11. Common Items and Others .................................................................................................. 130

11.1 Communication Cable....................................................................................................... 130

11.2 Connection of Communication Cable Connector.............................................................. 131

11.3 Power Supply Connection and Terminal Resistor............................................................. 131

11.3.1 Power Supply Connection.......................................................................................... 131

11.3.2 Terminal Resistor....................................................................................................... 131

11.4 Useful Functions You Should Know When Adjusting an XSEL Controller........................ 131

12. EDS File ...............................................................................................................................132

Change History............................................................................................................................133

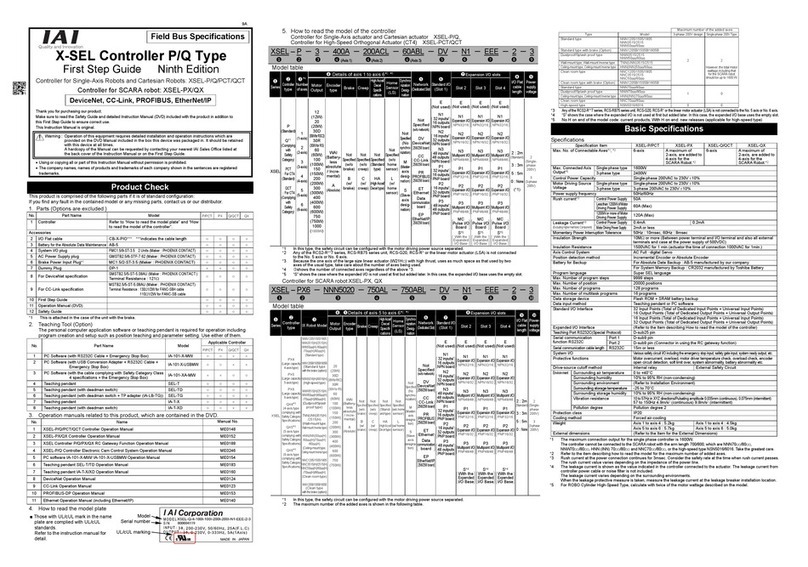

9.4 Setting of I/O Parameters.................................................................................................. 121

(1)Networktype setting................................................................................................... 121

(2)Node address............................................................................................................. 121

(3)I/O port assignments.................................................................................................. 121

(4)Networkerror monitor................................................................................................ 121

9.5 Assignment of I/O Port Numbers and DeviceNet Addresses ............................................ 124

(1)Basic example............................................................................................................ 124

(2) Using in the positioner mode...................................................................................... 125

10. Troubleshooting.................................................................................................................... 129

