CONTENTS

Important Information

Safety Precautions

Safety Operation Precautions

1. Machine Description .................................................................................... 1

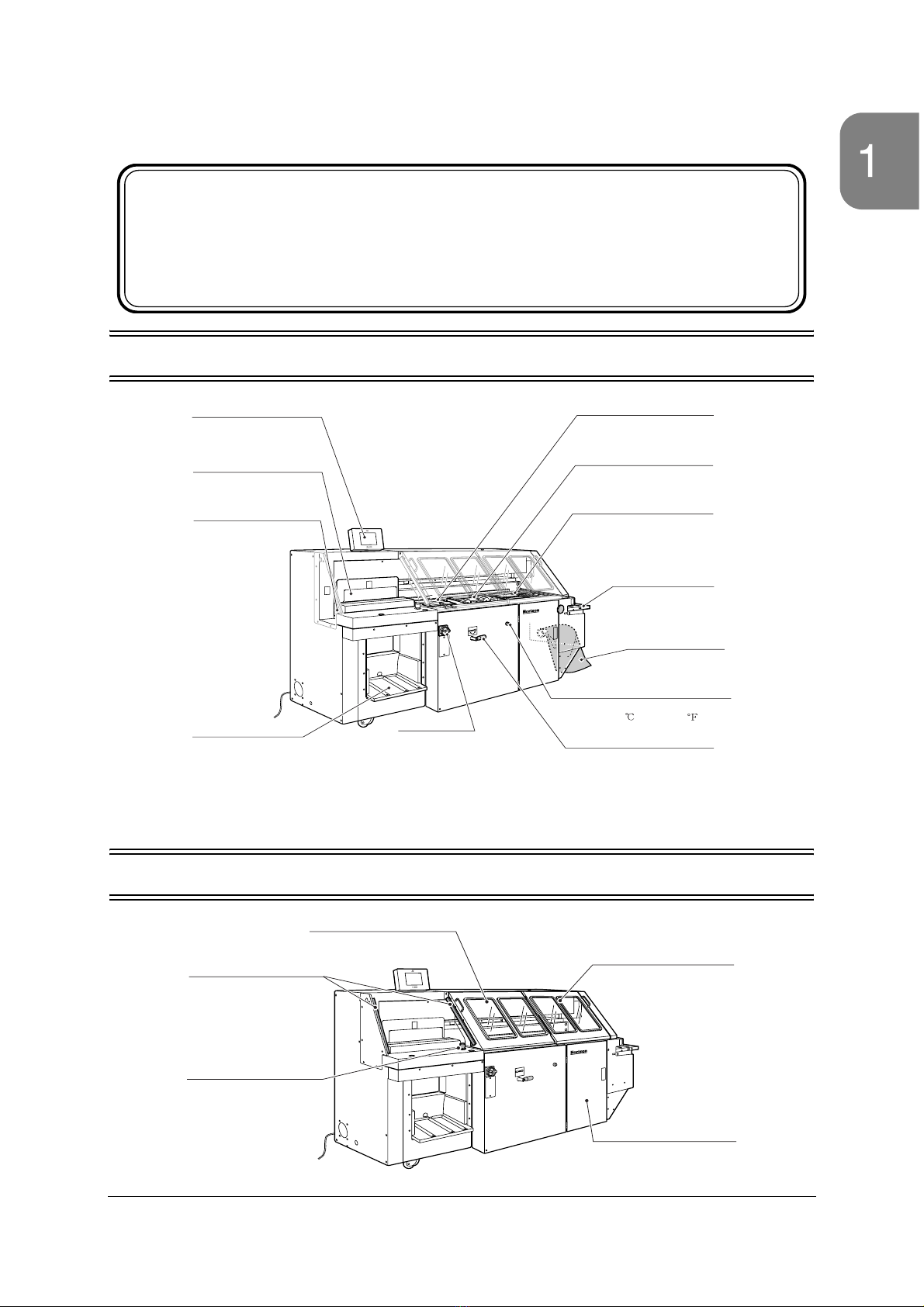

1-1 Machine Description............................................................................................... 1

1-2 Safety Functions .................................................................................................... 1

1-3 Parts Descriptions .................................................................................................. 2

1-3-1 Carriage Clamp Section ........................................................................................... 2

1-3-2 Level Plate Section................................................................................................... 2

1-3-3 Milling Section .......................................................................................................... 3

1-3-4 Melt Tank Section..................................................................................................... 4

1-3-5 Nipping Section ........................................................................................................ 5

1-3-6 Cover Feed Section.................................................................................................. 6

1-3-7 Delivery Section ....................................................................................................... 7

1-3-8 Touch Screen ........................................................................................................... 7

1-4 Screen Descriptions ............................................................................................... 8

2. Job Settings on Touch Screen ................................................................... 9

2-1 Entering the Job Information Using the Setting Screens ....................................... 9

Binding Mode Screen ...................................................................................................... 10

Start Mode Screen............................................................................................................ 11

Book Block Size Screen .................................................................................................. 12

Cover Sheet Size Screen ................................................................................................ 13

Function Screen............................................................................................................... 14

Milling and Nipping Screen ............................................................................................... 15

Gluing Screen Part 1 ....................................................................................................... 16

Gluing Screen Part 2 ....................................................................................................... 16

Gluing Screen Part 3 ....................................................................................................... 17

Gluing Screen Part 4 ....................................................................................................... 17

2-2 Bind the Books Using the Binding Screens.......................................................... 18

Binding Screens............................................................................................................... 19

2-3 Test Milling and Gluing..........................................................................................20

Test Milling and Gluing Screen........................................................................................ 20

2-4 Fine Adjustment .................................................................................................... 21

Clamp and Milling Fine-Adjust Screen............................................................................. 21

Glue Fine-Adjust Screen Part 1 ....................................................................................... 22

Glue Fine-Adjust Screen Part 2 ....................................................................................... 22

Glue Fine-Adjust Screen Part 3 ....................................................................................... 23

Nipping Fine-Adjust Screen ............................................................................................. 24

Scoring Fine-Adjust Screen ............................................................................................. 25

Cover Sheet Fine-Adjust Screen Part 1........................................................................... 26

Cover Sheet Fine-Adjust Screen Part 2........................................................................... 27

Cover Sheet Fine-Adjust Screen Part 3........................................................................... 27

Cover Sheet Fine-Adjust Screen Part 4........................................................................... 28

Cover Sheet Fine-Adjust Screen Part 5........................................................................... 28

2-5 Saving or Recalling or Deleting Job Settings. ...................................................... 29

2-6 Using the Single Operation Screen...................................................................... 30

Single Operation Screen Part 1 ....................................................................................... 30

Single Operation Screen Part 2 ....................................................................................... 31

Single Operation Screen Part 3 ....................................................................................... 31

Home Positioning Screens .............................................................................................. 32

Milling Brake Release Screen.......................................................................................... 32

2-7 Information Screen............................................................................................... 33