1.1 Introduction

We appreciate your business and your choice of Welker products. The installation, operation, and maintenance liability for this

equipment becomes that of the purchaser at the time of receipt. Reading the applicable Installation, Operation, and

Maintenance (IOM) Manuals prior to installation and operation of this equipment is required for a full understanding of its

application and performance prior to use.*

If you have any questions, please call Welker at 1-281-491-2331.

*The following procedures have been written for use with standard Welker parts and equipment. Assemblies that have been modified may have additional

requirements and specifications that are not listed in this manual.

1.2 Product Description

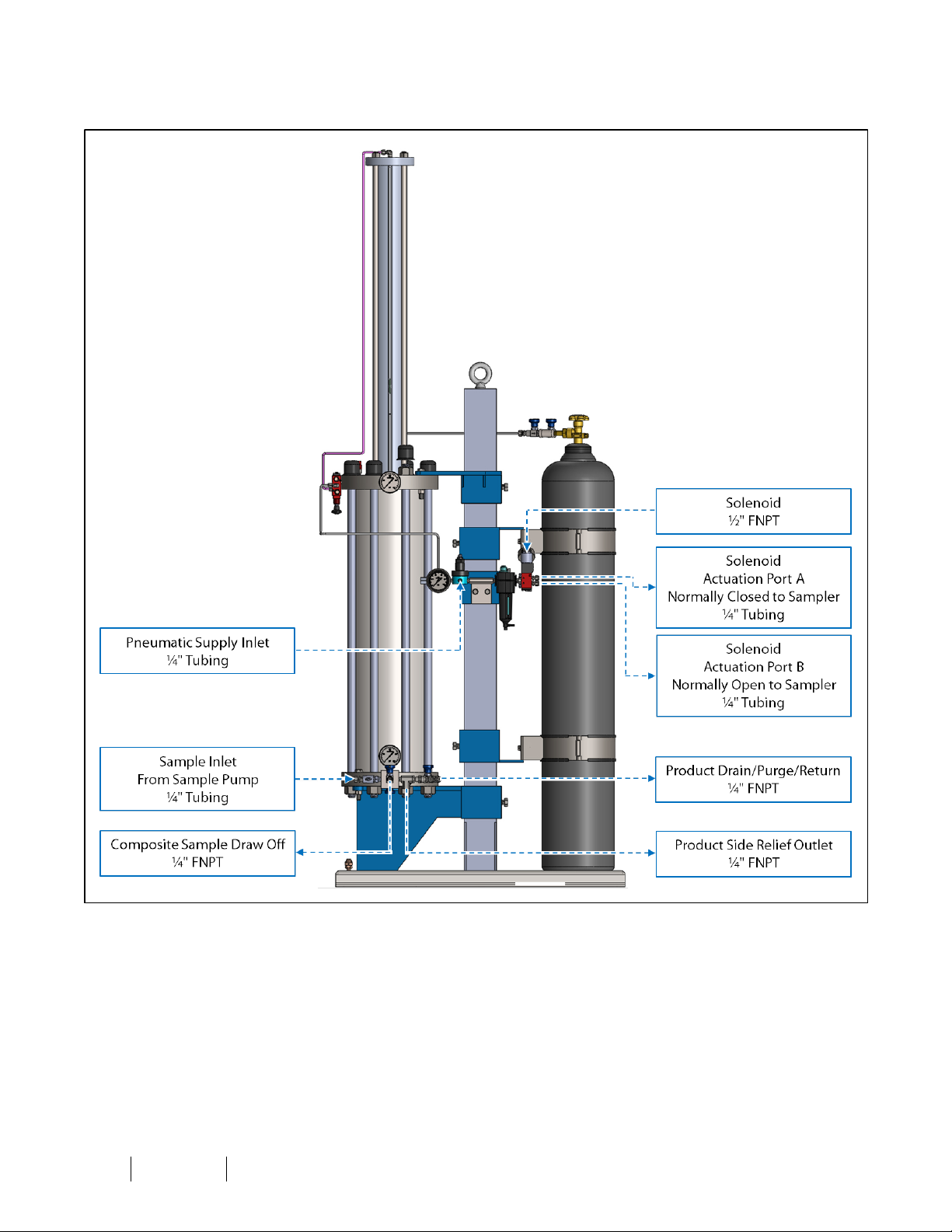

The Welker LS-14 Constant Pressure Sample Container is designed to collect, retain, and mix large volumes of representative

composite sample.

The LS-14 can be integrated into a system with a pneumatically driven sample pump that interfaces with a Programmable Logic

Controller (PLC) or other signal control system for proportional to flow or timed collection of sample grabs. Product level can be

visually verified on site by referring to the volume indicator with tracker magnet on the LS-14.

