Contents

1General Description.........................................................................................................................................4

1.1 Introduction.................................................................................................................................................4

2Principle of Operation......................................................................................................................................4

2.1 Reflex (V) Mode..........................................................................................................................................6

2.2 Double Reflex (W) Mode ............................................................................................................................6

2.3 Triple Reflex (WV) Mode ............................................................................................................................6

2.4 Quadruple Reflex (WW) Mode ...................................................................................................................6

2.5 Diagonal Mode............................................................................................................................................6

3Scope of Delivery.............................................................................................................................................7

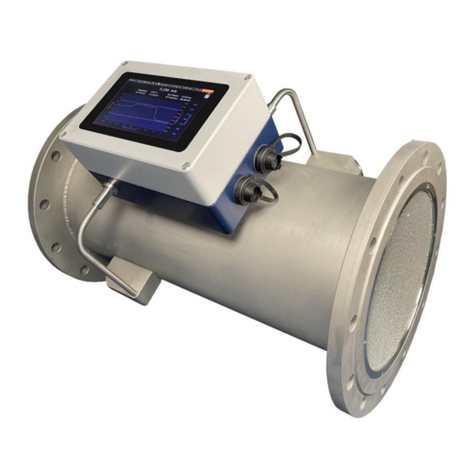

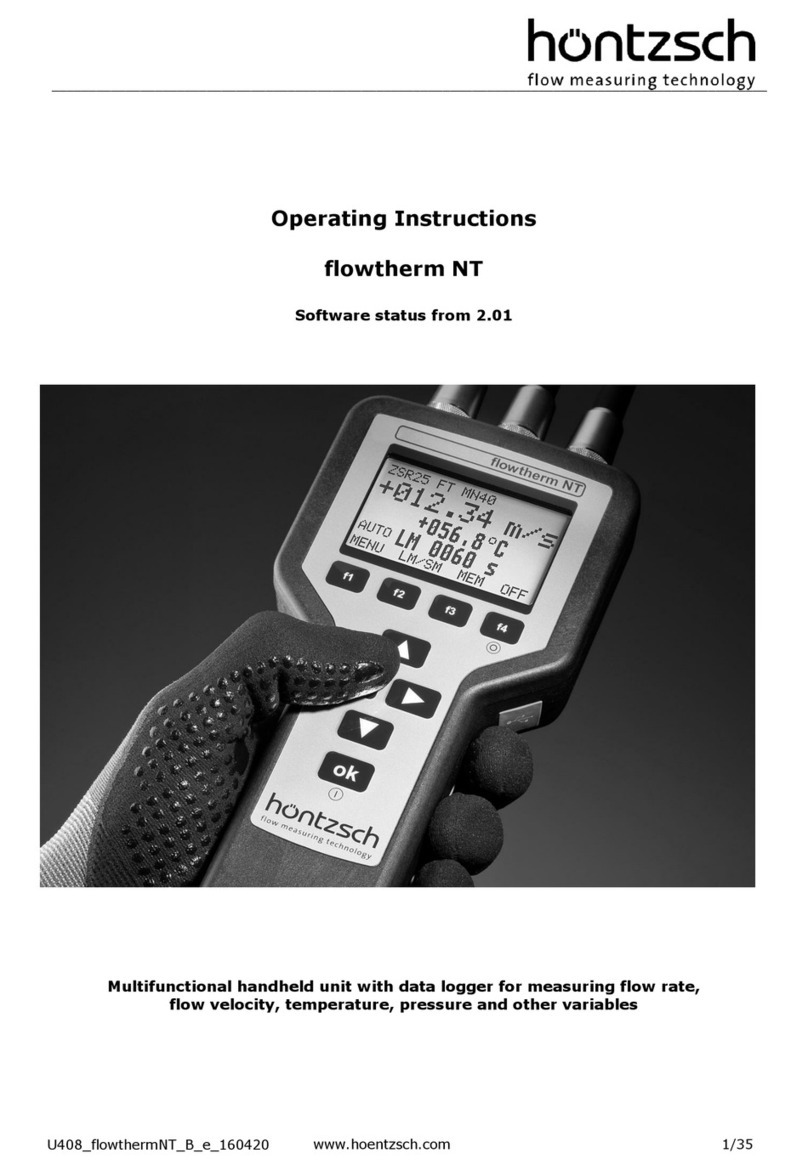

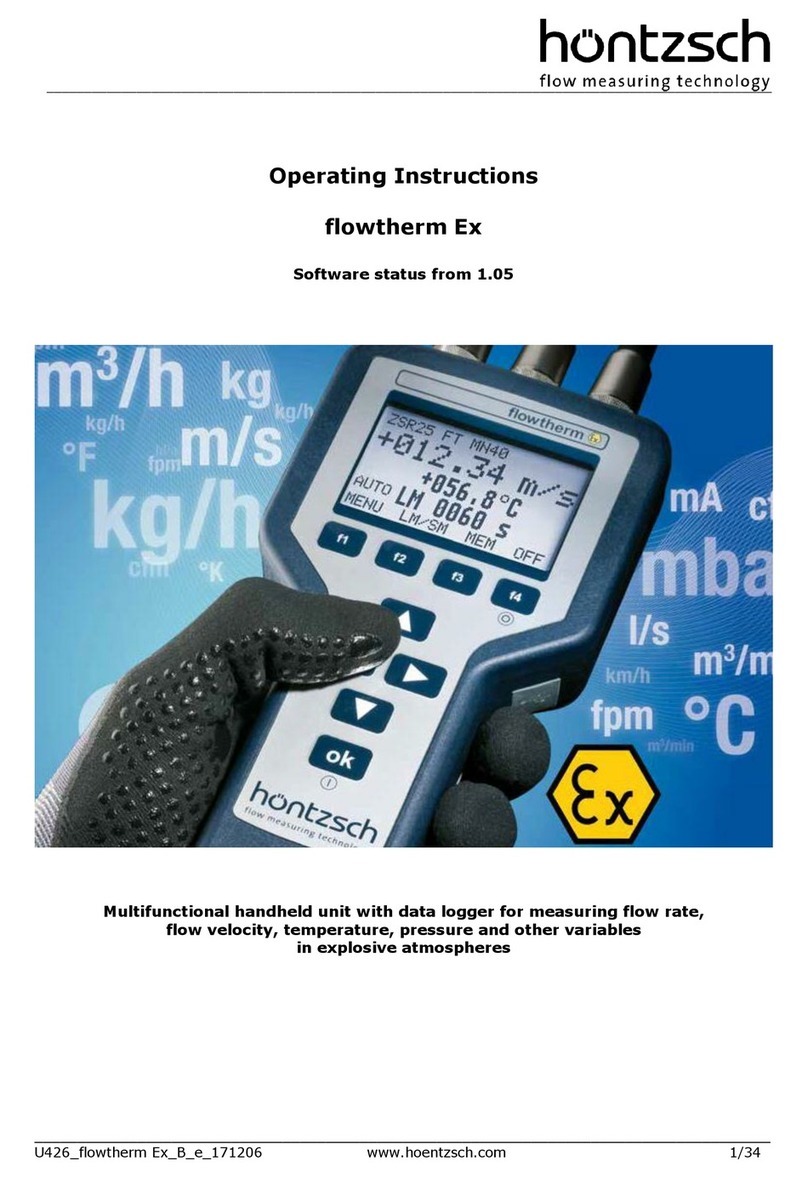

3.1 ExactSonic III Instrument............................................................................................................................8

3.1.1 Connections........................................................................................................................................8

3.1.2 Keypad................................................................................................................................................9

4Installation......................................................................................................................................................11

4.1 Transducer Positioning.............................................................................................................................11

4.2 Attaching the Transducers........................................................................................................................12

4.2.1 Preparation........................................................................................................................................12

4.2.2 Assembling the Guide Rails..............................................................................................................12

4.2.3 Fitting the transducers ......................................................................................................................13

4.3 Connecting Outputs..................................................................................................................................14

4.4 Connecting the Power Supply...................................................................................................................15

4.4.1 Charging the Battery.........................................................................................................................15

4.4.2 Optimising Battery Life......................................................................................................................15

4.5 Initial use and adjustment of the instrument.............................................................................................16

4.5.1 Checking System Health...................................................................................................................16

4.5.2 Selecting a Language .......................................................................................................................16

4.5.3 Setting Date & Time..........................................................................................................................17

