PAGE 4

PIZZAS OF EIGHT PIZZA SYSTEMS

OPERATOR'S MANUAL

MODEL PC18

OPERATION

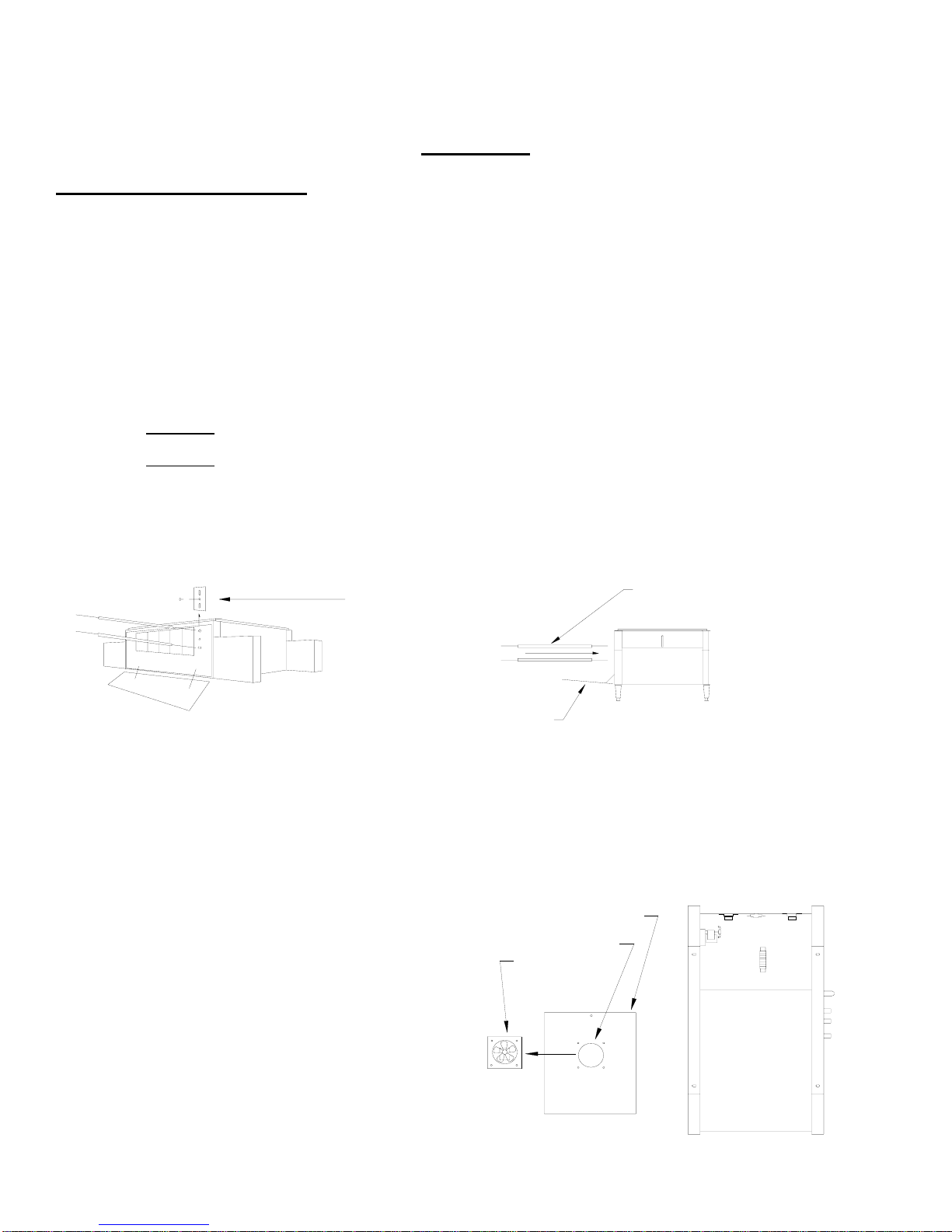

A. Switch master on/off switch to the ON position and turn top and bottom heat controls to number 10,

turn conveyor speed control to fastest time setting.

B. Allow 10 to 15 minutes for unit(s) to warm up.

C. Baking in these units is a combination of heat and belt speed. Some foods may require more top heat

or vice versa; other foods may require low top and bottom heat and slow belt speeds. Every product

should, therefore, be tested using the separate top and bottom heat controls and the variable speed

Control to arrive at the correct balance of heat and belt speed. When changing heat and/or belt speed

settings allow approx. 5 minutes for the oven to stabilize itself at the new settings.

COOKING PROCEDURES

THE FOLLOWING SUGGESTED SETTINGS FOR THE VARIOUS PRODUCTS LISTED ARE

INTENDED TO ASSIST THE USER OF THESE OVENS WITH ARRIVING AT THE CORRECT

BALANCE OF HEAT AND SPEED. SOME ADJUSTMENTS MAY STILL HAVE TO BE MADE TO BOTH

HEAT AND SPEED DEPENDING ON THE PRODUCTS FRESHNESS AND/OR THICKNESS AND

DENSITY.

PRODUCT TOP HEAT BOTTOM HEAT BELT SPEED

PIZZA

12" FRESH 350°F 450°F 8 MINUTES

16" FRESH 300°F 450°F 12 MINUTES

12" BLANCHED 300°F 400°F 6 MINUTES

16" BLANCHED 300°F 400°F 8 MINUTES

12" FROZEN 300°F 300°F 8 MINUTES

16" FROZEN 350°F 350°F 12 MINUTES

SANDWICHES

MEAT/CHEESE 450°F 300°F 4 MINUTES

MEATBALL 500°F 350°F 2 MINUTES

BAGEL (OPEN) 500°F 400°F 2 MINUTES

COOKIES

1 TO 1 1/2 Oz 200°F 250°F 12 MINUTES

GARLIC BREAD

LIGHTLY SEASONED 500°F 500°F 2 MINUTES

FISH

SIZZLE PLATTER 400°F 500°F 6 MINUTES