• Nach dem Herausnehmen des Geräts aus der Verpackung ist der Bügel (5)auf der Enbindung

splatte (6) mit den mitgelieferten Schrauben zu befestigen.

• Mit den mitgelieferten Innensechskantschlüsel ist der Arm (1) an das Gerät zu montieren.

• Zwei Bindeeinsätze A und B sowie Entbindekeil (10) befinden sich in den Räumen im Hinter-

teil des Gehäuses. Die Führung Cover guide C ist über dem Bindebacken angeordnet.

• Die magnetische Messvorrichtung zur Anpassung optimaler Größe des Kanals an die Abzahl

der Blätter (7) kann im Gehäuse des Geräts montiert werden.Die Form der dem gerät beigel-

egten Einsätzen A unc B sowie Führung Cover guide ist auf solche Weise profiliert, damit das

Einlegen der Dokumente in das Kanal einfacher wird. Zusätzlich reduzieren die Bindeeinsätze

A und B die Größe des Bindespalts. Vor Einleitung der Bindearbeiten ist eine der Bindeein-

sätze (A oder B) an der Entbindeplatte zu befestigen. Die abgeschnittene Seite der Einsätze

sollen in Richtung Spalt angeordnet sein (3). Die richtige Anordnung der Einsätze wird auf

dem Bild mit Querschnitt dargestellt (auf der Seite mit der Gerätebezeichnung).

Ermöglicht die Kontrolle des Kanaldrückstärke und registriert den Wert dieser Kraft, um seine

Wiederholbarkeit zu erreichen.

1. Drücken Sie die START/SET-Taste. Der Zeiger zeight den letzten registriertern Wert

und dann geht zum Messmodus über (LED1 leuchtet).

2. Währen des Bindend, wenn die Kanaldrückkraft steigt, erleuchten weitere LEDs

und ein Ton informiert, wann die programmierte Kraftwert erreicht wird. Wenn

kein Binden innerhalb von einigen Sekunden erfolgt, geht der Zeiger in den

Energiesparmodus über (LED blinkt). In dieser Zeit kann man arbeiten (Wenn

die Kanaldrückkraft vorkommt, beginnen die LEDs dauerhaft zu leuchten).

3. Wenn Sie den Zeiger Überprogrammieren wollen (Änderung der Kraftwert, bei

der ein Ton generiert wird), drücken und halten Sie die START/SET-Taste -> die

LED zeight nächste Stufen auf der Skala. Wenn sie den gewünschten Wert

erreicht, soll die Taste gelöst werden.

4. Nach einigen Minuten nach dem letzten Binden geht der Zeiger in

Stand-by-Modus über (Zeige- und Messelemente werden ausgechaltet).

Wechsel der Batterie

1. Der Zeiger wird mit einer CR2032-Lithium Batterie betrieben,

die im hinteren Teil des Gerätes lokalisiert wird. Ein blinkendes

durchgestrichenes Batteriesymbol über der Skala informiert,

dass sie leer ist. Je grössere die Pulsfrequenz, desto schwächer

ist die Batterie*.

2. Eine leere Batterie soll mit Hilfe eines Schlitzschraubers

ausgewechselt werden Schieben Sie eine neue Batterie unter

einem entsprechenden Winkel ein.

*Leere Batterien müssen selektiv entsorgt werden und dürten zusammen mit anderen Abfällen gesammelt werden.

Informationen uber Sammeistellen der leeren Batterien können bel lokaren Standt-oder Gemeindebehörden bezogen werden.

VORBEREITUNG

5

6

4

5

•It is necessary to check and supervise if the equipment being operated correctly

In case of any malfunctions before contacting, the service department or dealer.

•Equipment must not be located outside

•Equipment must be operated in accordance with the general Health & Safety rules.

