3

Contents

Section 1: Introduction ............................................................................................................................... 5

Overview .......................................................................................................................................... 5

Section 2: Installation ................................................................................................................................. 6

General............................................................................................................................................. 6

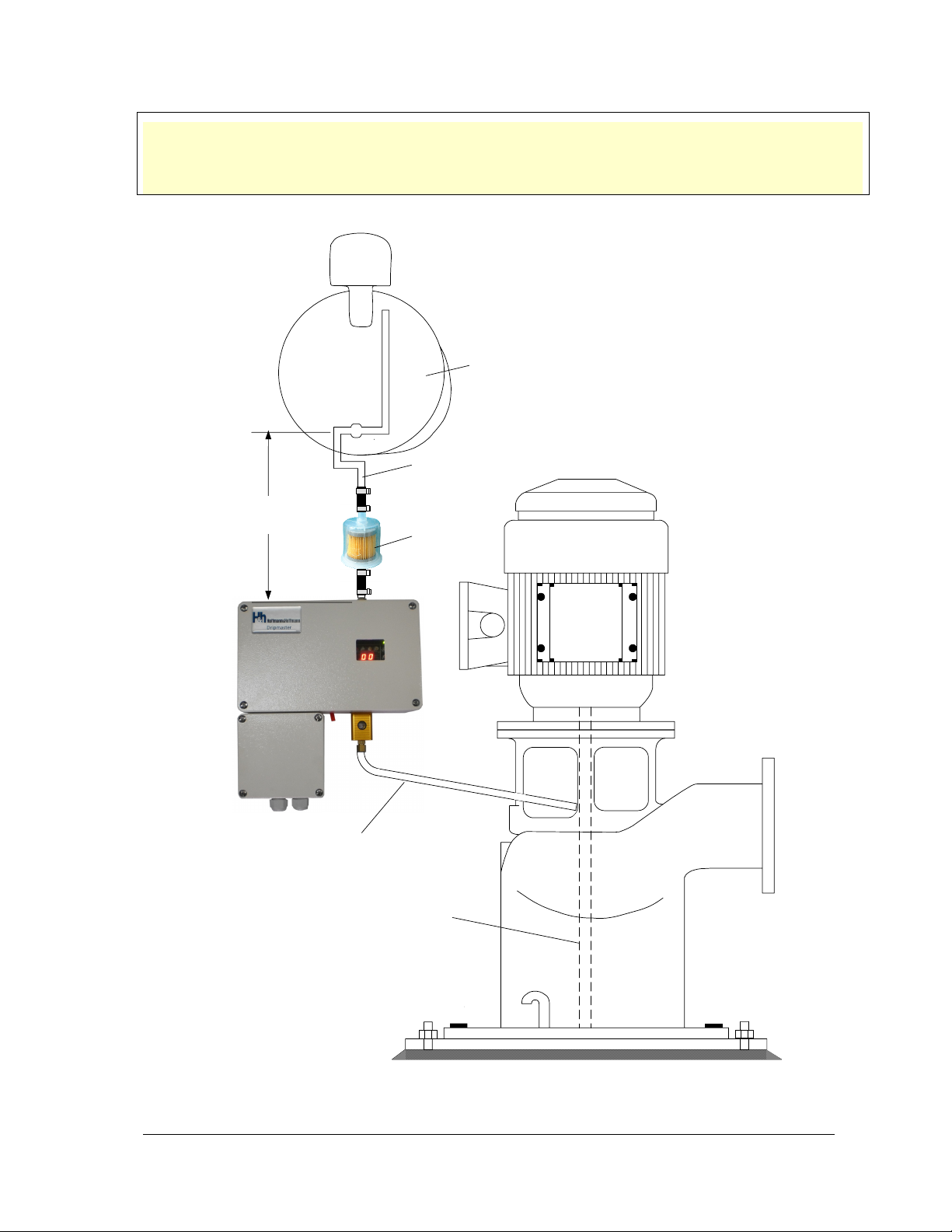

Well Site Requirements.................................................................................................................... 6

Installation Kit................................................................................................................................... 8