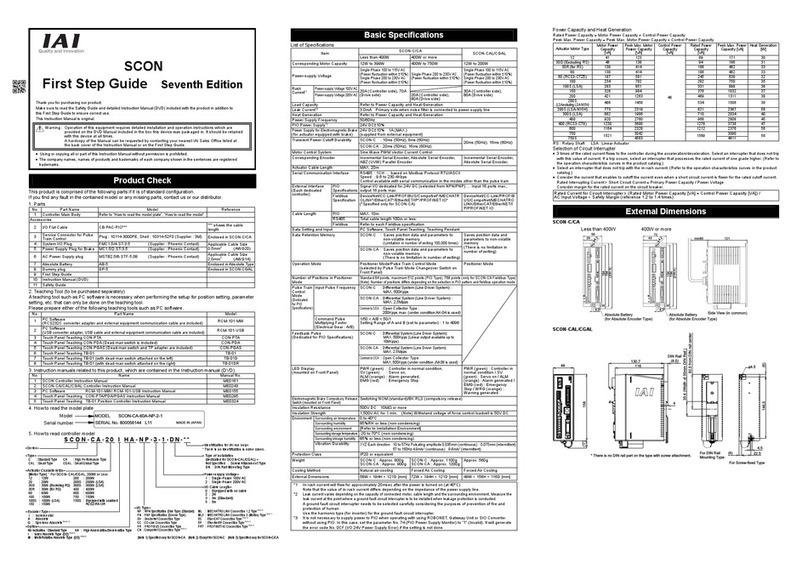

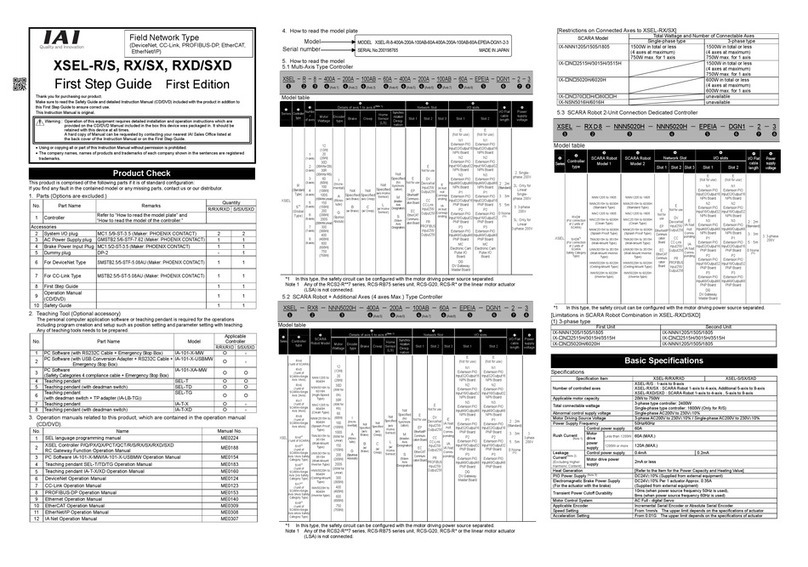

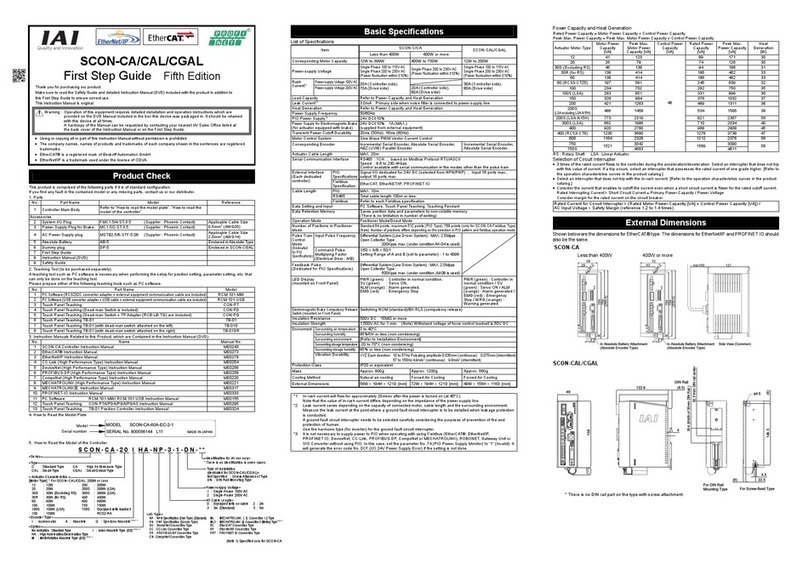

8. SCON-C ...............................................................................................................................107

8.1 Model.................................................................................................................................107

8.2 Interface Specifications......................................................................................................108

8.3 DeviceNet Interface...........................................................................................................109

8.3.1 Name of Each Part.....................................................................................................109

8.3.2 DIP Switch Settings....................................................................................................110

(1) Setting the node address (MAC ID)...........................................................................110

(2) Setting the baud rate..................................................................................................110

8.3.3 Monitor LED Indicators...............................................................................................111

8.4 Assignment of I/O Signals.................................................................................................112

8.5 Assignment of DeviceNet Addresses ................................................................................114

