3

5.1 CHANGING FILTERS

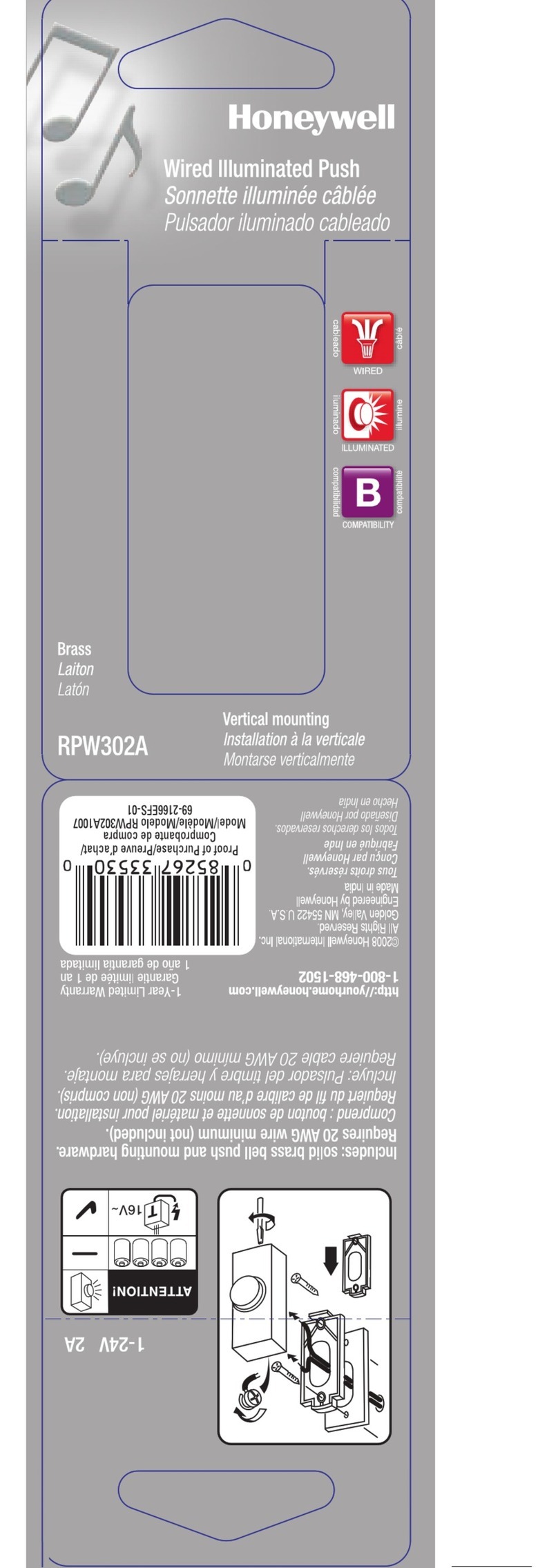

- Remove the grey plastic retainer or accessory.

- Remove the old filter and replace with a fresh filter.

- Replace the grey plastic retainer or accessory.

