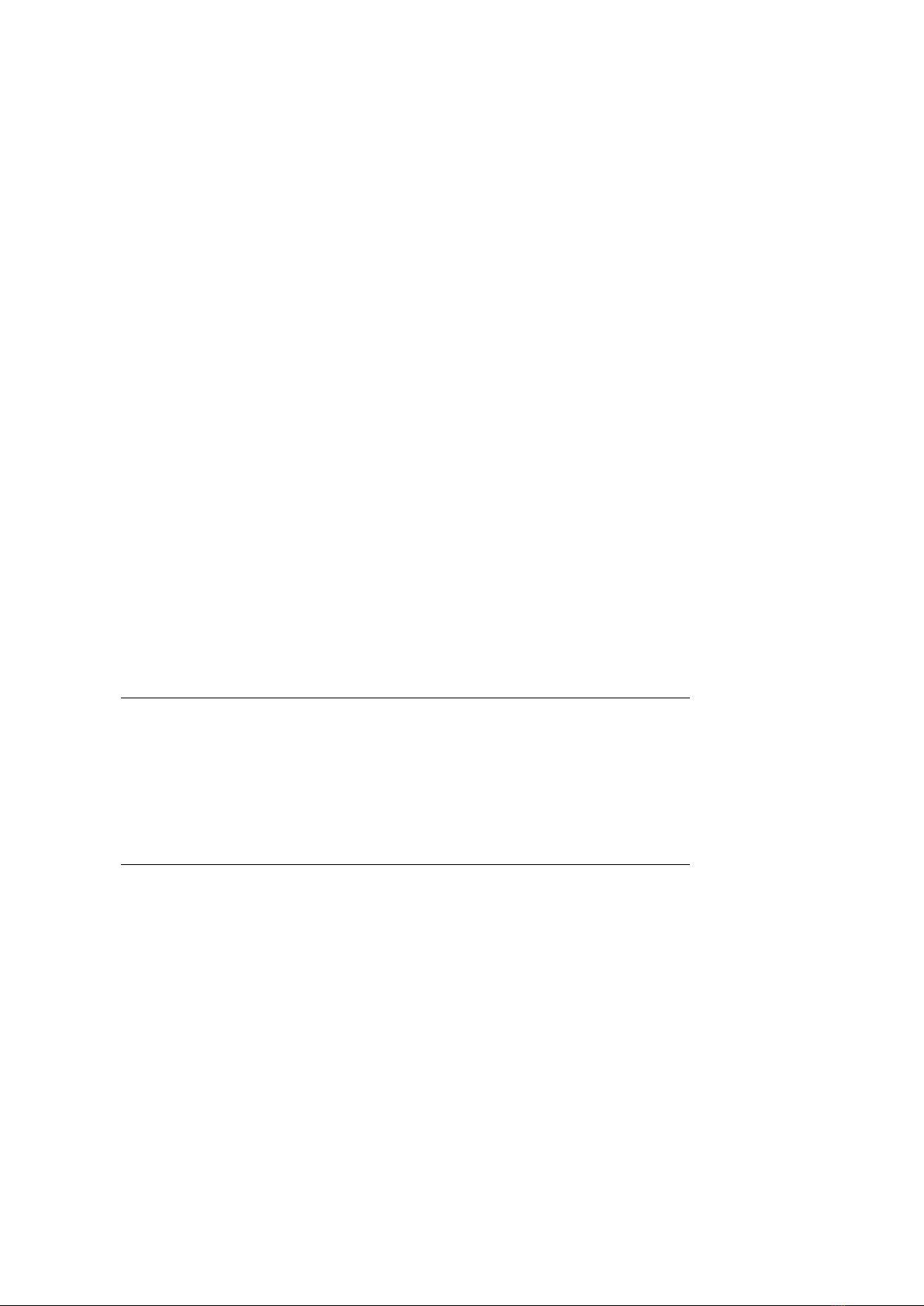

Contents

1 Preface 5

1.1 Terminology and method of notation 5

1.1.1 General information 6

1.1.2 Components, stickers and names 6

1.1.3 Method of notation 7

1.2 Documentation overview 7

1.2.1 Provided with every FertiMiX model: 7

1.2.2 FertiMiX-Go! 7

2 Product information and safety instructions 8

2.1 Intended use 8

2.1.1 Original Equipment Manufacturers (OEM) information 8

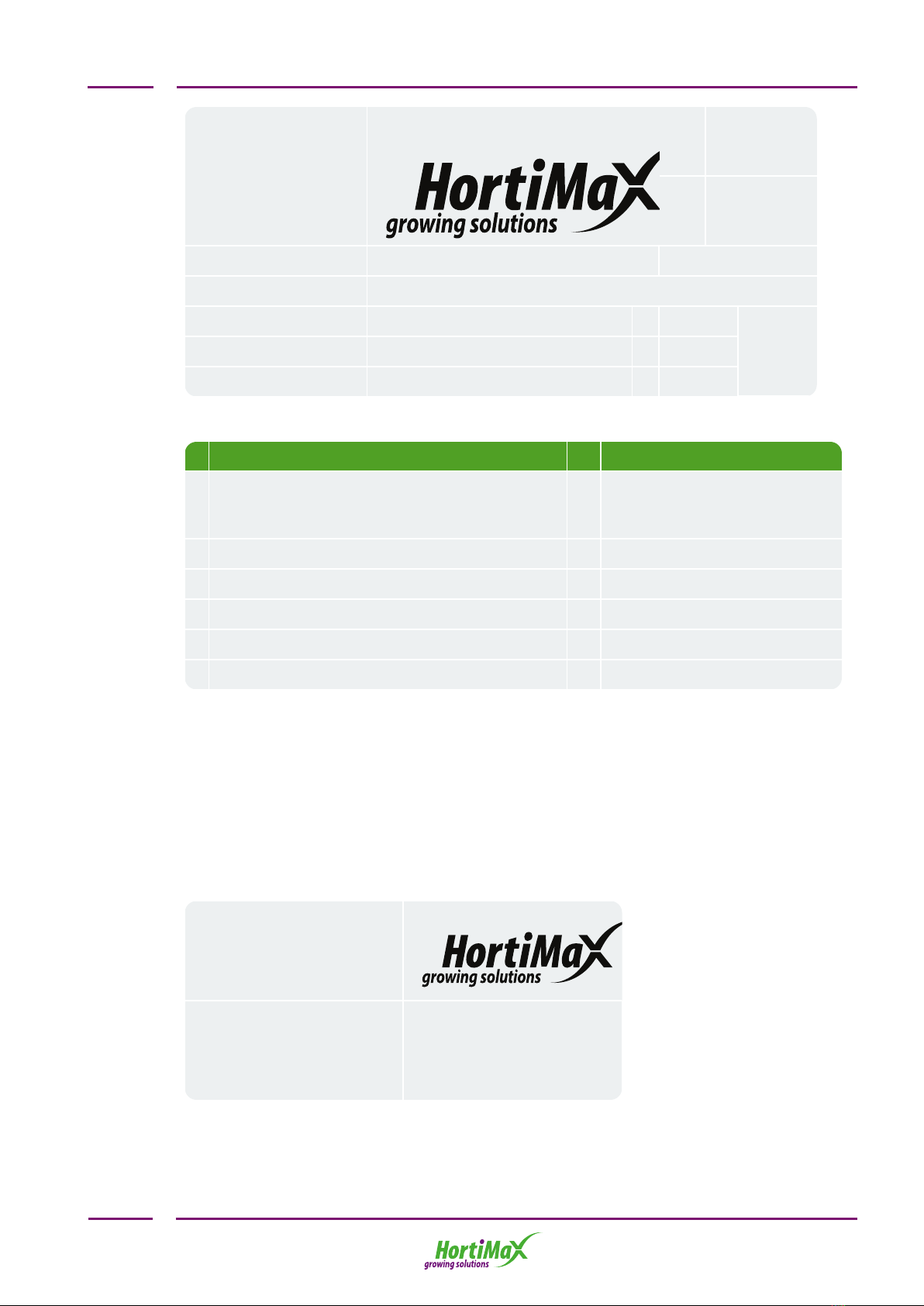

2.2 Certificates and declarations 8