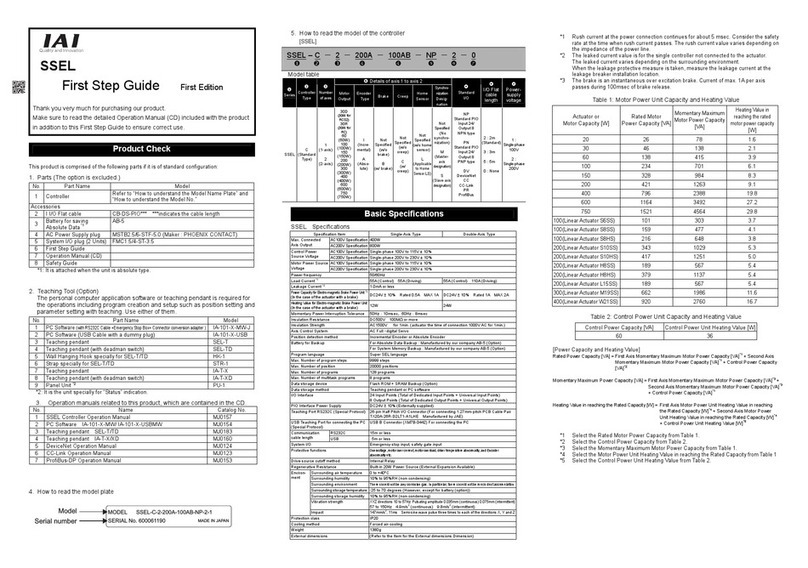

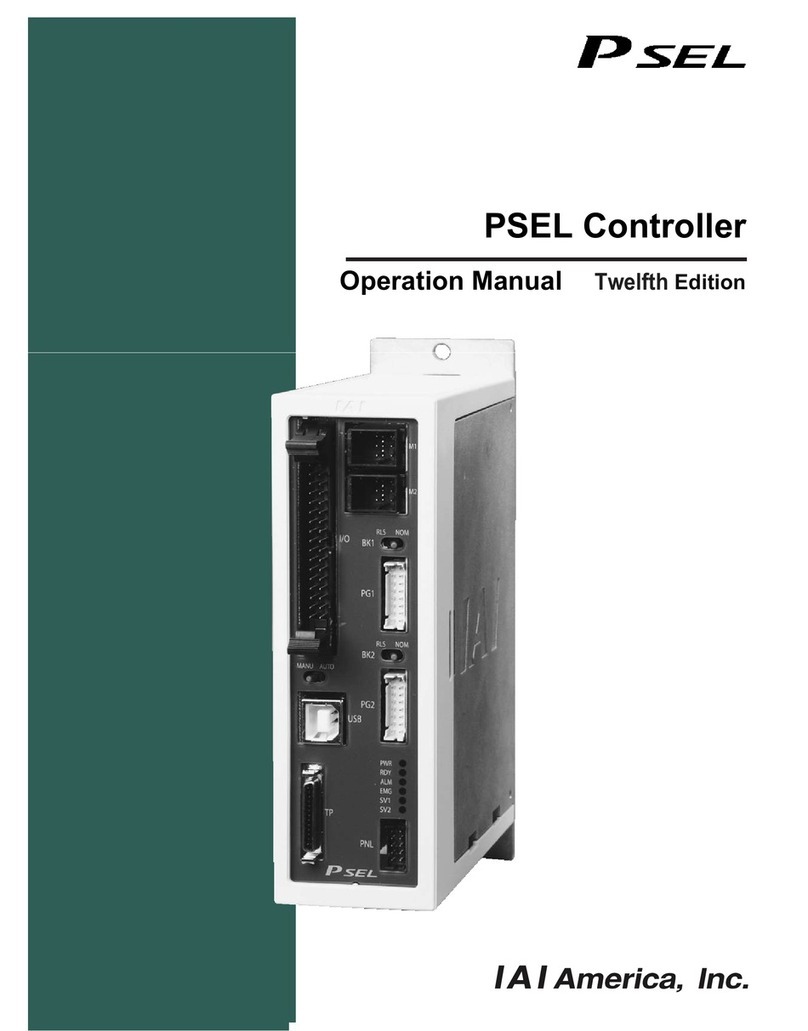

9. ASEL, PSEL and SSEL........................................................................................................115

9.1 Models ............................................................................................................................... 115

9.1.1 ASEL, PSEL...............................................................................................................115

9.1.2 SSEL..........................................................................................................................116

9.2 Interface Specifications......................................................................................................117

9.3 DeviceNet Interface...........................................................................................................118

(1) Name of Each Part.....................................................................................................118

(2)StatusLED indications...............................................................................................119

(3)DeviceNet connectors................................................................................................120

7.2 Interface Specifications.....................................................................................................100

7.3 DeviceNet Interface..........................................................................................................101

7.3.1 Name of Each Part....................................................................................................101

7.3.2 DIP Switch Settings...................................................................................................102

(1) Setting the node address (MAC ID)..........................................................................102

(2) Setting the baud rate.................................................................................................102

7.3.3 Monitor LED Indicators..............................................................................................103

7.4 Input/Output (I/O)..............................................................................................................104

(1) RCS-C signal assignments.......................................................................................104

(2) E-Con signal assignments........................................................................................105