5. MAINTENANCE

4 5

4. OPERATIONS

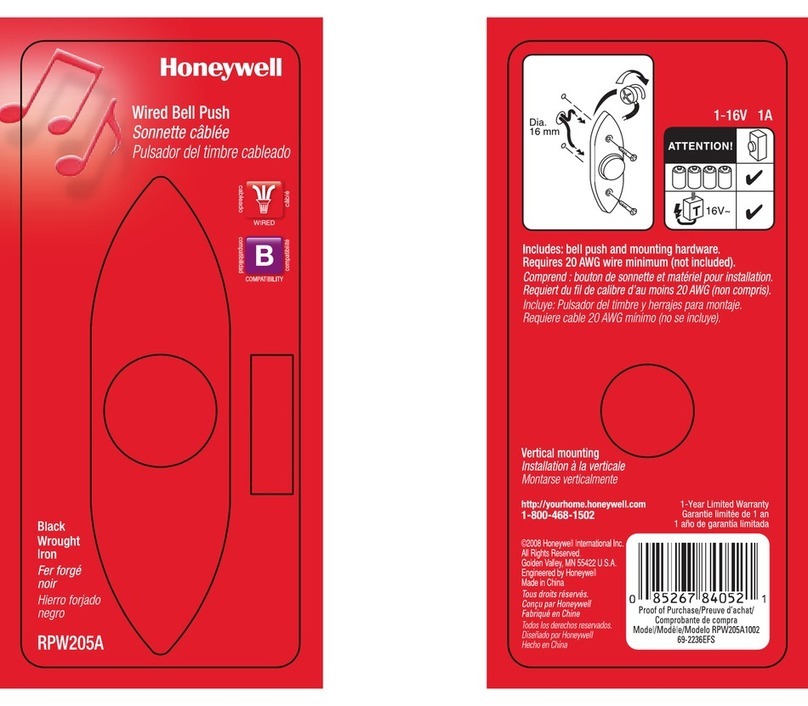

Table 2: Meter Settings

* Rating of Gas to be Detected

* Calibration

Gas 8* 7* 6* 5* 4* 3* 2* 1*

8* 50 62 76 95 - - - -

7* 40 50 61 76 96 - - -

6* 33 41 50 62 78 98 - -

5* 26 33 40 50 63 79 100 -

4* 21 26 32 40 50 63 80 -

3* - 21 26 32 40 50 64 81

2* - - - 25 31 39 50 64

1* - - - - 25 31 39 50

Note: These settings must only be used with a calibration

gas concentration of 50% LEL.

Cross Calibration example:

The target gas to be detected is Butane. The calibration

gas available is Methane (50% LEL).

Look up the star rating for each gas (Table 1):

Butane 4*, Methane 6*

Check the meter settings for 50% LEL calibration gas

(Table 2).

The control card meter should therefore be set to 78%

to give an accurate reading for Butane, using 50% LEL

Methane as a calibration gas.

4.3 FAULT FINDING

Sensor reads non zero all the time:

-gas could be present, ensure there is no combustible

gas in the atmosphere.

Sensor reads non zero when no gas is present:

-adjust the zero of the control system.

Sensor reads low when gas is applied:

-adjust the span of the control system.

Sensor reads high when gas is applied:

-adjust the span of the control system.

Sensor reads zero when gas is applied:

-check the wiring.

-check that the dust protection cap has been removed.

-check that the sinter is not obstructed.

-replace the sensor if poisoning is suspected.

