INDEX

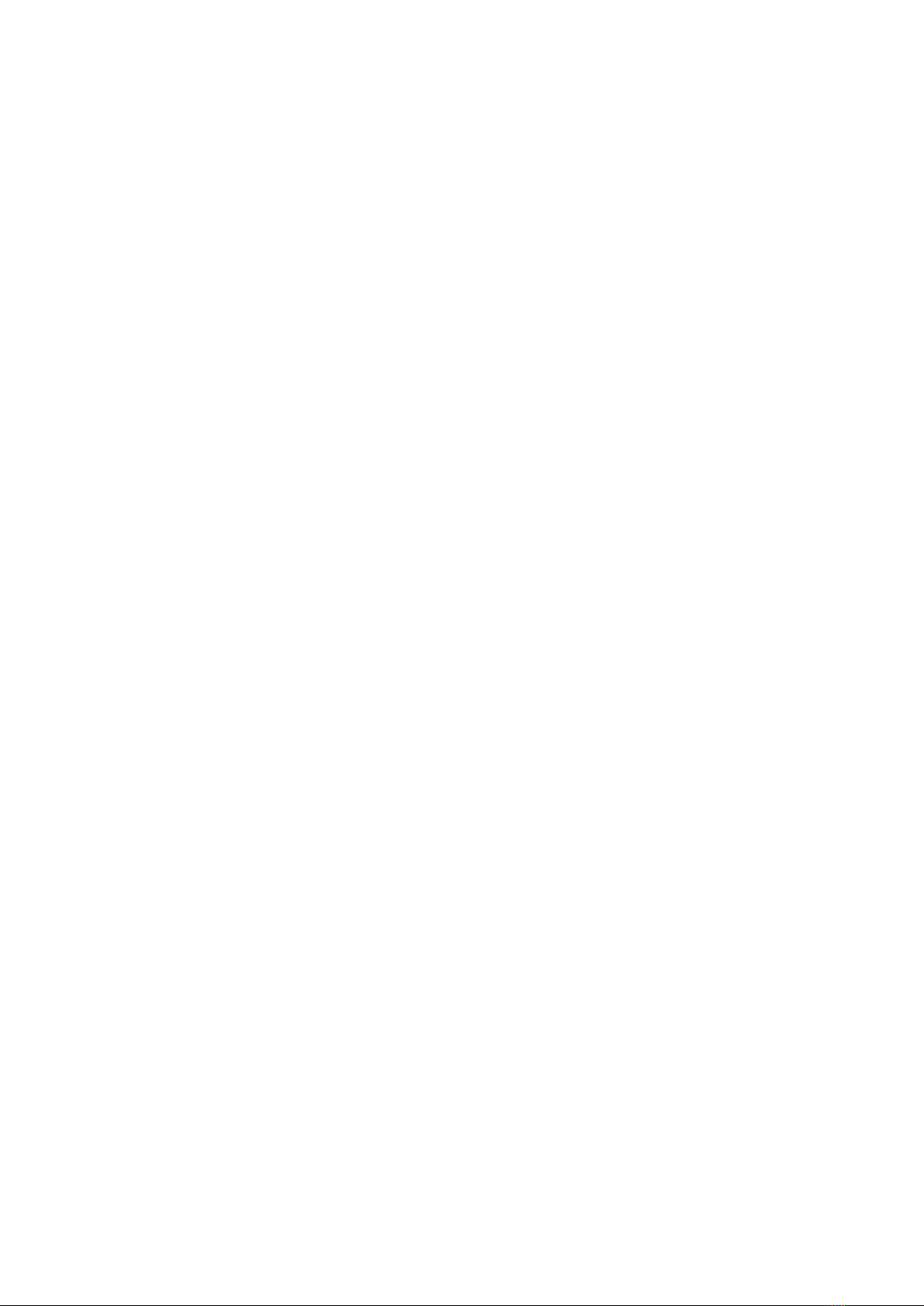

Changing External Parts

Face cover .................................................................................................................................................................. 1

Top cover .................................................................................................................................................................... 1

Belt cover.................................................................................................................................................................... 2

