BIFFI HLRA User manual

Bi HLRA

Hydraulic Double-Acting Linear Actuator

Installation, Operation and Maintenance Manual

MAN 627 Rev. 0

September 2023

Copyright © Bi. The information in this document is subject to change without notice. Updated data sheets can be obtained from our website www.bi.it or from your nearest Bi

Center: Bi Italia s.r.l. - Strada Bi 165, 29017 Fiorenzuola d'Arda (PC) – Italy PH: +39 0523 944 411 – bi_italia@bi.it

Notes

September 2023

Installation, Operation and Maintenance Manual

MAN 627 Rev. 0

This page intentionally left blank.

iTable of Contents

Installation, Operation and Maintenance Manual

MAN 627 Rev. 0

Table of Contents

September 2023

Table of Contents

Section 1: General Warnings

1.1 Generalities ..............................................................................................................1

1.1.1 Electrostatic Charge...................................................................................1

1.1.2 Noise Emission............................................................................................1

1.2 Identication Plate..................................................................................................1

1.3 Description of the Actuator..................................................................................2

Section 2: Installation

2.1 Checks upon Actuator Receipt ............................................................................3

2.2 Actuator Handling ..................................................................................................3

2.3 Storage......................................................................................................................4

2.4 Assembling the Actuator Onto the Valve ..........................................................4

2.5 Hydraulic Connections...........................................................................................5

2.6 Electrical Connections (if Any)..............................................................................6

Section 3: Operation and Use

3.1 Setting of the Linear Stroke..................................................................................7

3.2 Preparation for Start-Up .......................................................................................8

3.3 Start-Up and Commissioning...............................................................................8

3.4 Operation Description...........................................................................................9

3.5 Residual Risks ..........................................................................................................9

3.6 Operations ...............................................................................................................9

Section 4: Operational Tests and Inspections

Operational Tests and Inspections ............................................................................ 10

Section 5: Maintenance

5.1 Routine Maintenance.......................................................................................... 11

5.2 Special Maintenance........................................................................................... 12

5.2.1 Replacement of Cylinder Seals ............................................................. 12

5.2.2 Seals Replacement .................................................................................. 12

5.2.3 Reassembly ............................................................................................... 14

5.3 Extraordinary Maintenance............................................................................... 17

5.3.1 Lubrication of Mechanism..................................................................... 17

5.4 Dismantling and Demolition ............................................................................. 18

Section 6: Troubleshooting

6.1 Failure or Breakdown Research........................................................................ 19

Section 7: Layouts

7.1 Spare Parts Order................................................................................................ 20

7.2 Parts List for Maintenance and Replacing Procedure................................. 21

Section 8: Date Report for Maintenance Operations

Date Report for Maintenance Operations ................................................................ 23

Notes

September 2023

Installation, Operation and Maintenance Manual

MAN 627 Rev. 0

This page intentionally left blank.

NOTICE

Bi Italia has taken every care in collecting and verifying the documentation

contained in this instruction and operating manual. Nevertheless, Bi Italia does not

provide any guarantees for this instruction manual. Bi Italia will not be responsible

for any mistakes contained in it or for any damage either accidental or due to the use

of this manual. The information herein contained is reserved property of Bi Italia

and is subject to being modied without notice.

Section 1: General Warnings

1.1 Generalities

Bi Italia s.r.l. actuators are conceived, manufactured and controlled according to the

Quality Control System in compliance with EN-ISO 9001 international regulation.

1.1.1 Electrostatic Charge

An electrostatic charge risk is present on the actuator surface; in case of cleaning,

use only antistatic cloth; in case of maintenance, avoid all rubbing/frictions that could

electrostatically charge the equipment.

1.1.2 Noise Emission

The verication of the noise of the actuated valve is at valve maker care. Bi points

out that the actuator's noise can be considered negligible since it is an equipment for

regular on-o or intermittent use.

If the integral quick exhaust valve is present, we recommend using ear PPE

(Personal Protective Equipment) to avoid any possible acoustic discomfort.

1.2 Identication Plate

! WARNING

It is forbidden to modify the information and the marks without previous written

authorization by Bi Italia s.r.l. The plate fastened on the actuator contains the

following information (Figure 1).