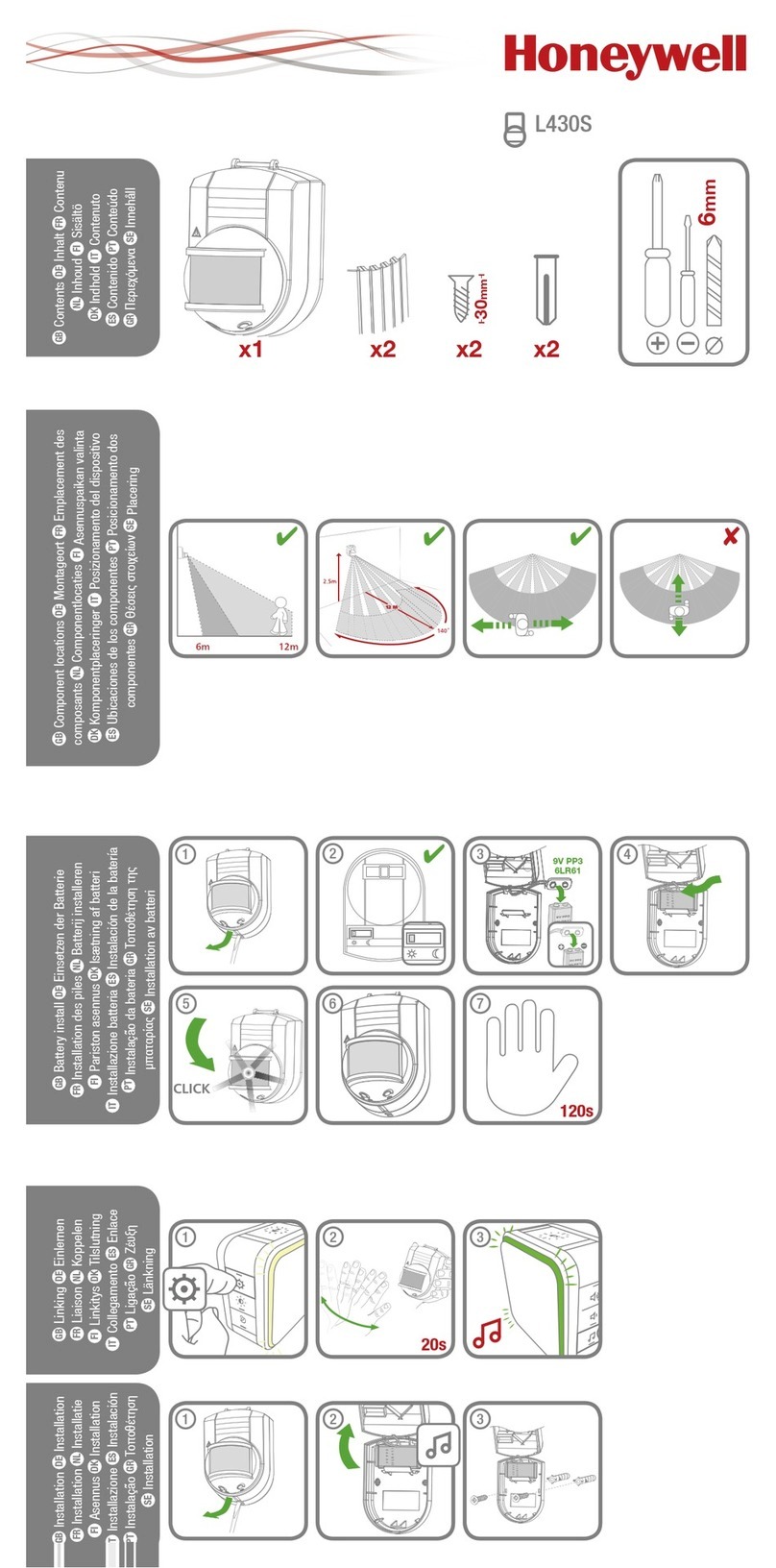

Table 3: Meter Multiplication Factors

Unit calibrated Unit used to detect

To Detect 8* 7* 6* 5* 4* 3* 2* 1*

8* 1.00 1.24 1.52 1.89 2.37 2.98 3.78 4.83

7* 0.81 1.00 1.23 1.53 1.92 2.40 3.05 3.90

6* 0.66 0.81 1.00 1.24 1.56 1.96 2.49 3.17

5* 0.53 0.66 0.80 1.00 1.25 1.58 2.00 2.55

4* 0.42 0.52 0.64 0.80 1.00 1.26 1.60 2.03

3* 0.34 0.42 0.51 0.64 0.80 1.00 1.27 1.62

2* 0.26 0.33 0.40 0.50 0.63 0.79 1.00 1.28

