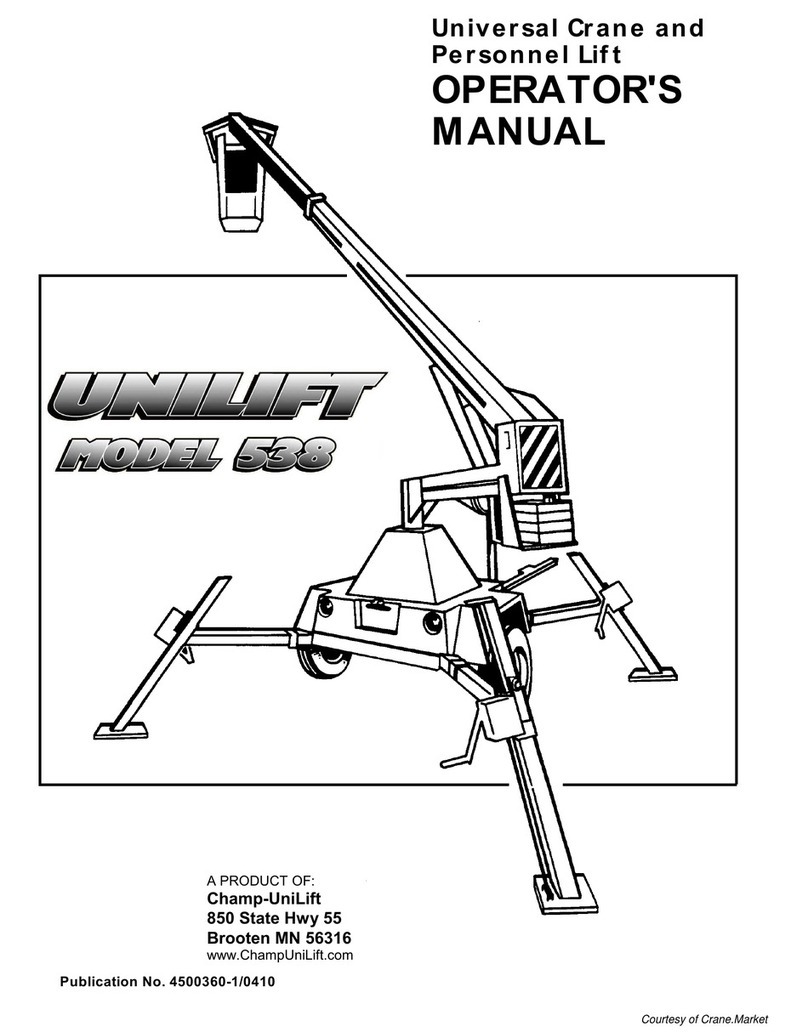

Wienold Lifte MFC750/K User manual

OPERATING MANUAL

.de

-

MFC/K

MFC/Ks

MFC

Mini Floor Crane

Release: 1.4

14.Nov.2017

Contents

3

4

5

6

8

10

15

17

18

20

21

22

24

26

27

28

30

31

2

MFC Mini Floor Crane

Basic procedures

General description

MFC Series typ overview

COMPONENTS

MFC/Ks

MFC/K

SAFETY

Safety instructions

Pre-operation inspection

Working area inspection

Function tests

Operating instructions

INSTALLATIONS

MFC/Ks

MFC/K

OPERATION

Telescope and Hydraulic Cylinder

Lateral outrigger

Loading

Transportation

Technical data

Declaration of conformity

Copyright © Norbert Wienold GmbH 2015. All rights reserved.

Contact:

3

MFC Mini Floor Crane

The manufacturer‘s instructions and safety regulations.

The operating and safety instructions for this crane.

The inscriptions, labels and warning signs on this crane.

The safety instructions and operating instructions at the job site.

The current, local and legal safety regulations.

Basic Procedures

Please read and comply with:

This crane fulfils the current CE regulations and norms, EN

ISO 12100, as well as the machinery directive 2006/42/EG,

when used and operated according to the manufacturer‘s

recommendations.

It is the duty and responsibility of each operator to obey all

regional rules and regulations concerning the safe usage

of this crane.

Please read carefully and follow all of the safety

instructions for this appliance before

maintenance, repair or operation.

This is in compliance with all the manufacturer‘s

recommendations and all of the legal guidelines as

required by the government and local authorities.

In order to allow for a safe and appropriate use of this

crane, it may only be used by persons who have been

instructed by authorised specialists and who have been

granted operative authorisation.

Repairs and maintenance of this crane are only to be

undertaken by qualified and trained personnel without

exception.

This crane is subject to an annual UVV-inspection by an

authorised tester. Without a current UVV-test seal this

crane must not be operated.

The owners and anyone hiring/borrowing this crane

should have all construction parts undergo a complete

inspection. All of the crane‘s functions must be thoroughly

examined and inspected before sale or lease takes place.

Damaged and malfunctioning parts must be repaired or

replaced.

This operating manual is an essential requirement

for all operators of this equipment. For this reason

it must always remain in its appropriate place on

the crane and always be readily available.

Norbert Wienold GmbH is constantly developing and

improving this and other Wienold products.

For this reason our appliances and products may be

subject to modification without prior notice.

If you have any questions or queries, or if you notice any

mistakes and/or deviations concerning the contents of this

operating manual, please do not hesitate to contact us.

Norbert Wienold GmbH

Industriegebiet Waldstr. 35a

48488 Emsbüren

Tel. 0 59 03 - 93 94 0

Fax 0 59 03 - 93 94 50

www.wienold-lifte.de

e-mail: info@wienold-lifte.de

Der Mini Floor Crane consists of a chassis with crane

construction and extendable Telescope. The height of the

Telescope is determined by pumping on the hydraulic

cylinder.

The lowering speed of the Telescope is controlled by opening

the valve on the Hydraulic cylinder. The further the valve is

opened, the faster the Telesope lowers.

The extension of the Telescope is done manually and step by

step.

The MFC payload depends on:

a) Types

b) Telescope extension / Distance load center to front axle

d) Weight of attachment

The MFC offers two Models, differed by the outrigger

arrangement on the Chassis:

MFC/K: Two long outrigger with counterweights.

MFC/Ks (Shorty): Without outrigger, with counterweights.

MFC Wienold Mini Floor Crane

The MFC Installation is done as following:

MFC/K: Chassis with 2 long outrigger aligned rearwarded,

and 2 boxes with 14 weights each

MFC/ Ks: Chassis with 2 boxes, 14 weights each

To accommodate loads, the Mini Floor Crane is equipped

with a crane hook as standard.

Positioning of the MFC during operation has to be reduced to

minor and manually movements.

The Mini Floor Crane is not designed for continuous

operation. Never leave the Mini Floor Crane with the

telescope lifted. Never leave the MFC unattended.

Transportation of persons with the MFC is strictly prohibited!