2.2.1 Type plates 8

2.2.2 Quality control 9

2.3 Packaging, storage and shipment 10

2.3.1 Packaging and storage 10

2.3.2 Transport 10

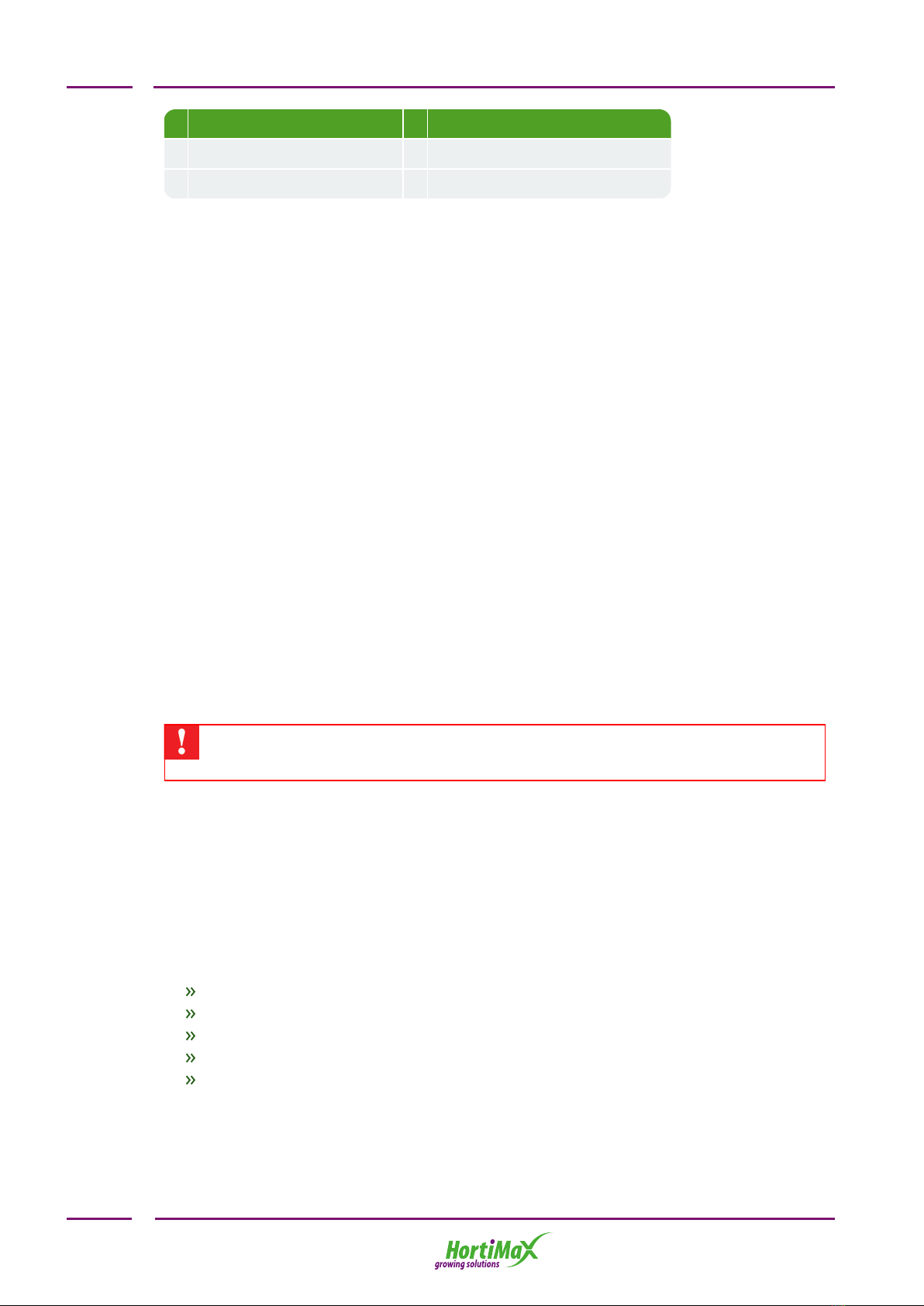

2.4 Safety precautions and requirements 10

2.4.1 Personal protective equipment (PPE) 10

2.4.2 Chemicals 11

2.4.3 Electrical system - emergency stop 11

2.5 Installation requirements 11

2.5.1 Dealer/installer requirements 11

2.5.2 General installation requirements 12

2.5.3 Water installation requirements 12