1* 0.21 0.26 0.32 0.39 0.49 0.62 0.78 1.00

4. OPERATIONS

4. OPERATIONS

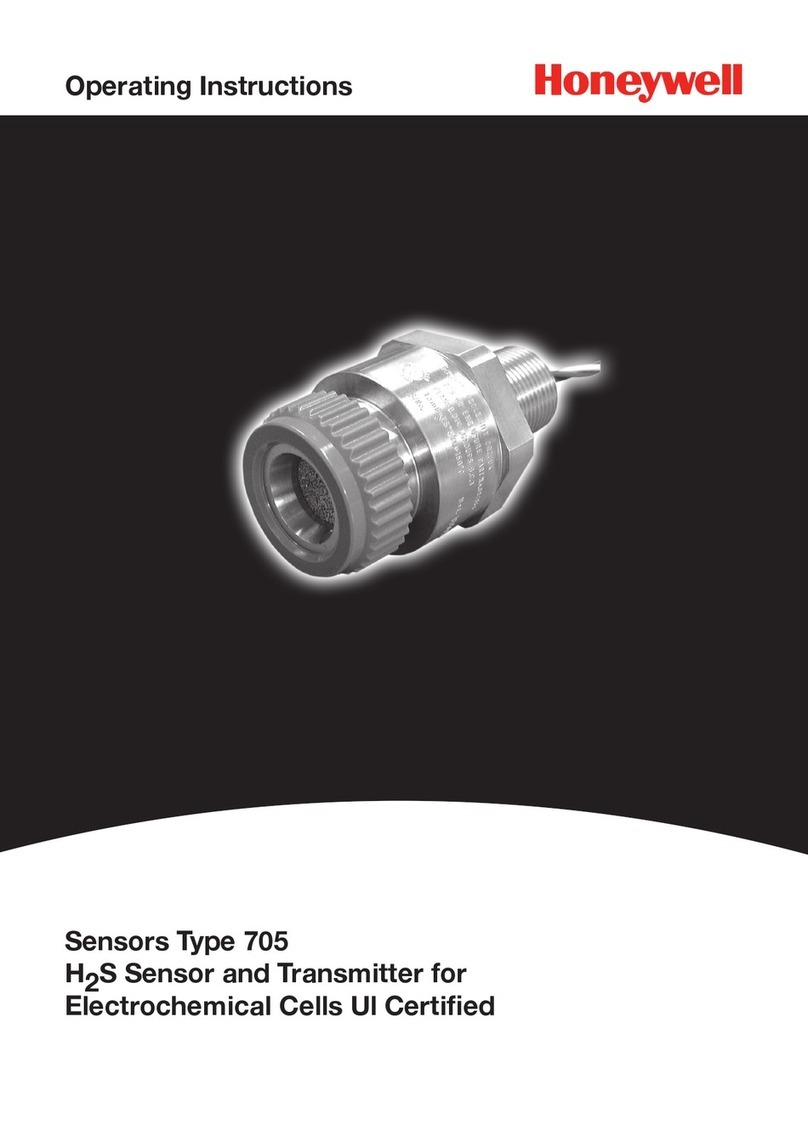

Grey plastic retainer

Filter

Main body of sensor

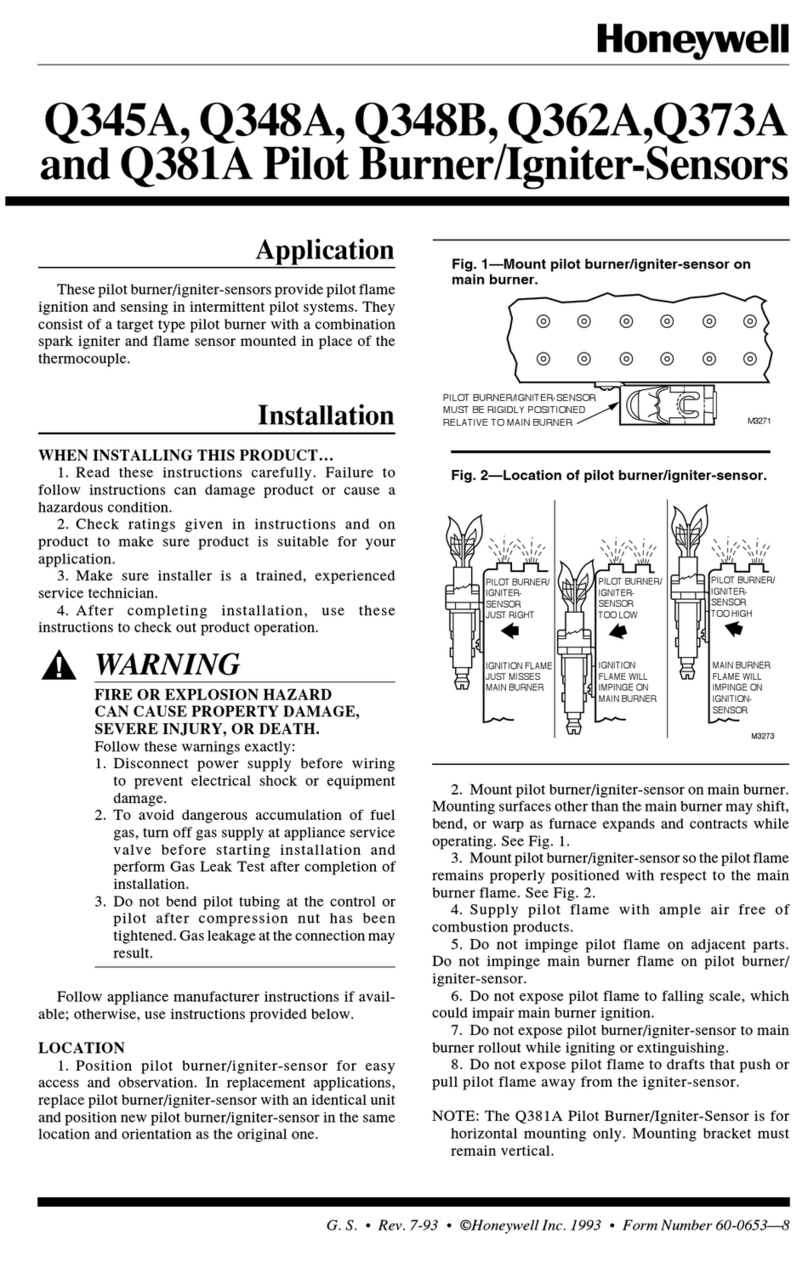

4.1 INSTALLATION

The SensePoint must be fitted into a suitably approved Exe

or Exd junction box fitted with a suitably approved cable

gland. This should be correctly installed before use. Cabling

should be multicore, three wire minimum, of conductor size

2.5 mm2 max.