Do not operate the MFC in areas where an explosion hazard

exists.

ALWAYS READ AND UNDERSTAND THE OPERATOR MANUAL BEFORE OPERATION!

All components must be checked for the specified payloads before use.

The payload of the MFC is generally depending on the extension of the Telescope.

Always take care for the ratio of PAYLOAD and TELESCOPE EXTENSION by considering the weight

of the used attachment.

Always observe the following for safe operation:

1. Load capacity of the MFC taking into account the Telescope extension

2. Payload of the attachment

3. Weight of the attachment

Copyright © Norbert Wienold GmbH 2016. All rights reserved.

4

MFC Mini Floor Crane

General Description

5

MFC Mini Floor Crane

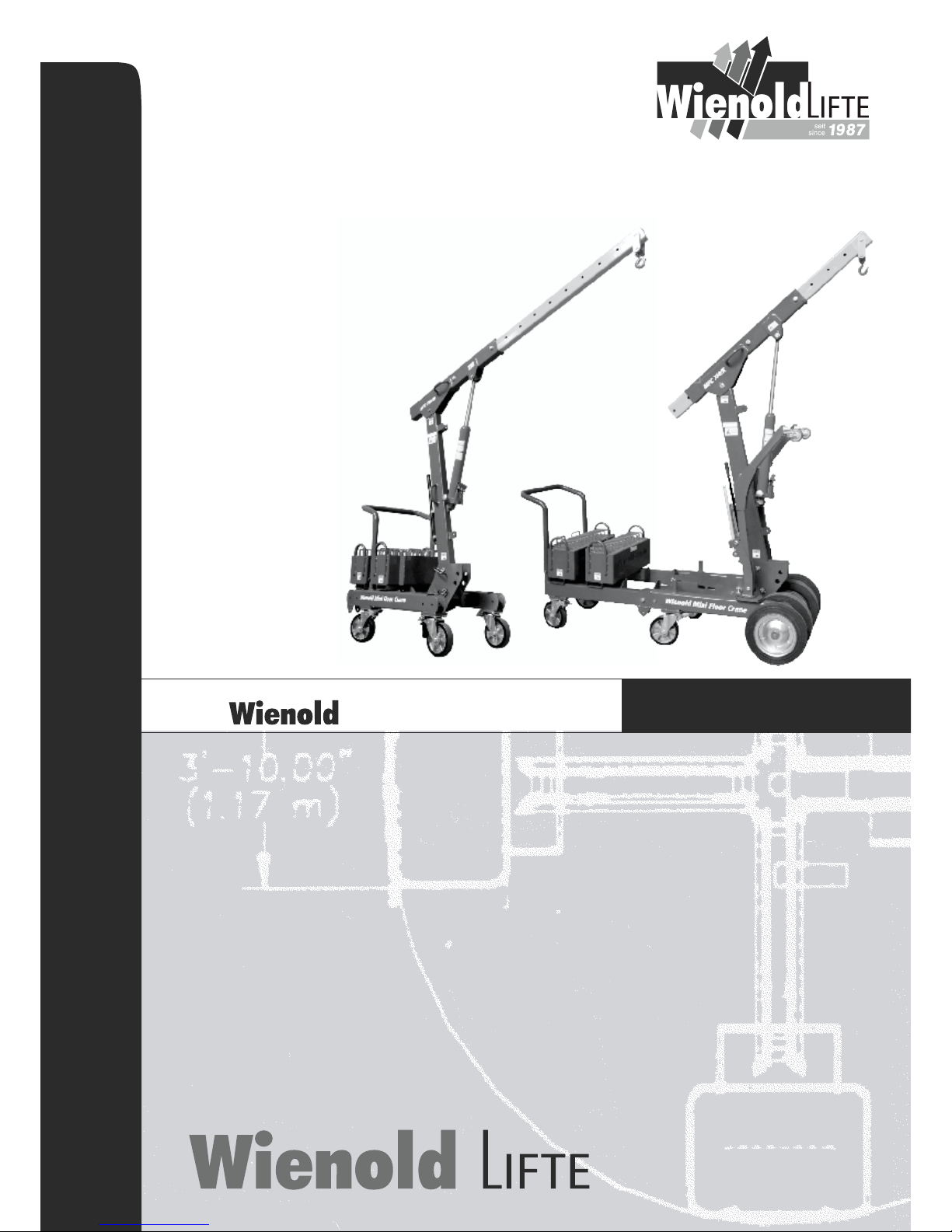

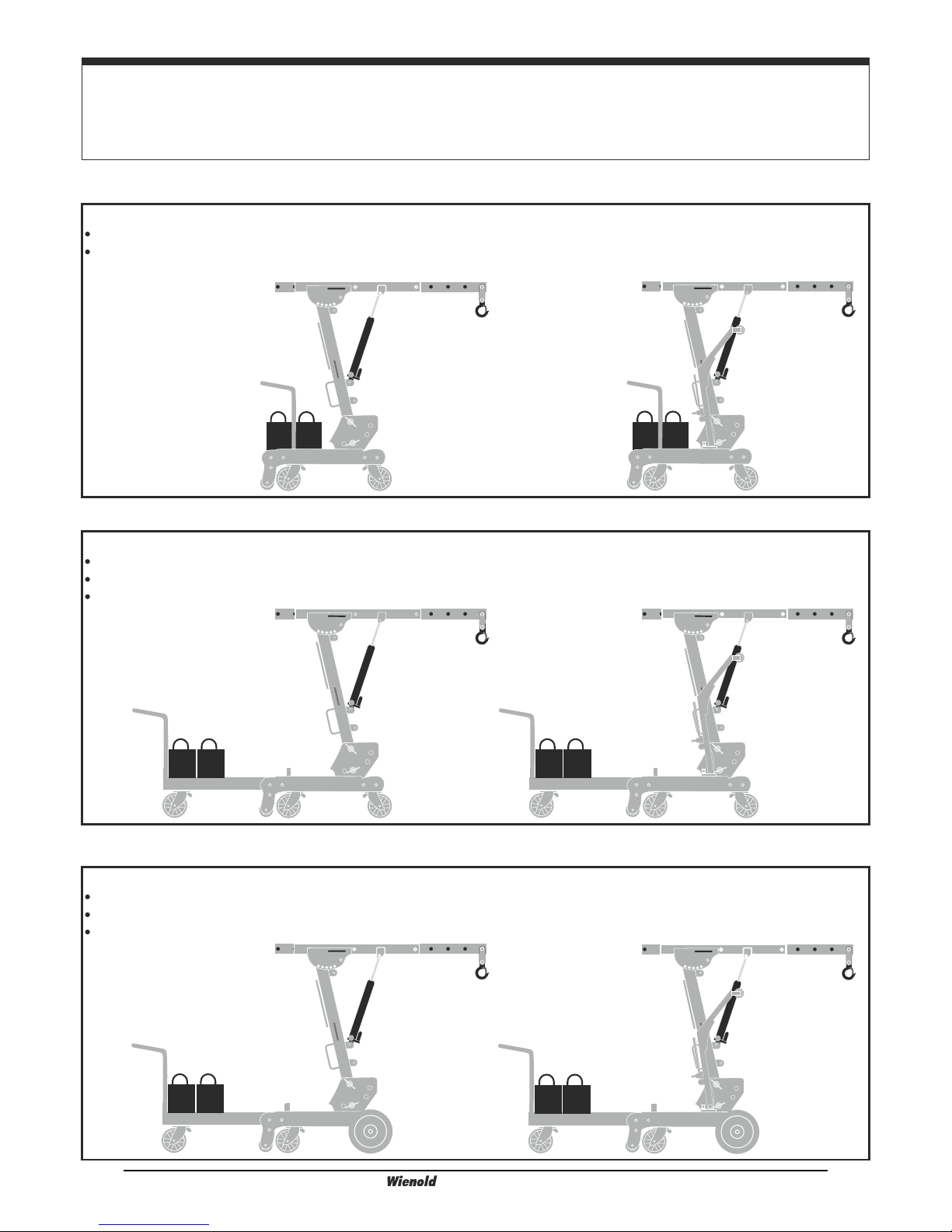

MFC750 Models

Standard: without lateral outrigger

Standard:

MFC750/K

Chassis as long version with

2 long outrigger (aligned rearwarded)

2 Weight boxes with 14 weights each

Option: 2 lateral outrigger With lateral outrigger:

Standard:

MFC750/Ks

Chassis in short version (Shorty)

2 Weight boxes with 14 weights each

Option: 2 lateral outrigger

With lateral outrigger:

Standard:

MFC750/K Outdoor

