VRW2 DYNAMIC PRESSURE- REGULATING FLANGED CONTROL VALVES

62-3116—01 4

Application Notes

Accurate valve sizing and adjustment is crucial for efficient

system operation. Pressure regulated control valves optimize

hydronic HVAC systems at all load conditions as well as

balancing the system at design conditions.

Low flow rates maximize coil efficiency, but require pressure

regulated valves for stable operation.

High temperature change (ΔT) is needed to maintain thermal

transfer at low flow rates, and maximizes efficiencies in chillers

and condensing boilers.

In new construction, low flow rates at high ΔT reduce the size

requirements for pumps, chillers, boilers, and piping

components. In retrofit applications, lower flow rates reduce

pump energy consumption and peak power requirements.

Pressure regulated control valves work as effectively as

reverse return piping designs, but use less material.

If a system balancing report is required, coil flow must be

verified by measuring pressure drop across the coil, not the

control valve, using the coil manufacturer's specifications.

Bubble-tight close-off will require use of a resilient-seat

butterfly valve in series with the load.

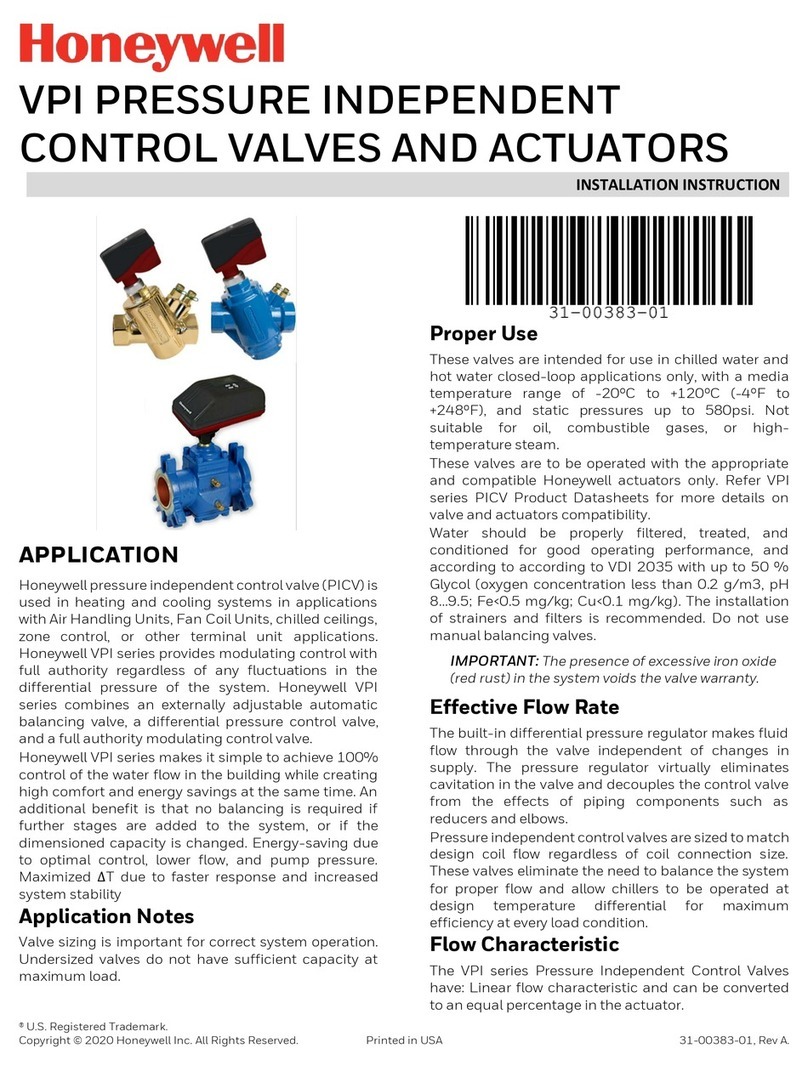

Proper Use

These valves are only for use in cold, warm, and hot water

systems applications with ethylene glycol or propylene glycol

up to 50% concentration. They are designed for a medium

temperature range of from -4°F (-20°C) to 228°F (120°C) at a

maximum pressure of 580 psig (40 bar). VRW2 valves are to

be operated with supplied multi-turn actuators only.

IMPORTANT

Water should be properly filtered, treated and condi-

tioned according to local conditions and the recom-

mendations of the boiler or chiller manufacturers. The

installation of strainers and side-stream filters is

strongly recommended to protect the pressure regula-

tor cartridge

The presence of excessive iron oxide (red rust) in the

system voids the valve warranty. Rust is highly abra-

sive.

EPDM rubber used in this valve absorbs oil. Do not

use petroleum-based additives and thoroughly flush

system to remove petroleum-based cutting oil, solder

flux, etc. Do not use solvents that will dissolve silicon

grease

INSTALLATION

When Installing this Product...

1. Read these instructions carefully. Failure to follow them

could damage the product or cause a hazardous condi-

tion.

2. Check ratings given in instructions and on the product to

ensure the product is suitable for your application.

3. Installer must be a trained, experienced, licensed service

technician.

4. After installation is complete, check out product opera-

tion as provided in these instructions

Preparation

Equipment Damage Hazard

• Foreign particles like sand and metal chips can

damage valve seals and regulator diaphragm.

