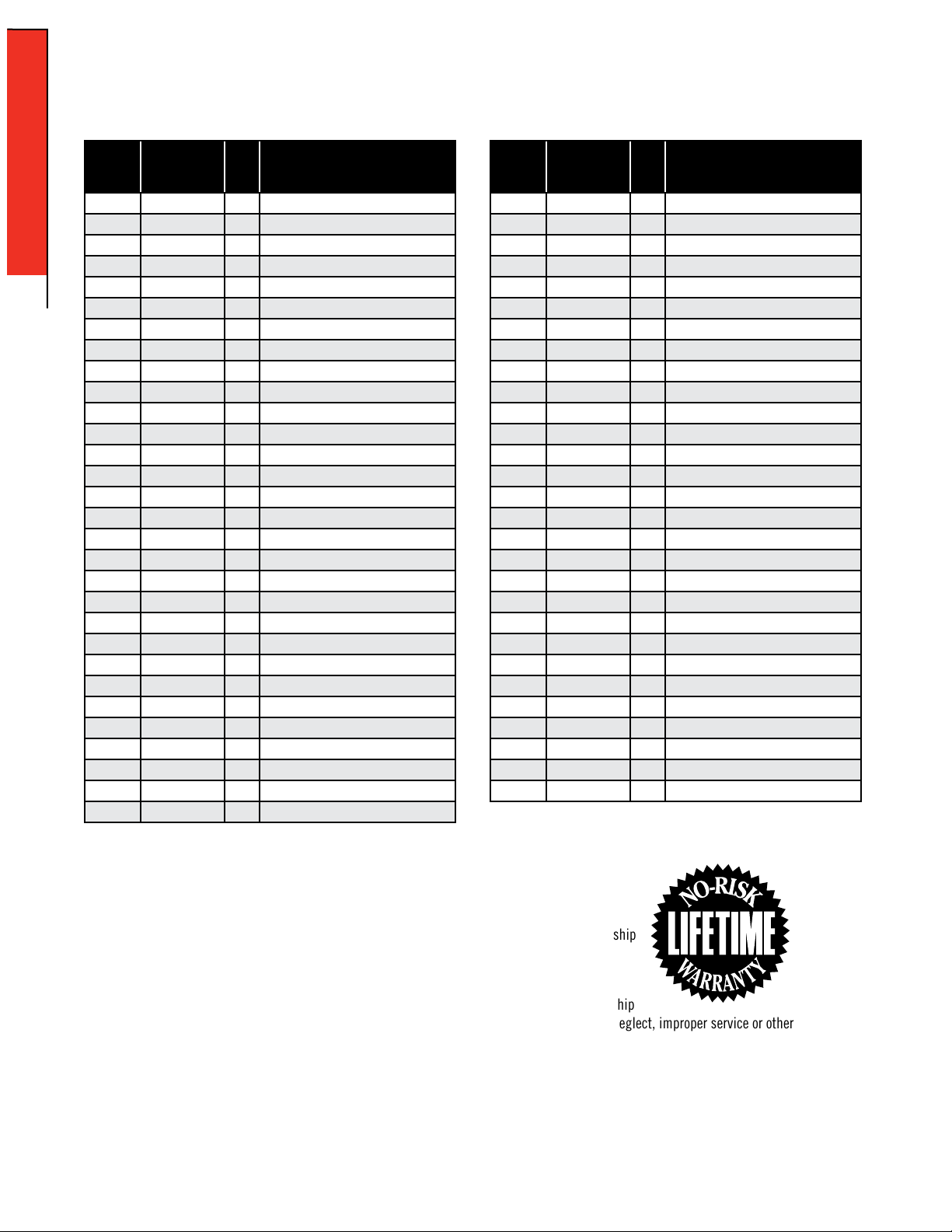

Item No.

Production

Part No. Qty. Description

1398318 1Support Primer Tube

2398356 1Tube Primer Pickup, Large

3398355 1Tube Primer Pickup, Small

4398358 1Tube Primer, Large

5398357 1Tube Primer, Small

6398322 1Housing Tube Primer

7392220 1Screw, BHCS 1/4-20 X 1/2

8399686 1Lock-N-Load®AP Bracket

9392342 1SHCS SS 3/8-16 X 3/4

10 398359 1Primer Follower

11 392338 1Screw, SHCS 10-24 X 1/2

12 —Shell Plate (Sold Separately)

13 392455 1Bracket Box Cartridge

14 398319A 1Housing Body Primer Tube

15 392218 1Primer Slide, Large Assembly

15 392219 1Primer Slide, Small Assembly

16 392336 1Spring Primer Slide

17 392363 1Spring Case Retainer

18 398695 1AP Breakaway Cam Wire

19 398698 1Nut, 8-32

20 190216 1Frame

21 392368 6Clip C, C-50

22 480039 1Box Catcher

23 392408 2Lock-N-Load®AP™Link

24 398309T 1Sub Plate

26 398505 1Primer Seater Punch, Small

26 398507 1Primer Seater Punch, Large

27 392467 1Counter Balance Spring

28 392345 13/8 Flat Washer SS

29 392355 1Drive Hub

Item No.