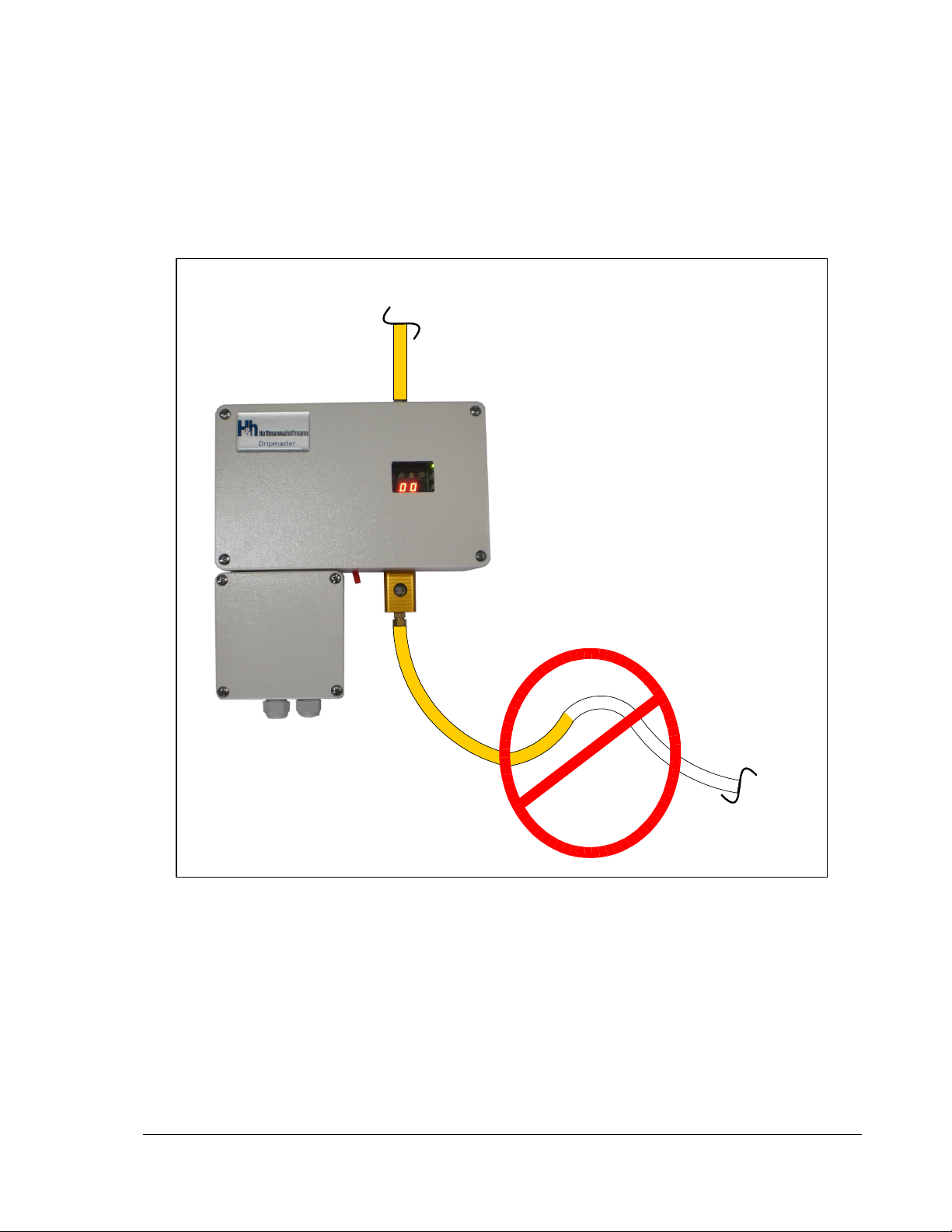

Mounting the Dripmaster.................................................................................................................. 8

