Page 2A

OPERATOR'S MANUAL

HOLMAN CONVEYOR TOASTERS

MODELS S710(H), S714(H)

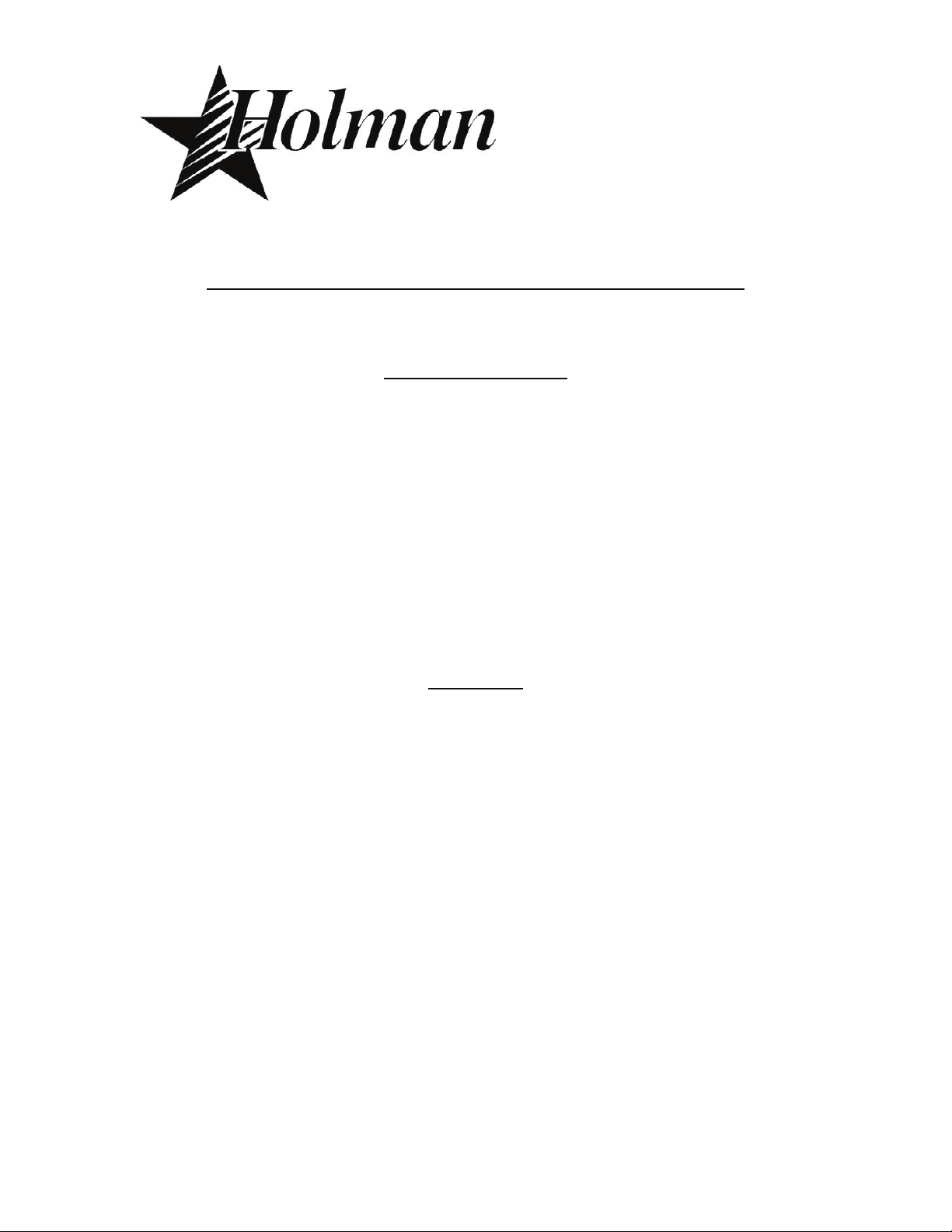

FULL KEY LOCKING COVER

FITS OVER CONTROLS AND

SIDE PANELS TO PREVENT

TAMPERING

S710LOK.WMK

HOLMAN

Fig. 1

SECURITY COVER :

Your Holman models S710 and S714 are quipped

with a full front key locking cover (fig.1). This over fits

over the front and sides of the unit. The security

cover must be removed with a key in order to gain

access to the controls, side panels, legs and toast

chute to be removed.

To remove, unlock the cover using the key. Pull

locked side of cover out and away from the unit. The

right side will release at the same time.

To replace the cover, Hook the right side of the cover

over the latch on right front of the unit while sliding

the left side of the cover over the lock. Secure cover

using key.