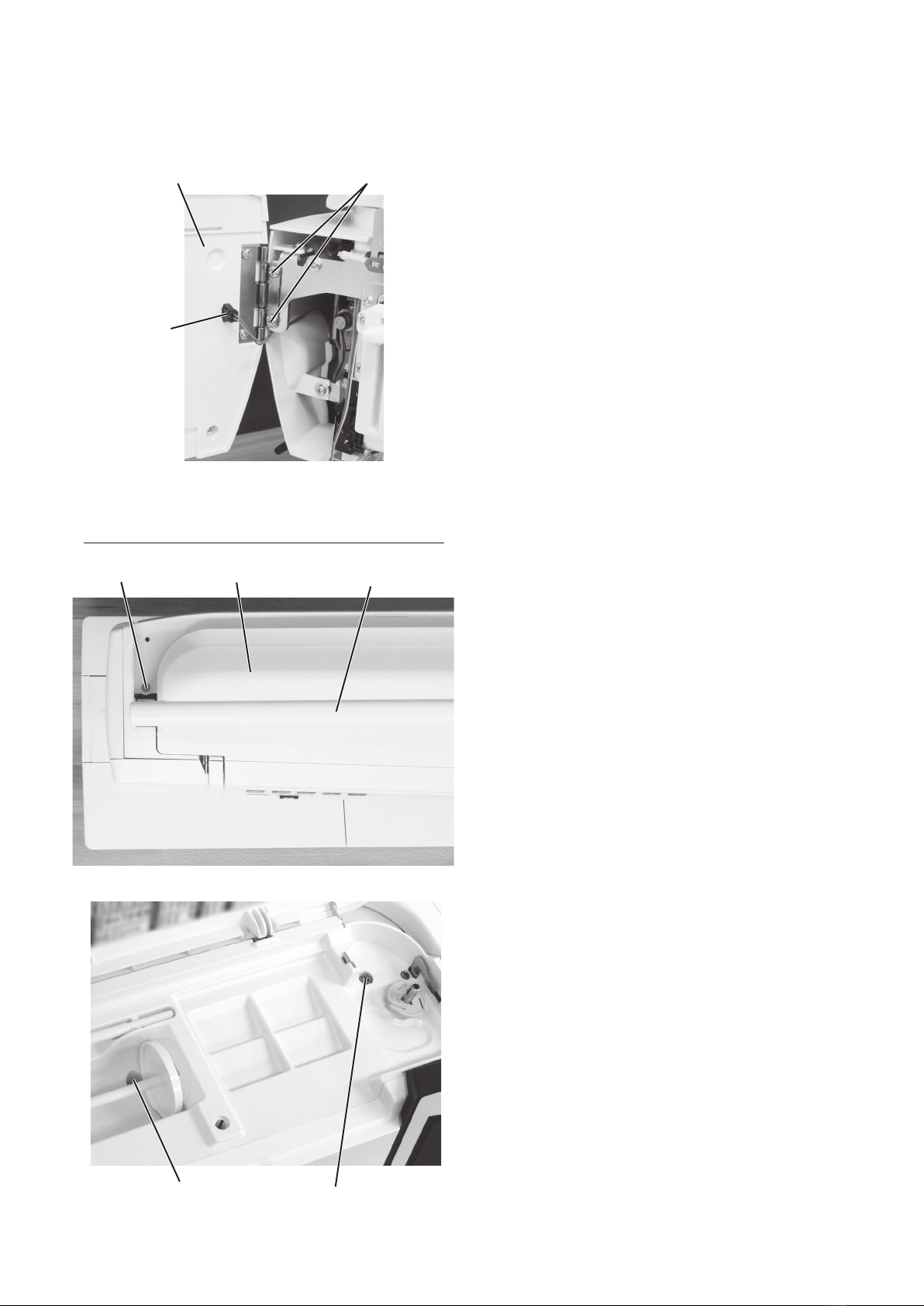

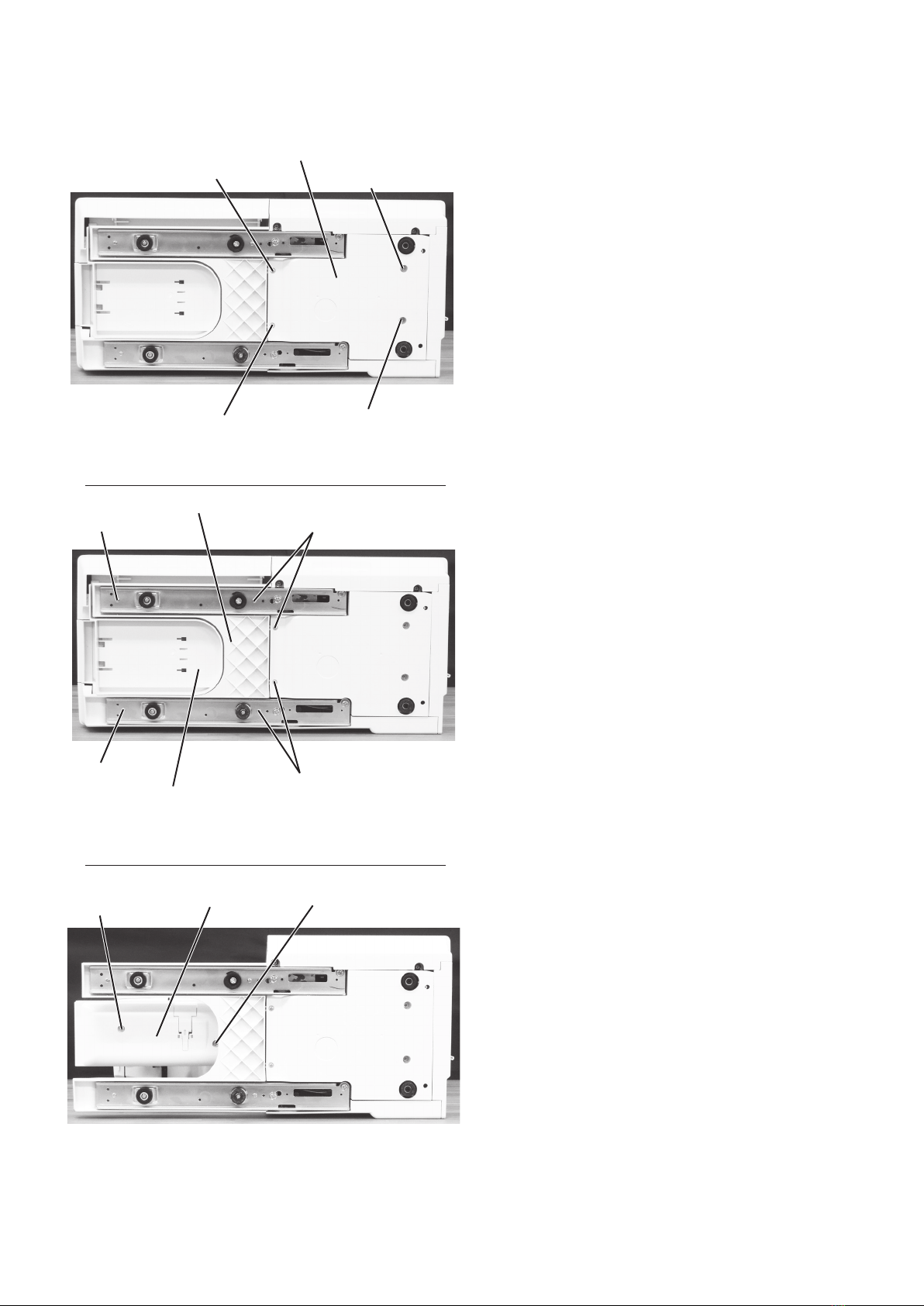

Base plate................................................................................................................................................................... 3

Base cover.................................................................................................................................................................. 3

Bed cover ................................................................................................................................................................... 3

Free arm cover ........................................................................................................................................................... 4