•Repairs must be carried out by authorized staff during the guarantee period

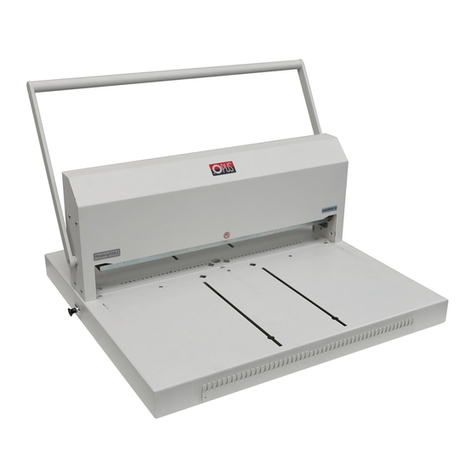

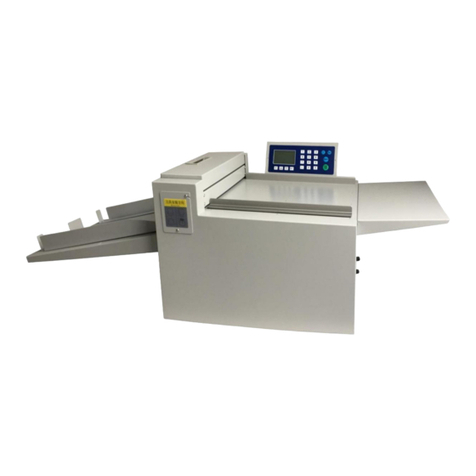

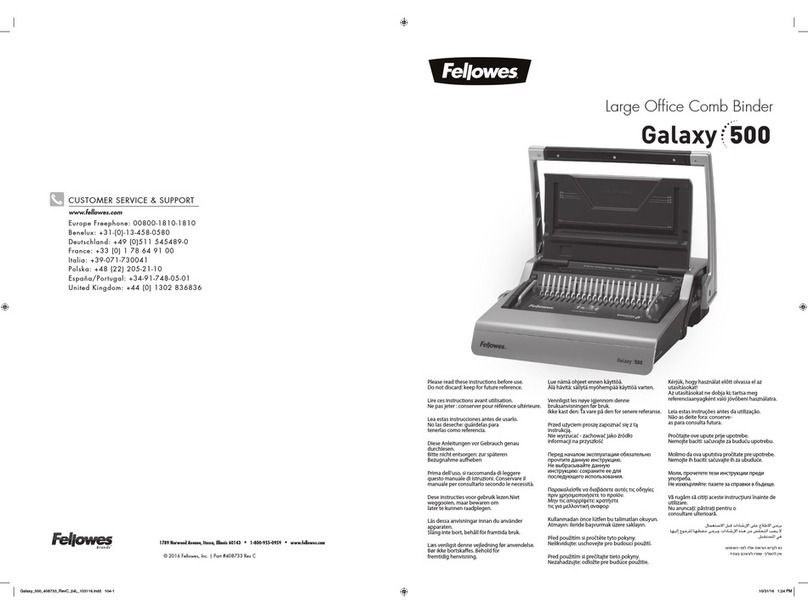

PREPARATION TO WORK

•Unpack the equipment and fit the extended back support on the top of the main back

support plate in the pre-drilled holes with the screws and Allen key supplied.

•Fit the binding handle to the equipment with the screw and Allen key supplied, tighten

firmly.

•In the slots in back (10) of the equipment are two binding bars and the de-binding wedge.

•Tool for selecting the channel size has a magnet so you can keep it on the equipment hous-

ing.

•The binding guide bars A & B fit at the back of the binding slot by magnetics and has a

scale on each.

The third guide bar fits over the binding jaw. These three bars form the COVERGUIDE SYSTEM

and were specially designed to make it quick and easy to put covers and pagers into the

Metalbind channel for binding. A clear view this is shown in point 2 "DESCRIPTION".

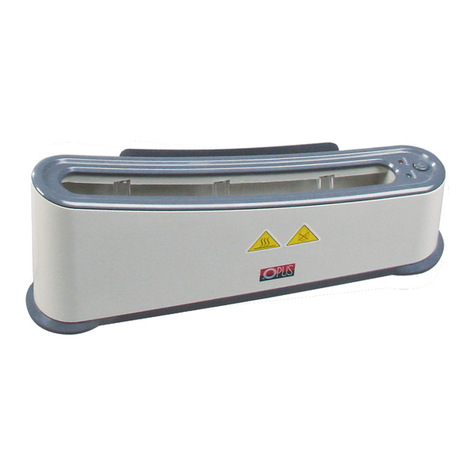

PRESSURE INDICATOR LED DISPLAY UNIT

The pressure indicator gives you the facility to save the best pressure for the channel when

binding large numbers of the same presentations/documents giving you a perfect result and

speeding up the job. The LED,s will move up the scale from 1 to 10 when the right binding

pressure you set is reached, you can hear a single sound then release the binding handle.

1. Press START/SET button on the LED display, it will show the last value set.

If this value is good for the next job, you can start binding right away.

2. To set a new binding pressure, press the START/SET button and hold it on until the LED light reaches

the number you wish to set then release the button and the level is set.

3. During binding process, as you increase the pressure with the handle the LED, s move up the scale

until it reaches the level set and makes a single sound release the handle.

4. When you stop binding for over a minute, the unit goes into an energy-saving mode and LED flash,

when it is in this mode you can still bind and it will sound when you reach the correct pressure.

5. When the binding equipment is not used for 5 minutes, the pressure unit will turn its self off to save

the battery, to start again just press the START/SET button once and continue binding.

CHANGING THE BATTERY

The unit is powered by the CR2032 lithium battery, which is on the right side

on the back of the equipment. When the battery is, low the sign at the top

of the scale comes on warning you to change the on the battery the lower

the battery get the faster the light flashes.

See diagram opposite

1. To remove the battery* slide it out by using a small thin screwdriver.

2. Slide the new battery in with the plus sign + to the right away from equipment.

* Batteries when empty must be collected separately and cannot be put together with normal type of wastes. Information concerning

collection points for empty batteries are available at your local city or municipal authorities offices or on the internet.

4

5

•It is necessary to check and supervise if the equipment being operated correctly

In case of any malfunctions before contacting, the service department or dealer.

•Equipment must not be located outside

•Equipment must be operated in accordance with the general Health & Safety rules.

