Adding an LCD Display (600W Model)

An LCD display can also be added to models without this function by using the optional LCD Display &

Frame Kit

1. Connect 6 metre extension lead to display port Jon inverter

2. Fit frame where display is required and attach 6 metre cable to rear

3. Snap fit endplates to cover screw fixings

4. Turn the power on/off switch to the ON (I) position.

5. Inverter can now be controlled remotely from the LCD display

Current Sensor Installation (optional)

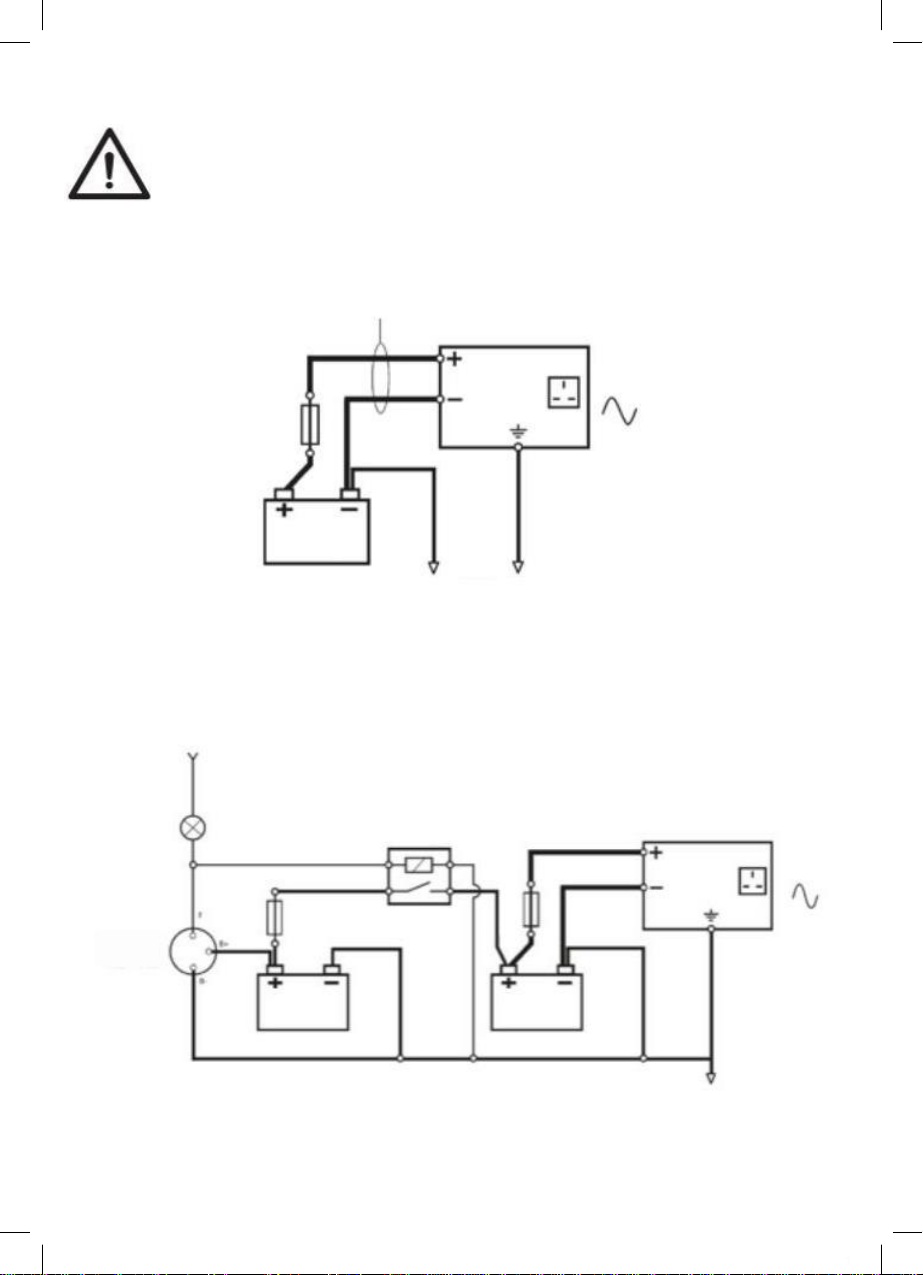

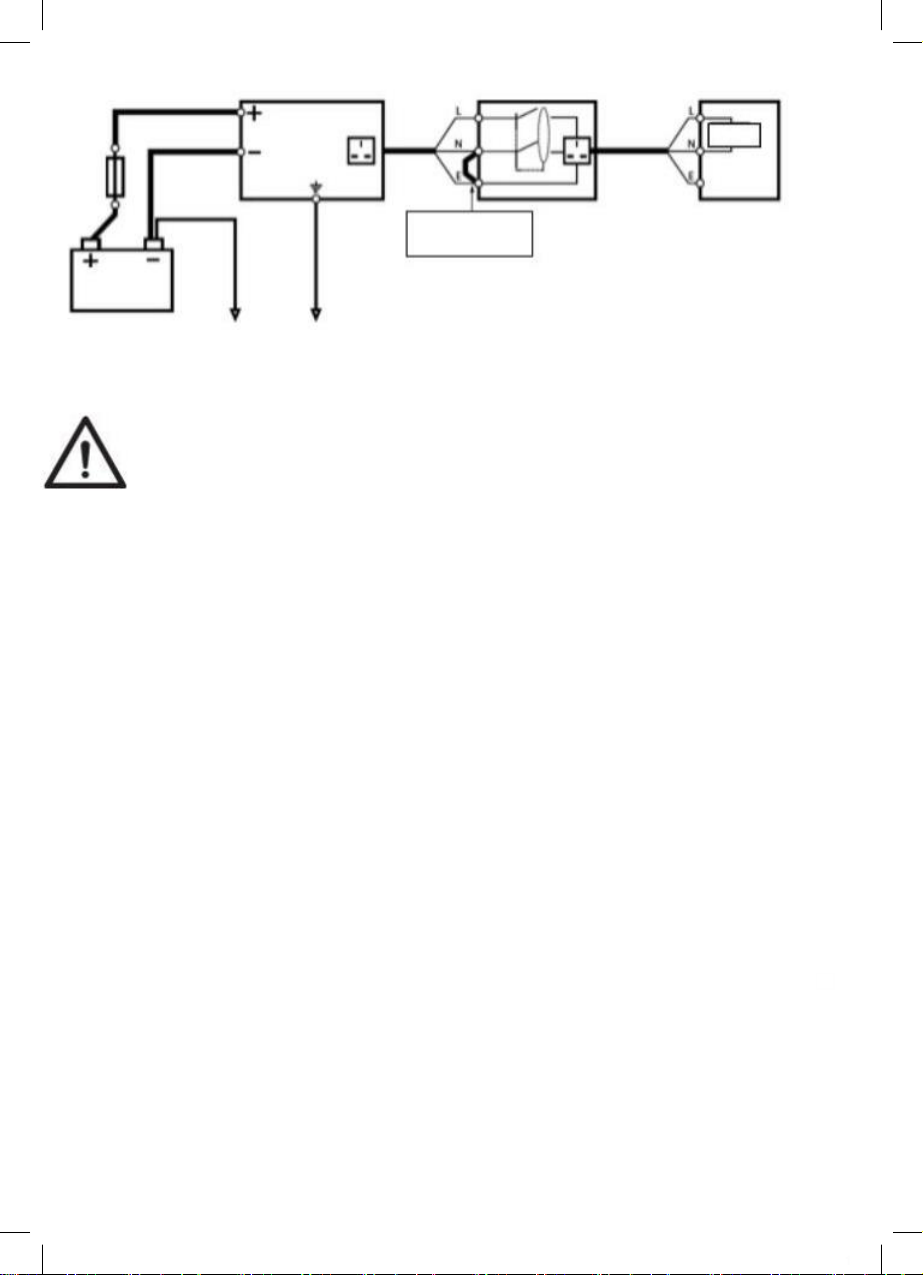

To enable monitoring of the input current and hours remaining function, the optional current sensor

should be fitted as shown in Fig4

1. Using black battery cable supplied with inverter, attach one end to battery(-) terminal and other

end to batt(-) terminal on Current Sensor

2. Using red battery cable supplied with inverter, attach one end to battery(+) terminal and other

end to inverter(+) terminal

3. Now connect cables 1-4 (supplied with current sensor) as shown in Fig4

1- Load(-) cable, negative connection from inverter to sensor

Use 1x4AWG cable for 600/1000W models

Use 2x2AWG cable for 2000/3000W models

2 - Comms cable, data connection from sensor port Kon inverter to current sensor

3- +12V Power cable, 12V power supply to sensor

4- Temperature sensor cable, temperature compensation for a more accurate current reading