Long version with outdoor wheels

2 long outrigger (aligned rearwarded)

2 Weight boxes with 14 weights each

Option: 2 lateral outrigger With lateral outrigger:

Operating Manual

MFC Mini Floor Crane

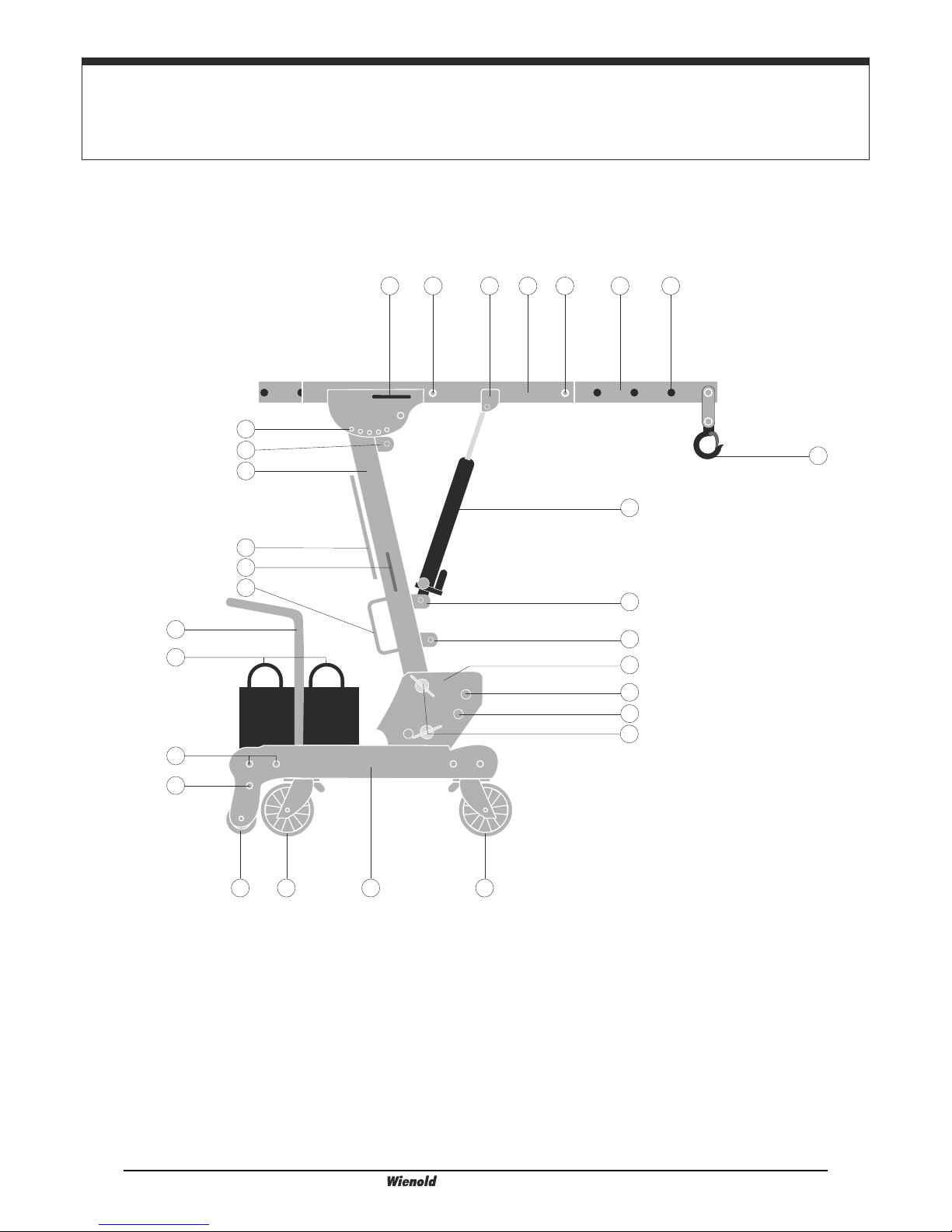

Components MFC750/Ks (Shorty)

1) Carry handle

2) Locking screw telescope

3) Adapter hydraulic cylinder

4) Telescope arm

5) Telescope

6) Telescope adjustment

7) Load hook

8) Hydraulic cylinder

9) Additional Hydraulic cylinder

10) Adapter main arm

11) Transport drillings

12) Mounting bolts

13) Swivel caster

14) Chassis

15) Support caster

16) Fixation / Drillings for long outrigger

17) Counterweights and Boxes

18) Steering bracket

19) Pump lever for hydraulic cylinder

20) Main arm

21) Fixing hole for transport position

22) Locking holes

6

MFC Mini Floor Crane

11

12

10

9

8

7

652

4

31

22

21

20

19

1

1

18

17

16

13 14 1315

16

2

11

Standard: Without Lateral Outrigger

Operating Manual

MFC Mini Floor Crane

3

7

MFC Mini Floor Crane

1) Carry handle

2) Locking screw telescope

3) Adapter hydraulic cylinder

4) Telescope arm

5) Telescope

6) Telescope adjustment

7) Load hook

Additional accessories:

