3

of the enclosure.

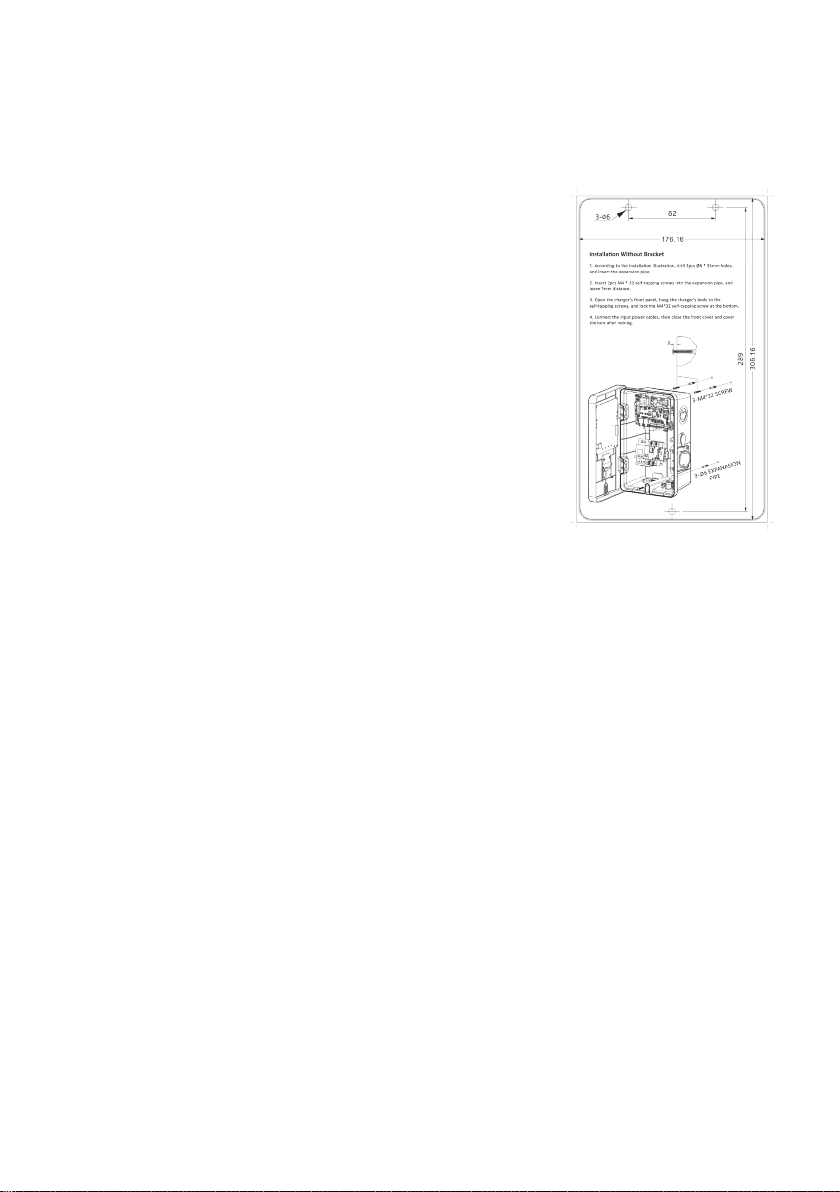

• Fasteners used to mount the product in its working location must

be sucient for the task and the specic mounting point.

• Damage to the product may render it unsafe. The product must

be electrically isolated and NOT used until appropriate remedial

action has been performed.

Installation must only be performed by someone who is

properly qualified and competent to do so in accordance

with the current legislation applicable in the geographical

region of the installation.

NOTE: Damage to the equipment, connected systems or to

property caused by improper installation are the responsibility of the

installer.

Our packaging materials are environmentally friendly and

can be recycled. Please put the packaging in applicable

containers to recycle it. Do not dispose of this equipment

with the household waste. It should be taken to a suitable

facility for recycling of electrical and electronic devices. For

more detailed information about recycling of this equipment,

please contact your local city/town council office or your

household waste disposal service.

HomEv Charging,Ltd cannot accept any responsibility for

any problems arising from incorrect installation.