Installation, Operation and Maintenance Manual

MAN 627 Rev. 0

September 2023

1

Section 1: General Warnings

General Warnings

September 2023

Installation, Operation and Maintenance Manual

MAN 627 Rev. 0

2

Section 1: General Warnings

General Warnings

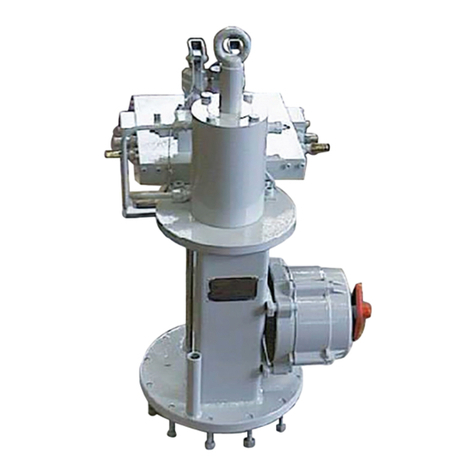

1.3 Description of the Actuator

The line of Double-Acting Hydraulic Linear Actuators, has been designed and

produced by Bi mainly to satisfy specic needs present on plants. For the above

reason, the Bi production of the above linear actuators, even based on a xed

criteria of design, is normally done job by job to adapt the actuator to the dierent

parameters and thrust/stroke of valves.

Features

• Electroless nickel plated and polished cylinder for corrosion resistance and

minimum friction.

• Hard chromium plated stainless steel piston rod for corrosion resistance and

minimum friction.

• Teon type piston rod seals and piston seals for low hysteresis and high

sensitivity preventing sticking problems. Piston seal is (A-Q seal) type

(zero leakages).

• Piston rod supported by bushing made of bronze with sinterized Teon to

provide minimal friction and extended service life.

• Stroke adjustment with mechanical travel stop in one direction.

• Adapter spool in fabricated carbon steel, specically designed for adaptation

to any type of valve with provision for local indicator, limit switches and other

accessories (on request).

Figure 1. Data Plate

Section 2: Installation

2.1 Checks upon Actuator Receipt

Checks to be carried out on receiving the actuator:

1. If the actuator arrived already assembled onto the valve, the settings of the

mechanical stops and of the microswitches (if existing) has already been

made by the person who assembled the actuator onto the valve.

2. If the actuator arrived separated from the valve, the settings of the

mechanical stops and of the microswitches (if existing) must be checked, and

if necessary, carried out while assembling the actuator onto the valve.

3. Check if the actuator has not been damaged during transport.

If necessary, repair all damages to the paint-coat, etc.

4. Check if the model, the serial number of the actuator and the performance

data written on the data-plate are in accordance with those described on the

order acknowledgement, test certicate and delivery note.

5. Check if the tted accessories comply with those listed in the order

acknowledgement and the delivery note.

2.2 Actuator Handling

NOTICE

The lifting and handling should be made by qualied sta and in compliance with the

laws and provisions in force.

! WARNING

The fastening points are appropriate for the lifting of the actuator alone and not for

the valve + actuator assembly. Avoid that during the handling, the actuator passes

above the sta. The actuator should be handled with appropriate lifting means. The

weight of the actuator is reported on the delivery bill.

Installation, Operation and Maintenance Manual

MAN 627 Rev. 0

September 2023

3

Section 2: Installation

Installation

2.4 Assembling the Actuator Onto the Valve

To assemble the actuator onto the valve proceed as follows:

1. Check that the coupling dimensions of the valve ange and stem, or of

the relevant extension, meet the actuator coupling dimensions (valve stem

and ange). Lubricate the valve stem with grease in order to make the

assembly easier.

2. Connect a sling to the support point of the actuator and lift it. To make easier

the assembly, the valve stem has to be in perfect vertical position.

NOTICE

The eyebolt is sized for the lifting of the only actuator (NOT ACTUATOR+VALVE).

Proper lifting points have to be foreseen for the valve.

3. Screw the actuator coupling joint onto the valve by rotating the actuator,

or screw down the valve stem stroke-ring with Red Loctite® 542 and x

the half-bearings when the threaded holes of the actuator ange are in

correspondence with the holes on the valve ange, screw the proper stud

bolts. Screw the nuts on the stud bolts and tighten up the valve ange is in

contact with the actuator ange.

4. Tighten the nuts of the connecting stud bolts evenly with the torque

prescribed in the table. The stud bolts must be made of ASTM A320 L7 steel,

the nuts must be made of ASTM A194 grade 2 steel as minimum.