11

12

10

9

8

7

652

4

31

22

21

20

19

1

1

18

17

16

13 14 1315

16

2

11

23

Components MFC750/Ks (Shorty)

With Optional Lateral Outrigger

8) Hydraulic cylinder

9) Additional Hydraulic cylinder

10) Adapter Main arm

11) Transport drillings

12) Mounting bolts

13) Swivel caster

14) Chassis

15) Support caster

16) Fixation / Drillings for long outrigger

17) Counterweights and Boxes

18) Steering bracket

19) Pump lever for hydraulic cylinder

20) Main arm

21) Fixing hole for transport position

22) Locking holes

23) Lateral outrigger

3

8

MFC Mini Floor Crane

Components MFC750/K

11

12

10

9

8

652

4

31

22

21

20

19

1

1

18

17

16

13 14 1315

2

11

7

2313

1) Carry handle

2) Locking screw telescope

3) Adapter hydraulic cylinder

4) Telescope arm

5) Telescope

6) Telescope adjustment

7) Load hook

8) Hydraulic cylinder

9) Additional Hydraulic cylinder

10) Adapter Main arm

11) Transport drillings

12) Mounting bolts

13) Swivel caster

14) Chassis

15) Support caster

16) Fixation / Drillings for long outrigger

17) Counterweights and Boxes

18) Steering bracket

19) Pump lever for hydraulic cylinder

20) Main arm

21) Fixing hole for transport position

22) Locking holes

23) Long outrigger

Operating Manual

MFC Mini Floor Crane

3

Standard: Without Lateral Outrigger

9

MFC Mini Floor Crane

Components MFC750/K

With Outdoor Wheels And Lateral Outrigger

11

12

10

9

8

652

4

31

22

21

20

19

1

1

18

17

16

13 1415

2

11

7

2313

25

1) Carry handle

2) Locking screw telescope

3) Adapter hydraulic cylinder

4) Telescope arm

5) Telescope

6) Telescope adjustment

7) Load hook

Additional accessories:

8) Hydraulic cylinder

9) Additional Hydraulic cylinder

10) Adapter Main arm

11) Transport drillings

12) Mounting bolts

13) Swivel caster

14) Chassis

15) Support caster

16) Fixation / Drillings for long outrigger

17) Counterweights and Boxes

18) Steering bracket

19) Pump lever for hydraulic cylinder

20) Main arm

21) Fixing hole for transport position

22) Locking holes

23) Long outrigger

24) Lateral outrigger

25) Outdoor wheels

Operating Manual

MFC Mini Floor Crane

3

24

10

MFC Mini Floor Crane

Safety Instructions

Operating Manual

MFC Mini Floor Crane

Non compliance with the instructions and safety rules in this

operating manual may result in serious injury or accidents

including death!

The personnel have been trained on this type of unit

and are deemed competent. All operators should read

the operating manual carefully.

1. Avoid hazardous situations.

Know and understand the safety regulations

before going on to the next section.

2. Always perform a pre-operation inspection on

the MFC.

3. Inspect the working area thoroughly before

using the MFC.

4. Always perform the function test as per the

operating manual prior to use.

5. Only use the MFC as per the operating instructions.

Any deviations are not acceptable. In case, you

must always contact the owner of the equipment.

Do Not Operate Unless:

Read, understand and obey:

a) the manufacturer‘s instructions and safety instructions.

b) the operating manuals and safety instructions for the MFC.

c) the inscriptions, labels and warning signs on the MFC.

d) the safety instructions and work procedures on the job site.

e) the relevant legislation in force for the equipment in use.

11

MFC Mini Floor Crane

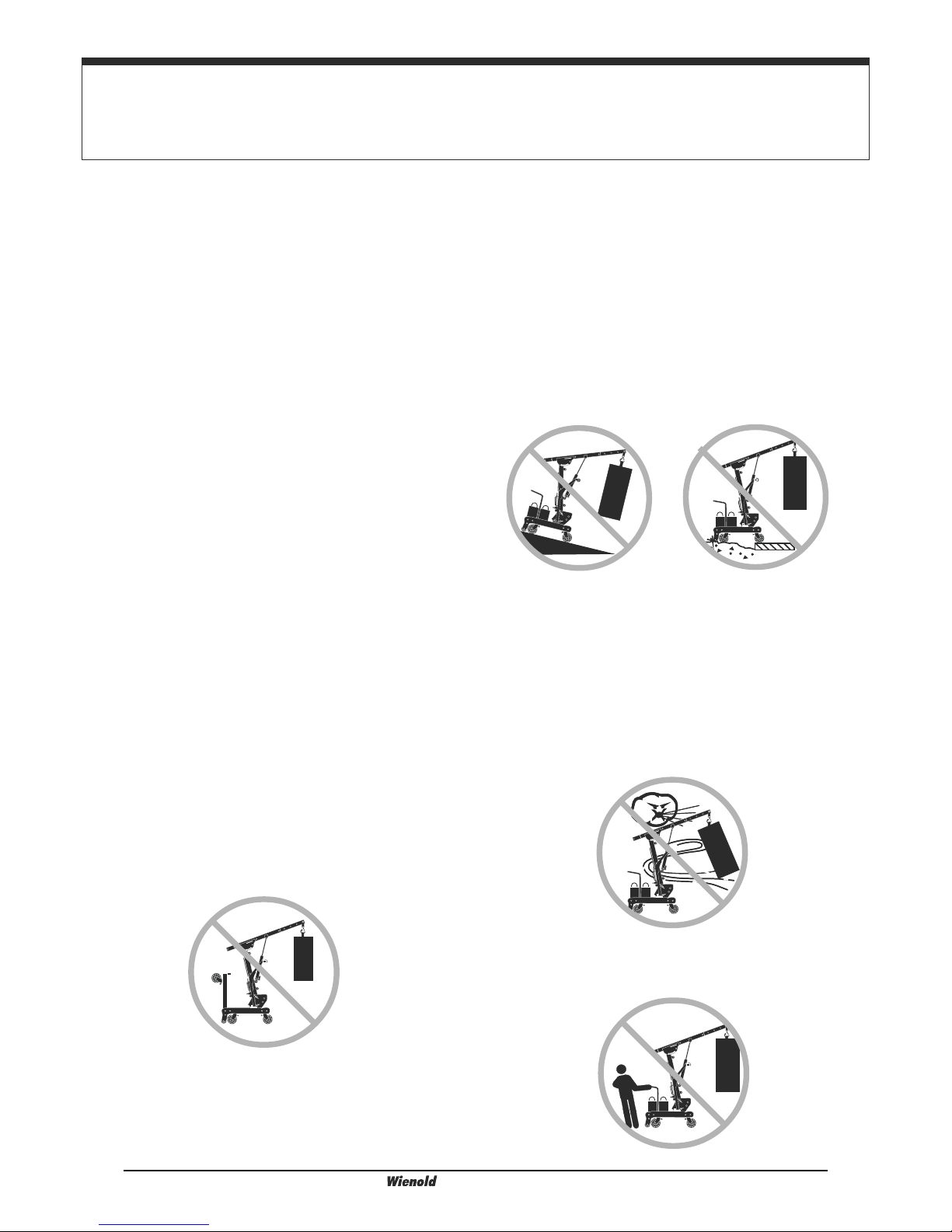

Prior to use, check the working area for steep slopes and

drop-offs, holes and debris. Also check for instable, slippery

or icy surfaces and other possible sources of danger.