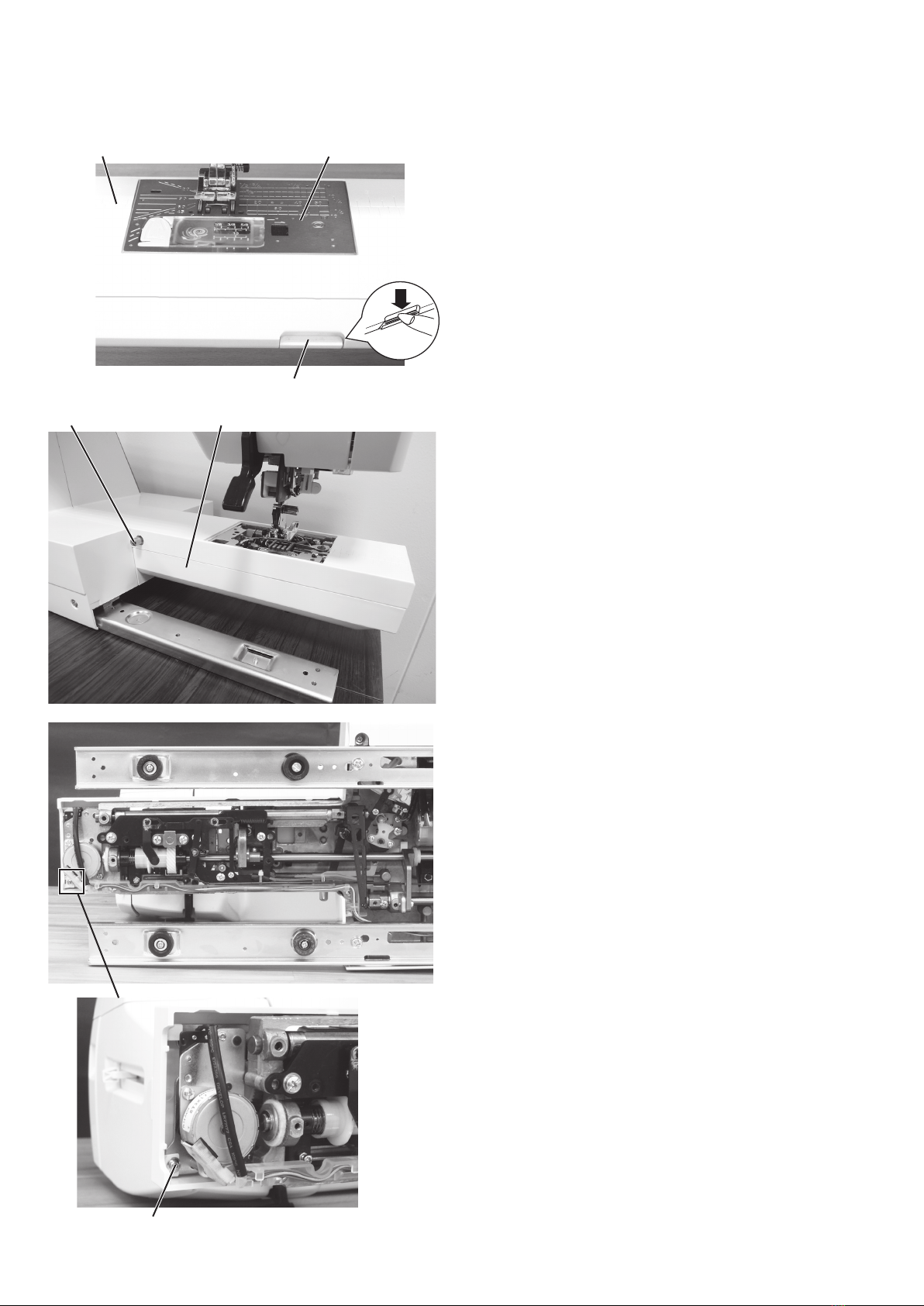

Front cover ................................................................................................................................................................. 6

Rear cover .................................................................................................................................................................. 8

Replacing Electronic Components

Printed circuit board A case ...................................................................................................................................... 10

Printed circuit board A................................................................................................................................................11

Printed circuit board A connection .............................................................................................................................11

Printed circuit board F .............................................................................................................................................. 12

Switching power supply ............................................................................................................................................ 13

DC motor .................................................................................................................................................................. 14

Thread tension.......................................................................................................................................................... 15

Mechanical Adjustment

Feed dog height........................................................................................................................................................ 16

Needle drop position................................................................................................................................................. 17

Clearance between needle and tip of the rotary hook (method 1) ........................................................................... 18

Clearance between needle and tip of the rotary hook (method 2) ........................................................................... 19

Hook timing............................................................................................................................................................... 20

Needle bar height ..................................................................................................................................................... 21

