__________________________________________________________________________________________________

___________________________________________________________________________________________________

U398_UVATP_B_e_190425 5/17

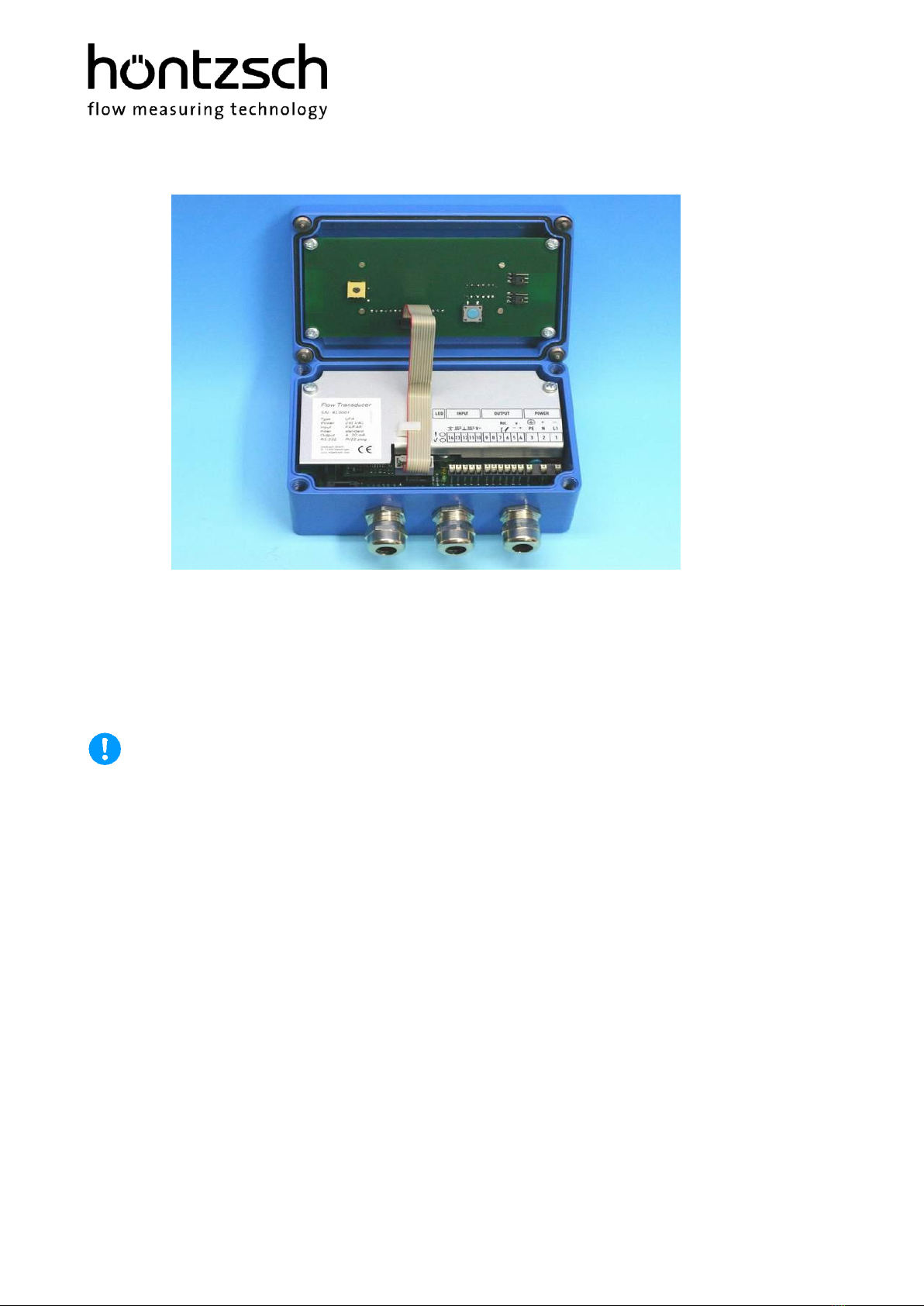

5.4 Housing and Connectors

Protection class : IP65

Material : aluminium

External dimensions : L/W/H = 150/100/80 mm

Cable entry point : nickel-plated brass screwed cable glands

for cable diameter 5 ... 10 mm

with cable shielding connections

Connections : 'push in' PCB terminals

for wire cross-section 0.14 ... 1.5 mm²

No tools necessary for core connection –simply insert strands

(twisted or with end sleeve) into the terminal.

To separate strands apply pressure to the terminal release spring using

a pen or screwdriver.

5.5 Electrical Data

Supply voltage:

24 V DC (20 ... 27 V DC), power < 5 W

alternatively:

12 V DC (10 ... 17 V DC), power < 5 W

The mains supply is electrically isolated from the UVATP inputs and outputs.

Input flow v/VA: (separate transducers only)

for Höntzsch vortex flow sensors VA as measuring tube (VA Di ...),

resolution 0.125 Hz.

Input temperature T:

for Pt100 temperature probe in 4-wire system,

acquisition time constant 2 s,

resolution 0.1 K.

Input pressure P:

for absolute pressure sensors 4 .. 20 mA, 12 .. 36 V in 2-wire system,

acquisition time constant 0.125 s,

resolution 1 hPa,

initial and terminal values configurable.

Analog outputs A1 and A2:

optionally, the analog outputs can be electrically isolated with each other and from the inputs using an

additional isolating amplifier.

Analog output A1 precision:

high precision analog output,

update every 0.125 s,

time constant 4 s, with frequency hopping > 25 % 2 s,

time constants up to 99 s are configurable.

4 ... 20 mA = 0 ... x kg/h, (NV/t)

terminal value x configurable / resistance max. 500 Ohm,

alternatively:

0 ... 10 V = 0 ... x kg/h, (NV/t)

terminal value x configurable / impedance 1 kOhm