1. Overview

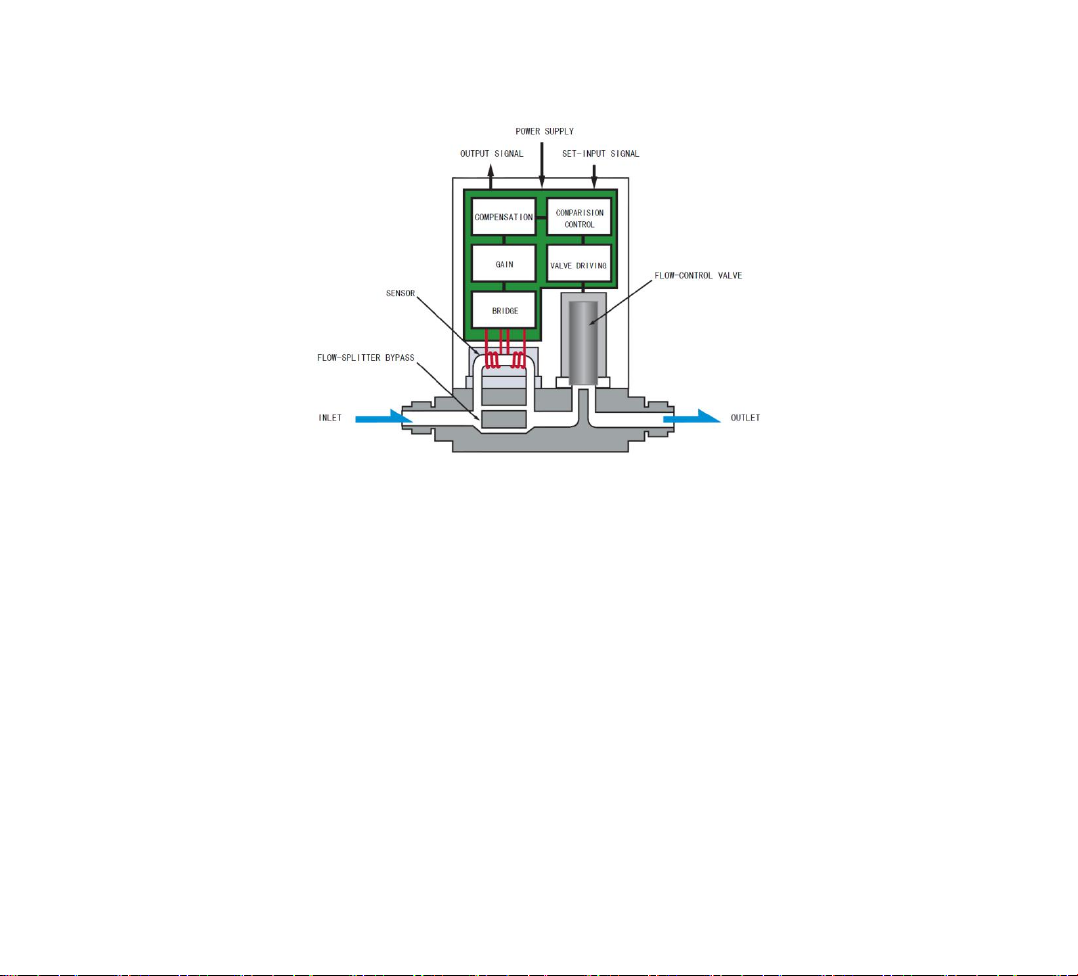

The S500 thermal mass flow controller is able to control gas mass flow rate within a large range in

real time accurately. Gas goes through a stainless steel capillary, to change the capillary

temperature distribution, resulting in upstream and downstream temperature difference, therefore

the flow rate can be measured. Unlike flow controllers or meters that measure gas pressure or

volume, this product’s accuracy won’t be affected by gas pressure or ambient temperature. The

electrical signal that represents upstream and downstream temperature difference is always a

real-time reflect of instantaneous flow rate. The PID circuit is used to control a proportional

solenoid valve constantly, thus control the flow rate precisely. It is particularly applicable for gas

precise measurement and control in control processes .

1.1 Range

The mass flow controller is widely used for flow measurement and control in the semiconductor,

vacuum coating, chemical, environmental and other industries.

1.2 Mass Flow Controller (Meter)

The mass flow controller (meter) is abbreviated as MFC (MFM). There are two functions in it: flow

measurement and control.

1.3 Features of S500 MFC (MFM)

☆High accuracy, fine linearity, small zero drift, fast gas flow response, small overshoot, and

so on.