SOLID AND SPLIT CORE 0-5/10VDC OUTPUT CURRENT SENSORS

Home and Building Technologies

In the U.S.:

Honeywell

715 Peachtree Street NE

Atlanta, GA 30308

customer.honeywell.com

® U.S. Registered Trademark

© 2018 Honeywell International Inc.

31-00144—02 M.S. Rev. 05-18

Printed in United States

By using this Honeywell literature, you agree that Honeywell will have no liability for any damages arising out of

your use or modification to, the literature. You will defend and indemnify Honeywell, its affiliates and subsidiaries,

from and against any liability, cost, or damages, including attorneys’ fees, arising out of, or resulting from, any

modification to the literature by you.

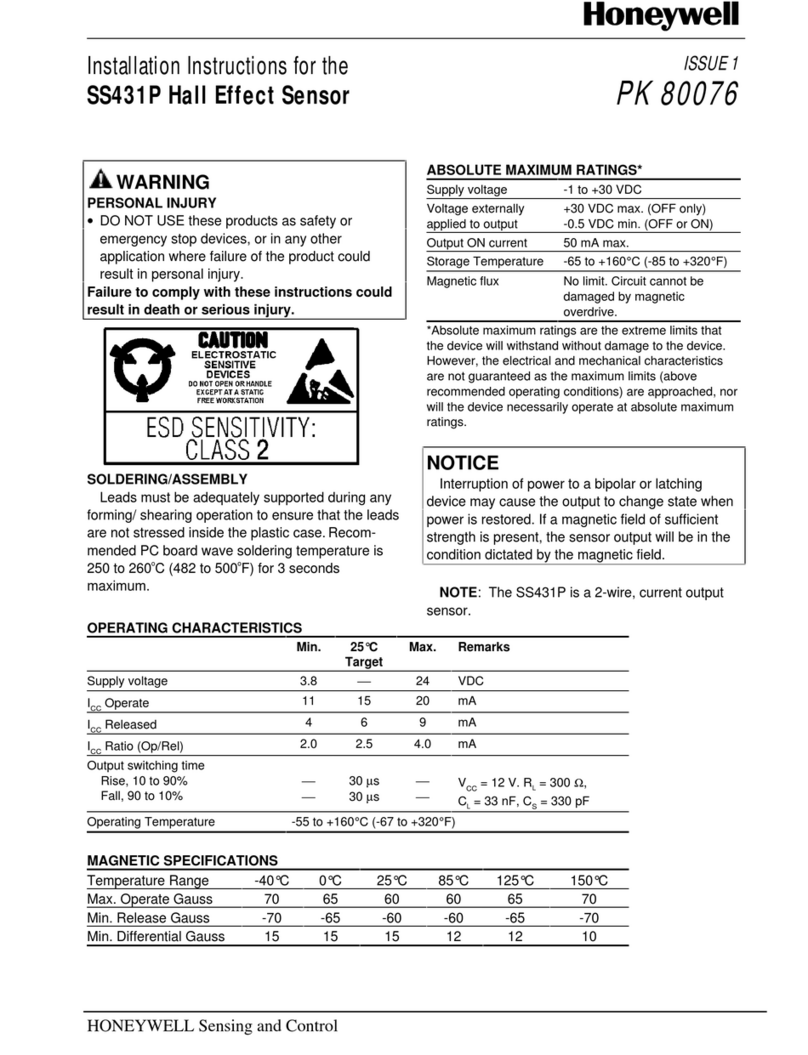

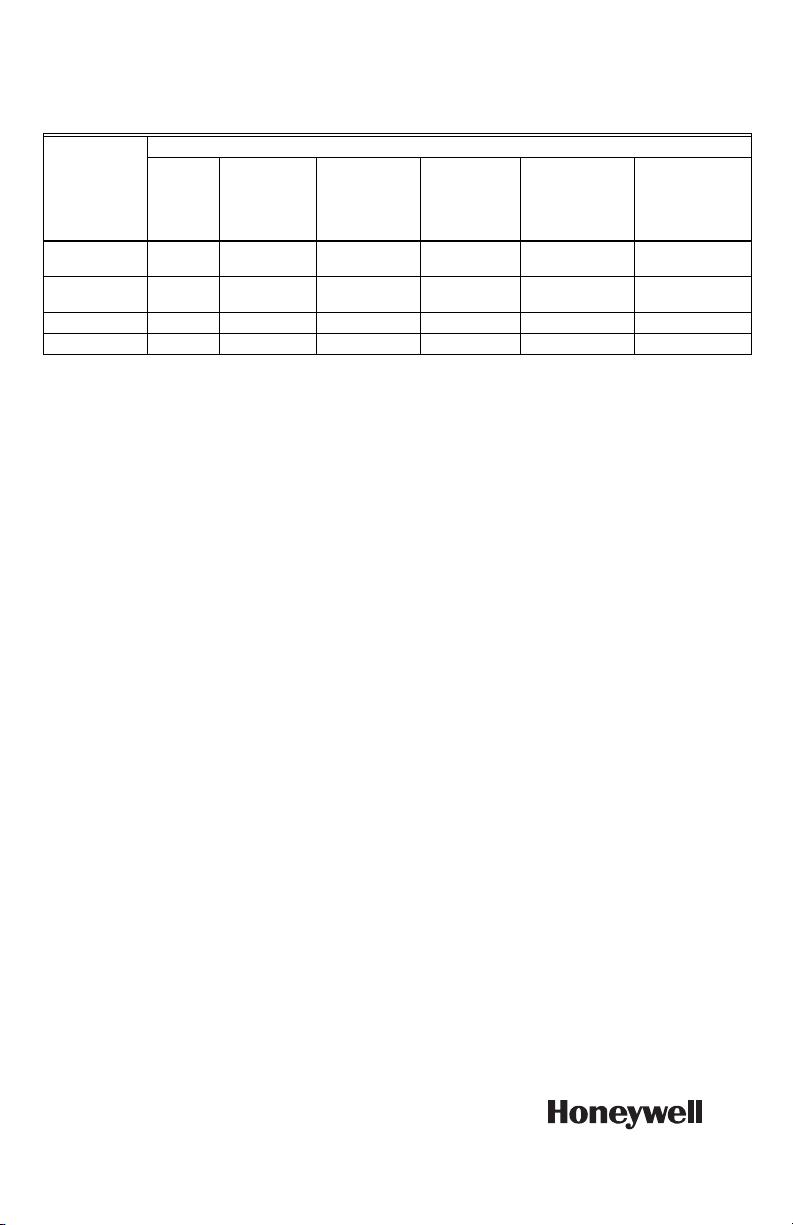

CHINA ROHS COMPLIANCE INFORMATION

ENVIRONMENT-FRIENDLY USE PERIOD (EFUP) TABLE

SJ/T 11364

O: GB/T 26572

X: GB/T 26572

This table is prepared in accordance with the provisions of SJ/T 11364.

O: Indicates that said hazardous substance contained in all of the homogeneous materials for this part is below

the limit requirement of GB/T 26572.

X: Indicates that said hazardous substance contained in all of the homogeneous materials for this part is above

the limit requirement of GB/T 26572.

All other components, not listed in the table, do not contain restricted substances above the threshold level.

REGULATORY INFORMATION

FCC REGULATIONS: § 15.19 (A)(3)

This device complies with part 15 of the FCC Rules.

