Ortlinghaus-Werke GmbH Operating instructions TPI 215 EN

2 03.2012

Table of contents

1. Notes regarding use of the operating manual 3

1.1. Who are the operating instructions aimed at? 3

1.2. What can be found in the operating instructions? 4

1.3. Use of these instructions 4

1.4. Notes on the symbols used in the text 4

1.4.1. Personal injury 4

1.4.2. Product / machinery / plant system damage 5

1.5. Personnel qualifications and training 5

1.6. The Ortlinghaus numbering system 5

2. Technical data / intended purpose 6

2.1. Intended Use 6

2.2. Appropriate use 6

2.3. Improper use 7

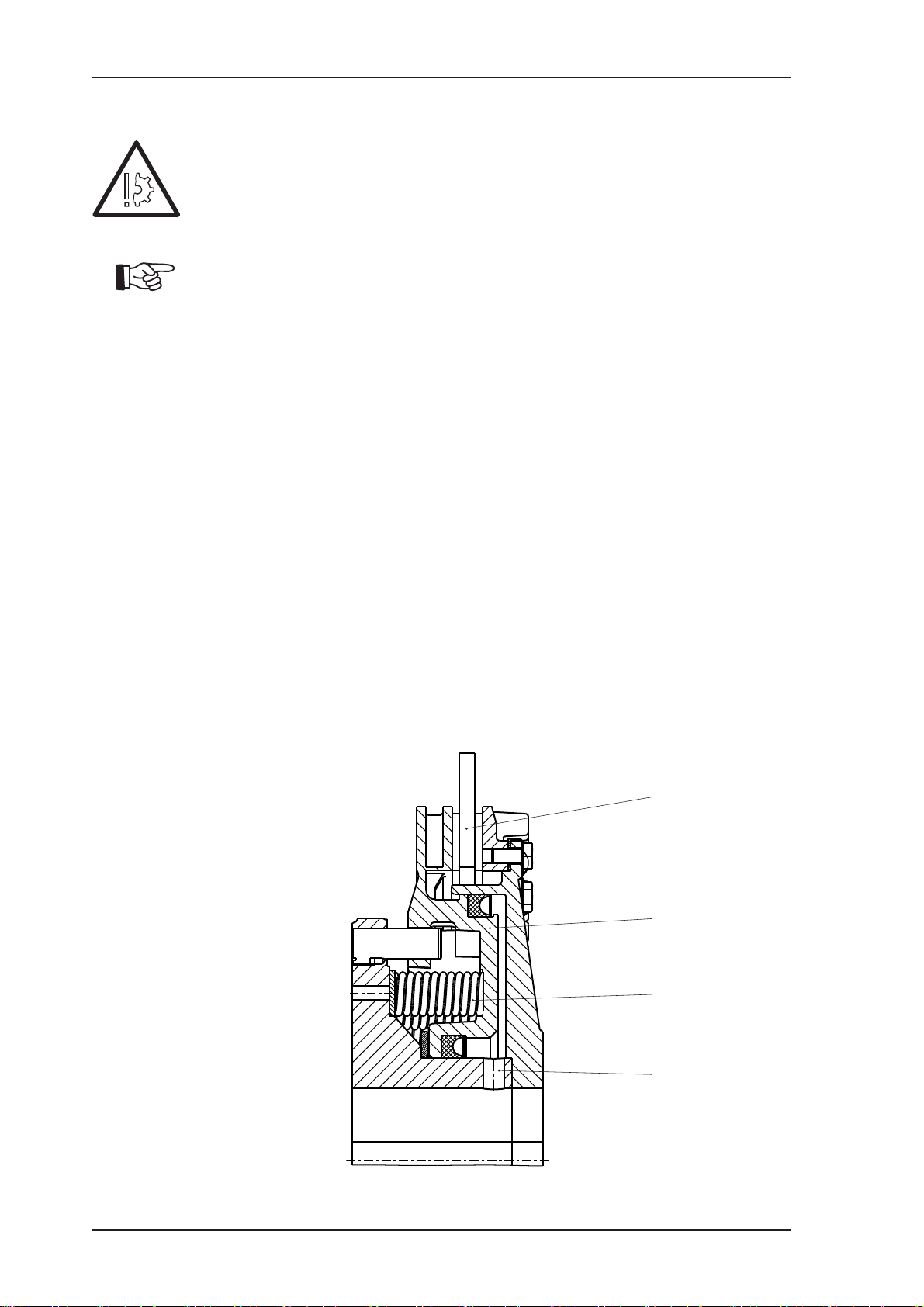

2.4. Functional description 8

2.4.1. Braking 8

2.4.2. Engaging the clutch (optional version) 8

2.5. Variants 9

2.5.1. Different ways in which the plates are

suspended 9

2.5.2. Different friction linings 9

2.5.3. Special versions 9

3. Transport, packaging 10

3.1. Hazard notes on transport, packaging 10

3.2. Condition on delivery 10

3.3. Transport 11

4. Installation and assembly instructions 12

4.1. Installation conditions 12

4.2. Fundamental installation variants 13

4.3. Installation with twelve-point suspension of

the plates 13

4.4. Installation with twelve-point housing plate

mounting (friction block version) 14

4.5. Installation with two-point plate suspension 15

4.6. Installation with combined suspension of the

plates 15

5. Commissioning 16

5.1. Hazard notes on commissioning 16

5.2. Function test 18

6. Operation 19

6.1. Hazard notes for operation 19

6.2. Inspection while the machine is in operation 21

6.3. Setting the oiler 21