2.5.4 Electrical installation requirements 13

2.6 Maintenance 13

2.6.1 Yearly maintenance 13

2.6.2 Monthly maintenance 14

2.6.3 Weekly maintenance 14

2.7 Recycling and removal 14

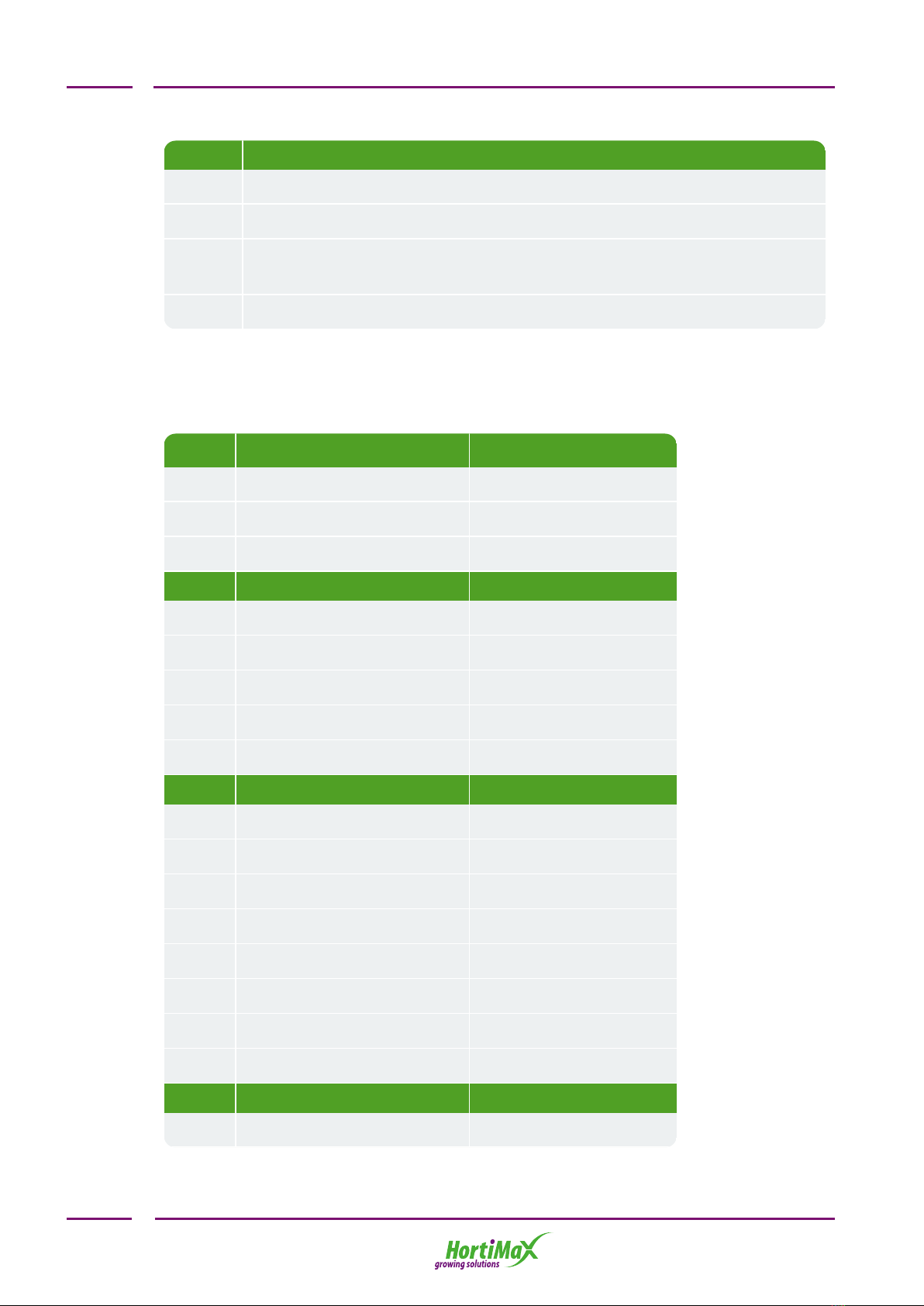

3 Hardware 15

3.1 Basic configuration 15

3.1.1 Dosing street and measurement module 16

3.1.2 Filling module with float valve 17

3.1.3 Pressure module with filter 18

3.1.4 Measurement module 18

3.1.5 Main cabinet 19

3.2 Spare components, extra options and peripheral equipment 20

3.2.1 Extra options 20

3.2.2 Peripheral equipment and accessories 21

3.2.3 Accesoz 21

4 Installing the unit 23

4.1 Installation steps 23

4.1.1 Connecting the filling pump 23

4.2 Connecting extra options 23

4.2.1 Connecting an additional dosing channel 23

4.2.2 Connecting additional sensors 25

4.2.3 Connecting additional valve cards 25

5 Preparing the unit for initial use 26

5.1 Commissioning instructions for the dealer 26

5.1.1 Checking EC control settings 26