Operation is subject to the following two conditions:

1. This device may not cause harmful interference,

and

2. This device must accept any interference

received, including interference that may cause

undesired operation.

IC REGULATIONS: RSS-GEN

This device complies with Industry Canada’s license-

exempt RSSs.

Operation is subject to the following two conditions:

1. This device may not cause interference; and

2. This device must accept any interference,

including interference that may cause unde-

sired operation of the device.

Le présent appareil est conforme aux CNR d’Industrie

Canada applicables aux appareils radio exempts de

licence. L’exploitation est autorisée aux deux

conditions suivantes :

1. l’appareil ne doit pas produire de brouillage;

2. l’utilisateur de l’appareil doit accepter tout

brouillage radioélectrique subi, même si le

brouillage est susceptible d’en compromettre le

fonctionnement.

FCC WARNING (PART 15.21) (USA ONLY)

Changes or modifications not expressly approved by

the party responsible for compliance could void the

user’s authority to operate the equipment.

Component

Name

- Hazardous Substances

(Pb)

Lead (Pb)

(Hg)

Mercury (Hg)

(Cd)

Cadmium (Cd)

(Cr6+)

Chromium VI

Compounds

(Cr6+)

(PBB)

Polybrominate

d Biphenyls

(PBB)

(PBDE)

Polybrominated

Diphenyl Ethers

(PBDE)

Assorted

capacitors

OO O O O O

Assorted

resistors

OO O O O O

Core O O O O O O

Screw O O O O O O