•Repairs must be carried out by authorized staff during the guarantee period

PREPARATION TO WORK

•Unpack the equipment and fit the extended back support on the top of the main back

support plate in the pre-drilled holes with the screws and Allen key supplied.

•Fit the binding handle to the equipment with the screw and Allen key supplied, tighten

firmly.

•In the slots in back (10) of the equipment are two binding bars and the de-binding wedge.

•Tool for selecting the channel size has a magnet so you can keep it on the equipment hous-

ing.

•The binding guide bars A & B fit at the back of the binding slot by magnetics and has a

scale on each.

The third guide bar fits over the binding jaw. These three bars form the COVERGUIDE SYSTEM

and were specially designed to make it quick and easy to put covers and pagers into the

Metalbind channel for binding. A clear view this is shown in point 2 "DESCRIPTION".

PRESSURE INDICATOR LED DISPLAY UNIT

The pressure indicator gives you the facility to save the best pressure for the channel when

binding large numbers of the same presentations/documents giving you a perfect result and

speeding up the job. The LED,s will move up the scale from 1 to 10 when the right binding

pressure you set is reached, you can hear a single sound then release the binding handle.

1. Press START/SET button on the LED display, it will show the last value set.

If this value is good for the next job, you can start binding right away.

2. To set a new binding pressure, press the START/SET button and hold it on until the LED light reaches

the number you wish to set then release the button and the level is set.

3. During binding process, as you increase the pressure with the handle the LED, s move up the scale

until it reaches the level set and makes a single sound release the handle.

4. When you stop binding for over a minute, the unit goes into an energy-saving mode and LED flash,

when it is in this mode you can still bind and it will sound when you reach the correct pressure.

5. When the binding equipment is not used for 5 minutes, the pressure unit will turn its self off to save

the battery, to start again just press the START/SET button once and continue binding.

CHANGING THE BATTERY

The unit is powered by the CR2032 lithium battery, which is on the right side

on the back of the equipment. When the battery is, low the sign at the top

of the scale comes on warning you to change the on the battery the lower

the battery get the faster the light flashes.

See diagram opposite

1. To remove the battery* slide it out by using a small thin screwdriver.

2. Slide the new battery in with the plus sign + to the right away from equipment.

* Batteries when empty must be collected separately and cannot be put together with normal type of wastes. Information concerning

collection points for empty batteries are available at your local city or municipal authorities offices or on the internet.

4

5

•It is necessary to check and supervise if the equipment being operated correctly

In case of any malfunctions before contacting, the service department or dealer.

•Equipment must not be located outside

•Equipment must be operated in accordance with the general Health & Safety rules.

•Repairs must be carried out by authorized staff during the guarantee period

PREPARATION TO WORK

•Unpack the equipment and fit the extended back support on the top of the main back

support plate in the pre-drilled holes with the screws and Allen key supplied.

•Fit the binding handle to the equipment with the screw and Allen key supplied, tighten

firmly.

•In the slots in back (10) of the equipment are two binding bars and the de-binding wedge.

•Tool for selecting the channel size has a magnet so you can keep it on the equipment hous-

ing.

•The binding guide bars A & B fit at the back of the binding slot by magnetics and has a

scale on each.

The third guide bar fits over the binding jaw. These three bars form the COVERGUIDE SYSTEM

and were specially designed to make it quick and easy to put covers and pagers into the

Metalbind channel for binding. A clear view this is shown in point 2 "DESCRIPTION".

PRESSURE INDICATOR LED DISPLAY UNIT

The pressure indicator gives you the facility to save the best pressure for the channel when

binding large numbers of the same presentations/documents giving you a perfect result and

speeding up the job. The LED,s will move up the scale from 1 to 10 when the right binding

pressure you set is reached, you can hear a single sound then release the binding handle.

1. Press START/SET button on the LED display, it will show the last value set.

If this value is good for the next job, you can start binding right away.

2. To set a new binding pressure, press the START/SET button and hold it on until the LED light reaches

the number you wish to set then release the button and the level is set.

3. During binding process, as you increase the pressure with the handle the LED, s move up the scale

until it reaches the level set and makes a single sound release the handle.

4. When you stop binding for over a minute, the unit goes into an energy-saving mode and LED flash,

when it is in this mode you can still bind and it will sound when you reach the correct pressure.

5. When the binding equipment is not used for 5 minutes, the pressure unit will turn its self off to save

the battery, to start again just press the START/SET button once and continue binding.

CHANGING THE BATTERY

The unit is powered by the CR2032 lithium battery, which is on the right side

on the back of the equipment. When the battery is, low the sign at the top

of the scale comes on warning you to change the on the battery the lower

the battery get the faster the light flashes.

See diagram opposite

1. To remove the battery* slide it out by using a small thin screwdriver.

2. Slide the new battery in with the plus sign + to the right away from equipment.

* Batteries when empty must be collected separately and cannot be put together with normal type of wastes. Information concerning

collection points for empty batteries are available at your local city or municipal authorities offices or on the internet.

ZEIGER DER BINDENSTÄRKE

10

4VERWENDETE SYMBOLE