2.3 Storage

The actuators leave the factory in excellent working conditions and with an

excellent nish (these conditions are guaranteed by an individual inspection

certicate); in order to maintain these characteristics until the actuator is installed

on the plant, it is necessary to observe a few rules and take appropriate measures

during the storage period.

1. Make sure that plugs are tted in the oil connections and in the cable entries.

The plastic plugs which close the inlets do not have a weatherproof function,

but are only a means of protection against the entry of foreign matter during

transport. If long-term storage is necessary and especially if the storage is

outdoor, the plastic protection plugs must be replaced by metal plugs, which

guarantee a complete weatherproof protection.

2. If the actuators are supplied separately from the valves, they must be placed

in a wooden pallet to protect the coupling ange to the valve. In case of

long-term storage, the coupling parts (ange, drive sleeve, insert bush) must

be coated with protective oil or grease. If possible, blank o the ange with a

protection disk.

3. In case of long-term storage, it is advisable to keep the actuators in a dry

place or to provide at least some means of weather protection. If possible,

it is also advisable to periodically operate the actuator with ltered,

dehydrated and lubricated air; after such operations, all the threaded

connections of the actuator and the valves of the control panel (if existing)

should be carefully plugged.

September 2023

Installation, Operation and Maintenance Manual

MAN 627 Rev. 0

4

Section 2: Installation

Installation

Thread Size Recommended Tightening Torque (Nm)

M8 20

M10 40

M12 70

M14 110

M16 160

M20 320

M22 420

M24 550

M27 800

M30 1100

M33 1400

M36 1700

Table 1.

2.5 Hydraulic Connections

! WARNING

Check that the values of hydraulic supply available are compatible with those

reported on the identication plate of the actuator.

NOTICE

The connections should be made by qualied sta.

Use pipes and connections appropriate as for type, material and dimensions.

! WARNING

Use motor uid with purity degree ISO 4406 17/14 or NAS 1638 Class 8 (AS4059

Class 4B-F). For special applications, the lower contamination degree is required.

Please refer to the documentation supplied.

• Properly deburr the ends of rigid pipes.

• Properly clean the interior of pipes sending through them plenty of the supply

uid used in the system.

• Mold and fasten the connection pipes so that no irregular strains at entries or

loosening of threaded connections occur.

• Make the connections according to the operating diagram.

• Check the absence of leakages from hydraulic connections. If necessary,

tighten the nuts of the pipe-ttings.

Installation, Operation and Maintenance Manual

MAN 627 Rev. 0

September 2023

5

Section 2: Installation

Installation

2.6 Electrical Connections (if Any)

! WARNING

Use components appropriate as for type, material and dimensions.

The connections should be made by qualied sta.

Before carrying out any operation, cut line power o.

Safety provisions as per CEI 64-8 regulation should be complied with (same as

IEC 60364).

Remove plastic plugs from cable entries.

• Screw the cable glands rmly.

• Introduce connection cables.

• Make the connections in compliance with applicable wiring diagrams on the

documentation supplied.

• Screw the cable gland.

• Replace the plastic plugs of unused entries with metal plugs.

September 2023

Installation, Operation and Maintenance Manual

MAN 627 Rev. 0

6

Section 2: Installation

Installation

Section 3: Operation and Use

3.1 Setting of the Linear Stroke

The setting of the open valve position is performed by adjusting the travel stop screw

that is screwed into the end ange of the hydraulic cylinder.

For the adjustment of the travel stop screw in the end ange of the hydraulic cylinder,

proceed as follows:

1. Unscrew through plug from the cylinder end ange.

2. If the actuator linear stroke is stopped before reaching the end position

(fully open), unscrew the stop screw by turning it counterclockwise with an

Allen wrench until the valve reaches the correct position.

3. If the actuator linear stroke is stopped beyond the end position (fully open),

screw the stop screw by turning it clockwise until the valve reaches the

correct position.

4. Screw through plug into the cylinder end ange.

Figure 2. Travel Stop Screw Screwed into the End Flange of

Hydraulic Cylinder

Table 2.

Hydraulic Cylinder

Diameter Wrench C1 (mm) Wrench C2 (mm)

From 50 to 95 17 46

From 110 to 135 17 55

C2

C1

Installation, Operation and Maintenance Manual

MAN 627 Rev. 0

September 2023

7

Section 3: Operation and Use

Operation and Use

C1

C2

September 2023

Installation, Operation and Maintenance Manual

MAN 627 Rev. 0

8

Section 3: Operation and Use

Operation and Use

3.2 Preparation for Start-Up

Refer to Section 2.

