WWW.COMBISAFE.COM

5

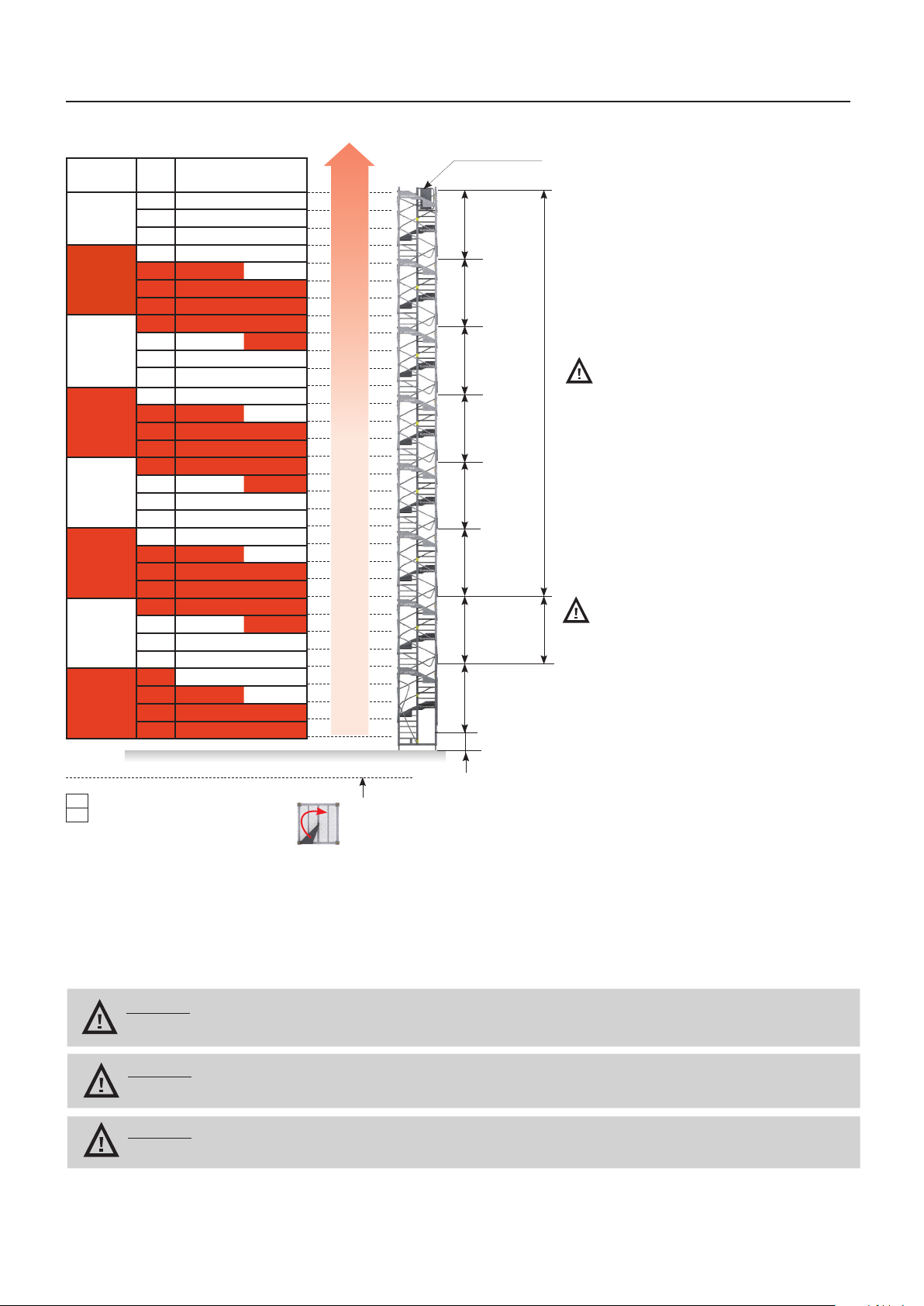

WARNING:

Check that the ground on which the staircase Escalib is to be erected is able to withstand the load.

WARNING:

Comply with the general rules for handling and stability.

1 - The base must be oriented

according to the height of the floor

which needs to be accesed.

Start the installation 8 cm away from

the wall to facilitate pivoting of the

guardrails at the access level.

Level the base.

2 - Access inside the module is

available for attaching the sling

to the center ring, for putting the

guardrails in closed position and

putting the erection rails in hori-

zontal position.

3- Fitting the module to the base.

Assembly of the 4 uprights with

M24 screws. Sling released.

4 - Installing a new module.

5- Erection guardrail

rotated to vertical

position and locked

onto stair above.

Bolt the uprights

together using M24

screws.

Slings released.

Repeat steps 2, 4 and 5 if needed

while anchoring the Escalib as

the height is increased.

REQUIREMENTS:

> Fit new anchorages as

new modules are added.

> Dismantle in the reverse

order of assembly.

Fixings:

- Module and base: M24x35-8-8

hex head screw + washer.

- Barrier gate: M16x100 hex

head bolt

Start bolting with the new

module’s first step (corner

A-D) and then continue clo-

ckwise.

InTermedIaTe modules

Example of an Escalib with 3 modules.

ASSEMBLING AND DISMANTLING