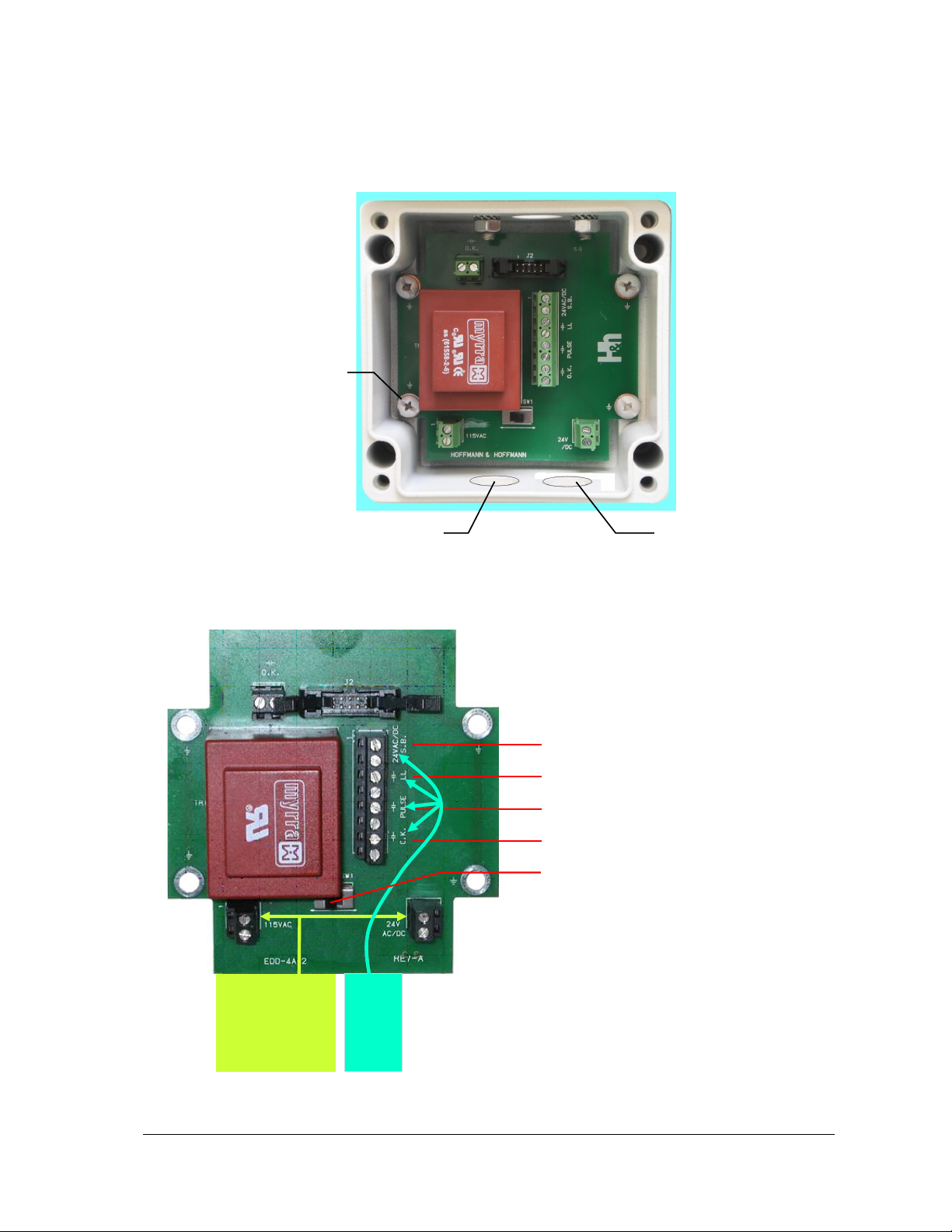

Wiring the Power and Control Cables.............................................................................................. 9

Setting the Drip Rate...................................................................................................................... 12

Section 3: Operation ................................................................................................................................ 13

Controls and Indicators .................................................................................................................. 13

Resetting the Dripmaster ............................................................................................................... 16

Automatic Control........................................................................................................................... 16

Setting Normal (pump on) Mode Drip Rates ....................................................................... 16

Pre-lube (pump off) Mode.................................................................................................... 19

Manual Control............................................................................................................................... 19

Section 4: Theory of Operation ................................................................................................................ 20

General........................................................................................................................................... 20

Search Feature .............................................................................................................................. 22

Push-Down and Push-up Features................................................................................................ 23

Section 5: Maintenance and Troubleshooting.......................................................................................... 24

Section 6: Specifications .......................................................................................................................... 26