3.3 Start-Up and Commissioning

! WARNING

Installation, commissioning and maintenance and repair works should be made by

qualied sta.

Upon actuator commissioning, please carry out the following checks:

• Check that paint is not damaged during transport; if necessary, repair the

damages to paint coat.

• Check that the values of hydraulic supply available in the system are compatible

with those reported on the identication plate of the actuator (Figure 1) and on

the documentation supplied.

• Check that the feed voltage values of the electric components (solenoid

valve coils, microswitches, pressure switches, etc.) are compatible with those

reported on the identication plate of the actuator (Figure 1).

• Check that the setting of the components of the actuator control unit

(pressure regulator, pressure switches, ow control valves, etc.) meet the

plant requirements.

• Carry out all kinds of operations and check their proper execution (Section 3.6).

• Check the absence of leakages in the hydraulic connections. If necessary,

tighten the nuts of the pipe-ttings.

• Check proper operation of all the due signalling (valve position, hydraulic

supply pressure, etc.).

• Make a complete functional test in order to verify all the operations are

executed according to operating schematic diagram supplied.

Installation, Operation and Maintenance Manual

MAN 627 Rev. 0

September 2023

9

Section 3: Operation and Use

Operation and Use

3.4 Operation Description

The supply uid pressurizes the hydraulic cylinder chamber relevant to the operation

to carry out (opening or closing) (see following pages).

This pressure starts the linear motion of the piston and the consequent motion of the

valve stem that is coupled.

Figure 3.

For local or remote operations, please refer to technical documentation furnished

with actuators.

The power and control systems are supplied on specic customer demand.

NOTICE

For all the relevant information, please refer to the specic documentation supplied.

3.5 Residual Risks

! WARNING

The actuator has parts under pressure.

Use due caution.

Use individual protections provided for by the laws and provisions in force.

3.6 Operations

Refer to specic document: operating diagram furnished.

Section 4: Operational Tests

and Inspections

NOTICE

To ensure the guaranteed SIL grade, according to IEC 61508, the functionality

of actuator must be checked with regular intervals of time, as described in the

Safety Manual.

September 2023

Installation, Operation and Maintenance Manual

MAN 627 Rev. 0

10

Section 4: Operational Tests and Inspections

Operational Tests and Inspections

Installation, Operation and Maintenance Manual

MAN 627 Rev. 0

September 2023

11

Section 5: Maintenance

Maintenance

Section 5: Maintenance

! WARNING

Before carrying out any maintenance operation, it is necessary to close the

hydraulic feed line and exhaust the pressure from the actuator cylinder and from the

control unit, to ensure safety of maintenance sta.

5.1 Routine Maintenance

NOTICE

Periodicity and regularity of inspections is particularly inuenced by specic

environmental and working conditions. They can be initially determined

experimentally and then be improved according to actual maintenance

conditions and needs.

Anyway every 2 years of operation, the following is recommended:

HLRA actuators have been designed to work for long periods in the severest

conditions with no need for maintenance.

1. Check if the actuator operates the valve correctly and with the required

operating times. If the actuator operation is very infrequent, carry out a few

opening and closing operations with all the existing controls (remote control,

local control, emergency controls, etc.), if this is allowed by the conditions of

the plant.

2. Check if the signals to the remote control desk are correct. Check if the

supply pressure value is within the required range.

3. Check if the external components of the actuator are in good conditions.

4. Check all the paint-coat of the actuator. If some areas are damaged, repair

the paint-coat according to the applicable specication.

5. Check if there are no leakages in the hydraulic connections. If necessary,

tighten the nuts of the pipe ttings.

September 2023

Installation, Operation and Maintenance Manual

MAN 627 Rev. 0

12

Section 5: Maintenance

Maintenance

5.2 Special Maintenance

If there are leaks in the hydraulic cylinder or a malfunction in the mechanical

components, or in case of scheduled preventive maintenance, the actuator must be

disassembled and seals must be replaced with reference to the attached sectional

drawing and adopting the following procedures.

5.2.1 Replacement of Cylinder Seals

1. Unscrew the plug (28) from the cylinder end ange.

2. Measure the distance of the stop screw (23) with reference to the end ange

(13) surface, so as to be able to easily restore the setting of the actuator

mechanical stop, once the maintenance procedures have been completed.

3. Unscrew the stop screw (23) by turning it counterclockwise with an Allen

wrench until the screw is completely withdrawn inside the end ange

threaded hole.

