4 of 44

TABLEOFCONTENTSPAGE

1.0OWNER/EMPLOYEROBLIGATIONS........................................................................2

2.0IMPORTANTSAFETYINSTRUCTIONS.......................................................................3

3.0GENERALSPECIFICATION........................................................................................6

4.0TOOLSREQUIREDFORINSTALLATION....................................................................6

5.0CONTENTS...............................................................................................................7

6.0GENERALLIFTSPECIFICATIONS...............................................................................8

7.0INSTALLATIONINSTRUCTIONS................................................................................9

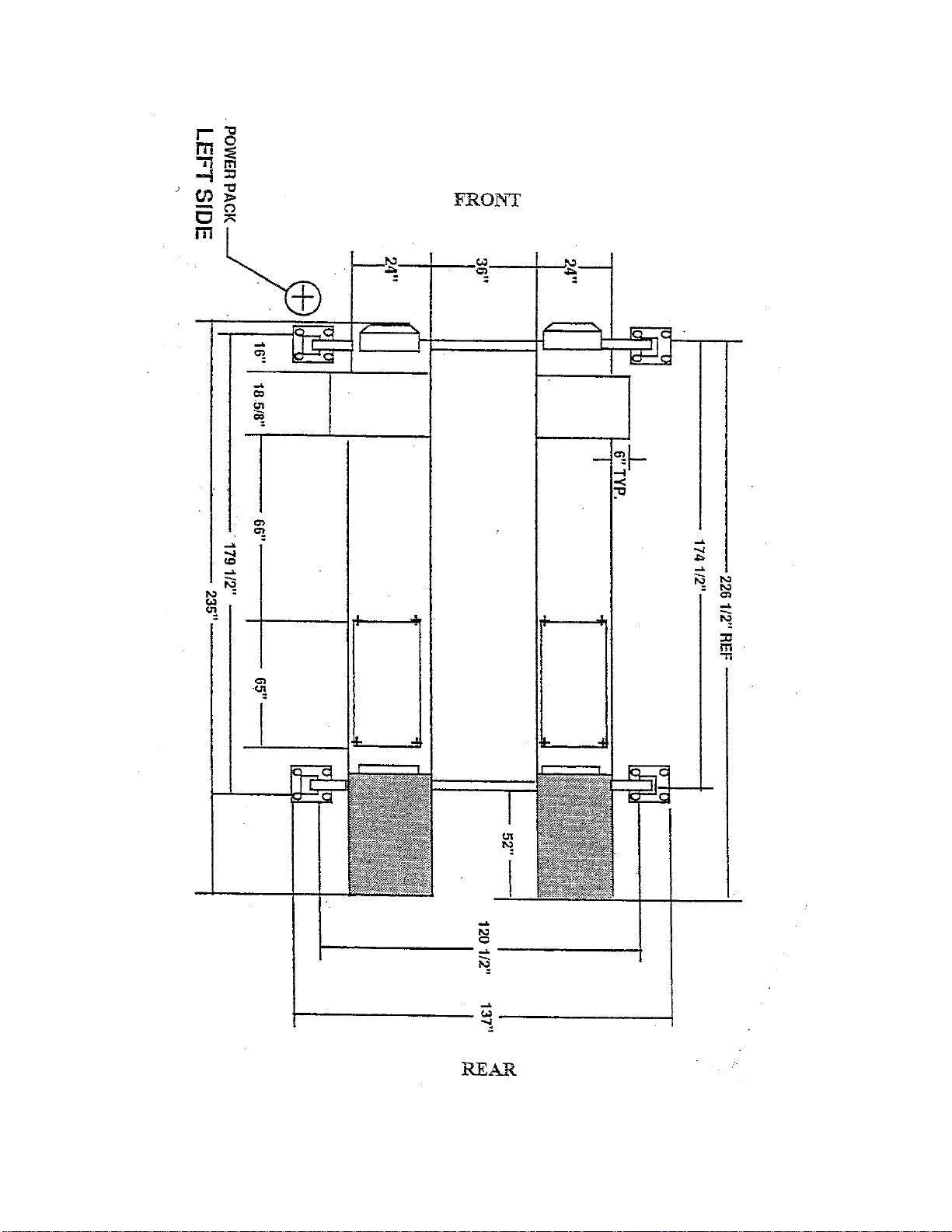

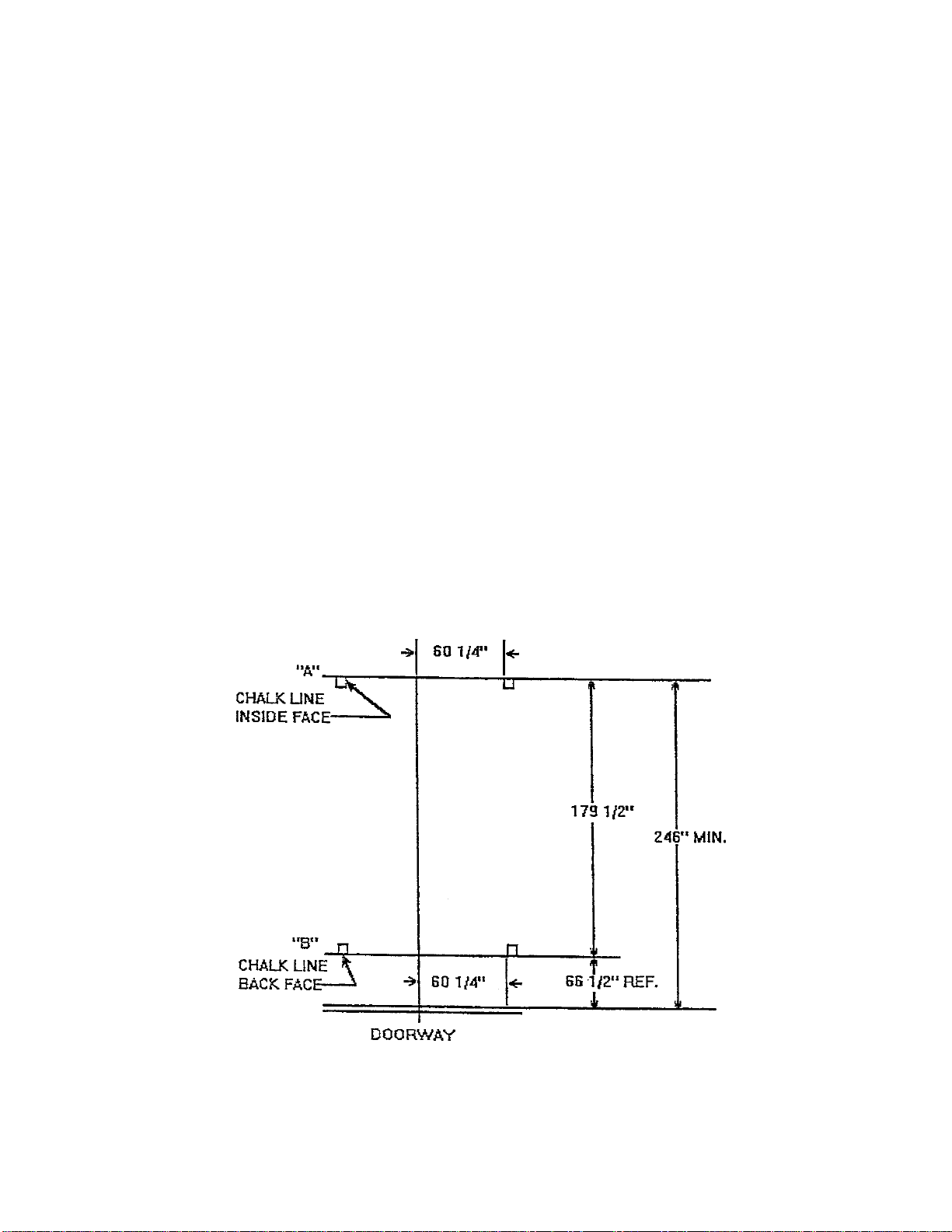

7.1CHALKLINELAYOUT.........................................................................................9

7.2FRONTANDREARCROSSMEMBERASSEMBLY..............................................11

7.3SHEAVEINSTALLATION...................................................................................12

7.4CABLEINSTALLATION.....................................................................................13

7.5POWERPACKINSTALLATION..........................................................................15

7.6ELECTRICALCONNECTIONS............................................................................16

7.7HYDRAULICINSTALLATION.............................................................................16

7.8AIRINSTALLATIONS........................................................................................17

4.9SAFETYRETAININGSYSTEM...........................................................................18

7.9LEVELINGPROCEDURE...................................................................................19

7.9.1LEVELINGLIFTTOFLOOR.............................................................19