4.5.4 Enabling/Disabling the Backlight.......................................................................................................17

5Using the Quick Start Menu...........................................................................................................................18

5.1 Entering the Site Data...............................................................................................................................18

5.2 Attaching and Connecting the Transducers..............................................................................................20

5.3 Taking a Flow Reading.............................................................................................................................20

5.4 Flow Monitoring.........................................................................................................................................20

5.5 Total Flows................................................................................................................................................20

5.5.1 Calculating the Average Flow ...........................................................................................................21

5.5.2 Resetting Totals................................................................................................................................21

6Managing Named Sites .................................................................................................................................22

6.1 Selecting an Existing Site..........................................................................................................................22

6.2 Adding a New Site.....................................................................................................................................23

6.3 Changing a Site Name..............................................................................................................................23

6.4 Editing Site Data .......................................................................................................................................23

6.5 Calibration of the Instrument.....................................................................................................................24

6.5.1 Adjusting the Zero Cutoff..................................................................................................................24

6.5.2 Adjusting the Zero-Flow Offset (ZFO)...............................................................................................24

6.5.3 Adjusting the Calibration Vactor........................................................................................................24

6.5.4 Adjusting the Roughness Factor.......................................................................................................25

6.5.5 Adjusting the Damping Factor...........................................................................................................26

7Logging Functions .........................................................................................................................................26

7.1 Manual Logging.........................................................................................................................................26

7.2 Scheduling Logging...................................................................................................................................27

7.3 Stopping Logging......................................................................................................................................27

7.4 Copying Logged Data to a USB Memory Stick.........................................................................................27

7.5 Clearing Log Files von Protokolldateien ...................................................................................................28

7.6 Logger Status............................................................................................................................................28

8Outputs..........................................................................................................................................................29