2

TECHNICAL FEATURES

1. Flame detection

- Yellow- as well as blue-burning oil- and gas flames can be

monitored.

- The flame detector is suitable for operation where the

ambient temperature is within the range -20°to +60°C.

- The flickering detector IRD 1020.1 becomes active not

before a minimum threshold-level of steady light is

exceeded. That guarantees that neither electromagnetic-

nor ignition-spark noise are affecting the IRD.

- Sensitivity is adjustable.

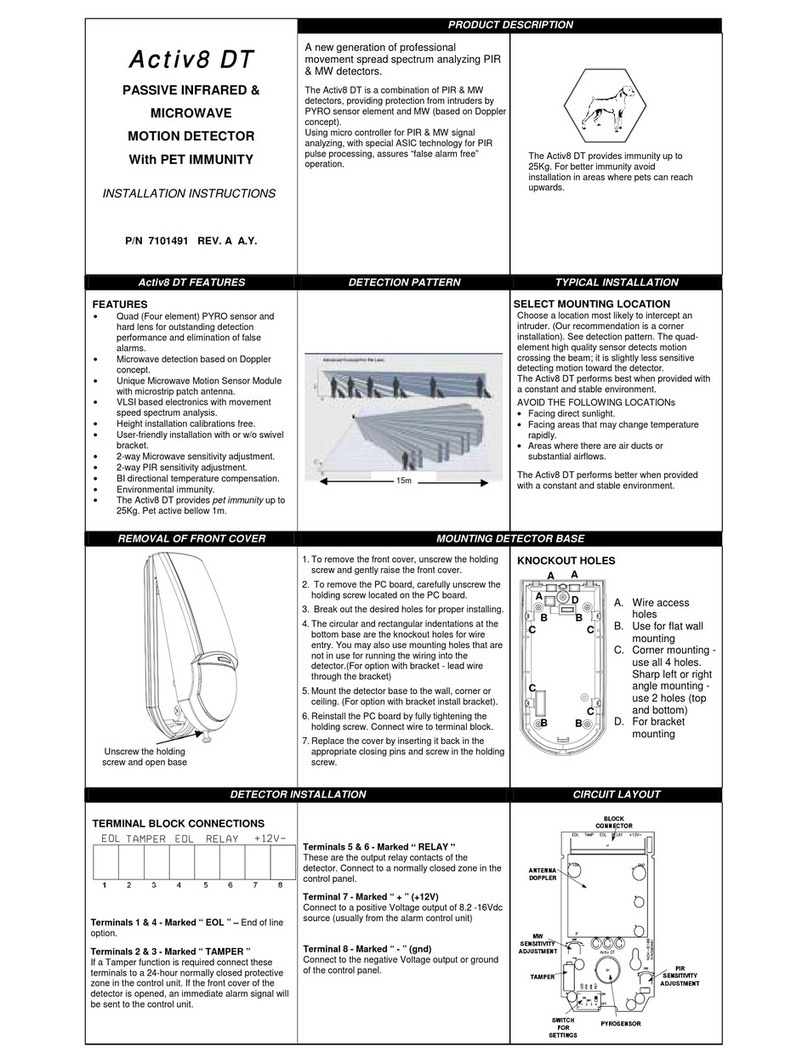

- LED 1 is a warning indicator for the pre-purge phase as

well as normal operation. LED 2 indicates the actual status

of the detector: On or off.

- During pre-purge, LED 1 indicates possible stray light,

which may be produced either by a flickering or by

a steady light source, before the detector switches on

(LED 2).

- When the burner is operating normally, LED 1 acts as a

warning indication of the flame signal current sensitivity

being set too low - it begins to flicker or extinguishes

before the detector switches off.