Production

Part No. Qty. Description

30 392356 1Drive Shaft

31 392231 2Screw, BHSCS 8-32 X 3/8

32 392344A 2Pawl

33 392423 2Spring Pawl

34 392306 2Dowel Pin 1/8 X 1/2

35 392221 2Screw, FHCS 1/4-28 X 3/8

36 290029 1Spent Primer Tube

37 398163 1Ram Assembly

38 398422 3Grease Zerk™

39 392343 1Toggle

40 392340 1Pin Yoke

41 392424 5Spring Washer

42 392417 2Pin Link Toggle

43 390027 1Nut Jam, 5/8-18

44 390657 1Handle

45 480003 1Knob

47 392358A 1Index Wheel

48 390081 2Clip E 1/2

49 392302 5Lock-N-Load®Bushing, Male

50 392303 5Lock-N-Load®Bushing O-Ring

51 392301 5Lock-N-Load®Bushing, Female

52 398697 1Breakaway Cam Plunger

53 398696 1Breakaway Cam Wire Spring

54 399853 1 Spent Primer Hose Clamp

55 392365 1 Spent Primer PVC Tube

56 399850 1 Spent Primer Bottle Barbed Fitting

57 399851 1 Spent Primer Bottle Cap

58 399852 1 Spent Primer Bottle

—9987 1DVD

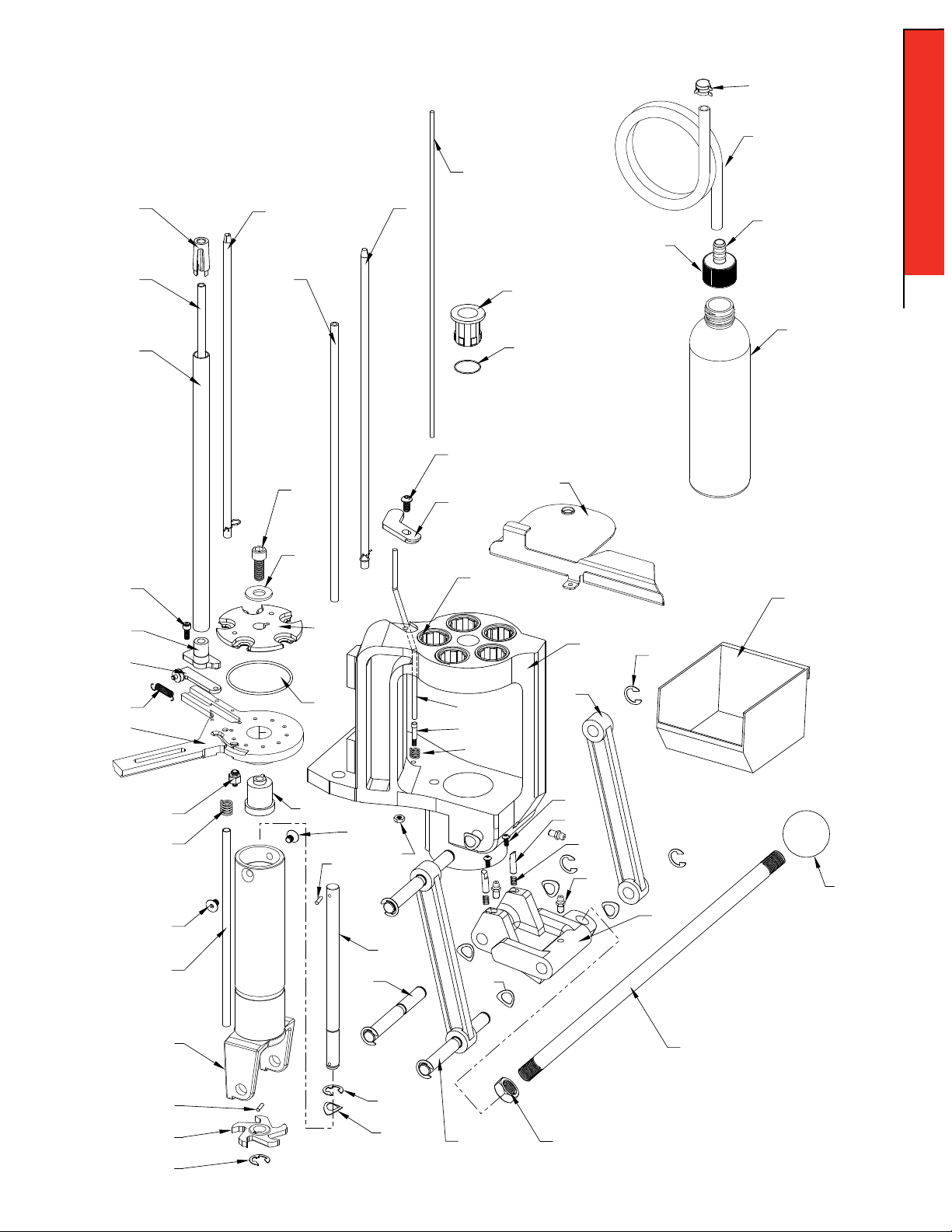

Lock-N-Load®Auto Progressive (AP) Reloading Press

PARTS LIST

No-Risk Lifetime Warranty

All Hornady reloading tools and accessories are warranted against material defects and workmanship

for the life of the product. Simply stated – if it breaks, we’ll repair it or replace it at no charge

(at Hornady Manufacturing Company’s option).

Hornady reloading tools and accessories are warranted against defective materials and workmanship

only. This warranty is void if the product (1) has been damaged by accident or unreasonable use, neglect, improper service or other

causes not arising out of defects in material or workmanship; or (2) has been altered or repairs have been made or attempted by

other than authorized factory personnel; (3) is used commercially; or (4) has been altered or defaced in any way.

This warranty supersedes all other warranties for Hornady products either written or oral. No other warranty is expressed or implied.