4. Unscrew the nuts (25) from the tie rods (7) they must be gradually unscrewed

all at the same time.

5. Slide o the end ange (13), the upper cylinder tube (22), the intermediate

ange (11) and the lower cylinder tube (18).

6. If the piston rod seal ring (3) needs to be replaced, remove the screw (17).

Unscrew the piston rod (19) threaded end from the adaptor bush (16). Slide

o the piston rod (19) from the head ange (1).

7. Disassemble the head ange.

5.2.2 Seals Replacement

Prior to reassembly, check if the actuator components are in good condition and

clean. Lubricate all the surface of the parts, which move in contact with other

components, by a recommended grease. If the O-ring must be replaced, remove

the existing one from its groove, clean the groove carefully and lubricate it with a

protective oil or grease lm. Assemble the new O-ring into its groove and lubricate it

with a protective oil or grease lm.

1. Replace the O-ring (5) and the back-up ring (4) of the anges (1) (11).

2. Replace the scraper (2) into the head ange.

Installation, Operation and Maintenance Manual

MAN 627 Rev. 0

September 2023

13

Section 5: Maintenance

Maintenance

To replace the piston rod seal rings (3) proceed as follows:

1. Remove the existing Teon seal ring (3) with its O-ring from their groove.

2. Clean the groove carefully and lubricate it with a protective oil or grease lm.

3. Assemble the new O-ring into its groove and lubricate it with a protective oil

or grease lm.

4. Assemble the new Teon seal ring (3) into the ange groove, inside its rubber

O-ring, by bending it. The bending radius is as large as possible make sure

to avoid damaging the seal. Then enlarge the seal ring with your ngers

to restore its round shape, pay attention not to utilize any tools which can

damage the seal ring.

To replace the piston seal ring (9) proceed as follows:

1. Remove the existing Teon seal ring (9) with its O-ring from their groove.

2. Clean the groove carefully and lubricate it with a protective oil or grease lm.

3. Assemble the new O-ring into its groove and lubricate it with a protective oil

or grease lm.

4. Assemble the new Teon seal ring (9) on its rubber O-ring by introducing

one side of it into the groove, then enlarge it with your ngers so as to t

it into the groove: take care to enlarge it uniformly without any tools which

could possibly damage it. The elastic memory of the kind of Teon the seal

ring is made of allows the ring to shrink back to its previous dimension after

a short time.

To replace the piston rod seal rings (12) proceed as follows:

1. Remove the existing Teon seal ring (12) with its O-ring from their groove.

2. Clean the groove carefully and lubricate it with a protective oil or grease lm.

3. Assemble the new O-ring into its groove and lubricate it with a protective oil

or grease lm.

4. Assemble the new Teon seal ring (12) into the ange groove, inside its

rubber O-ring by bending it, take care since the bending radius is as large

as possible to avoid damaged the seal. Then enlarge the seal ring with your

ngers so as to restore its round shape, pay attention not to utilize any tools

which can damage the seal ring.

September 2023

Installation, Operation and Maintenance Manual

MAN 627 Rev. 0

14

Section 5: Maintenance

Maintenance

5.2.3 Reassembly

1. Assemble the head ange (1), on pedestal (15).

2. Lubricate the piston rod (19) surface, with a protective oil or grease lm and

introduce it into the head ange hole, taking care not to damage the piston

seal ring (3). Carefully clean the threaded end of the piston rod (19) and the

threaded hole of the adaptor. Spread some sealant Loctite 452, or equivalent,

on the rod threaded end and tighten.

3. Carefully clean the inside of the tube (18) and check that the entire surface,

particularly that of the bevels, is not damaged. Lubricate with a protective

oil or grease lm the tube internal surface and the bevels at the ends. Slide

the tube onto the piston taking care not to damaged the Teon seal ring (9):

the tube bevel has to smoothly compress the seal ring; take care also not to

damage the head ange O-ring (5).

4. Before reassembling the intermediate ange (11), lubricate the upper piston

rod (21) with a protective oil or grease lm.

5. Assemble the intermediate ange (11) take care not damage the seal ring

(12) and the O-ring (5). Assemble the upper cylinder tube and the end ange

by centering it on the inside diameter of the tube.

6. Assemble the nuts (25) onto the tie rods (7). Tighten the nuts to the

recommended torque, alternating between opposite corners.