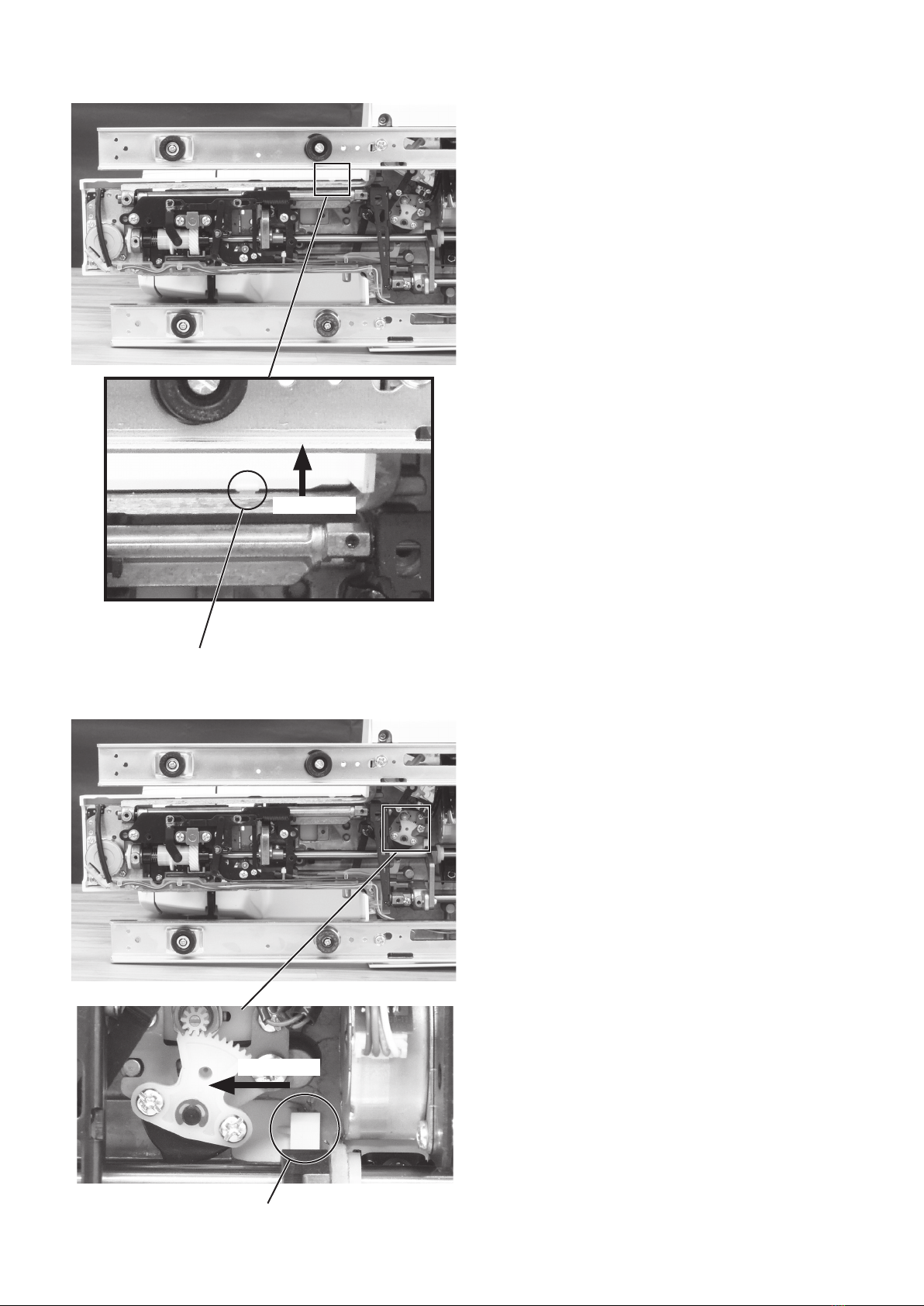

Backlash between hook drive gear and lower shaft gear ......................................................................................... 22