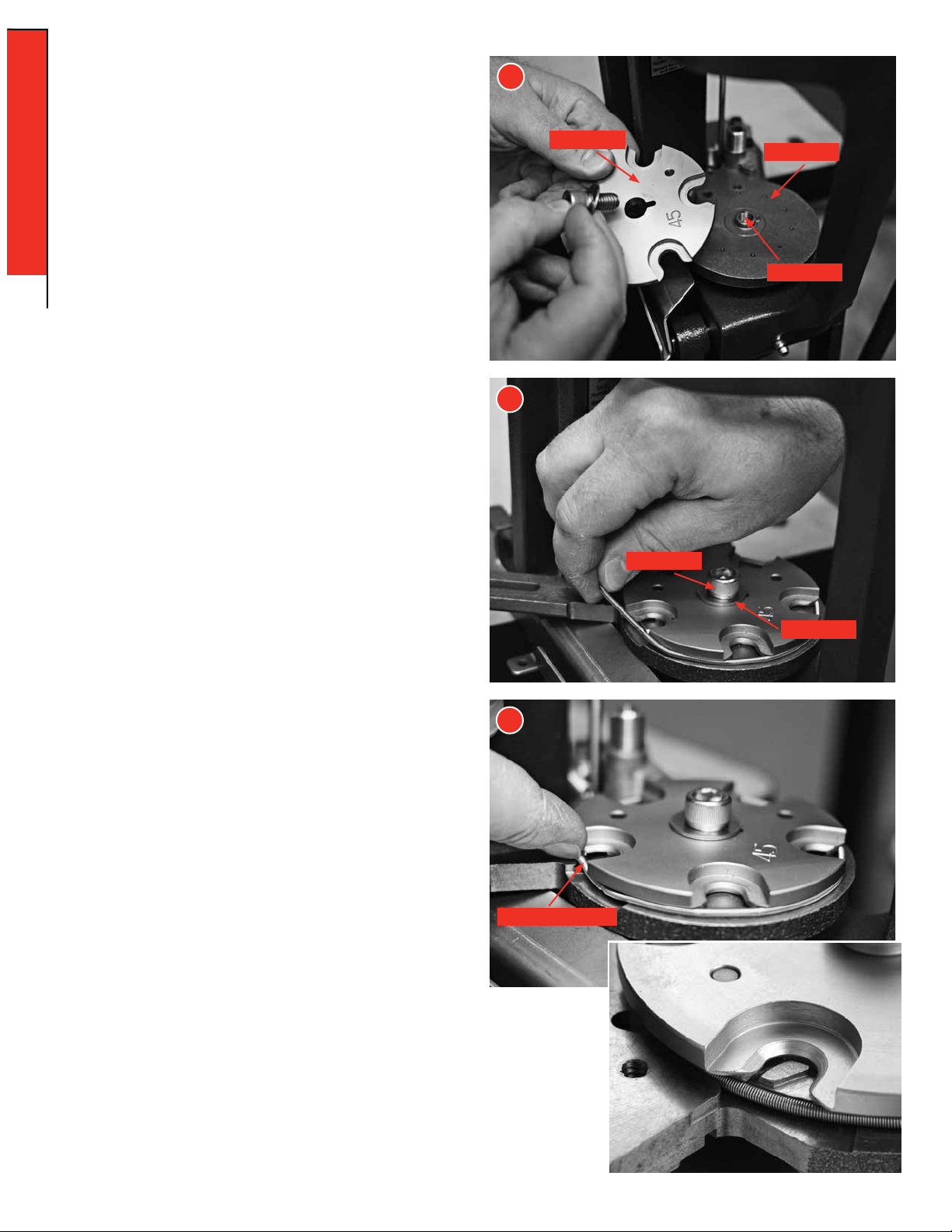