7.9.2DECKLEVELINGPROCEDURE.......................................................19

7.9.3LEVELINGPROCEDURE‐SAFETYLADDERS..................................20

7.10APPROACHRAMPS,WHEELSTOPS,PULLEYCOVERS......................................21

7.11ANCHORINSTALLATION.................................................................................21

7.12SAFETYANDOPERATINGINSTRUCTIONS.......................................................23

7.13FINALCHECKOFASSEMBLEDLIFT..................................................................24

7.14OPERATIONTESTWITHVEHICLE....................................................................25

8.0RECOMMENDEDINSPECTIONANDMAINTENANCE.............................................25

8.1LUBRICATIONSPECS.......................................................................................25

8.2WIREROPES....................................................................................................27

8.2.1WIREROPECONDITIONSGUIDE..................................................27

8.2.2WIREROPEREPLACEMENTCRITERIA:.........................................28

8.2.3WIREROPEINSPECTION..............................................................28

8.2.4WIREROPELUBRICATION............................................................28

8.2.5WIREROPEADJUSTMENT............................................................28

8.2.6INSPECTCABLEFLANGE...............................................................29

8.3FASTENERS......................................................................................................29

8.4SHEAVESANDPINS.........................................................................................29

8.4.1VISUALINSPECTIONOFSHEAVES................................................29

8.4.2MEASURESHEAVEWEAR............................................................29

8.4.3SHEAVEPINS................................................................................30

8.5MECHANICALSAFETYLATCHES(DOGS).........................................................30