V

CONTENTS

1. General ............................................................ 1-1

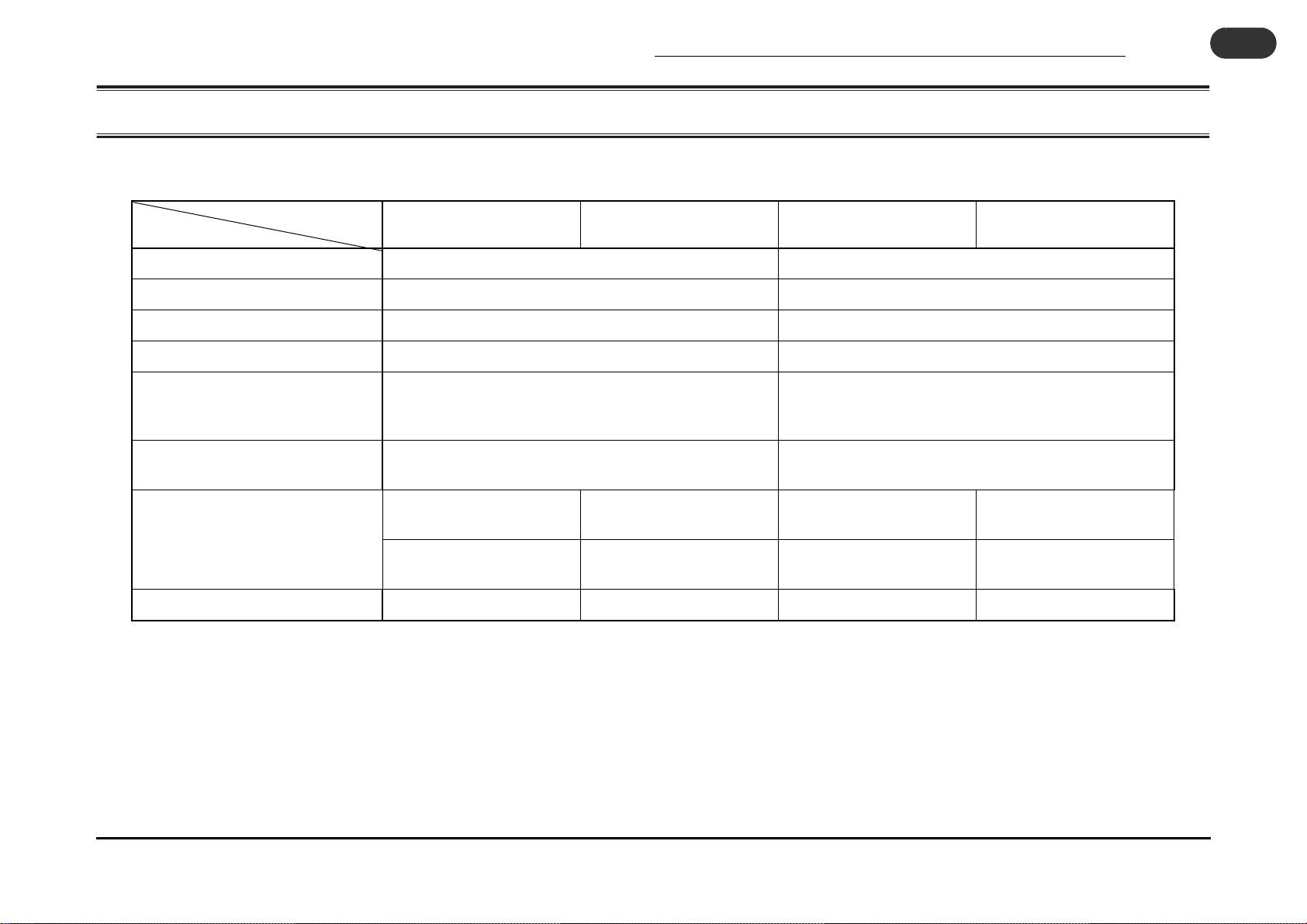

1-1 Model of the Collator and Configuration.............................. 1-2

1-1-1 Table for Model of the collator and Configuration.............................. 1-2

1-2 Delivery Mechanism............................................................ 1-3

1-2-1 Delivery Mechanism .......................................................................... 1-3

1-3 Service Screen ........................................................................... 1-4

1-3-1 Description of the Service Screen ..................................................... 1-4

1-3-2 Initial Setting Screen.......................................................................... 1-5

1-3-3 Service Mode Screen-P1................................................................... 1-6

1-3-4 Service Mode Screen-P2................................................................... 1-7

1-3-5 Service Mode Screen-P3................................................................... 1-8

1-3-6 Service Mode Screen-P4................................................................... 1-9

1-4 Setting the QC-S30 ........................................................... 1-10

1-4-1 Setting the Frequency/SPF/Connecting Order ................................ 1-10

1-4-2 Setting the Overlap Amount............................................................. 1-11

1-5 Transferring the Image Data ............................................. 1-12

1-5-1 Transferring the Image Data............................................................ 1-12

1-6 Resetting the Connecting Order........................................ 1-13

1-6-1 Resetting the Connecting Order (Tower No.) .................................. 1-13

2. Troubleshooting ............................................... 2-1

2-0 Problem Recovery 2............................................................ 2-2

2-0-1 Problem Recovery List....................................................................... 2-2

2-1 Error is Indicated on the Panel................................................. 2-3

2-1-1 Misfeed or Double Feed Error is Indicated ........................................ 2-3

2-1-2 Jam or No Sheet Error is Indicated.................................................... 2-4

2-1-3 Tray Full Error is Indicated................................................................. 2-5

2-1-4 Door Open Error is Indicated ............................................................. 2-6

2-1-5 Option Error or Communication Error is Indicated............................. 2-7

2-1-6 Bin Up/Down Error is Indicated.......................................................... 2-8

2-2 Problem in Collating Quality ..................................................... 2-9

2-2-1 Offset is not Performed Correctly....................................................... 2-9

2-2-2 Sheets are Scratched or Stained ..................................................... 2-10

2-3 Problem in Machine Operation............................................... 2-11

2-3-1 Machine Does not Start ................................................................... 2-11

2-3-2 Offset Function Malfunction ............................................................. 2-12

2-3-3 Bin Does not Rise (Lower) on QC-S300 ..........................................2-13

2-3-4 Gate Does not Switch ...................................................................... 2-14

2-3-5 Machine Does not Stop although the Tray is Full ............................ 2-15

2-4 Problem in LCD Monitor.....................................................2-16

2-4-1 Trouble in LCD Monitor.................................................................... 2-16

3. Mechanism of QC-S300/-S30........................... 3-1

3-1 Feed Section........................................................................3-2

3-1-1 Feed Section Mechanism .................................................................. 3-2

3-2 Drive Link Section ................................................................3-3

3-2-1 Drive Link Section Mechanism........................................................... 3-3

3-3 Transport Belt Frame Section ..............................................3-4

3-3-1 Transport Belt Frame Section Mechanism......................................... 3-4

3-4 Gate Switch Section.............................................................3-5

3-4-1 Gate Switch Section Mechanism ....................................................... 3-5

3-5 Bin Up Section (1/2) ................................................................... 3-6

3-5-1 Bin Up Mechanism of QC-S300......................................................... 3-6

3-5-2 Bin Up Mechanism of QC-S30........................................................... 3-7

3-6 Offset/Swing Section............................................................3-8

3-6-1 Offset/Swing Section Mechanism ...................................................... 3-8

3-7 Conveyor Section.................................................................3-9

3-7-1 Conveyor Section Mechanism ...........................................................3-9