7. Troubleshooting 22

8. Maintenance 24

8.1. Hazard notes on maintenance 24

8.2. Checking wear by measuring the air gap 25

8.3. Wear compensation at friction lining half-

wear point (from size 61 and upwards)) 26

8.3.1. Setting of the wear indicator (with reduced

cylinder volume) 27

8.4. Removing and fitting the plates/housing plates 27

8.4.1. Twelve-point suspension of the plate 28

8.4.2. Twelve-point suspension of the housing

plates (friction block version) 28

8.4.3. Two-point suspension of the plates 28

8.5. Maintenance intervals 28

8.5.1. Changing the seals (elastomer) 29

8.5.2. Changing the springs 29

8.6. Care 29

9. Servicing and repair, modification 30

9.1. Hazard notes on servicing and repairs 30

9.2. Dismantling of the brake 31

9.3. Assembly of the dismantled brake 32

9.4. Hazard notes on modification 34

10. Spare parts 35

10.1. Spare parts list for brake 0450- . . . -23- 36

10.2. Isometric diagram for brake 0450-...-23- 37

10.3. Replacement parts list for brake 0450-...-

29- to 0450-...-61- 38

10.4. Isometric diagram for brake 0450-...-29- to

0450-...-61- 39

10.5. Replacement parts list for brake 0450-...-

62- to 0450-...-93- 40

10.6. Isometric diagram for brake 0450-...-62- to

0450-...-93- 41

11. Storage, de-commissioning 42

11.1. Hazard notes on storage, de-commissioning 42

11.2. Storage 43

11.3. De-commissioning 43

12. Disposal 44

12.1. Hazard notes on disposal 44

13. Annex 45

13.1. Declaration of Conformity 45

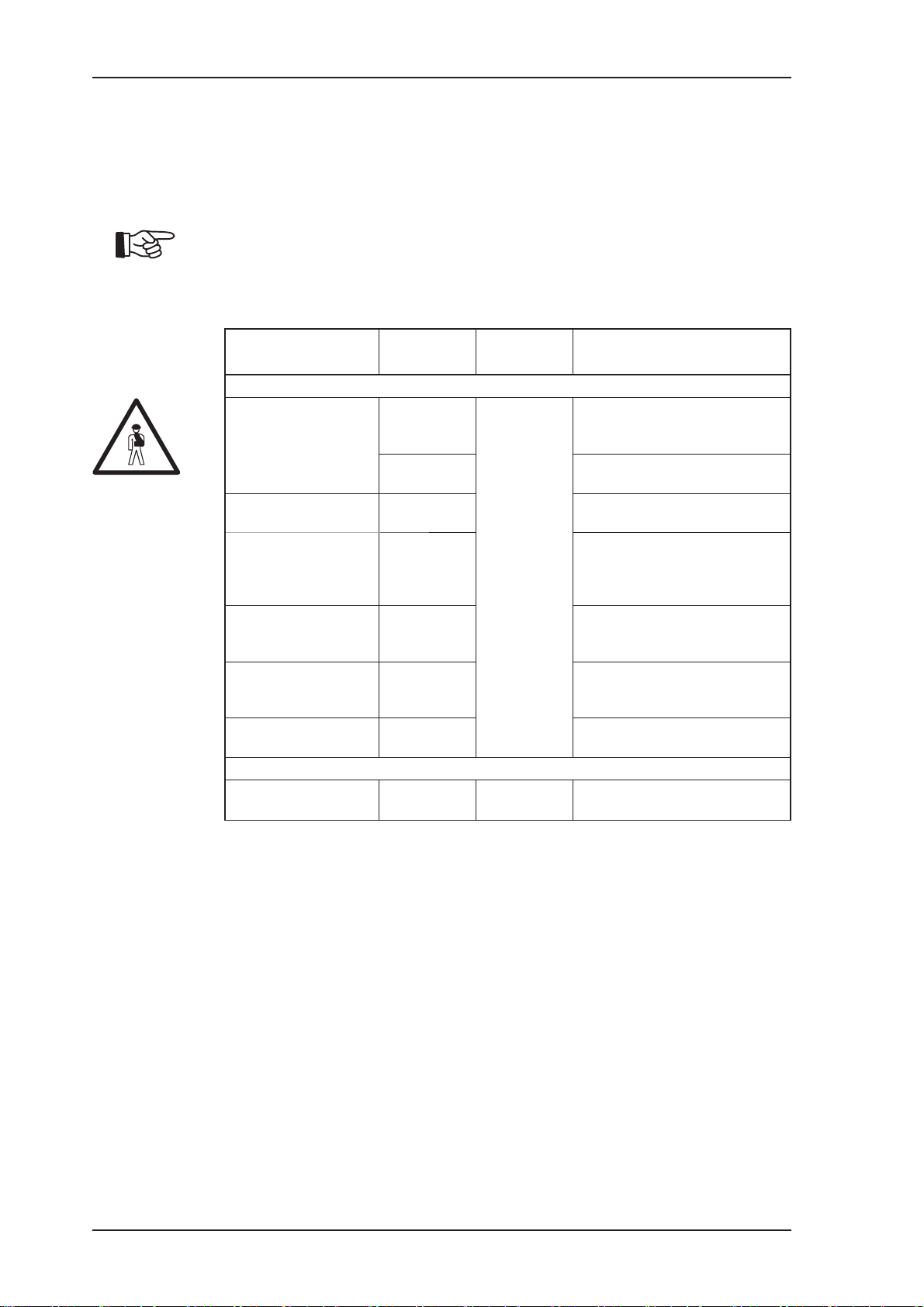

Table 1: List of amendments

Amendment Edition date

BA rev. no. 215.002 03.2012