .................................................................................... 7

4.1 CLEANING THE BOILER..........................................................................................................7

4.2 CLEANING THE SIGHT GLASS..............................................................................................7

4.3 BLOWING DOWN THE BOILER .............................................................................................7

4.4 CLEANING THE STRAINER....................................................................................................7

5.0 TROUBLESHOOTING & SERVICING...................................................... 8

5.1 TROUBLESHOOTING TABLE .................................................................................................. 8

5.2 ADJUSTING THE STEAM PRESSURE ..................................................................................10

5.2.1 THERMOSTAT CONTROL ...............................................................................................10

5.3 REPLACING THE THERMOSTAT

5.4 REPLACING THE GAUGE SIGHT GLASS............................................................................11

5.5 REPLACING THE HEATING ELEMENT

5.6 REPLACING THE LOW WATER SWITCH........................................................................... 12

5.7 REPLACING THE ELECTRIC FOOT SWITCH AND/OR CORD........................................ 12

5.8 REPLACING THE ON/OFF SWITCH................................................................................... 13

5.9 CLEANING THE ELECTRIC SOLENOID VALVE..................................................................14

5.10 REPLACING THE ELECTRIC SOLENOID VALVE ...............................................................14

6.0 TABLES ................................................................................................15

6.1 PRESSURE VS. TEMPERATURE............................................................................................15

6.2 ELECTRICAL SPECIFICATIONS ..........................................................................................15

7.0 DRAWINGS & PARTS LIST ..................................................................16