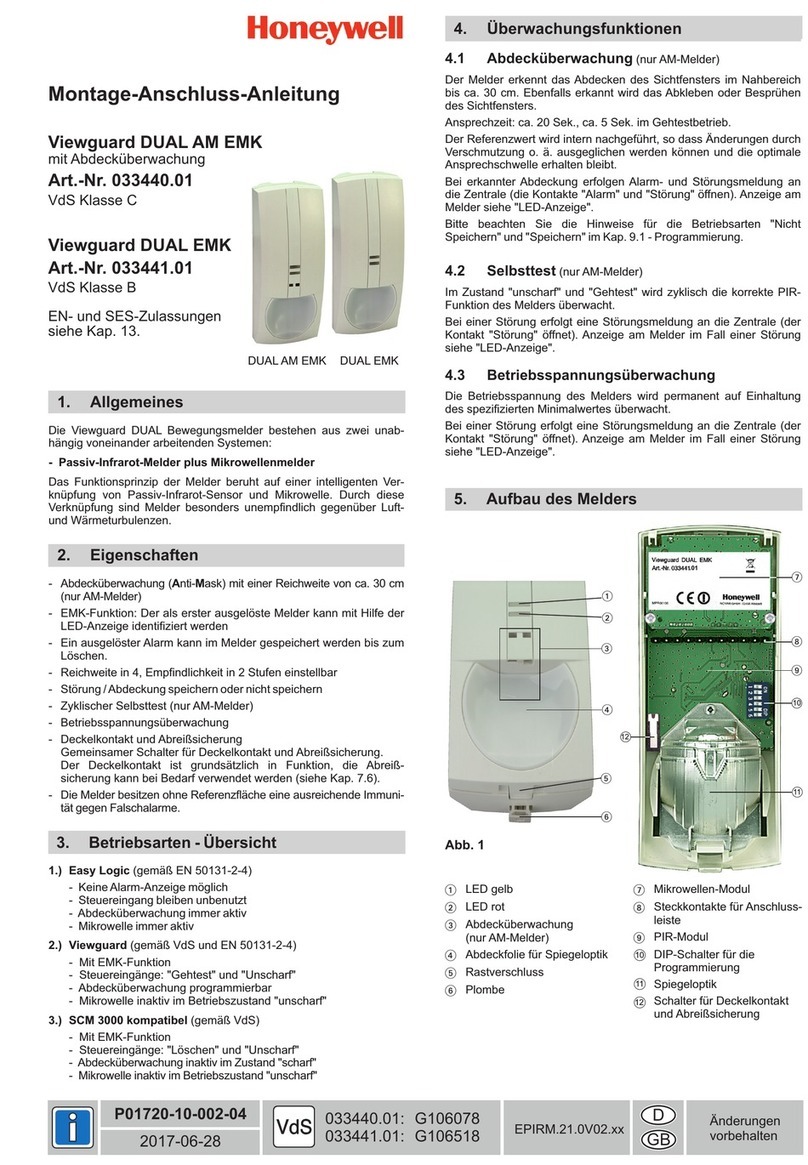

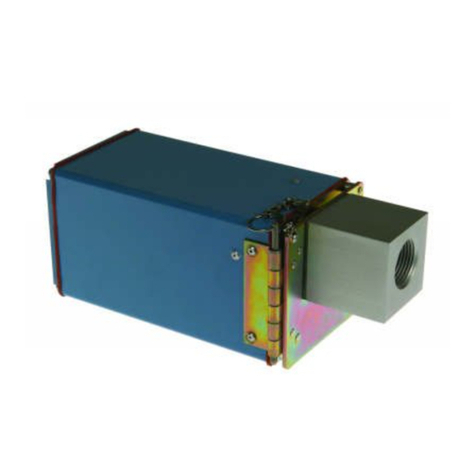

- The compact size makes it possible to mount the detector

on any burner. For this reason the IRD mounting flange

M93 has the same dimensions and fixing holes as the FZ

flange M74. This magnetic flange provides the switch-off

facility specified in the European standard. The IRD 1020.1

therefore only functions with the M93 flange.

2. Installation instructions

- The detector probe should be fitted so that it receives the

light which pulsates most strongly. This can be achieved

by positioning the detector as close as possible to the

flame or by directing it at a particular zone of the flame (e.g.

by using a sighting tube).

- No stray light must be allowed to fall on the detector (e.g.

through cracks or from a sight glass). Pulsating stray light

(e.g. from fluorescent lighting or light bulbs) could cause

the system to switch to lockout. Due to the very high

sensitivity of the detector, it should not be exposed

directly or indirectly (reflections) to the ignition spark.

- The infra-red flicker detector should be fitted in such a way

that the ambient temperature cannot under any

circumstances rise above 60 °C. At higher temperatures,

there is a risk of incorrect operation and the life expectancy

of the unit could be reduced. In addition, care should be

taken that the detector is not subjected to unusually harsh

vibration and receives no hard knocks.

- It is necessary for the magnetic IRD M93 flange to be

mounted on a flat surface to avoid any mechanical stress

which could otherwise damage it.

COMMISSIONING AND MAINTENANCE

During commissioning and after servicing, the flame

monitoring system should be checked for faultless operation

as follows:

1. Check that the detector is connected properly. Wrong

connections are a risk to safety, and could cause damage

to the detector unit or burner system.

2. Adjust to maximum sensitivity and start the burner: If the

LED indicator is lit after the start impulse, carefully adjust

the sensitivity control until LED 1 extinguishes. No LED

should light up during the pre-purge phase.

3. When the burner is operating normally, carefully turn

back the sensitivity control until LED 1 begins to flicker.

Increase the setting again by one or two increments until

both LED’s are lit. If LED 1 does not flicker even at

position 1: Leave potentiometer at position 1-2. This

adjustment should be carried out when the flame signal

current is weakest (at a cold-start, shortly after flame

establishment or after stabilisation).

4. The flame detection device requires no maintenance of

any kind, and as it is classed as safety equipment, no

attempt should be made to open the housing.

5. Because the nature of the flame can change in time due

to the accumulation of dirt, the indicators on the detector

should be checked periodically.

Please note:

Burner operating normally = both LED’s on

Burner in pre-purge phase = both LED’s off

For safety reasons the sensitivity must not be set

higher than necessary.

Safety Checks:

1. Shut off the fuel supply when the burner is in the "run"

position. The indicator LEDs should extinguish and the

control box go to lockout.

2. Start the burner with the fuel supply shut off. The control

box must go to lockout at the end of the safety time due

to absence of flame.

3. Remove the detector from its mounting flange during a

pause, fit onto it a second flange M93. Start the burner

with straylight on the detector (e.g. by a cigarette-lighter,

bulb or a neonlight. Daylight or a torch is not suitable).

The control box must go to lockout due to stray light

either immediately or at the end of the pre-purge,

depending on the model.

Test switch-off facility:

1. Remove the detector durning the "run" position from its

special M93 flange. The control box must go to lockout

due to the activated switch-off facility.

IRD 1020.1