Do not raise the load unless the loading devices are correctly

secured to the unit.

Do not use any blocks, stones, planks or any other items

to balance the MFC.

Do not move the MFC with a raised load except for very

minor positioning.

Never operate the MFC if it is iced. Never operate the MFC

in strong or gusty wind conditions. An increase in the load

surface area will decrease stability when operating in windy

conditions.

Never leave a load in a raised position when windy

conditions may occur.

Always ensure, when raising or lowering secured or

overhanging loads, that no obstructions can interfere

with the safe operation of the unit.

Safety Instructions

Wear Appropriate Personal Protective

Equipment (PPE)

Always wear PPE before operating the unit including:

1. Safety helmets

2. Safety goggles

3. Safety shoes

Always check which PPE is required at each particular

job site. Do not use the unit and do not execute any

function tests without wearing the appropriate PPE.

Keep loose clothes, jewelry, hair etc. away from any moving

parts and ensure appropriate PPE is worn whilst operating

the unit. Keep hands and feet within the areas acceptable

to operate the winch safely to raise or lower the unit.

Fall Hazards

Do not use this lift as a personnel lifting platform or step.

Do not stand on the loading accessories.

Do not climb on the mast, the chassis or other components.

Tip-over hazards

Lift the load only when all outrigger, stabilizers etc. are

completely lowered, aligned, locked and securely fixed.

Make sure that the casters have solid ground contact.

For models with lateral outriggers: Lift the load only,

when the outrigger are aligned correctly and the casters

have solid ground contact. Only operate the MFC with

completely filled weight boxes.

A fixed and secured outrigger must not be re-adjusted

as long as the crane is loaded or is in a raised position.

While operating with load, allways take care that the MFC

is positioned on solid, load-bearing and horizontal ground.

Operating Manual

MFC Mini Floor Crane

12

MFC Mini Floor Crane

Safety Instructions

Electrocution Hazards - Danger to Life

The MFC is not electrically insulated and will not provide

protection from contact with or proximity to electrical

current.

Keep away from the MFC if it contacts electrical power

cables.Personnel must not touch or operate the MFC until

the power conductors have been switched off.

Maintain safe distances away from electrical power

conductors and appliances.

Please take into account the relevant current legal

regulations and the following chart:

Do not lean any ladders or scaffolding against the crane or

the load.

Do not operate the MFC on a movable/mobile surface or

on a motor vehicle.

The Safe Working Load (SWL) must not be exceeded

under any circumstances. Aways refer to the load charts

on the unit.

Avoid moving the crane with closed outriggers over debris

or uneven ground.

Never replace crane parts that are important for stability

or construction with parts with different weights and

specifications. Only use original replacement parts.

If the equipment is damaged or operating incorrectly

you must contact the hirer immediately.

Only use the approved loading accessories with this crane.

Lifting Hazards

Always use the correct lifting techniques when loading or

tilting the MFC. Personnel should be trained and competent

to use the unit correctly.

Always use the correct lifting techniques when installing

and de-installing the loading devices.

Operating the MFC

Ensure that the safety brakes are engaged prior to operating

the MFC in order to avoid rolling.

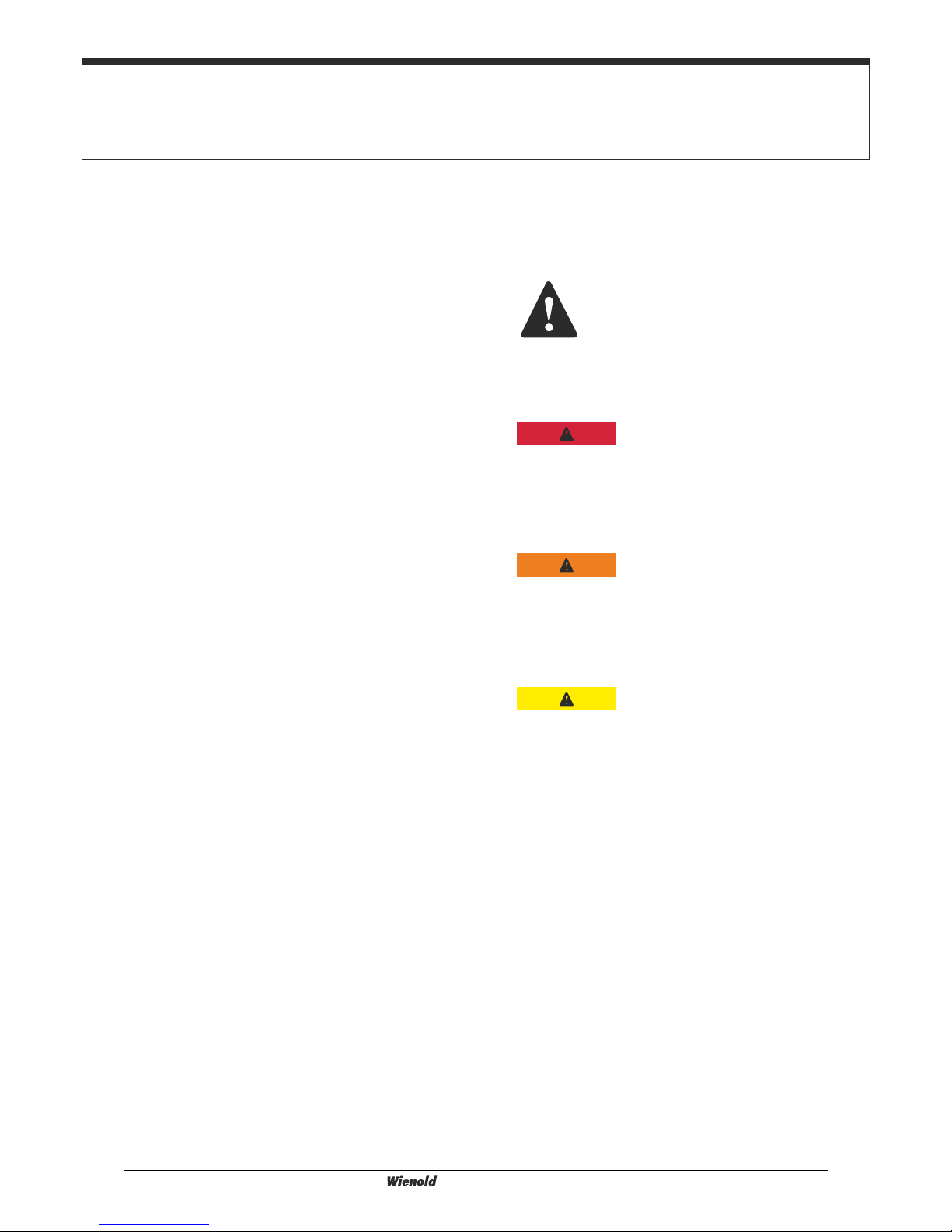

Do not ever stand or allow others to stand under the load

or loading devices. Do not stand on the chassis, outrigger

or any other components.