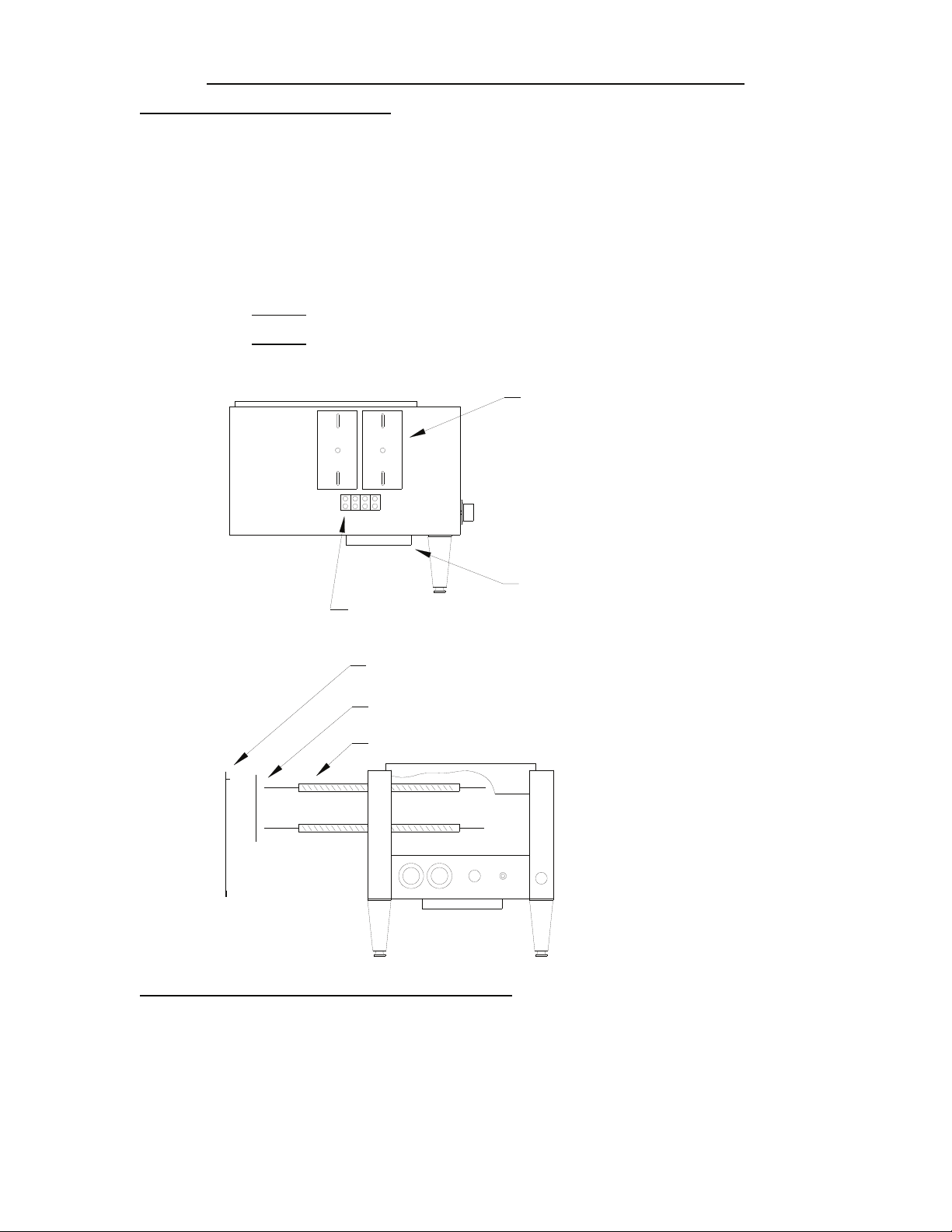

S710CHUT.WMF

SECURITY TOAST

CHUTE MOUNTING

ROD

TOAST CHUTE MOUNTING ROD

SLIDES THOUGH MOUNTING HOLE

IN CHASSIS AND THROUGH LOOP IN

TOP OF TOAST CHUTE

Fig. 2

TOAST CHUTE ;

To install the toast chute (fig. 2), Remove the left side

panel by removing two screws and pulling the top

part of the panel out while lifting up. Remove the

mounting rod by sliding it through chassis.

Next, place the toast chute beneath toaster as

shown. Line up the looped end of toast chute with

holes in the rear of toaster as shown. Insert mounting

rod through the holes in chassis and the toast chute

(If legs have not been installed, do so now).

Reinstall side panel and secure with screws. Toast

chute is now ready for use.