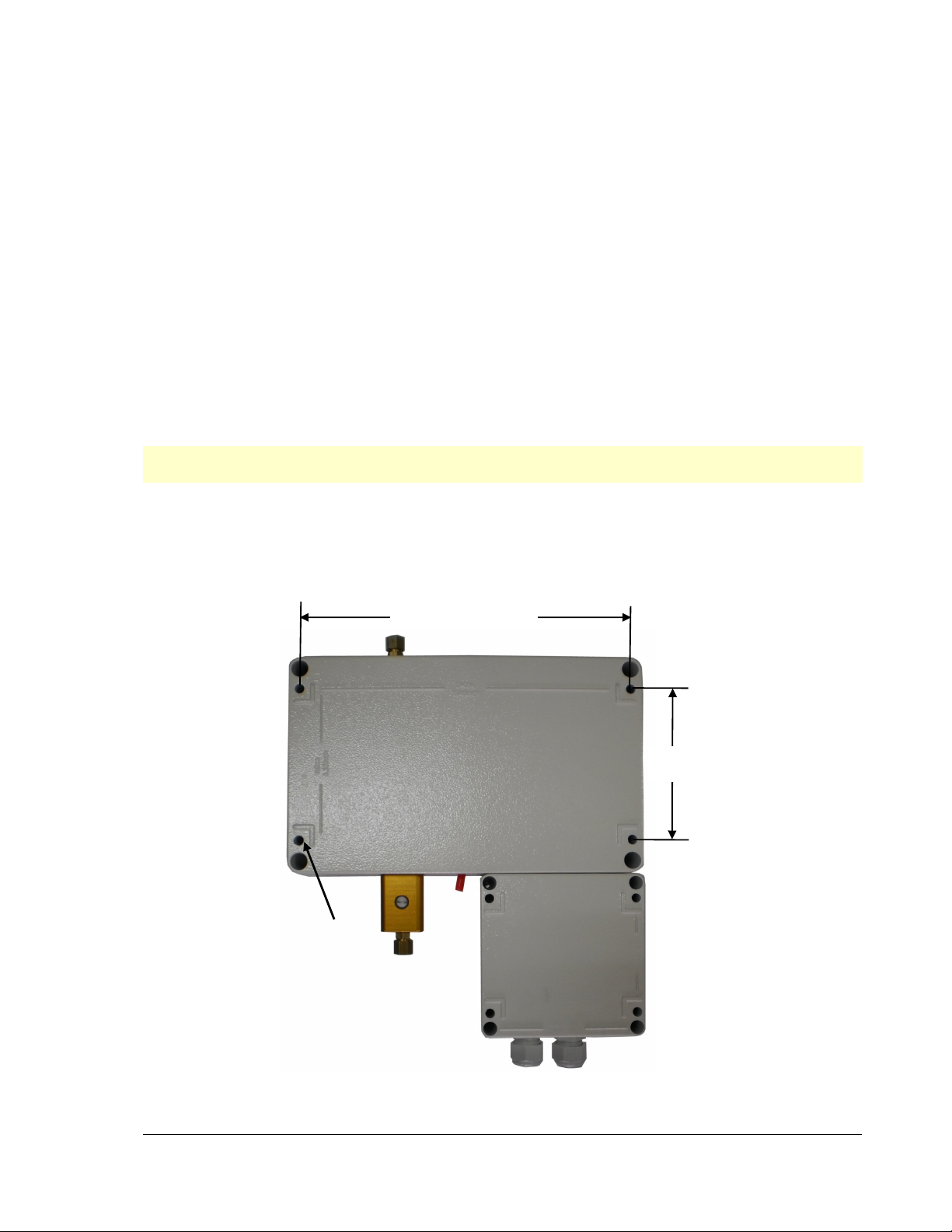

Overall Dimensions ........................................................................................................................ 27

Section 7: Dripmaster Service Policy....................................................................................................... 28

Installation ...................................................................................................................................... 28

Repair procedure ........................................................................................................................... 28

PC Board Replacement in the Field...............................................................................................29

Product within the Warranty Period ............................................................................................... 30

Product Out-of-Warranty Period .................................................................................................... 30

Return Instructions ......................................................................................................................... 30

Terms & Conditions on reverse ..................................................................................................... 31