7. Screw the stop screw (23) by turning it clockwise with an Allen wrench until

it reaches its original position (the same distance with reference to the end

ange surface).

8. Screw the plug (28) into the cylinder end ange.

NOTICE

After maintenance operations, carry out a few actuator operations to check that its

movement is regular and that there is no oil leakage through the seals.

Installation, Operation and Maintenance Manual

MAN 627 Rev. 0

September 2023

15

Section 5: Maintenance

Maintenance

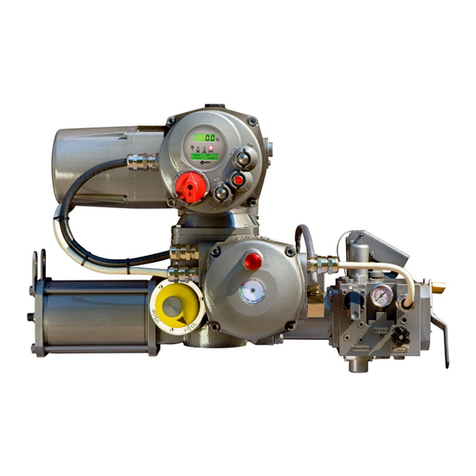

Figure 4. HLRA Double-Acting Hydraulic Linear Actuator

28

27

26

25

24

23

22

21

11

13

13

10

11

4

12

14

9

7

8

5

6

5

4

3

2

1

20

19

18

17

16

15

Table 3. Parts List

Item Description Material

1 Cylinder lower ange Carbon steel ASTM A 283 Gr. D

2 Scraper ring * Teon + nitrile rubber

3Piston rod seal ring * Teon + nitrile rubber

4Back-up ring * Nitrile rubber

5 O-ring * Nitrile rubber

6Piston rod bushing Steel + bronze + teon

7Tie rod Stainless steel ASTM A564 TP630

8Piston guide sliding

ring * Teon + graphite

9 Piston seal ring * Teon + nitrile rubber

10 Bushing Steel + bronze + teon

11 Intermediate ange Carbon steel ASTM A 283 Gr. D

12 Seal ring * Teon + nitrile rubber

13 Cylinder upper ange Carbon steel ASTM A 283 Gr. D

14 Dust excluder Stainless steel AISI 316

15 Pedestal Carbon steel ASTM A 283 Gr. D

16 Connecting joint Alloy steel AISI SAE 9840

17 Screw Alloy steel ASTM A193 B7

18 Lower cylinder tube Carbon steel (Nickel plated) API 5LX Gr. X52

19 Lower piston rod Stainless steel (Chronium plated)

ASTM A564-TP 630

20 Piston Carbon steel ASTM A 283 Gr. D

21 Upper piston rod Stainless steel (Chronium plated)

ASTM A564-TP 630

22 Upper cylinder tube Carbon steel (Nickel plated) API 5LX Gr. X52

23 Travel stop screw Stainless steel ASTM A193 B8M

24 O-ring * Nitrile rubber

25 Nut Stainless steel ASTM A194 8M

26 Eyebolt Carbon steel AISI SAE 1040

27 Travel stop screw cover Carbon steel ASTM A283 Gr. D

28 Plug Carbon steel AISI SAE 1040

NOTE:

* Recommended spare parts

September 2023

Installation, Operation and Maintenance Manual

MAN 627 Rev. 0

16

Section 5: Maintenance

Maintenance

Table of contents

Other BIFFI Controllers manuals

BIFFI

BIFFI HLAS-C Series User manual

BIFFI

BIFFI GILS User manual

BIFFI

BIFFI RPHD-10 User manual

BIFFI

BIFFI TPS Series User manual

BIFFI

BIFFI PLA User manual

BIFFI

BIFFI OLGA Series User manual

BIFFI

BIFFI HLA User manual

BIFFI

BIFFI OLGAS User manual

BIFFI

BIFFI ICON3000 Series User manual

BIFFI

BIFFI HLA Series User manual

BIFFI

BIFFI RPS User manual

BIFFI

BIFFI EHO User manual

BIFFI

BIFFI RP14 User manual

BIFFI

BIFFI ALGAS-QA EAC User manual

BIFFI

BIFFI ALGAS-MHP User manual

BIFFI

BIFFI RPS Series User manual

BIFFI

BIFFI ALGA Series User manual

BIFFI

BIFFI GIGS Series User manual

BIFFI

BIFFI ICON3000 Series User manual

BIFFI

BIFFI EFS2000v4 Parts list manual