The sensor should be fitted into a threaded hole within the

junction box and locked in place with a lock nut. Ensure that

junction box thread is compatible with sensor thread.

The sensor should be installed in a location free from direct

heat sources. It should be fitted such that it either points

downwards or horizontally. It is not recommended that the

sensor points upwards. See the technical handbook for

installation in forced air conditions.

Wiring connections are:-

4. OPERATIONS 4. OPERATIONS

3.1 WARNINGS

This apparatus is not suitable for use in

oxygen enriched atmospheres (>21%V/V).

Oxygen deficient atmospheres (<10%V/V)

may suppress sensor output.

Refer to local or national regulations

relative to installation at the site.

Operator should be fully aware of the action

to be taken if the gas concentration exceeds

an alarm level.

SensePoint should be protected from

mechanical impact. Installation should

consider not only the best placing for gas

leakage related to potential leak points,

gas characteristics and ventilation, but also

where the potential of mechanical damage

is minimized or avoided.

3.2 CAUTIONS

Atmospheres above 100% LEL may

suppress the sensor reading.

Do not modify or alter the sensor

construction as essential safety

requirements may be invalidated.

Install using certified Exe or Exd junction

box, connectors and glanding.

Dispose of in accordance with local disposal

regulations. Materials used -Fortron®

(PPS- Polyphenylene Sulphide).

3. SAFETY

4.2 CALIBRATION

Prior to calibration, allow the sensor to warm up for

approximately 10 minutes. Re-calibration should only be

attempted by qualified service personnel.

First zero the control system with no gas present on the

sensor. If combustible gas is suspected to be in the vicinity of

SensePoint, flow clean air over the sensor using a flow housing

(see below).

Fit a flow housing and connect a cylinder of either air, for a

zero, or a known concentration of gas in air, at approximately

the alarm point (e.g. 50% LEL), to the flow housing. Pass the

gas through the flow housing at a flow rate of approximately

1 l to 1.5 l per minute. Allow the sensor to stabilise. When

gassing with air, adjust the control card to indicate zero. For

span, the control card should be adjusted to indicate the

concentration of the target gas being applied. Remove the

flow housing and the gas supply.

Sensors should be calibrated at concentrations representative

of those to be measured. It is always recommended that

SensePoint is calibrated with the target gas it is to detect. If

this is not possible, then cross calibration can be used.

For calibration in fast flow conditions see the technical

handbook.

4.3 CROSS CALIBRATION PROCEDURE

When the SensePoint sensor is to be calibrated with a gas

which is different to the gas/vapour to be detected, the

following cross calibration procedure should be followed.

Table 1 lists gases according to the reaction they produce at

the detector. An eight star (8*) gas produces the highest

output while a one star (1*) gas produces the lowest output.

(These are not applicable at ppm levels.)

4. OPERATIONS

To calibrate the SensePoint sensor, obtain the star rating for

both the test gas and the gas to be detected from table 1.

These values may then be used in table 2 to obtain the

required meter setting when a 50% LEL test gas is applied to

the detector.

If a sensor is to be used to detect a gas other than that for

which it was calibrated, the required correction factor may be

obtained from table 3. The meter reading should be multiplied

by this number in order to obtain the true gas concentration.

IMPORTANT

Since combustible sensors require oxygen for correct

operation, a mixture of gas in air should be used for

calibration purposes.

Assuming an average sensor performance, the sensitivity

information in tables 1 to 3 is normally accurate to ± 20%.

Table 1: Star Rating of Gasses

7 8 9 10

6

Gas Star Rating

Acetone 4*

Ammonia 7*

Benzene 3*

Butane 4*

Diethyl ether 4*

Ethane 6*

Ethanol 5*

Ethyl acetate 3*

Ethylene 5*

Gas Star Rating

Hexane 3*

Hydrogen 6*

Methane 6*

Octane 3*

Propan-2-ol 4*

Propane 5*

Styrene 2*

Tetra hydrafuran 4*

Xylene 2*

The unit requires 200mA current with a nominal 3V supply.

Installation and service are to be performed by a qualified

installation engineer with the power to the sensor

disconnected.

SENSITIVE

(S)

NON

SENSITIVE

(NS) COMMON

(01)

SPARE

BROWN BLUE WHITE

SENSOR