Engineered features ensure that the sample is retained and representative for laboratory analysis. The connected inert gas supply

applies and maintains constant pressure on the sample in the LS-14 to prevent vaporization and the escape of entrained gases.

An operator can manually actuate the mixing plate in the LS-14 to thoroughly mix the sample prior to transfer to a transportable

container for laboratory analysis.

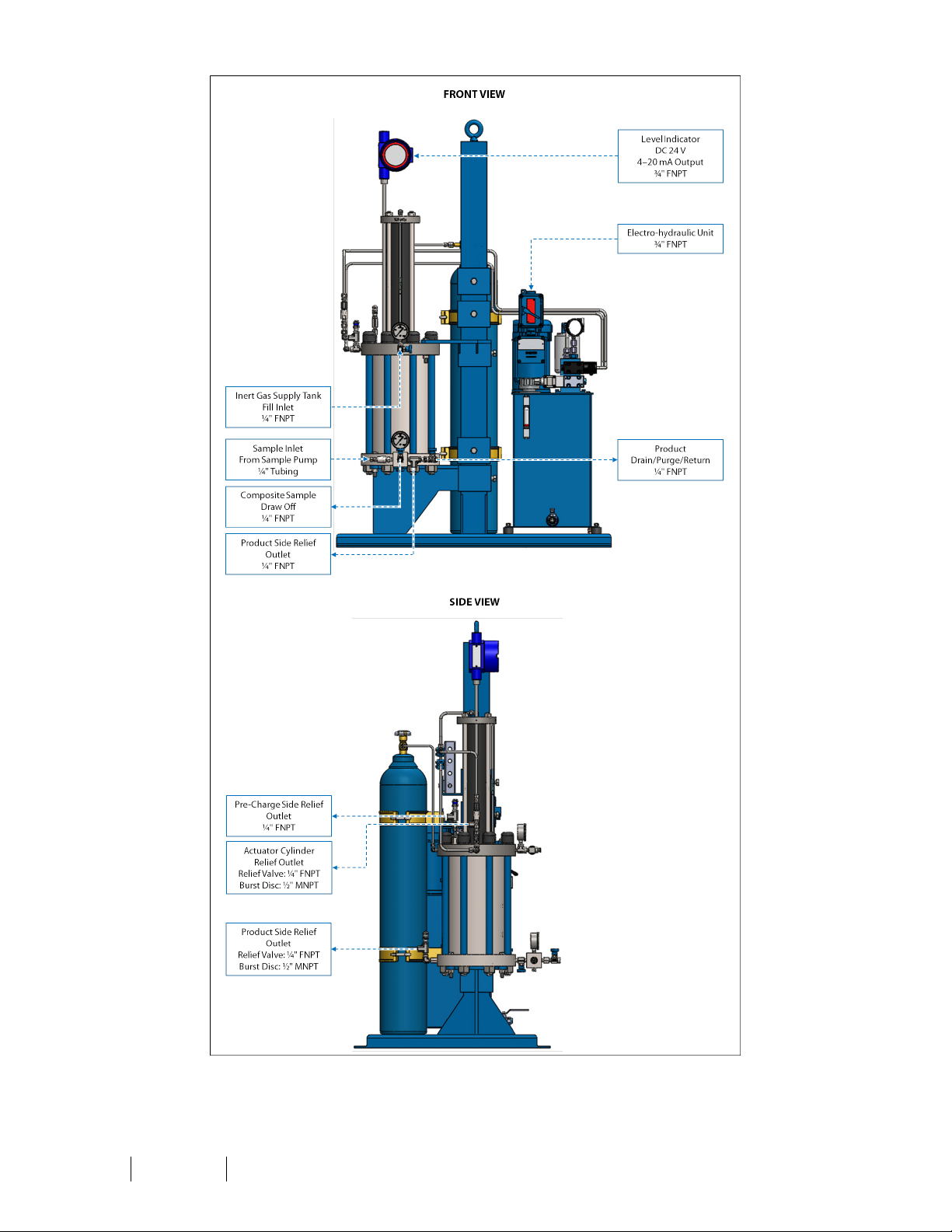

Optional equipment can be added to enable remote operation: a controller to take samples automatically, an electro-hyrdaulic

supply to drive the incorporated sample pump, a magnetostrictive level indicator to communicate product level to the PLC, and

a proximity switch to signal the PLC once the desired volume of sample has been collected.

For this manual, the term "PLC," or Programmable Logic Controller, will be used to refer to the PLC, DCS, or other signal control

system used by the customer to activate and operate the solenoid.

Welker may custom design the LS-14 to suit the particular application and specifications of each customer.

SECTION 1: PRODUCTINFORMATION

4IOM-131 MODEL: LS-14 REV: F 13839 West Bellfort Street, Sugar Land, TX 77498 welker.com Service Department 281.491.2331