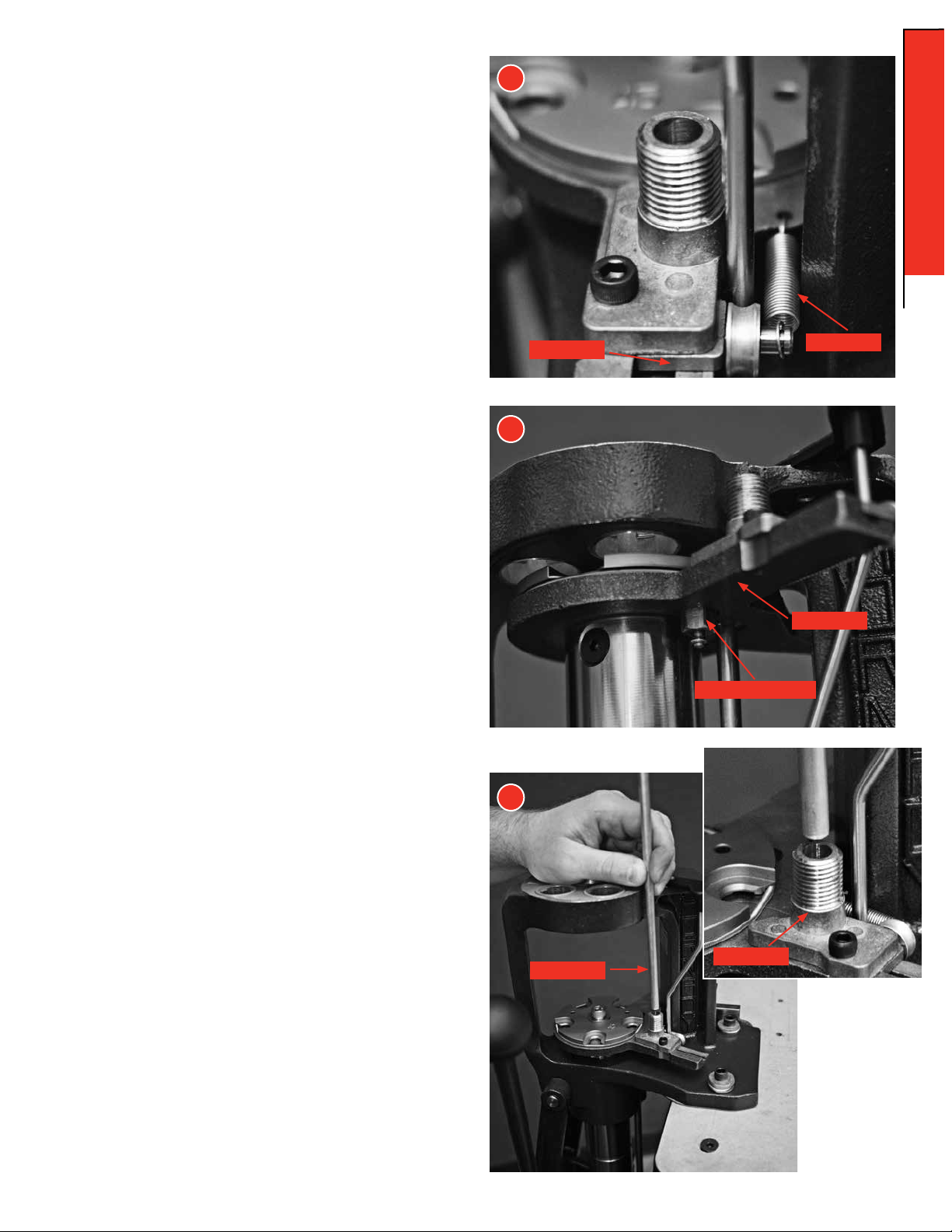

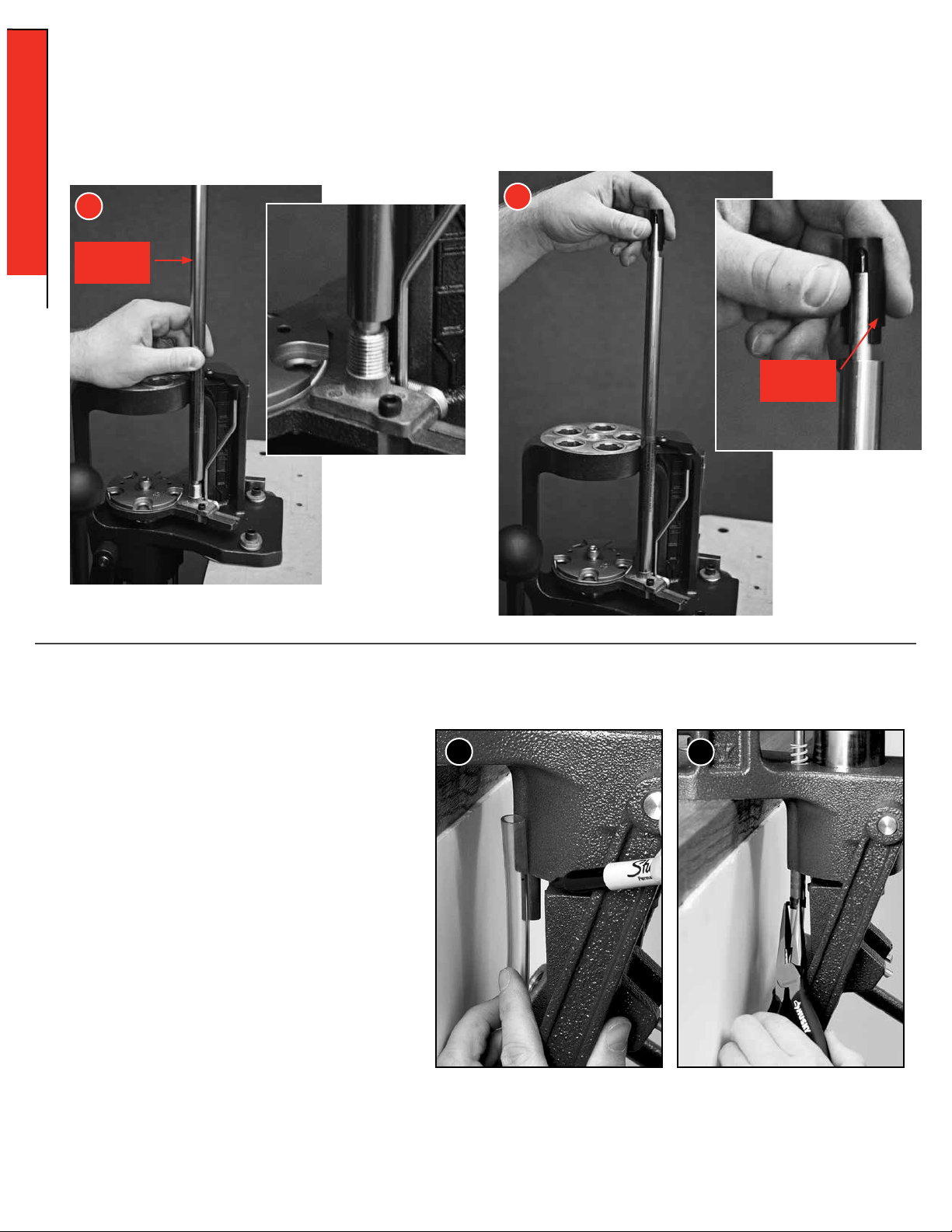

- 4 - ASSEMBLY: AP PRESS

ASSEMBLY