Beware of telescope movement and possible swaying and

sagging of electrical cables. Be especially careful in strong

or gusty wind conditions!

The unit is not to be used in conjunction with welding

units fitted to the chassis, outrigger etc. - under any

circumstances.

Injury Hazard

Do not grasp in the telescope arm, the cylinder and do

not grasp into adjustment head of Main arm and

Telescope arm.

VOLTAGE

Phase-to-Phase

0 - 300 V

300 V - 50 kV

50 kV - 200 kV

200 kV - 350 kV

350 kV - 500 kV

500 kV - 7550 kV

750 kV - 1000 kV

Avoid Contact

3,1 m

4,6 m

6,1 m

7,6 m

10,7 m

13,7 m

MINIMUM SAFETY DISTANCE

Meters

Operating Manual

MFC Mini Floor Crane

Collision Hazards

Check the working area for overhead obstructions or other

potential sources of danger.

Always be careful when rising or lowering a load on site

with the MFC. Avoid to move the unit. Avoid sharp turns,

inclines or voids in the ground. Only move the MFC in

transport position!

Loading

When loading the MFC, always ensure that the unit and

the transport vehicle are on an even subsurface.

Always use the correct lifting techniques. When loading with

a crane use the carry handles on the Main arm and the

Telescope arm. Do not lift the MFC in working position and

with attached load !

Before loading, always remove:

load,

weight boxes,

counterweights,

stearing bracket,

loading accessories (if used).

13

MFC Mini Floor Crane

•

Safety Instructions

Crushing Hazards

Do not raise if the load is not

1. fixed

2. centred

2. secured.

Never stand under the load as it is being raised or lowered

or suspended. Do not allow others to stand in the lifting

area when the unit is being operated.

Standing under the load is prohibited.

Before lowering the load make sure that nothing is below,

e.g. persons, obstacles etc.

While operating the MFC keep hands and fingers away

from the cylinder, the folding outriggers and other potential

pinch points.

Maintain a firm grasp on the outrigger when the safety

bolt is removed. Otherwise the outrigger will fall.

Load hook

Raise loads with a suitable load hook only. Make sure before

loading that the load hook is suitable for the load and

properly fastened. Raise loads only when the load hook is

properly installed and the load is sufficiently secured. When

lifting, observe the ratio of lifting height and load center.

Never overload the MFC.

Operating Manual

MFC Mini Floor Crane

•

•

•

•

14

MFC Mini Floor Crane

Safety Instructions

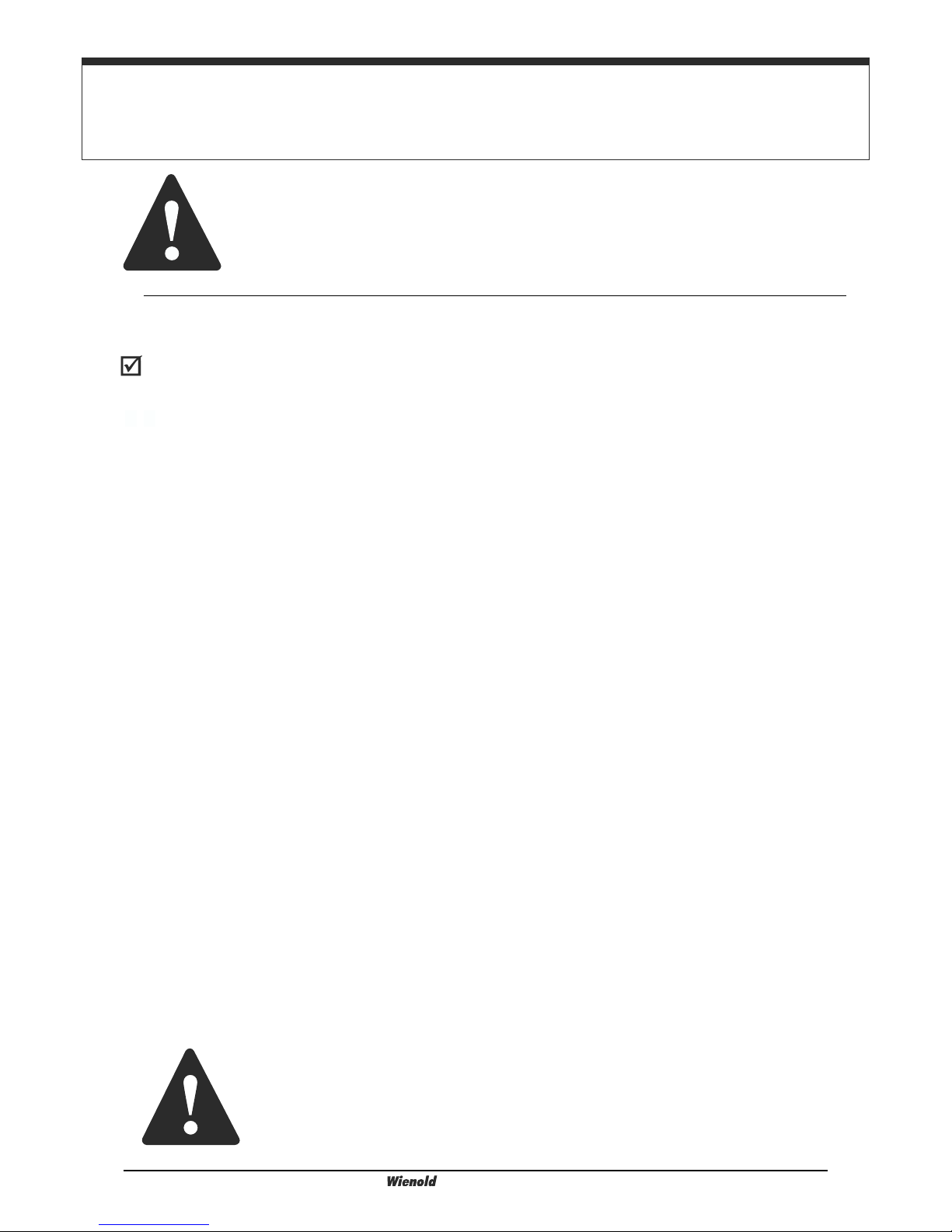

Legend - Warning Signs

Wienold lifts, appliances & machines use symbols,

colour codes and signal words to identify the following:

Safety Alert Symbol:

This is used to alert personnel to

potential injury hazards.

