10/15 www.hoentzsch.com U328_UFAUVAextAS102_B_e_091103

Operating Instructions

Transducers UFA and UVA in

AS102 housing

6.3 Tips on Electromagnetic Compatibility (EMC)

•all connecting cables are to be kept as short as possible

•with cable routes longer than 30 m or with strong electromagnetic disturbance along the cable route

between sensor and evaluation unit, the use of a double-shielded cable is recommended: to do this

lay inner shielding to one side of the evaluation unit and lay outer shielding on both sides over a large

area with low-impedance connection on the sensor and evaluation unit or on the control cabinet

•do not loop or kink the cable!

•lay non-allocated cable strands on both sides on protective potential!

•lay cables as close to ground as possible,as for example side panels, mounting plates or steel gird-

ers

•when using frequency converters there is a risk of HF interference.Therefore, decouple the power

input of the frequency converter against active emitted interference using a radio interference filter.

This also increases the passive interference resistance of the facility

•between engines and converters use only shielded engine cables with double-sided shielding overlay

•spatially separate cables which emit interference from measuring lines and evaluation units. If

necessary, lay measuring lines in a metallic tubular cable protection

•metallic parts in control cabinets such as sub racks with control electronics or sub plates – to be

connected over a large area and HF-wise suitably conductive

•wire relays, switches and magnetic valves installed in the same circuit,using spark extin-

guisher combinations or over-voltage limiting components.

•apply analog signal cable shielding on one side only – preferably on the evaluation unit - and low re-

sistant. Twist unshielded cables against balanced induction

•apply digital signal cable shielding on both sides over a large area. In the case of potential differences

between these points it is advisable to lay a separate equipotential bonding conductor

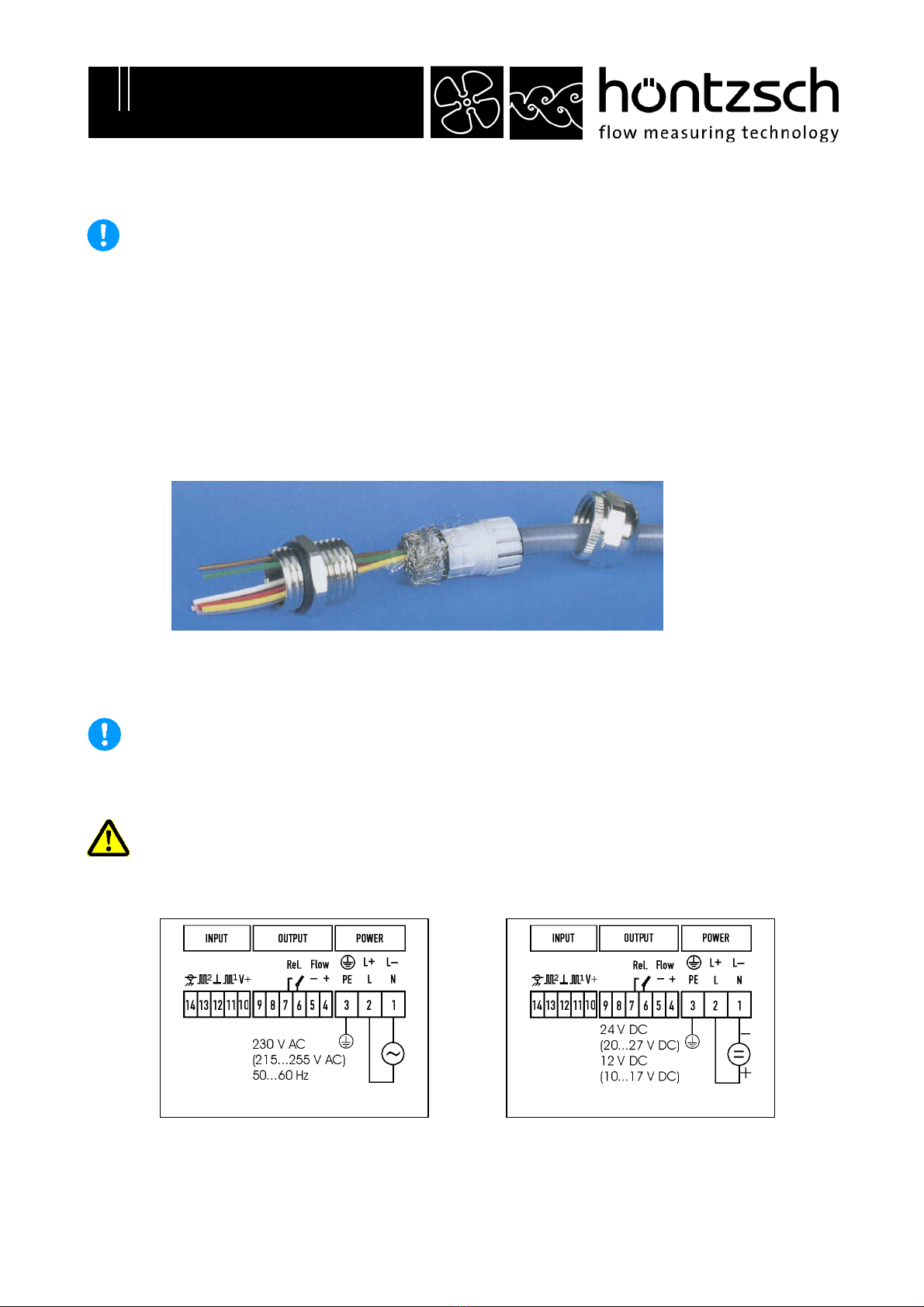

•allow for preferred shielded connector for connections to points of separation of connection ca-

bles.Terminals should be situated in HF-tight housing, with suitable EMC cable bush. Contact outer

shielding of the connection cables to the cable bush.

6.4 Connection Cable

For connecting between sensor and evaluation unit LiYCY cable with simple copper braiding screen can be

used if the cable route is short and there is marginal electromagnetic interference. Over longer distances

or with a high rate of electromagnetic interference, a double-screened cable of type LiYCY-CY should be

used.

Sensor FA 2 (3) x 0.25 mm²

Sensor FAR 3 (4) x 0.25 mm²

Max. permissible conductor resistance per strand is 25 Ohm.

Max. permissible operating capacity between 2 strands is 1.5 nF.

Sensor VA 3 x 0.25 mm2

Max. permissible conductor resistance per strand is 15 Ohm.

Conductor resistances for finely stranded conductors:

approx. 79 Ohm/km with wire cross section 0.25 mm2

approx. 39 Ohm/km with wire cross section 0.50 mm2

approx. 26 Ohm/km with wire cross section 0.75 mm2