_________________________________________________________________________________________________

______________________________________________________________________________________

U326_UVAintAS102_B_e_210316 1/15

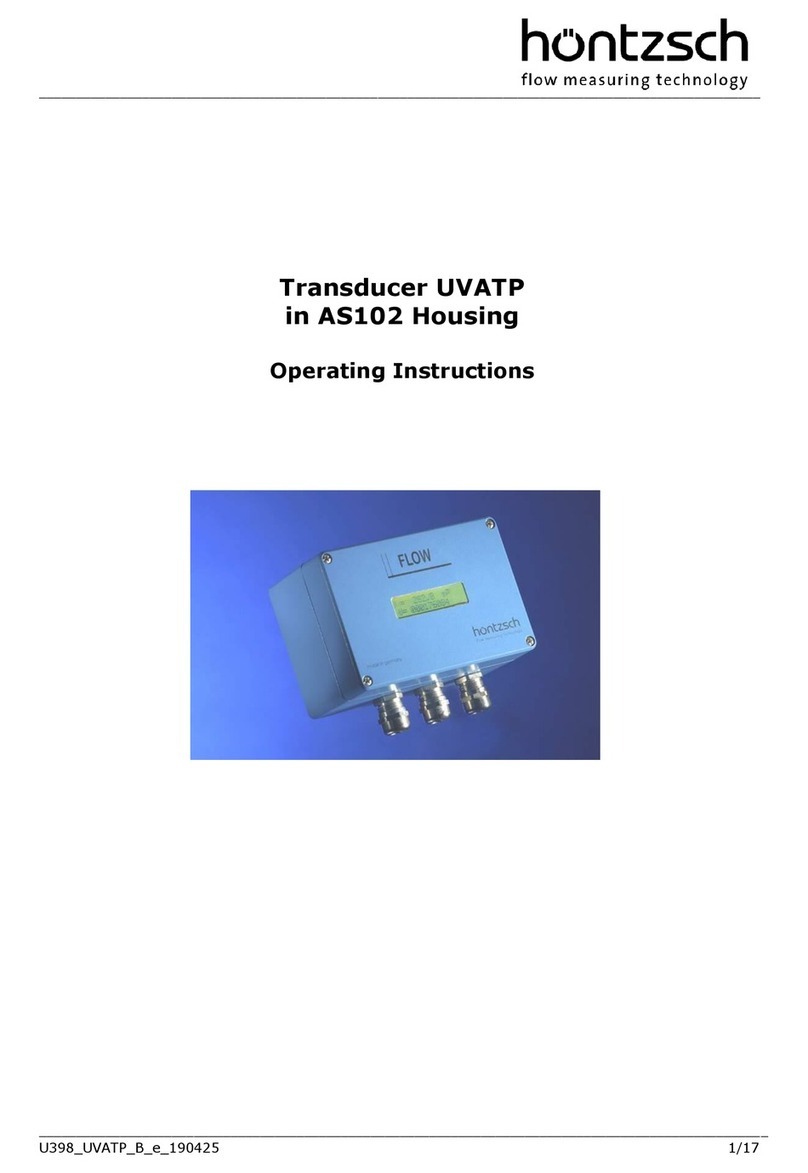

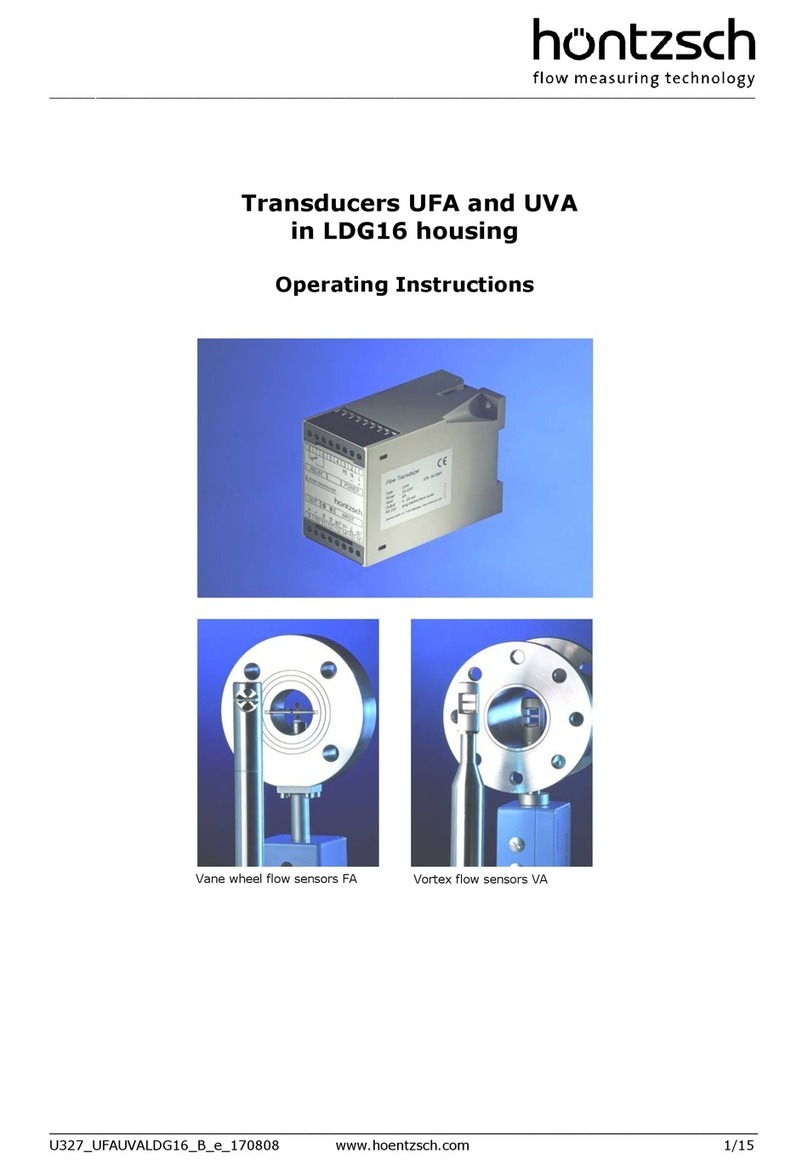

Operating Instructions

Transducer UVA

integrated in the connection housing AS102 of the

vortex probes VA40, VAT40 and

vortex measuring tubes VA Di

Inhaltsverzeichnis

1Safety Symbols .........................................................................................................................2

2Safety Instructions.....................................................................................................................2

3Intended Use.............................................................................................................................3

4Operating Safety .......................................................................................................................3

5Scope of Delivery.......................................................................................................................3

5.1 Description, Type Plates.....................................................................................................4

6Technical Specifications ..............................................................................................................4

6.1 Conformity with Standards .................................................................................................4

6.2 Storage Conditions ............................................................................................................4

6.3 Operating Conditions .........................................................................................................5

6.4 Housing and Connectors ....................................................................................................5

6.5 Electrical Data ..................................................................................................................5

6.6 Measurement Uncertainty ..................................................................................................6

7Installation................................................................................................................................6

7.1 Block Diagram ..................................................................................................................6

7.2 Wiring Diagrams ...............................................................................................................6

7.2.1 Shielding contact at cable bush ................................................................................7

7.2.2 Power supply .........................................................................................................7

7.2.3 Analog output v .....................................................................................................7

7.2.4 Relay output..........................................................................................................8

7.2.5 RS232 Interface.....................................................................................................8

7.2.6 LCD display in housing cover (optional).....................................................................9

7.2.7 Analog output t (temp) (optional)...........................................................................9

8Funktionsbeschreibung .............................................................................................................10

9Settings..................................................................................................................................11

10 Initial Operation.......................................................................................................................11

11 Operation ...............................................................................................................................12

12 Shut-down, Dismantling ...........................................................................................................12

13 Inspection...............................................................................................................................12

14 Maintenance............................................................................................................................12

15 Meaning of LEDs ......................................................................................................................12

16 Troubleshooting.......................................................................................................................13

17 Returns ..................................................................................................................................14

18 Disposal..................................................................................................................................14

19 Replacement Parts ...................................................................................................................14

20 Declaration of Conformity, Declaration of Incorporation ................................................................15