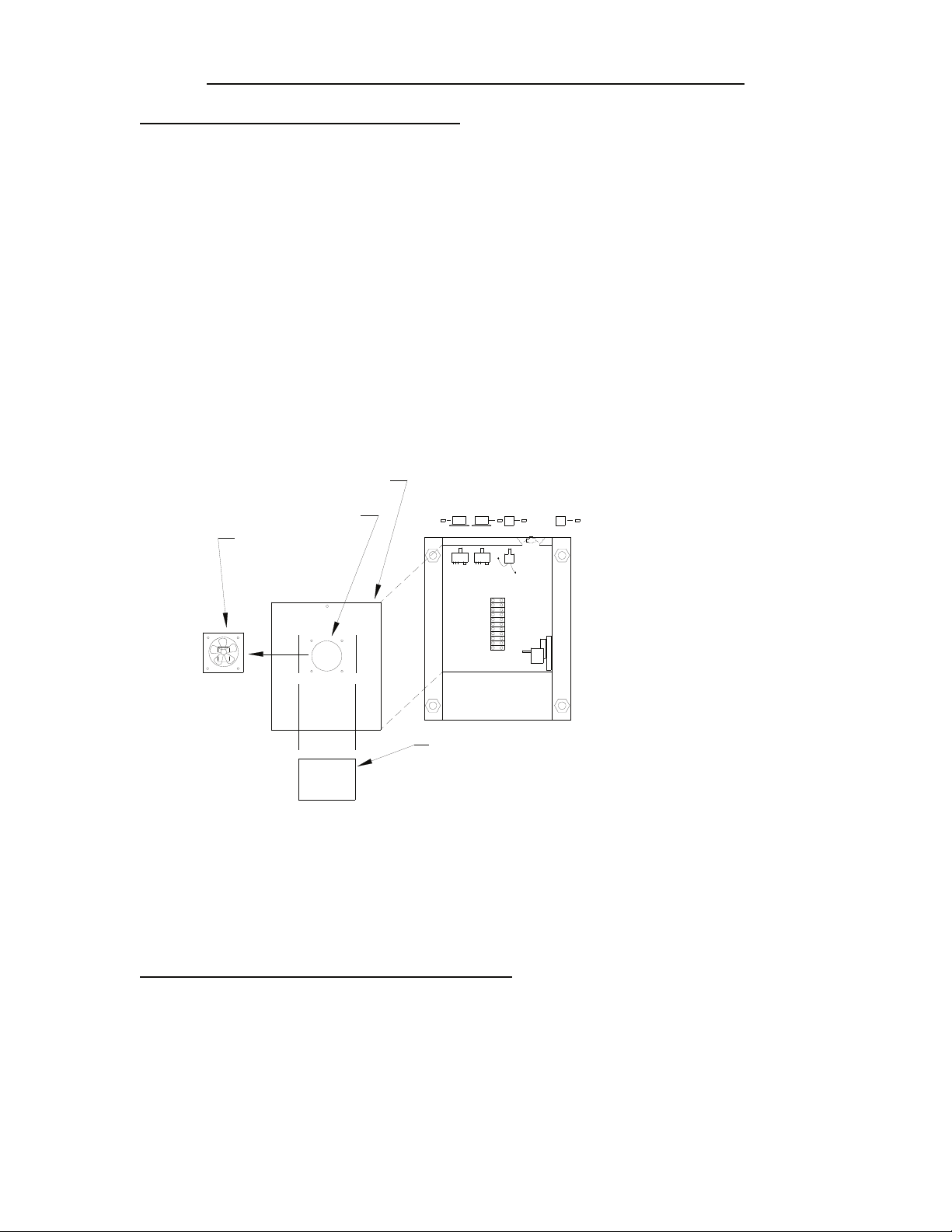

S710LEG.WMF

HOLMAN

SECURITY COUNTER MOUNTING

BRACKET ATTACHES TO LEG FOOT

AND IS SECURED TO COUNTER

WITH A SCREW.

MOUNTING

BRACKET

FOOT SCREWS

INTO BOTTOM

OF LEG

LEG SCREWS

INTO THE BOTTOM

OF TOASTER

COTTER PIN

KEY LOCK

COTTER PIN

Fig. 3

LEGS :

To secure the toaster to the counter (fig.3), Remove

both side panels by removing two screws and pulling

the top of the panel out while lifting up. Unscrew the

foot of each leg and slide counter-mounting brackets

onto the legs. Screw the foot back onto each leg and

install legs onto the toaster. Place the small cotter pin

through the holes in threaded portion of each leg.

Secure the mounting brackets to the counter with a

screw or bolt. Reinstall both side panels and secure

with screws.

NOTE: Security models are not supplied with a

power saver switch.

REVISED 9/10/2008

PAGE 3

OPERATOR'S MANUAL