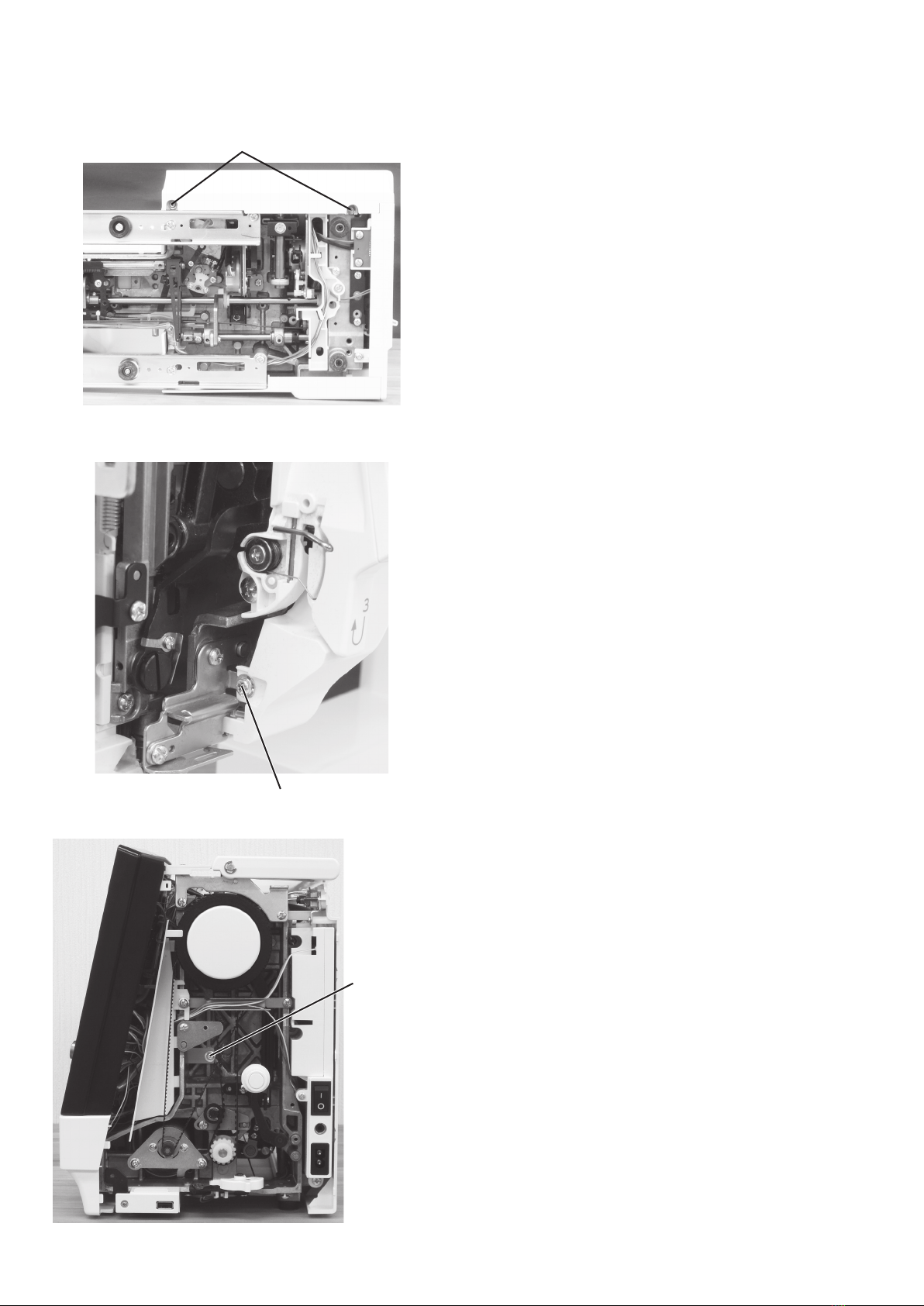

Upper shaft shield plate position .............................................................................................................................. 23

Upper thread tension ................................................................................................................................................ 24

Tension release mechanism ..................................................................................................................................... 25

Needle threader hook position ................................................................................................................................. 26

Needle threader release amount for the wire of the hook holder ............................................................................. 27

Thread drawing lever ................................................................................................................................................ 28

Upper feed dog (1) ................................................................................................................................................... 29

Upper feed dog (2) ................................................................................................................................................... 30

Upper feed dog (3) ................................................................................................................................................... 31

Buttonhole lever position .......................................................................................................................................... 32

Thread cutter ............................................................................................................................................................ 33

Presser bar lifter position .......................................................................................................................................... 34

Presser foot lifter stopper position (1)....................................................................................................................... 35

Presser foot lifter stopper position (2)....................................................................................................................... 36

Automatic presser foot lifter initializing position ........................................................................................................ 37

Preseer foot height on needle plate.......................................................................................................................... 38

Stretch stitch feed balance ....................................................................................................................................... 39

Needle plate switch .................................................................................................................................................. 40

Knee lifter ................................................................................................................................................................. 41

Embroidery foot height ............................................................................................................................................. 42

Brightness adjustment ....................................................................................................................................... 43

Touch panel key position adjustment ............................................................................................................ 44

Clear set mode ..................................................................................................................................................... 45

PARTS LIST .................................................................................................................................................. 46 to 75