Obey all safety messages that

follow this symbol to avoid

possible injury or death.

RED = DANGER

This is used to indicate the presence

of an imminently hazardous

situation which, if not avoided,

will result in death or serious injury.

.

ORANGE = WARNING

This is used to indicate the presence

of a potentially hazardous situation

which, if not avoided, could result

in death or serious injury.

YELLOW = CAUTION

This is used to indicate the presence

of a potentially hazardous situation

which, if not avoided, may cause

property damage or could result

in death or serious injury..

Damaged Crane Hazards

Do not operate a damaged or malfunctioning lift.

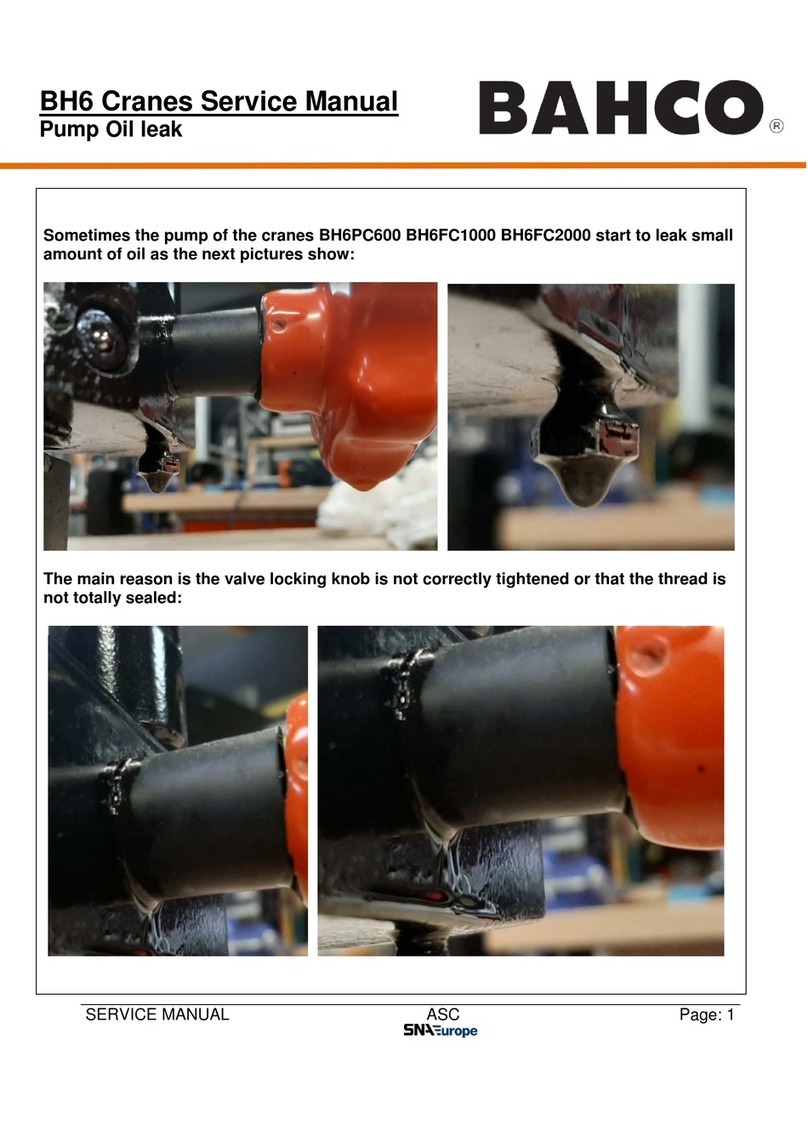

Do not use the MFC with a worn, leaking, oil-lubricated

or bent cylinder.

Always conduct a thorough pre-operation

inspection prior to each use.

Any damage, faults or failure of the unit must be assessed

by a competent person trained to identify such matters and

instructed for repair work on this unit.

Non appliance to this rule may lead to serious injury and

possible danger to life.

Always ensure that all warning signs are legible and in

place.

Always ensure that the operating manual is complete,

legible and placed in the storage container installed on the

unit.

Only use silicon spray when lubricating MFC components

(no oil or grease).

Hazard due to improper use

Never leave a loaded MFC unattended or suspended.

Unauthorised persons may attempt to operate the unit

without having been correctly briefed, they could create an

unsafe and dangeours situation.

The MFC is not designed for continuous operation. The load

could be sinking inintentionally and thereby create

dangerous situations.

Operating Manual

MFC Mini Floor Crane

Non compliance with the instructions and safety rules in this

operating manual may result in serious injury or accidents

including death!

15

MFC Mini Floor Crane

Pre-operation Inspection

The pre-operation inspection is a visual inspection which

must always be performed by the operator prior to each

work assignment.

This inspection is designed to identify and avoid possible

malfunctions of the unit before the operator tests it.

Check the unit for modifications, damages and loose or

missing parts.

A malfunctioning or modified unit must not be operated

under any circumstances.

If any damage or unauthorised deviation from factory

delivered condition is discovered, the unit must be removed

from service and appropriately tagged. Additionally, the

owner of the equipment must be informed.

Repairs to the unit may only be undertaken by a qualified

service technician in compliance with the manufacturer‘s

specifications.

The operator must perform a new pre-operation inspection

after any repairs are completed, before going on to the

function tests.

Operating Manual

MFC Mini Floor Crane

The personnel have been trained on this type of

unit and are deemed competent. All operators

should read the operating manual carefully.

1. Avoid hazardous situations.

Know and understand the safety regulations

before going on to the next section.

2. Always perform a pre-operation inspection

on the MFC.

3. Inspect the working area thoroughly before

using the MFC.

4. Always perform the function test as per the

operating manual prior to use.

5. Only use the MFC as per the operating instructions.

Any deviations are not acceptable. In case, you

must always contact the owner of the equipment.

Do Not Operate Unless:

Read, understand and obey:

a) the manufacturer‘s instructions and safety instructions.

b) the operating manuals and safety instructions for the MFC.

c) the inscriptions, labels and warning signs on the MFC.

d) the safety instructions and work procedures on the job site.

e) the relevant legislation in force for the equipment in use.

Fundamentals:

16

MFC Mini Floor Crane

Please ensure

that the operating manual is complete, legible and placed

in the storage container, installed on the unit.

Please ensure

that all warning signs and labels are both legible and

correctly positioned. For further information see

Warning Signs Section.

Check

the following components and areas for damage,

modifications and incorrectly installed or missing parts.

Make sure that every compnent of the unit is functional

and without any damage e.g.:

Chassis and base components

Outrigger, stabilisers, legs

Wheels and tyres

Cylinder

Main arm, Telescope arm and Load hook

Bolts, pins, screws and nuts

Other fastening and safety devices

•

Check the entire lift and loading

devices for:

Bents and damage

Corrosion and rust

Cracks in welds and structural components

Defects on the Cylinder

Please ensure

that all structural and other corresponding components

such as fasteners, pins, bolts and locks are correctly

installed and undamaged.