• For trouble-free operation of the product, good

installation practice must include initial system

flushing, and chemical water treatment.

• Use of a 50 micron (or finer) system side stream

filter is recommended and in-line Y-strainers are

suggested. Remove all sieves before flushing the

system to avoid trapping dirt in the filters.

• Acceptable antifreeze solutions, with minimum 50%

water dilution, are diethylene glycol, ethylene glycol,

and propylene glycol.

• Do not use boiler additives, solder flux and wetted

materials which are petroleum based or contain

mineral oil, hydrocarbons, or ethylene glycol

acetate. If in doubt, consult an HVAC water

treatment specialist.

• If installing these valves in a new addition, or if

retrofitting an existing building, do not assume that

the fluid in the existing piping meets these criteria.

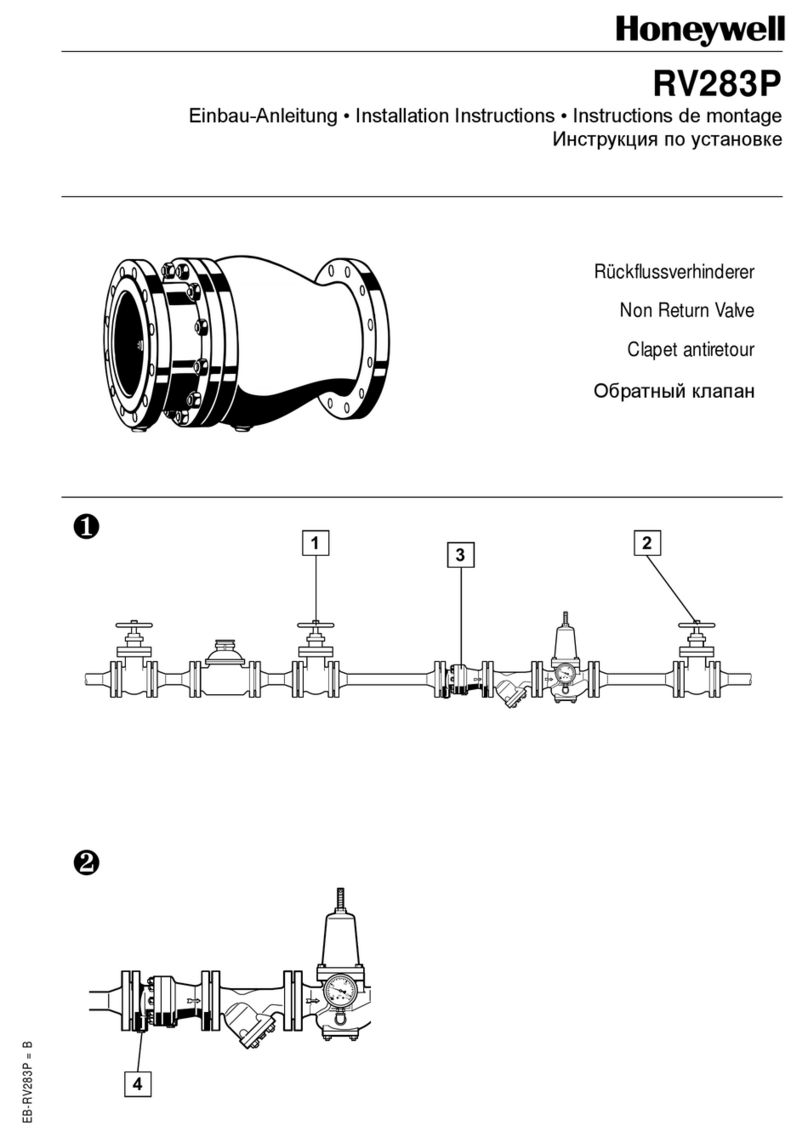

1. Clean the lines upstream of particles larger than 1/16 in.

diameter (welding slag, pipe scale and other contami-

nants).

2. Proceed with installation once the system specifics

(expansion/contraction of the system and its medium as

well as operating pressures) are within tolerances.

3. Eliminate air from system. Free oxygen will corrode iron

parts.

IMPORTANT

• Ensure that the valve is not in the fully closed position

when filling the system with water. TURN OFF

POWER and open manually if necessary.

• Do not exceed maximum pressure differential control

range for valve.

• Install valve indoors. If valve is installed outdoors,

water tight protection is required for the actuator.

• If the valve is to be installed in vertical pipe on a

chilled water system, ensure that the covered elec-

tronics are upwards above the valve spindle, to pre-

vent condensation from entering the electronics. If

necessary use a socket and ratchet to remove the

brass nut attaching the mounting bracket to the valve

body, re-position the Actuator and replace the brass

nut.

• Even torque on all flange bolts and connecting rods is

critical to pipe seals.

• Flow arrows must point in the direction of the flow for

proper operation.

4. Stem rotation as viewed from above:

a. Clockwise to close.

b. Counterclockwise to open

5. Valve must be mounted with the actuator/bracket above

pipe center line. Do not install the valve with the stem

below horizontal or upside down without NEMA 3, 4, or

4X actuator enclosure to prevent actuator damage due

to condensation or leaks. See Fig. 2 and 3.