Also ensure that the brakes on the crane are engaged

and that the unit is in a safe position.

Pre-operation Inspection

Operating Manual

MFC Mini Floor Crane

17

MFC Mini Floor Crane

Working Area Inspection

Non compliance with the instructions and safety rules in this

operating manual may result in serious injury or accidents

including death!

Fundamentals

The working area inspection helps the operator to determine

if the working area is suitable for safe operation of the unit.

The inspection should be performed by the operator prior to

moving the unit to the working area.

It is the operator‘s responsibility to read and know the

section on working area hazards and to avoid them while

moving, setting up or operating the unit.

Ensure the unit is working on solid ground and the loadings

applied by the unit will not cause damage or create

additional floor loading.

Avoid sources of danger!

Do not operate the unit if you cannot guarantee a safe

operation due to one or more of the following sources of

danger:

Inclines, holes or swells on the work surface or debris.

Unstable subsurfaces at the working area.

Insufficient subsurface foundation at the working area.

Subsurfaces with holes, obstructions etc.

Overhead obstructions such as:

Beams, electric cables and ropes/wires,

High voltage cables.

Unsuitable wind and weather conditions.

All other possible unsafe surfaces and conditions.

Operating Manual

MFC Mini Floor Crane

The personnel have been trained on this type of unit

and are deemed competent. All operators should read

the operating manual carefully.

1. Avoid hazardous situations.

Know and understand the safety regulations

before going on to the next section.

2. Always perform a pre-operation inspection on

the MFC.

3. Inspect the working area thoroughly before

using the MFC.

4. Always perform the function test as per the

operating manual prior to use.

5. Only use the MFC as per the operating instructions.

Any deviations are not acceptable. In case, you

must always contact the owner of the equipment.

Do Not Operate Unless:

Read, understand and obey:

a) the manufacturer‘s instructions and safety instructions.

b) the operating manuals and safety instructions for the MFC.

c) the inscriptions, labels and warning signs on the MFC.

d) the safety instructions and work procedures on the job site.

e) the relevant legislation in force for the equipment in use.

18

MFC Mini Floor Crane

Function Tests

Non compliance with the instructions and safety rules in this

operating manual may result in serious injury or accidents

including death!

Fundamentals

The function tests are designed to identify malfunctions

before the unit goes into service.

The operator must follow the step-by-step instructions and

test all functions.

A malfunctioning unit must not be operated under any

circumstances.

If any malfunctions are discovered the crane must be

removed from service and appropriately tagged. Further use

of the unit is prohibited.

Repairs to the unit may only be undertaken by a qualified

service technician in compliance with the manufacturer‘s

specifications.

When repair work has been successfully completed the

operator must perform another pre-operation inspection

and repeat the function tests. Only then may the unit be

operated again.

Operating Manual

MFC Mini Floor Crane

The personnel have been trained on this type of unit

and are deemed competent. All operators should read

the operating manual carefully.

1. Avoid hazardous situations.

Know and understand the safety regulations

before going on to the next section.

2. Always perform a pre-operation inspection on

the MFC.

3. Inspect the working area thoroughly before

using the MFC.

4. Always perform the function test as per the

operating manual prior to use.

5. Only use the MFC as per the operating instructions.

Any deviations are not acceptable. In case, you

must always contact the owner of the equipment.

Do Not Operate Unless:

Read, understand and obey:

a) the manufacturer‘s instructions and safety instructions.

b) the operating manuals and safety instructions for the MFC.

c) the inscriptions, labels and warning signs on the MFC.

d) the safety instructions and work procedures on the job site.

e) the relevant legislation in force for the equipment in use.

3. Place the pump lever on the right side of the hand-

wheel c). Raise up the telescope with a load a few

centimeters by up and down movements with the

pump lever, and wait aprox. 10-20 minutes.

>> The piston of the cylinder (= the telescope arm)

may not come low self-acting when the valve

is closed.

Hydraulic Cylinder

1. Remove the pump lever for the hydraulic cylinder

from the bracket on the Main arm a).

2. Close the valve on the hydraulic cylinder by turning

the handwheel b) to the right (clockwise) until it stops.

19

MFC Mini Floor Crane

Function Tests

Raising (close)

turn right

4. In the unlikely event of a leak in the hydraulic system, the

safety locking pin must be installed at any time when the

cylinder has not been pumped for a period of 15 minutes.

5. Turn the handwheel c) carefully to the left, to open the

valve.

6. Please grease the bolt of the handpump weekly.

>> The piston of the cylinder (= the telescope arm)

should sink easy, jerk-free and regularly.

Lowering (open)

turn left

Operating Manual

MFC Mini Floor Crane

a)

b)

b) c)

c)

20

MFC Mini Floor Crane

•

Fundamentals

Using the MFC for anything other than lifting loads is

unsafe.

If more than one operator is expected to use the MFC at

different times during the same work shift, each individual

operator is expected to know and follow all of the safety

regulations and instructions in the operating manual.

This means that every new lift operator should know and

adhere to the safety regulations and instructions described

in the previous chapters before operating the MFC.

Therefore, the following tasks must be undertaken by each

operator before initial operation:

Read and understand this operating manual

Pre-operation inspection

Function tests

Working area inspection

Operating instructions

Compliance with and application of the information in

the load capacity chart

Operating Instructions

Operating Manual

MFC Mini Floor Crane

The personnel have been trained on this type of unit

and are deemed competent. All operators should read

the operating manual carefully.

1. Avoid hazardous situations.

Know and understand the safety regulations

before going on to the next section.

2. Always perform a pre-operation inspection on

the MFC.

3. Inspect the working area thoroughly before

using the MFC.

4. Always perform the function test as per the

operating manual prior to use.

5. Only use the MFC as per the operating

instructions. Any deviations are not acceptable.

In case, you must always contact the owner of

the equipment.

Do Not Operate Unless:

Read, understand and obey:

a) the manufacturer‘s instructions and safety instructions.

b) the operating manuals and safety instructions for the MFC.

c) the inscriptions, labels and warning signs on the MFC.

d) the safety instructions and work procedures on the job site.

e) the relevant legislation in force for the equipment in use.

This manual suits for next models

2

Table of contents

Popular Construction Equipment manuals by other brands

MULTIQUIP

MULTIQUIP Stow MS-63 Operation and parts manual

stellar labs

stellar labs 9000 owner's manual

RaycoWylie

RaycoWylie i4507 instruction manual

Mounting Systems

Mounting Systems Premium Series installation manual

Palfinger

Palfinger PK9001-EH Operator's manual

Innovatech

Innovatech Teerminator-2000 Operation and maintenance manual